Rock fabrication device and method for simulating three-dimensional morphology of multi-structure surface

A technology for making a device and a three-dimensional shape, applied in the engineering field, can solve the problems of non-reusable, unsatisfactory effect, long production cycle, etc., achieving the effect of strong practicability, improving rigidity and deficiencies, and saving process and cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

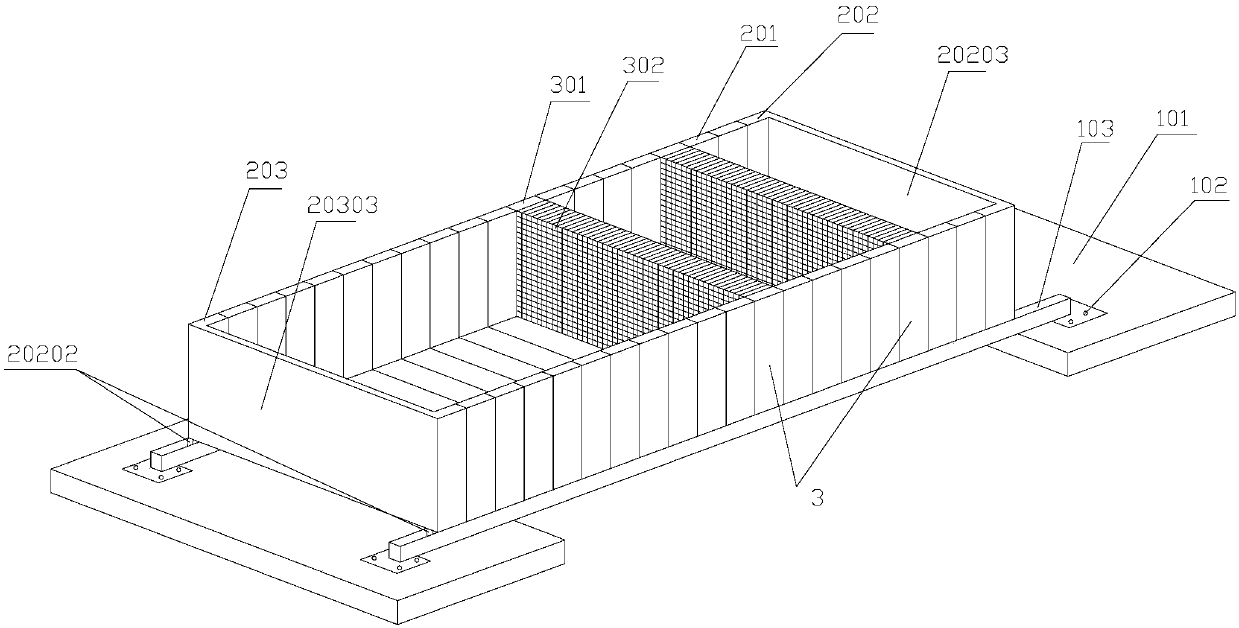

[0050] A rock mass production device for simulating the three-dimensional shape of multiple structural surfaces, comprising a chassis 1, a rock mass mold frame 2 and a structural surface mold frame 3, the structural surface mold frame 3 is plugged in the middle of the rock mass mold frame 2, and the rock mass mold frame 2 1. The structural surface mold frame 3 is slidingly connected with the chassis 1;

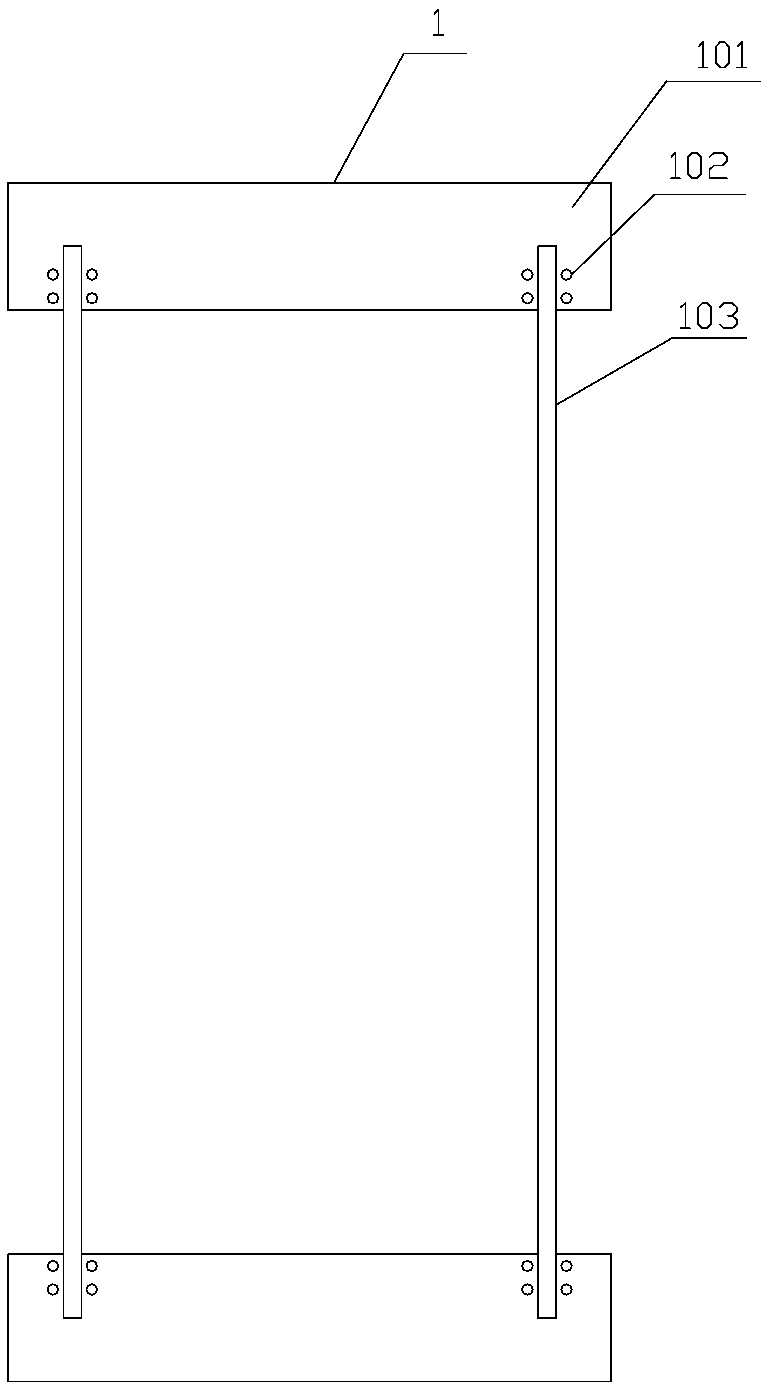

[0051] The chassis 1 includes a base 101, fixing screws 102 and mold frame rails 103, wherein the mold frame rails 103 are fixedly connected to the base 101 through the fixing screws 102;

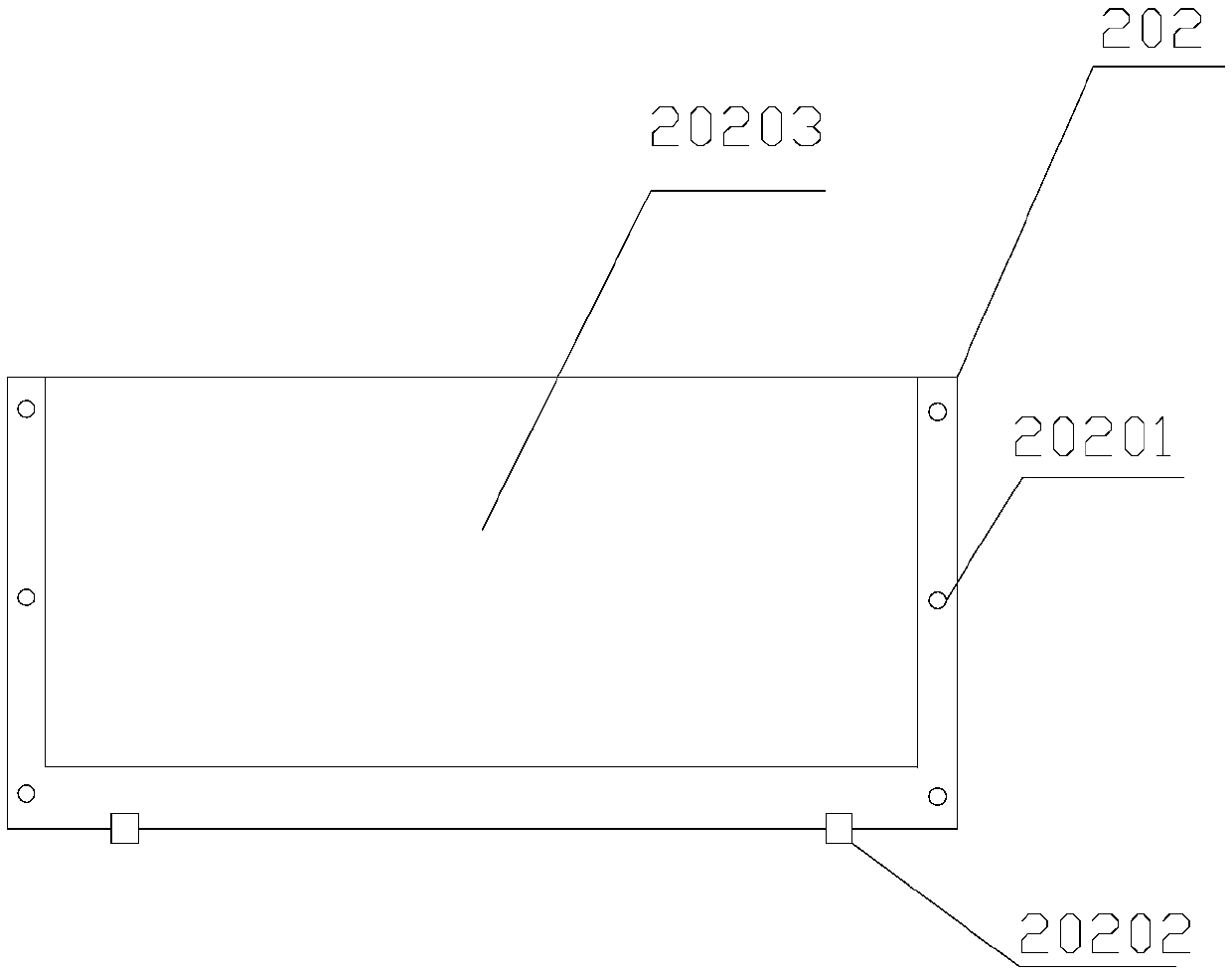

[0052] The rock mass mold frame 2 includes a thin concave-shaped plate 1 201, a thin concave-shaped plate 202 closed at the rear and a thin concave-shaped plate 203 closed at the front, wherein:

[0053] The front side of the thin concave-shaped plate-201 has a protrusion-20101, and the rear side has a groove-20102 for mutual assembly and combination, and the bottom of the thin concave-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com