Bearing system on paper transferring roller of printing machine

A printing machine and rolling bearing technology, which is applied in the field of printing machine parts, can solve the problems of printing drawings and paper inclination, waste of paper, vibration and wear, etc., and achieve the effect of preventing radial runout, reducing damage probability, and good rotation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

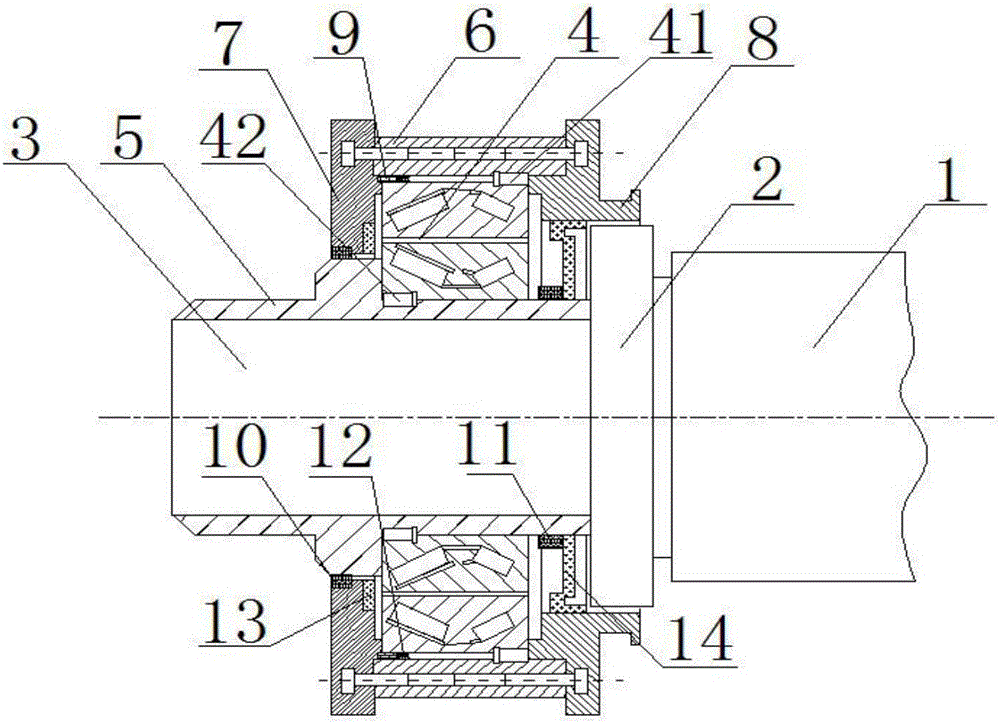

[0017] Such as figure 1 As shown, the present invention provides a bearing system on the transfer cylinder of a printing machine. A roller pillow 2 is provided on the end surface of the paper transfer cylinder 1, and a journal 3 is provided on the extension side of the roller pillow 2 . Its bearing system includes a rolling bearing 4, a shaft sleeve 5, an upper end cover 6, a left end cover 7 and a right end cover 8, wherein the shaft sleeve 5 is set on the journal 3, and the upper end cover 6, the left end cover 7 and the right end cover 8 are respectively located on the shaft The top, left and right sides of the cover 5, and the right end cover 8 is close to the rolling pillow 2. The shaft sleeve 5, the upper end cover 6, the left end cover 7 and the right end cover 8 form a sealed space, and the rolling bearing 4 is installed in the sealed space.

[0018] In addition, a dustproof ring 9 , a retaining ring and a sealing ring are installed in the sealed space, wherein the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com