Method for machining optical fiber stress rod

A technology of optical fiber stress and processing method, which is applied in the direction of metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems that affect the grinding accuracy and the jumping of optical fiber stress rod 2, and achieve the improvement of processing accuracy, smoothness, and The effect of enhancing the polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

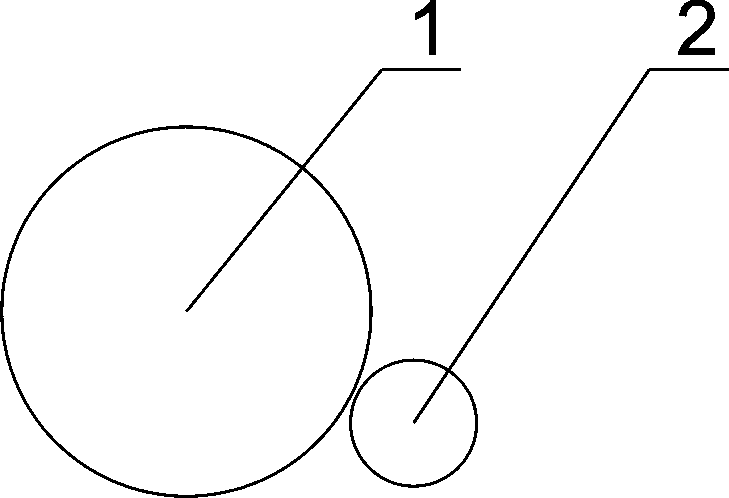

[0018] figure 1 The relative positions of the grinding wheel 1 and the optical fiber stress rod 2 in the existing grinding process of the optical fiber stress rod are illustrated, and since they have been described in detail in the background technology section, they will not be repeated here.

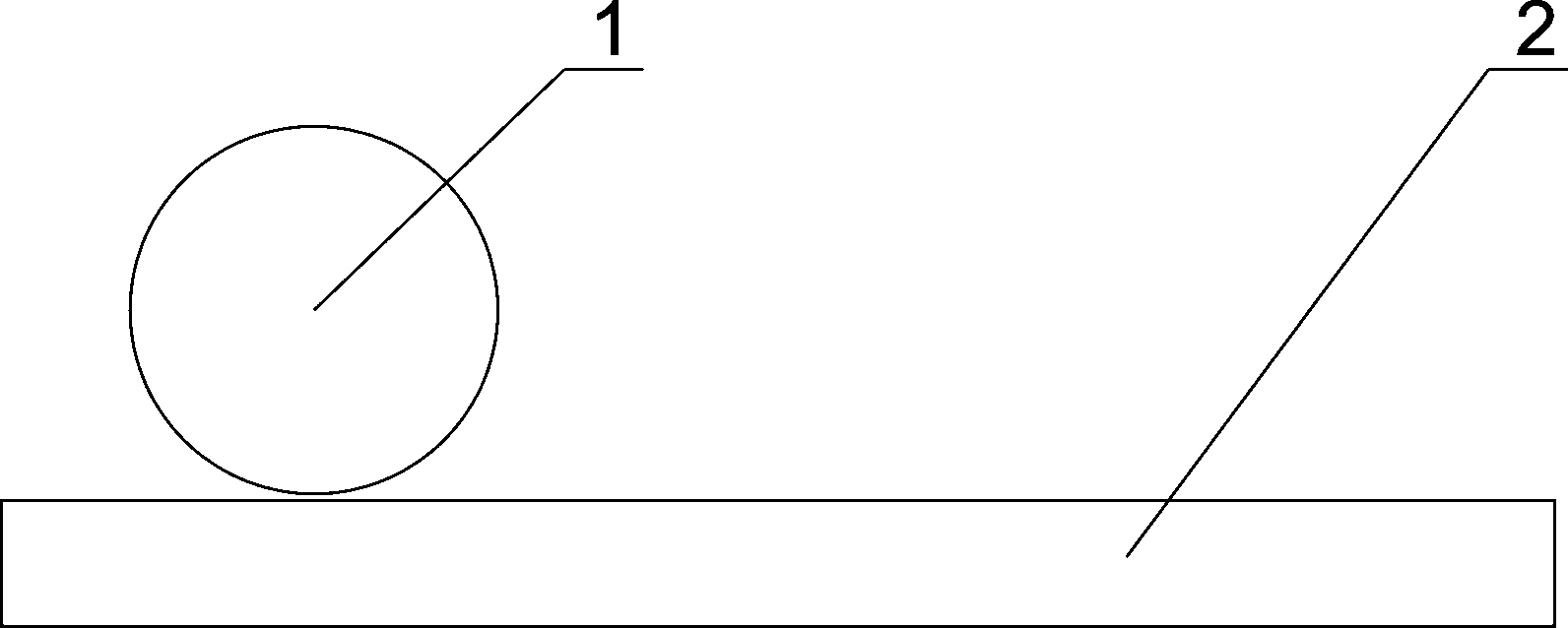

[0019] Such as figure 2 As shown, a processing method of an optical fiber stress rod of the present invention, first prepares an optical fiber stress rod 2 by a conventional method, and then grinds the optical fiber stress rod 2 . In the operation of grinding the optical fiber stress rod 2, the grinding wheel 1 of the grinding equipment and the optical fiber stress rod 2 are vertically arranged, and while the grinding wheel 1 and the optical fiber stress rod 2 rotate around their respective axes, the two along the direction of the optical fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com