Double-worm and worm gear transmission mechanism used for machine tool

A technology of worm gear transmission and double worm, which is applied in the direction of metal processing machinery parts, large fixed members, manufacturing tools, etc., and can solve the problem of inability to position sliding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

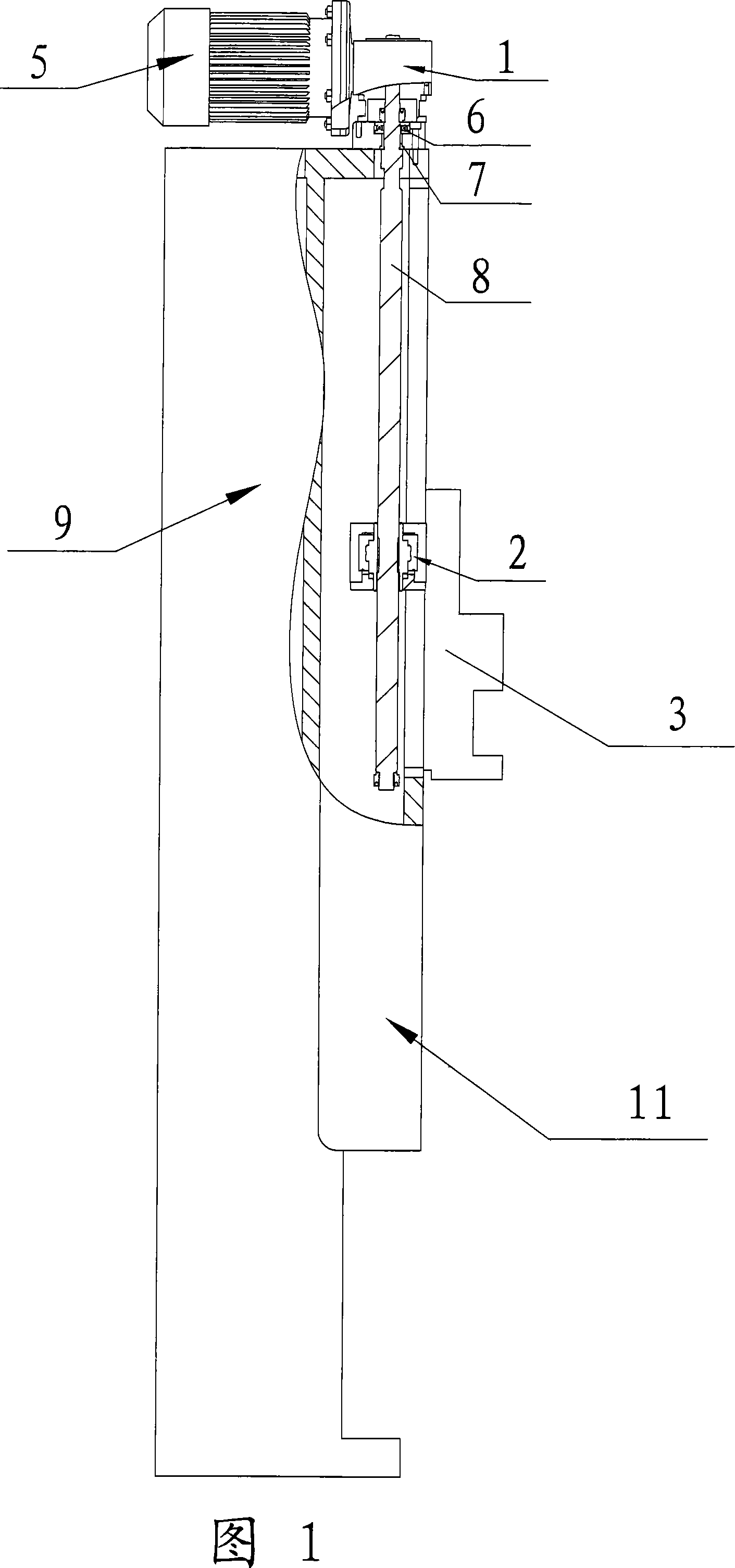

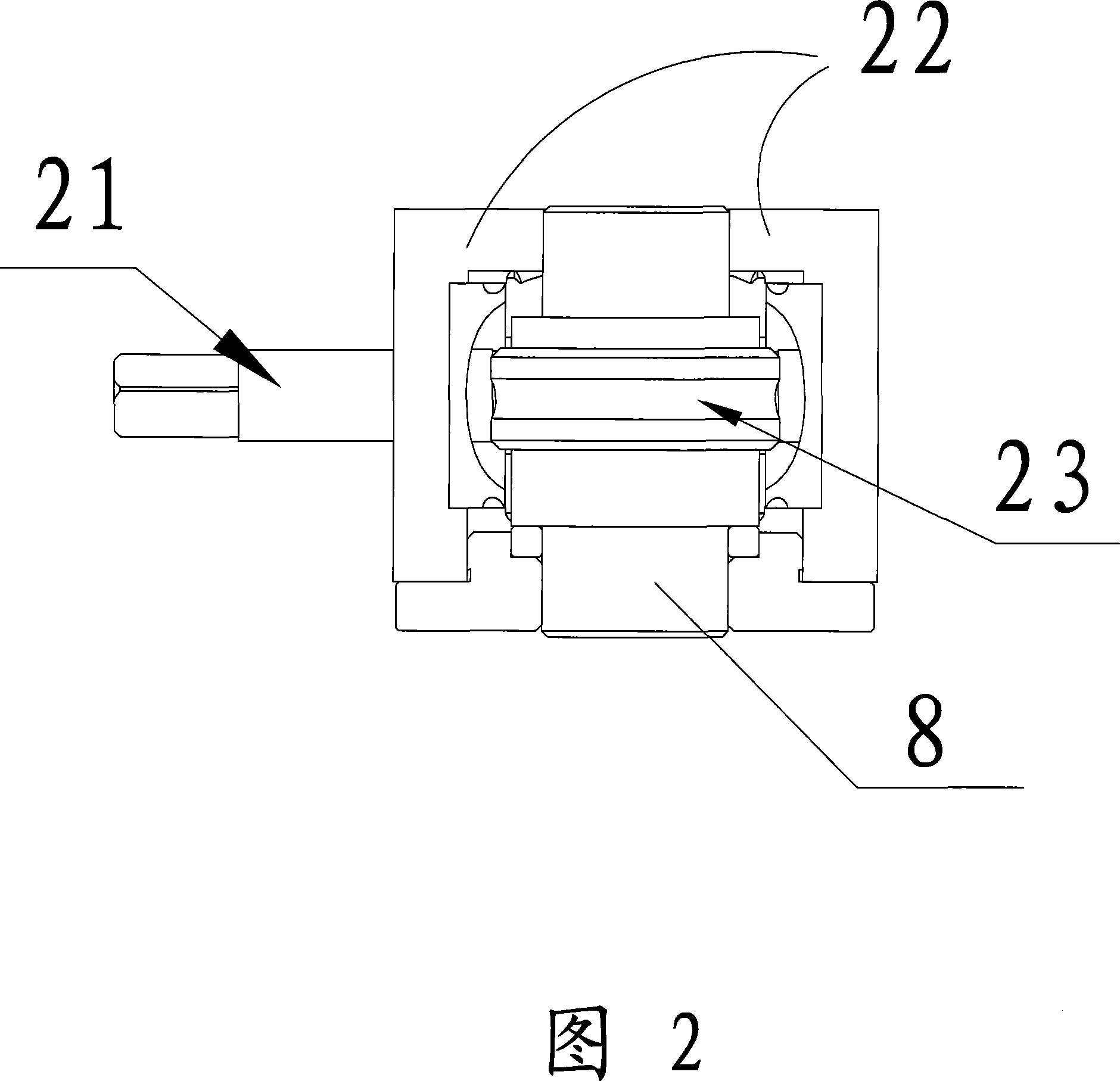

[0016] Referring to Fig. 1, a double worm gear transmission mechanism for a machine tool of the present invention includes a driving device 5, a primary worm gear reducer 1, a bearing 6 arranged on the primary worm gear reducer 1, a screw rod 8, a sliding Part 3, column or carriage 9, limit switch arranged on the column or carriage 9, the drive device 5 is connected with the worm shaft of the first-stage worm gear reducer 1, and the screw rod 8 is connected with the first-stage The worm shaft of the worm gear reducer 1 is vertically arranged and one end thereof is connected with the worm wheel of the first-stage worm gear reducer 1, and the sliding member 3 is slidably arranged with the column or the carriage 9, which also includes a The secondary worm gear reducer 2 on the described screw mandrel 8, as shown in Figure 2, described secondary worm gear reducer (2) comprises worm shaft 21, worm gear box 22, is arranged in worm gear box 22 and Worm wheel 23 with internal thread, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com