A ground reinforcement method

A foundation reinforcement and pre-reinforcement technology, which is applied in infrastructure engineering, construction, soil protection, etc., can solve the problems of waste of working hours, affecting the progress of the construction period, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

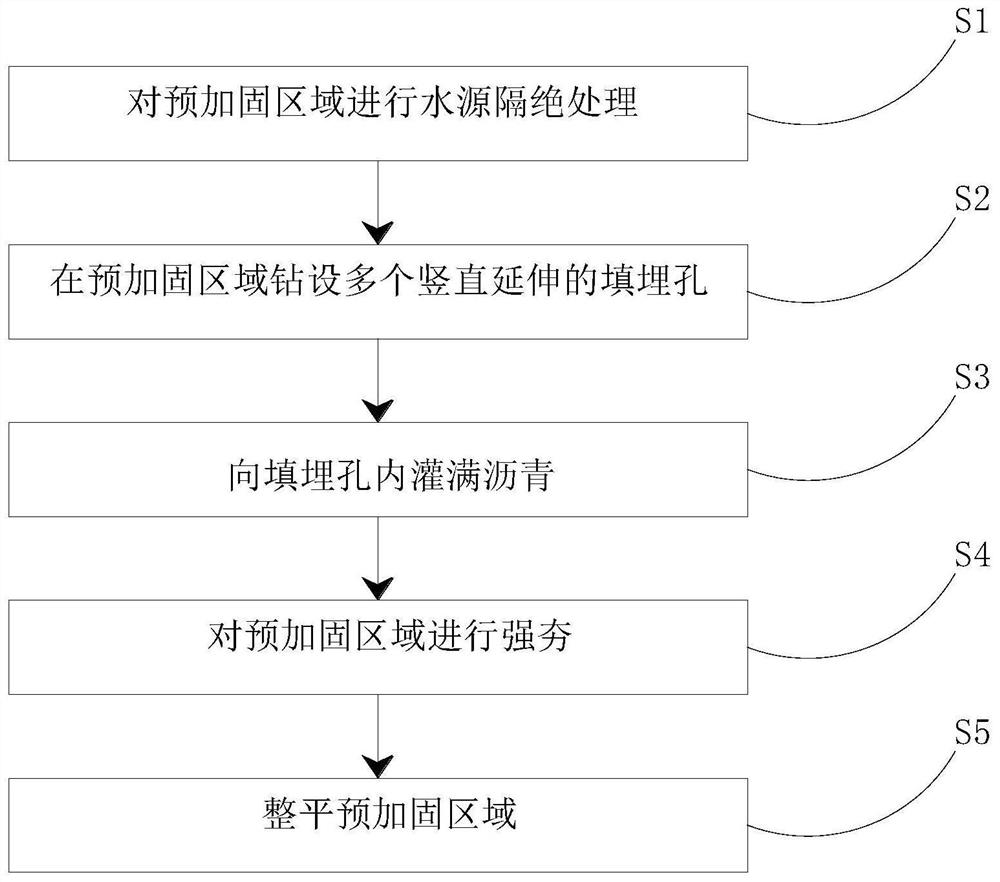

[0034] A ground reinforcement method, comprising the steps of:

[0035] S1. Carry out water source isolation treatment on the pre-reinforcement area, specifically including the following steps:

[0036] S11. Dig a water blocking ditch with a depth of 0.8m around the pre-reinforcement area, and fill the water blocking ditch with sand;

[0037] S12. Excavating multiple crisscross water storage ditches with a depth of 0.3m in the pre-reinforcement area;

[0038] S2. Drill multiple burial holes with a depth of 1.55m in rows and columns on the surface of the pre-reinforcement area at a distance of 1×1m;

[0039] S3, fill the asphalt in the landfill hole, specifically include the following steps:

[0040] S31, evenly laying a layer of activated carbon powder with a thickness of 0.5mm on the hole wall of the buried hole;

[0041] S32, pouring asphalt with a temperature of 75°C into the landfill hole;

[0042] S33. Vertically insert the tapered steel column into the asphalt and ex...

Embodiment 2

[0047] A ground reinforcement method, comprising the steps of:

[0048] S1. Carry out water source isolation treatment on the pre-reinforcement area, specifically including the following steps:

[0049] S11. Dig a water blocking ditch with a depth of 0.5m around the pre-reinforcement area, and fill the water blocking ditch with sand;

[0050] S12. Digging and setting multiple criss-crossing water storage ditches with a depth of 0.4m in the pre-reinforcement area;

[0051] S2. Drill multiple burial holes with a depth of 1.7m in rows and columns on the surface of the pre-reinforcement area at a distance of 1×1m;

[0052] S3, fill the asphalt in the landfill hole, specifically include the following steps:

[0053] S31, evenly laying a layer of activated carbon powder with a thickness of 0.5mm on the hole wall of the buried hole;

[0054] S32, pouring asphalt with a temperature of 70°C into the landfill hole;

[0055] S33. Vertically insert the tapered steel column into the as...

Embodiment 3

[0060] A ground reinforcement method, comprising the steps of:

[0061] S1. Carry out water source isolation treatment on the pre-reinforcement area, specifically including the following steps:

[0062] S11. Dig a water blocking ditch with a depth of 0.7m around the pre-reinforcement area, and fill the water blocking ditch with sand;

[0063] S12. Excavating multiple crisscross water storage ditches with a depth of 0.5m in the pre-reinforcement area;

[0064] S2. Drill multiple burial holes with a depth of 1.5m in rows and columns on the surface of the pre-reinforcement area at a distance of 1×1m;

[0065] S3, fill the asphalt in the landfill hole, specifically include the following steps:

[0066]S31, evenly laying a layer of activated carbon powder with a thickness of 0.5mm on the hole wall of the buried hole;

[0067] S32, pouring asphalt with a temperature of 72°C into the landfill hole;

[0068] S33. Vertically insert the tapered steel column into the asphalt and exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com