Spiral feeding device for solder splash

A technology of a screw feeding device and a feeding device, which is applied in furnaces, lighting and heating equipment, furnace components, etc., and can solve problems that affect the normal operation of the tin slag recycling machine, reduce the processing efficiency of the recycling machine, and easily cause material blocking events, etc. , to achieve the effect of solving the material blocking phenomenon, simple structure and high stability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

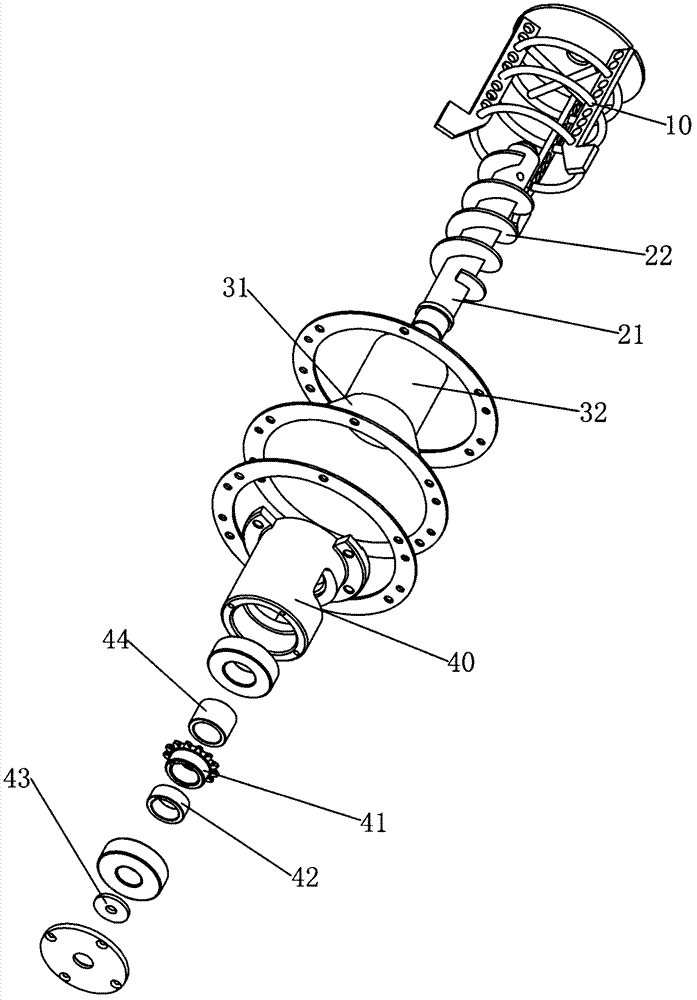

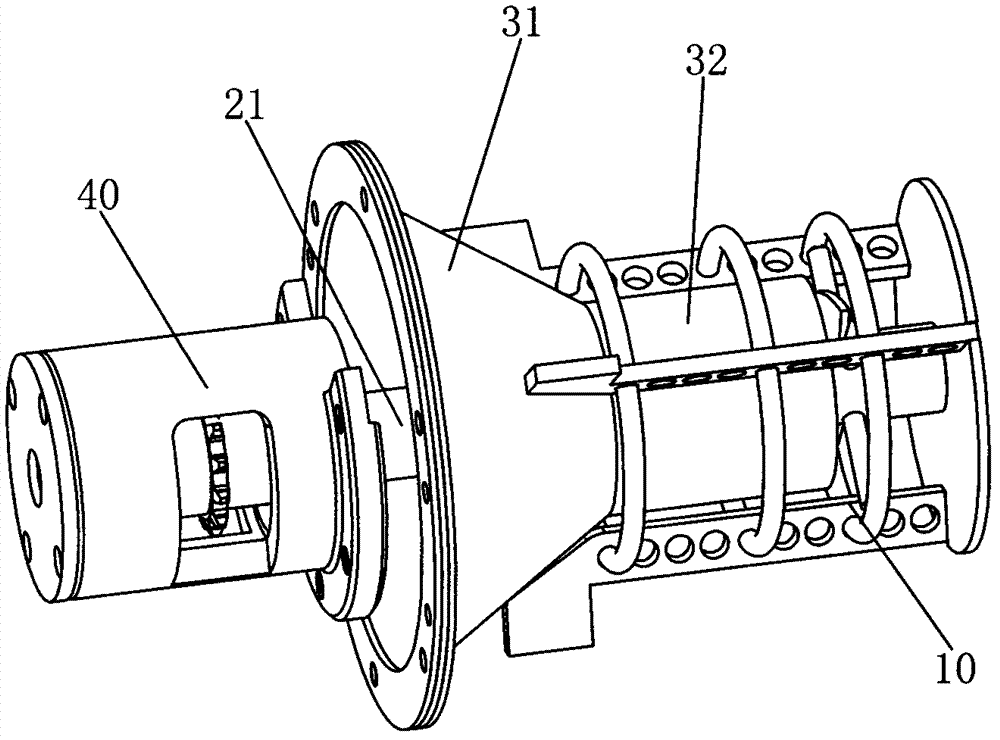

[0015] like figure 1 and figure 2 As shown, the tin slag screw feeding device has a tin slag separator, the tin slag separator includes a funnel-shaped slag inlet 31, and a circular cylinder 32 is arranged at the bottom of the slag inlet. The tin slag separator is provided with a feeding shaft 21 provided with a spiral piece 22 , and one end of the feeding shaft 21 is arranged on a bearing bracket 40 through a bearing 44 . The feed shaft 21 is passed through the slag inlet 31 and the circular cylinder 32 , and the other end of the feed shaft 21 outside the circular cylinder is fixedly provided with a stirring device 10 . Stirring device 10 has a base plate perpendicular to the feed axis and a screw rod arranged helically around the outer body of the circular cylinder. Stirring fins parallel to the feed axis are arranged on the screw rod. The upper part of the tin slag separator is fixedly connected with the bearing bracket 40, the feed shaft 21 is connected with the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com