High-frequency induction type dewaxing kettle with wax-water separation function

A high-frequency induction and dewaxing technology, applied in the direction of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of cumbersome replacement of heating tubes, slow heating speed, large power consumption, etc., and achieve a high degree of automation and heating Fast, clean results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

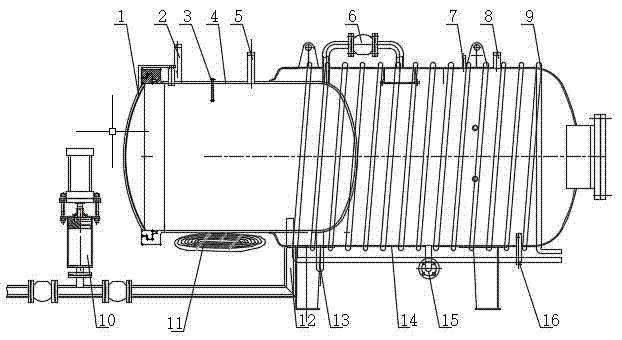

[0010] refer to figure 1 , High-frequency induction dewaxing and wax-water separation dewaxing kettle includes 1-kettle door, 4-dewaxing chamber, 6-dewaxing chamber intake control valve, 9-steam generating tank induction coil, 10-wax pump, 11-heating and dewatering induction coil, 14-steam generating tank.

[0011] The steam generating tank is welded by a cylinder made of carbon steel and a head, and a water inlet and a water outlet are left under the steam generating tank. 7-steam generating tank temperature sensor, 8-steam generating tank safety valve are installed above the steam generating tank. The outer layer of the steam generation tank is wrapped with thermal insulation material to reduce heat loss, and the outer thermal insulation material is evenly wound with 9-steam generation tank induction coils.

[0012] The 4-dewaxing chamber is welded together with the 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com