Three-directional roll riveting equipment of through-flow fan blade

A technology of cross-flow fan blades and rolling riveting is applied in the field of mechanical three-way rolling riveting equipment, which can solve the problems that the radial runout of the impeller cannot be completely avoided, and the coaxiality consistency between the middle disks cannot be ensured, and the work effect is good, The effect of simplifying the structure and avoiding radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

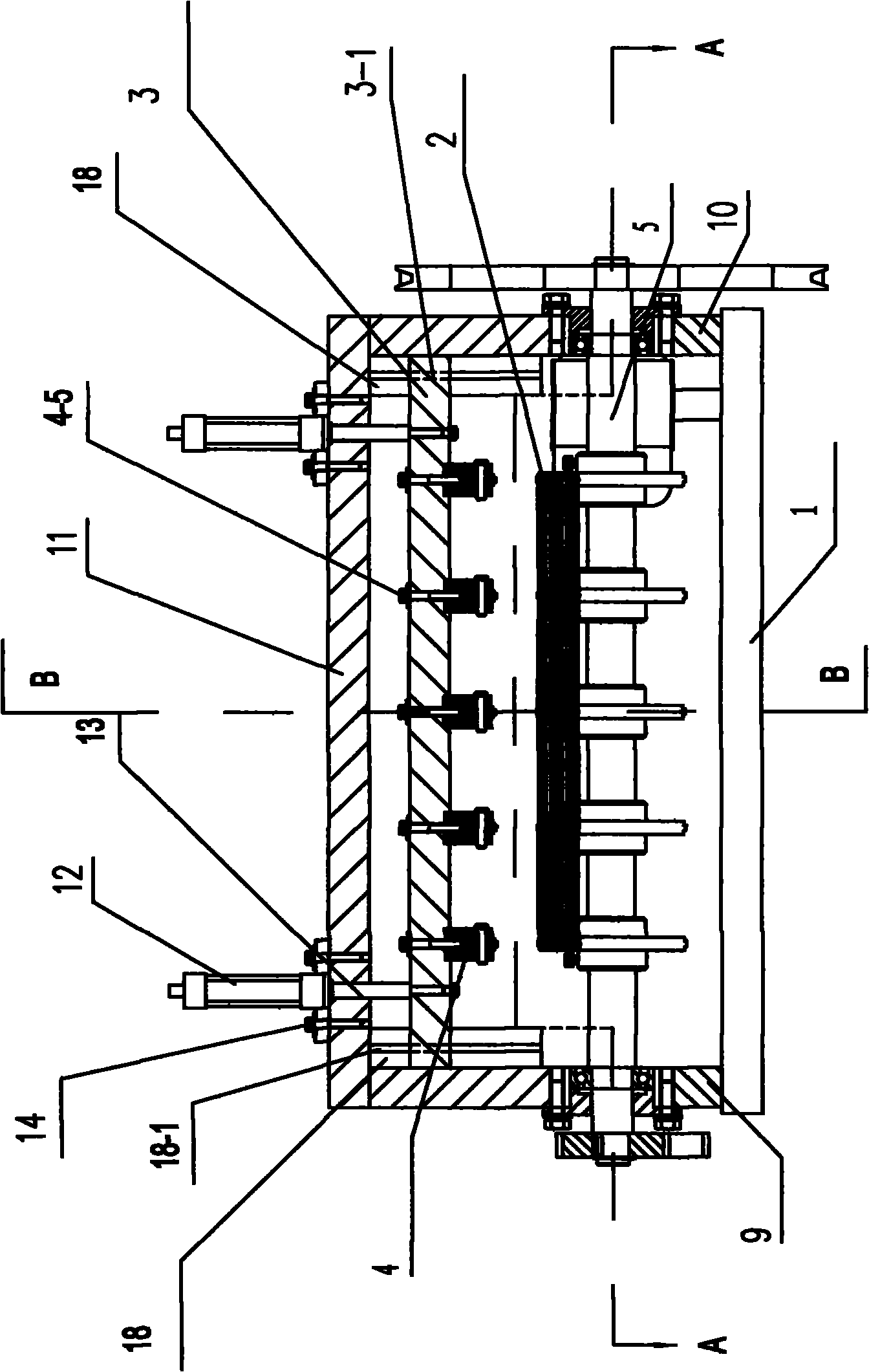

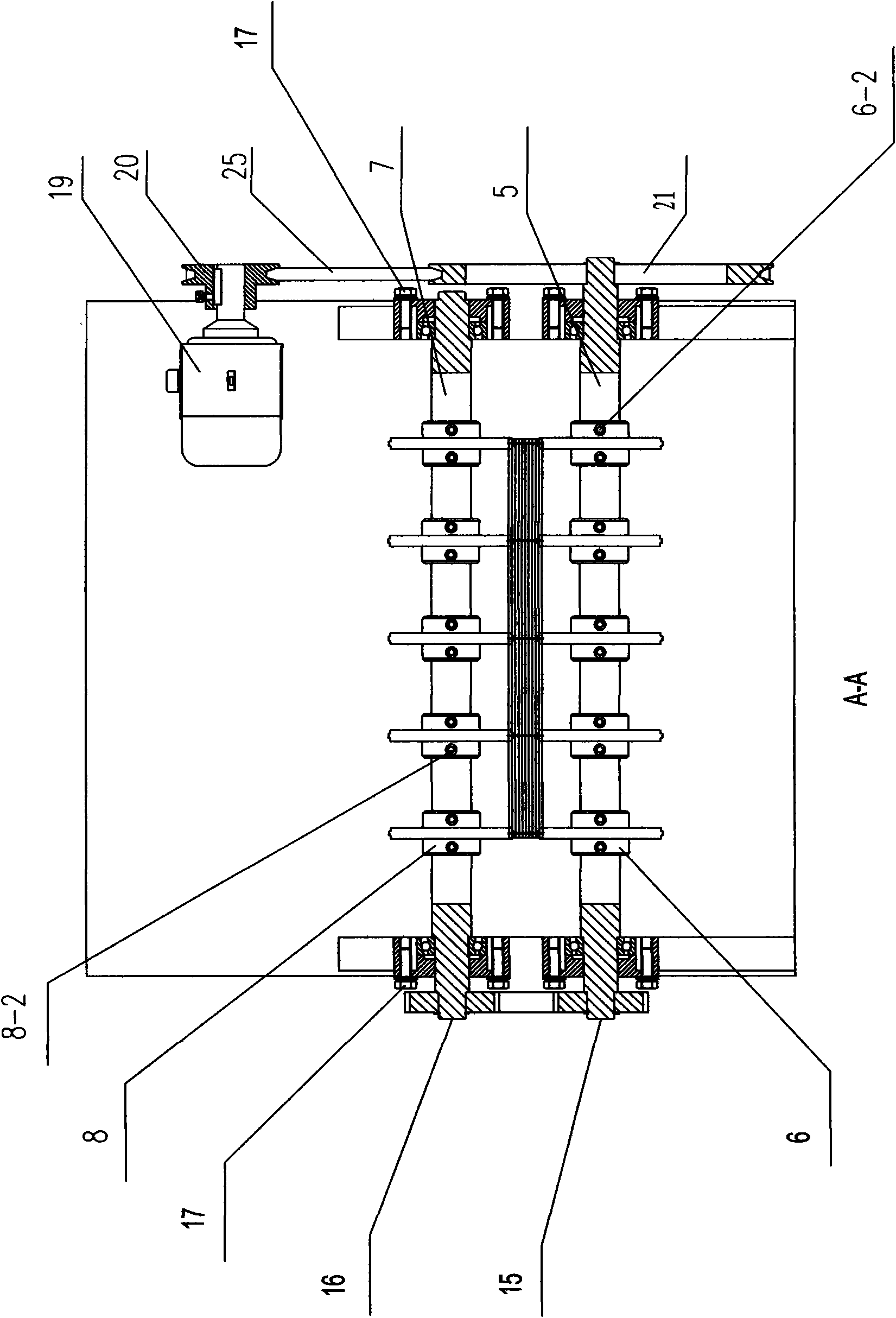

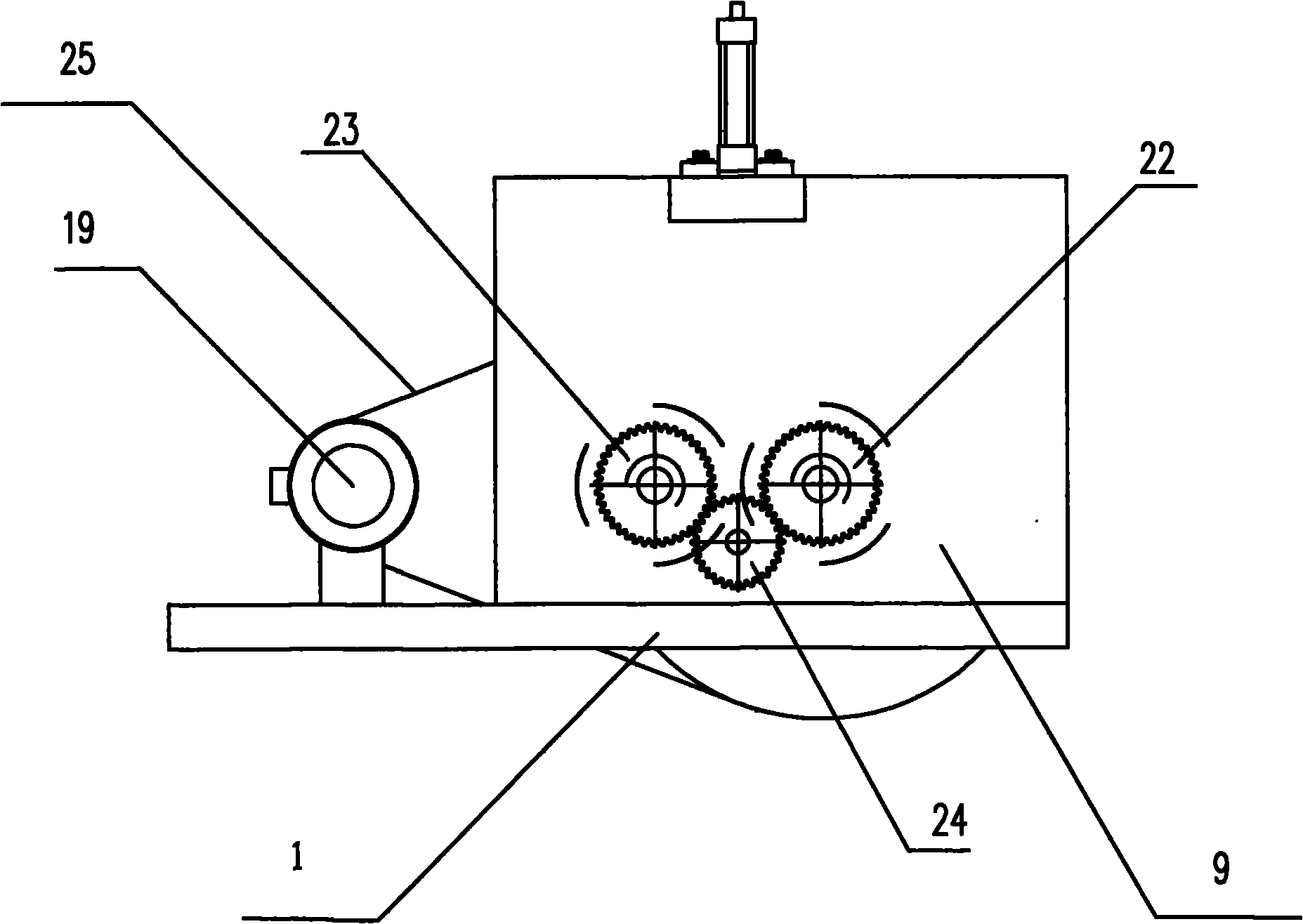

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention. Such as Figure 1-8As shown, a three-way rolling riveting equipment for cross-flow fan blades includes a base 1, a rolling riveting system, a fixing and driving system, a guiding system, and a conduction system. The rolling riveting system includes a roller row, and the roller row is arranged in parallel with the base 1. The cross-flow blade is the impeller 2, and the roller row includes an upper roller row 3, a lower front roller row 5 and a lower rear roller row 7; the upper roller row 3 is arranged directly above the impeller 2 to be processed, and the upper roller row 3 is provided with The upper riveting hob unit with the hob mouth vertically downward, the upper riveting hobs 4 are evenly distributed in the horizontal direction on the upper roller row 3; The two sides of the vertical surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com