Online shearing device of mesh sheet burr of mesh welding machine

A technology of shearing device and mesh welding machine, applied in the field of mesh welding machine, can solve the problems of wasting manpower, material resources, labor and time, and achieve the effects of improving productivity, saving labor and processes, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

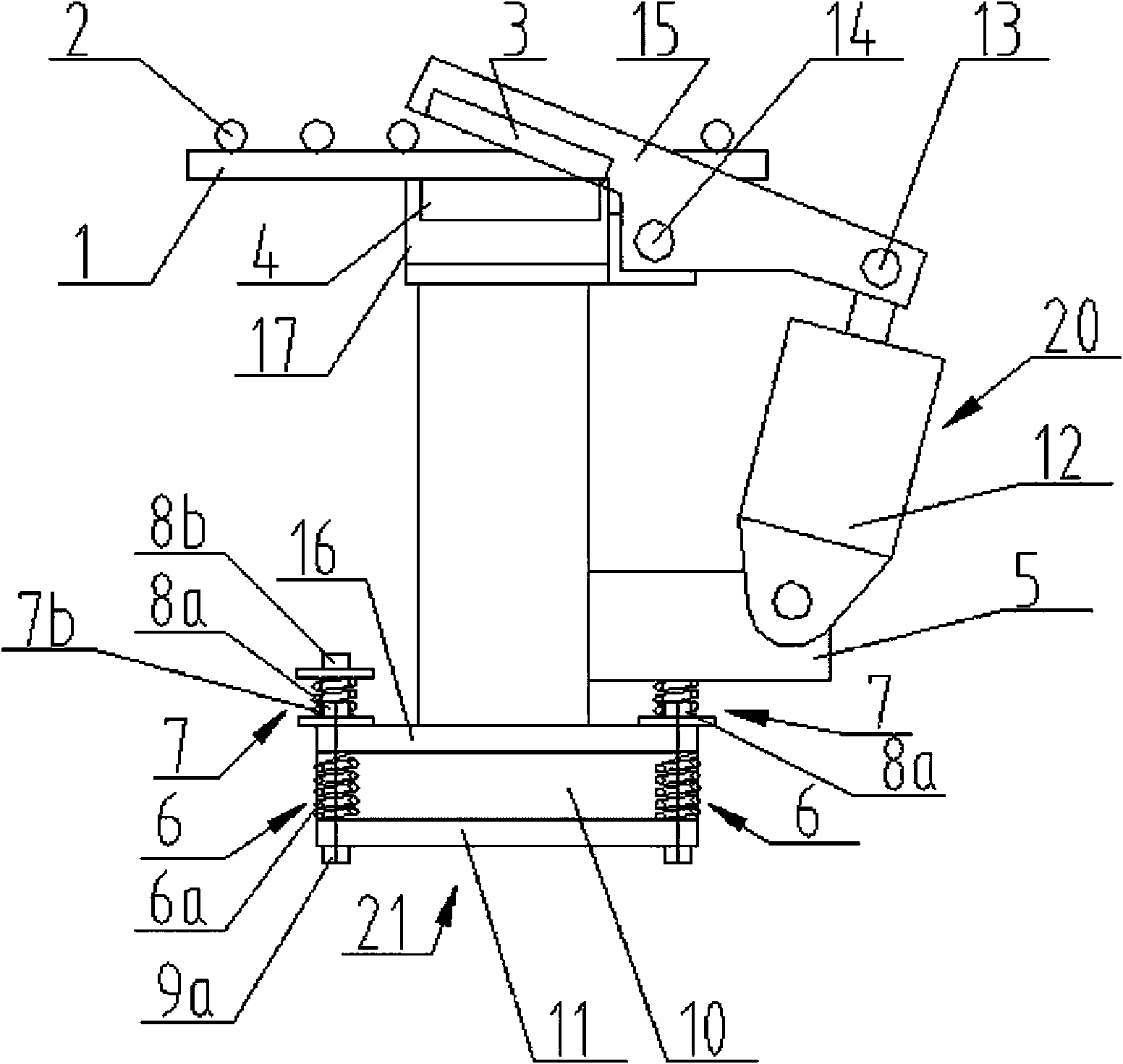

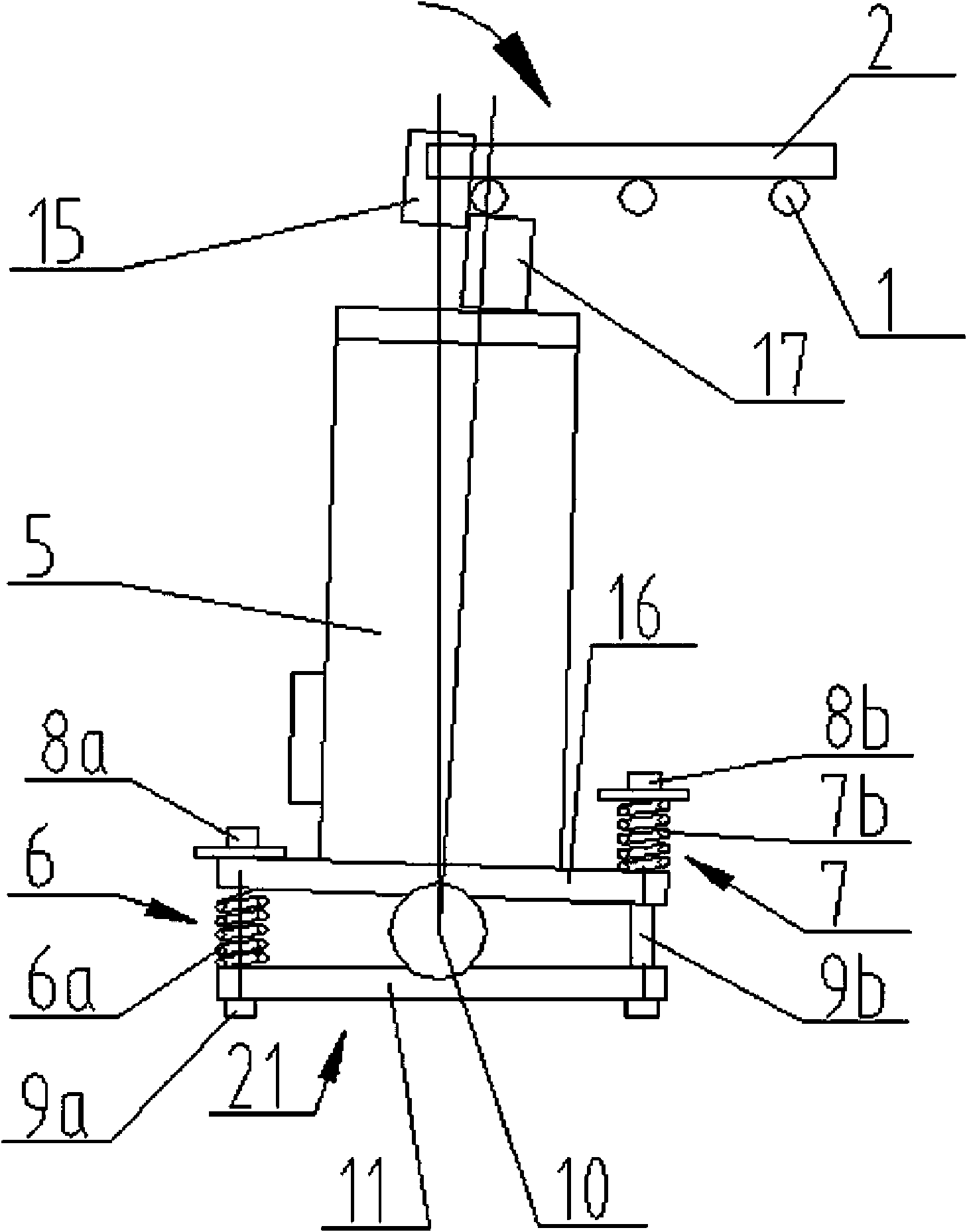

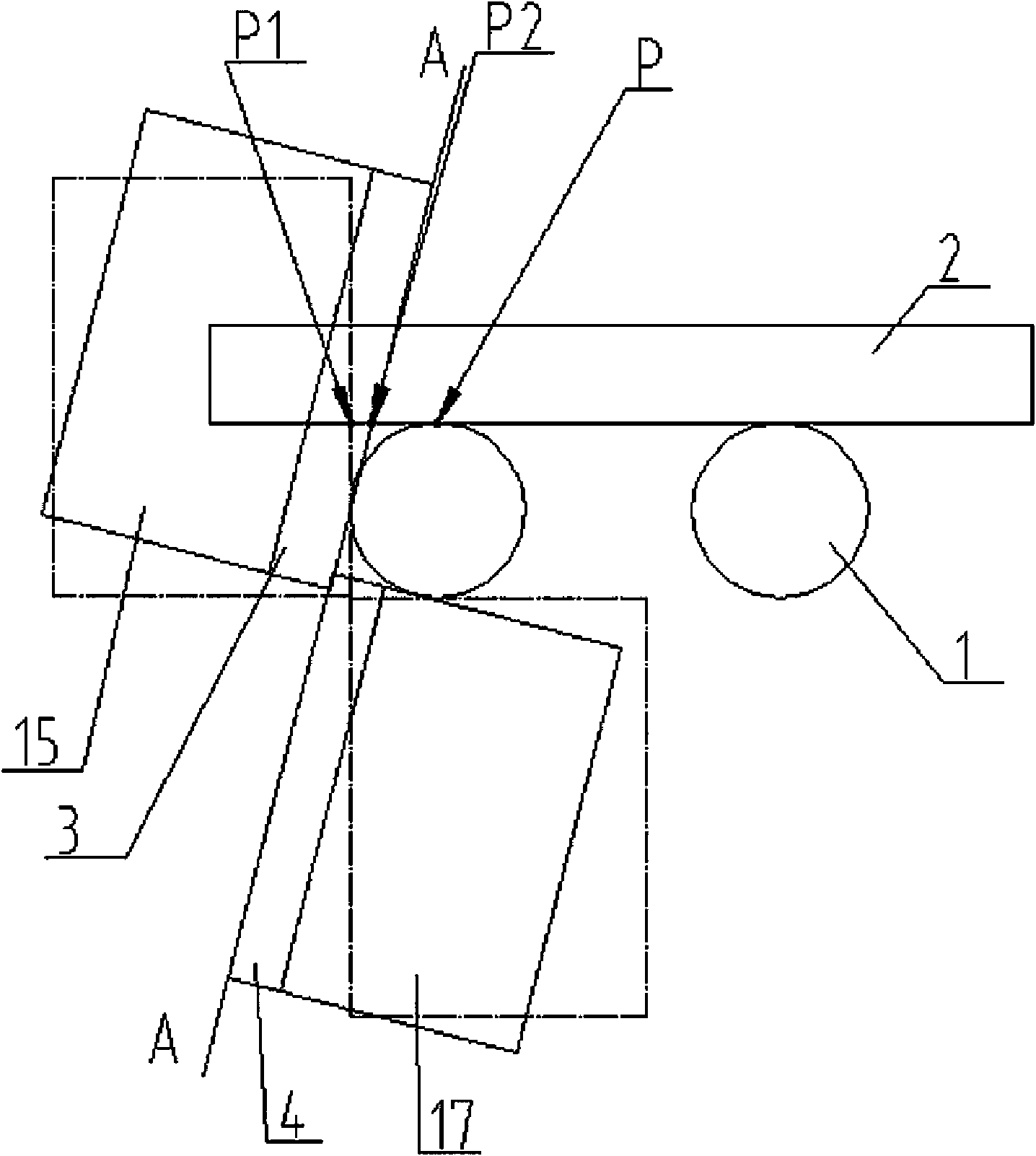

[0014] figure 1 It is a structural schematic diagram of the present invention; figure 2 Yes figure 1 right view of image 3 Yes figure 2 Enlarged view of the part where the middle upper knife and the lower knife cut the hair head.

[0015] As shown in the figure, the present invention provides an on-line shearing device for the mesh hair ends of a wire mesh welding machine arranged at the outlet of the wire mesh welding machine. The upper knife seat 15, the lower knife seat 17 with the lower knife 4, the support 5 that supports and fixes the lower knife seat 17, the lever drive mechanism 20 that drives the upper knife seat 15 to swing.

[0016] like Figure 1 to Figure 3 As shown, one end of the upper knife seat 15 is connected to the drive mechanism 20, the other end of the upper knife seat 15 is provided with the upper knife 3, and the hinge sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com