Mechanical arm device of centerless grinding machine

A technology of centerless grinding machines and manipulators, applied in the direction of manipulators, program-controlled manipulators, grinding machines, etc., can solve the problems of difficult machining accuracy and low machining efficiency, and achieve the effects of ensuring product quality, reducing scrap rate, and preventing radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

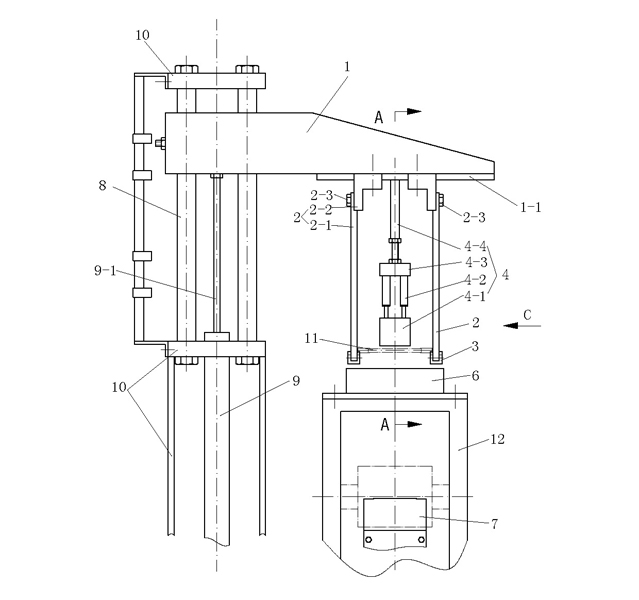

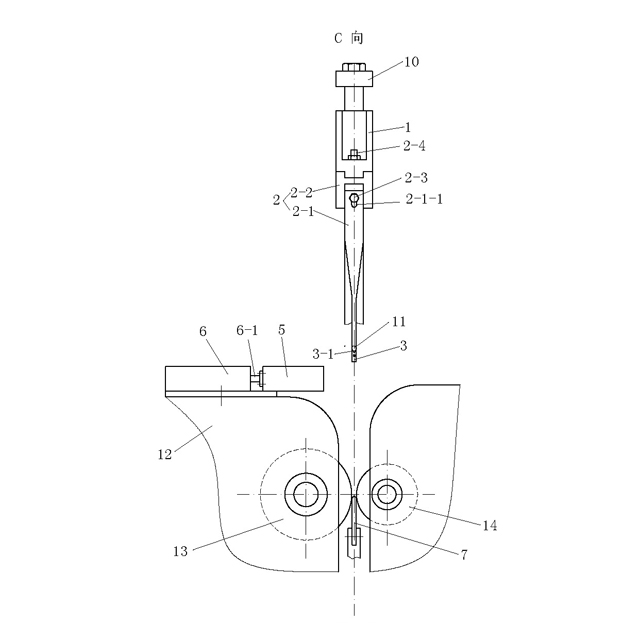

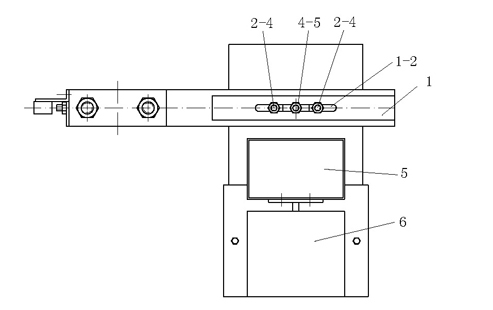

[0026] See Figure 1 to Figure 9 , this embodiment includes a pallet 7 fixed on the main machine frame and between the grinding wheel 13 and the guide wheel 14, and also includes a bracket 10 fixed on the main machine frame, a hydraulic cylinder 9 fixed on the bottom of the bracket 10, and a A pair of guide posts 8 on the top of the support 10 and a lifting seat 1 that is driven by the piston rod 9-1 of the hydraulic cylinder 9 to slide along the above-mentioned pair of guide posts 8, a pair of mechanical arms 2 are arranged on the lifting seat 1, and the two mechanical arms The thickness h of the lower part of the arm 2 is smaller than the diameter of the workpiece, and an elastic pressing plate assembly 4 is provided on the lifting base 1 and between the two mechanical arms 2 .

[0027] The casing 12 above the grinding wheel of the main machine is provided with a cylinder 6, and the piston rod of the cylinder 6 is connected to a receiving box 5. When the two mechanical arms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com