Brake caliper

A reset device and brake caliper technology, applied in the field of brake caliper, can solve problems such as noise, suspected brake system failure, poor vehicle quality, etc., and achieve the effect of avoiding random collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

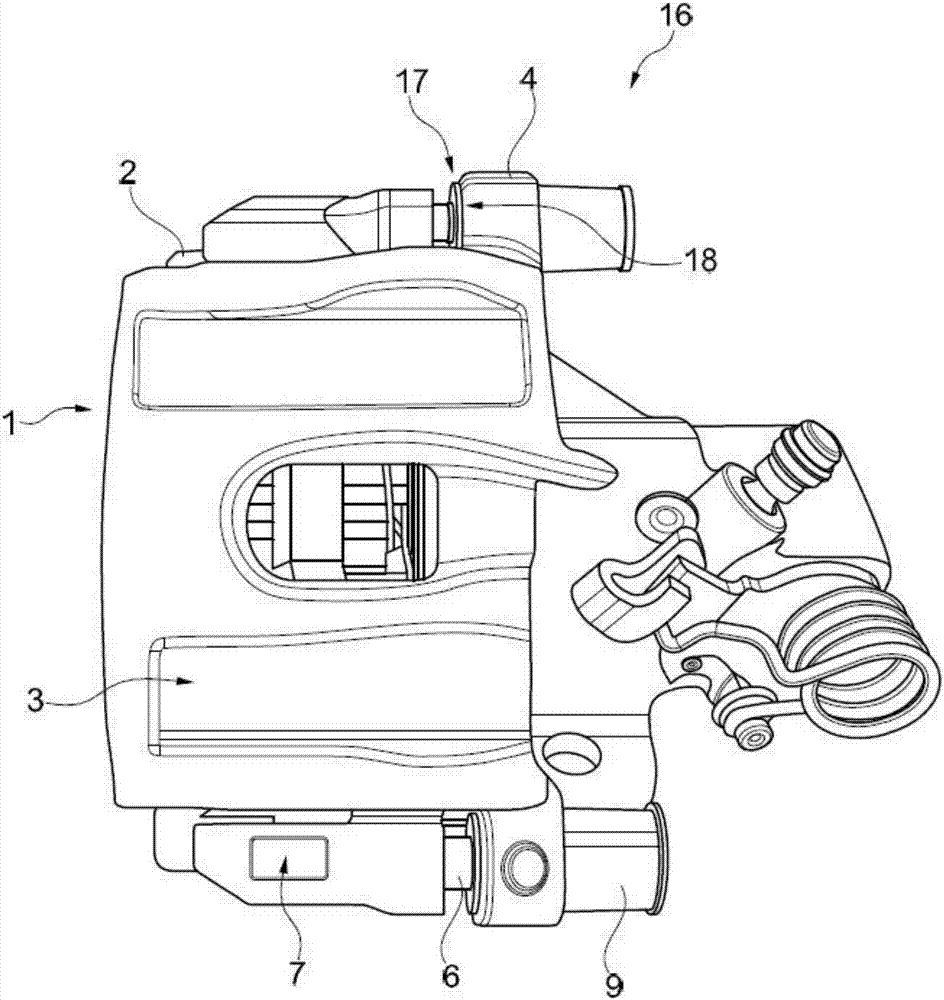

[0035] figure 1 The brake caliper is shown as floating caliper 1 in the exemplary embodiment. The floating forceps 1 has an anchor portion 2 , a fist forceps body 3 and a linear guide 4 . Brake pads (not shown) are held on the floating caliper. The inner brake pad is provided on one side of the floating caliper, which is the right side in the plane of the figure. Brake pistons (not shown) act directly on the inner brake pads. The other brake pad, ie the outer brake pad, is arranged in such a way as to be movably guided on the anchor 2 .

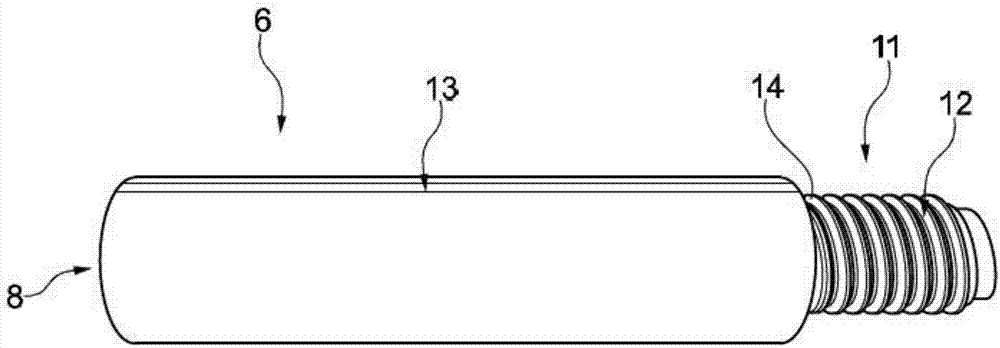

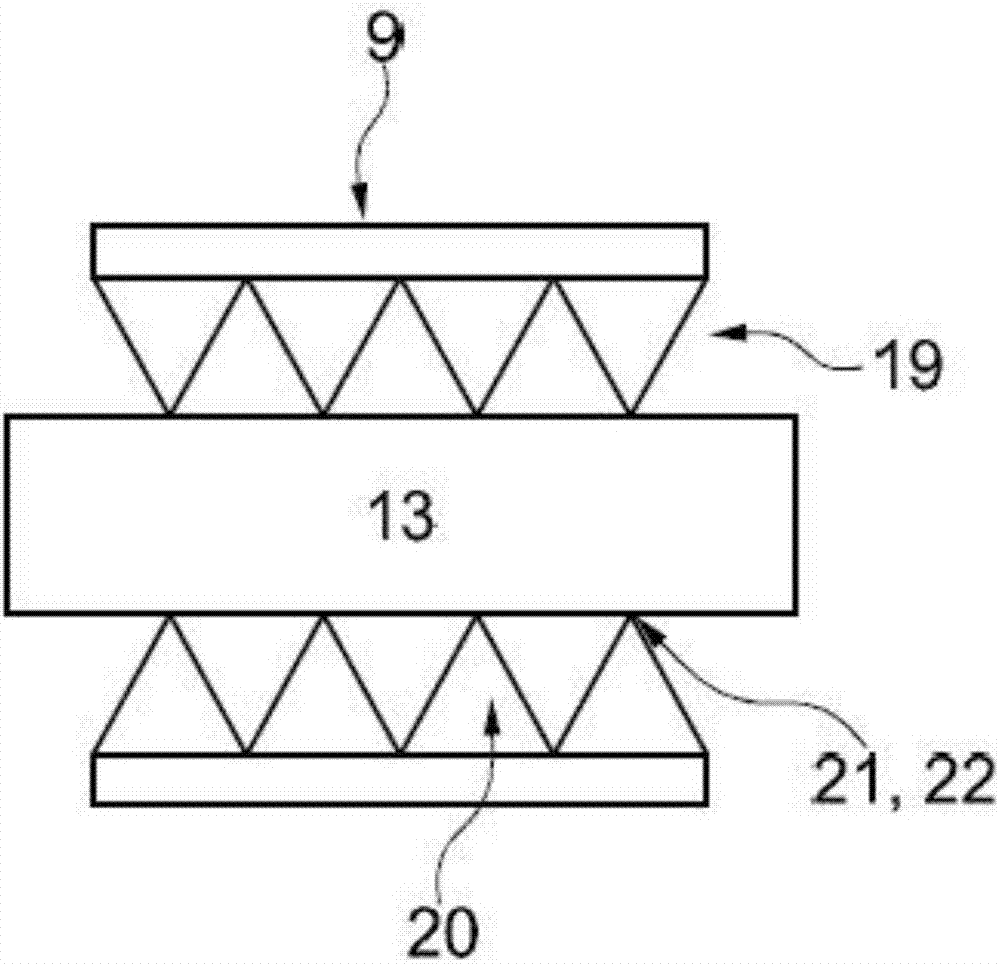

[0036] The linear guide 4 has guide elements 6 , which on the one hand are fastened in receptacles 7 of the anchor 2 . On the other hand, the guide element 6 passes through its free end 8 ( figure 2 ) is accommodated in the guide sleeve 9 of the fist-type forceps body 3 in a linearly movable manner. like figure 1 As can be seen, the floating pliers 1 has two guide elements 6, each of which is arranged laterally with respect to the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com