Positioning mechanism for machining pipes

A technology of positioning mechanism and pipe materials, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effects of high control precision, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

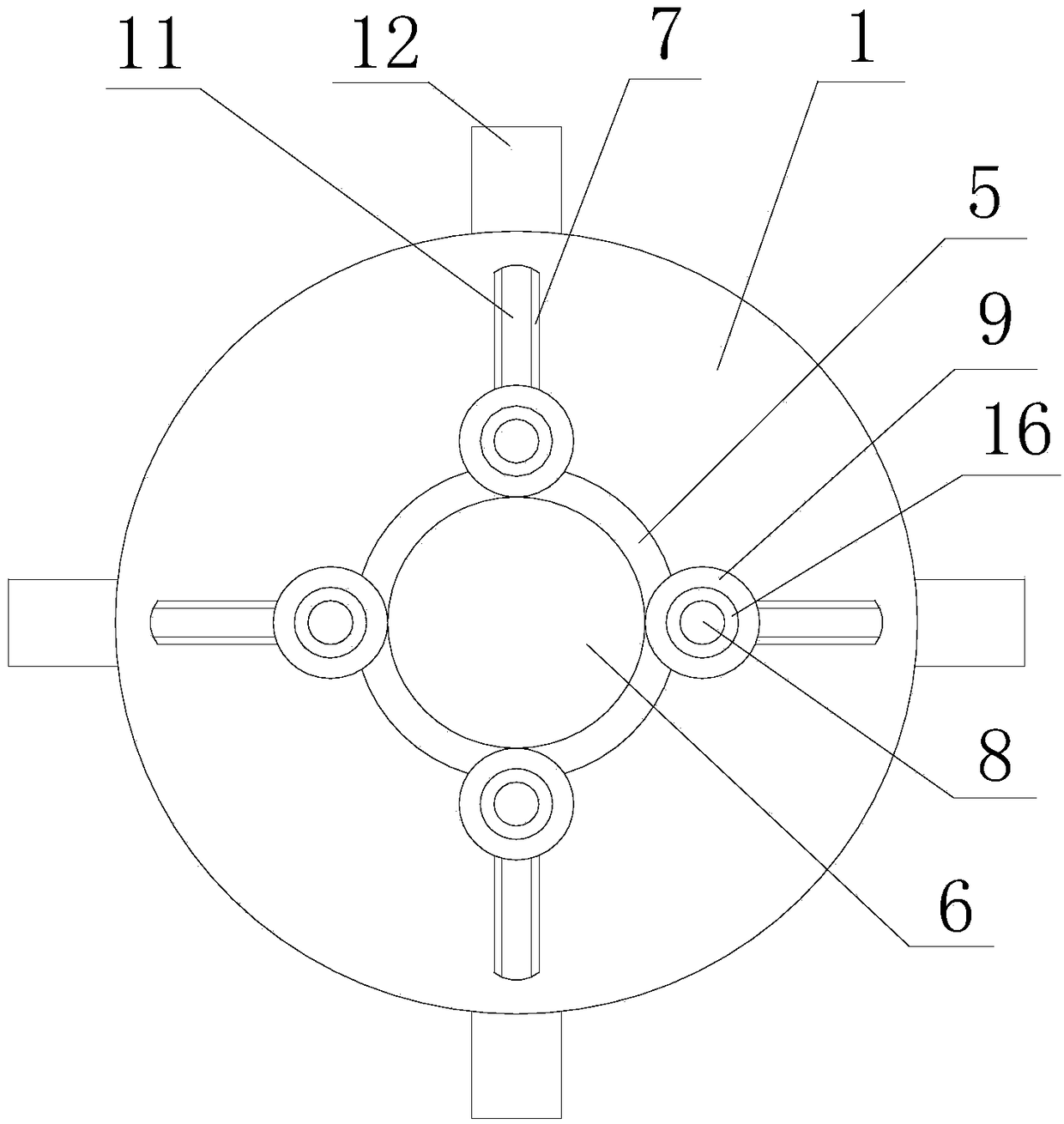

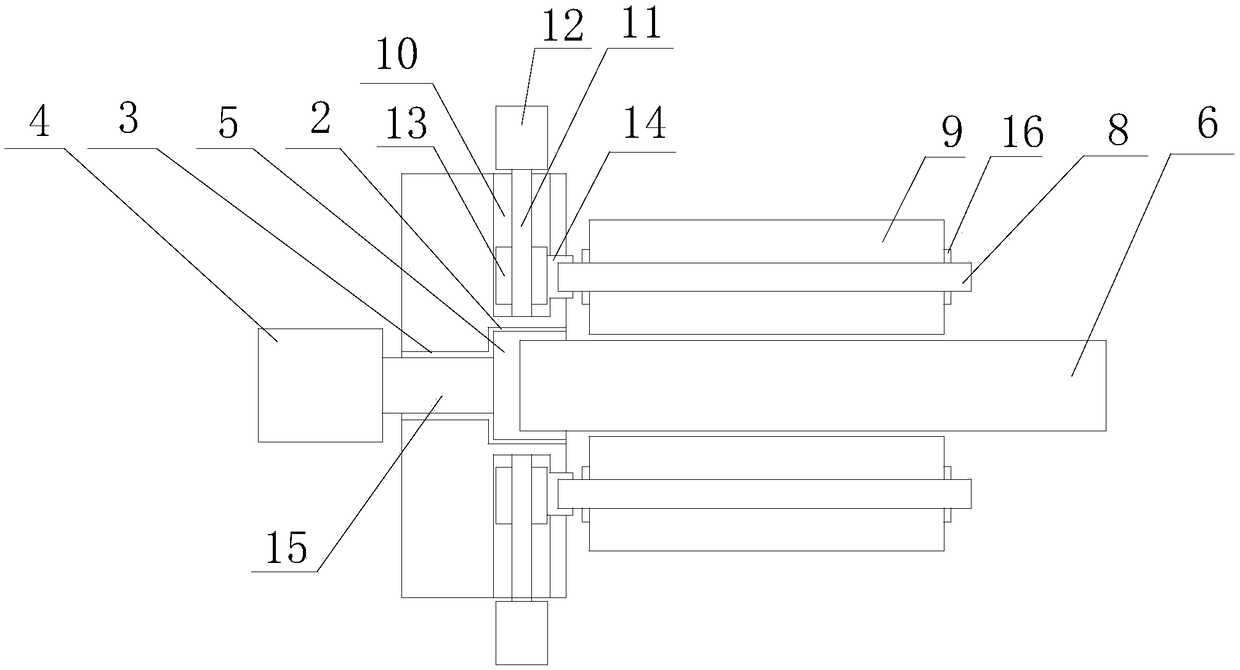

[0025] The invention provides a positioning mechanism for processing pipes, which includes a base 1 with a circular plate structure, a circular hole positioning groove 2 is opened on one side of the base 1, and a positioning groove 2 is opened on the base 1. There is a through hole 3 communicating with the positioning groove 2, and the axis lines of the through hole 3 and the positioning groove 2 coincide; the clamping device also includes a motor 4, and the output shaft 15 of the motor 4 passes through the through hole 3 and is installed The shell 5 is detachably connected, and the installation shell 5 is accommodated in the positioning groove 2; the axial end of the pipe 6 to be processed is detachably fixed on the installation shell 5; the base 1 is provided with a positioning groove 2 There are several slide grooves 7 arranged on the board surface, and the several slide grooves 7 are radially distributed at equal intervals with the positioning groove 2 as the base point, an...

Embodiment 2

[0027] Further improvement on the basis of Embodiment 1, the drive mechanism adopts a screw drive mechanism; a number of mounting holes 10 are opened on the side wall of the base 1, and the mounting holes 10 are evenly closed at equal intervals along the circumference of the base 1 , the axis line of the mounting hole 10 and the axis line of the positioning groove 2 are perpendicular to each other; the mounting hole 10 is provided with a screw 11, and the axial end of the screw 11 extends into the mounting hole 10 and is fixed by a bearing. The axial other end of 11 stretches out mounting hole 10 and is connected with the output end of driving motor 12; Screw mandrel 11 is provided with nut pair 13, and slide block 14 is fixed on the side wall of nut pair 13; Connected, and the radial width of the chute 7 is smaller than the inner diameter of the mounting hole 10, the free end of the slider 14 protrudes from the chute 7, and the axial end of the limiting shaft 8 is fixed on the...

Embodiment 3

[0029]Further improvement on the basis of Embodiment 2, the inner wall of the roller 9 and the outer wall of the limiting shaft 8 are in sliding contact with balls, and one axial end of the limiting shaft 8 is detachably fixed on the plate surface of the base 1 . The axial two ends of described position-limiting shaft 7 are provided with position-limiting collar 16, and the outer diameter of described space-limiting collar 16 is larger than the inner diameter of roller 8, and is smaller than the outer diameter of roller 8, and space-limiting collar 16 passes through The screw is fixed on the limit shaft 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com