Polysulfone series resin polymerization dehydration process

A polymerization dehydration and resin technology, applied in the production of bulk chemicals, can solve the problems of inability to physically separate and consume, and achieve the effects of rapid water removal and recycling, continuous and efficient process, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

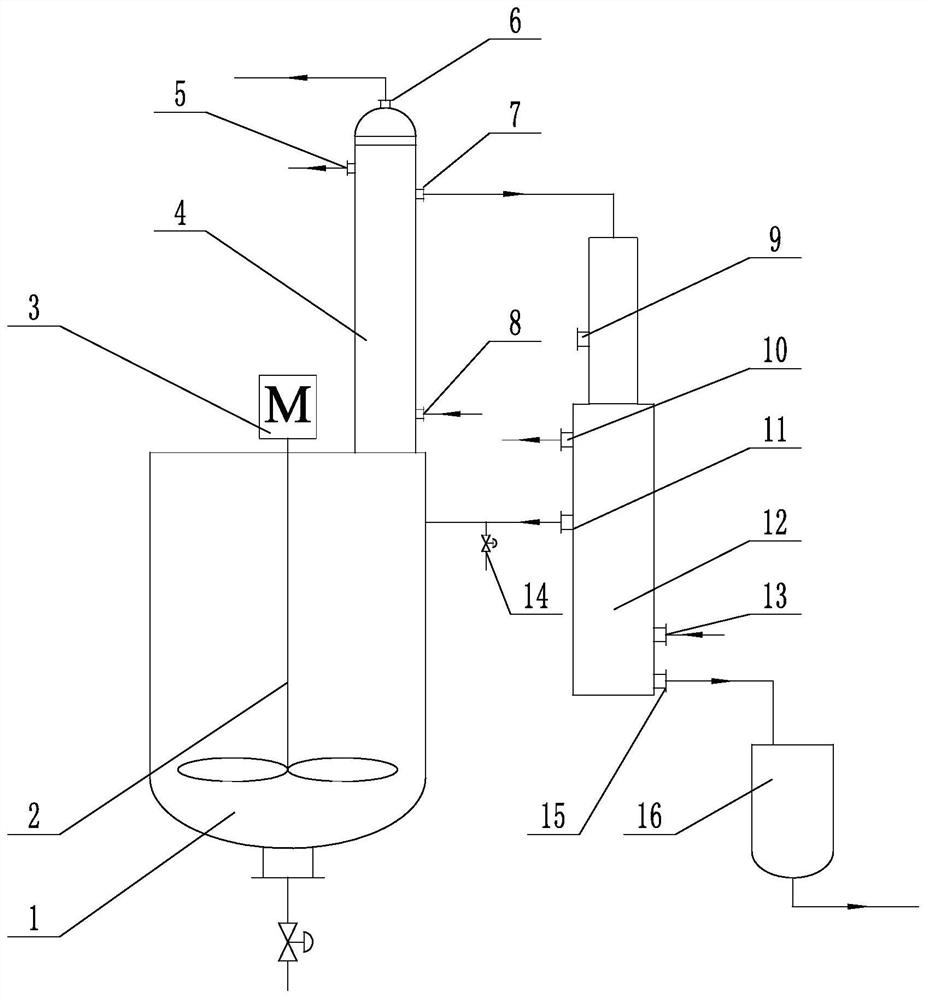

Method used

Image

Examples

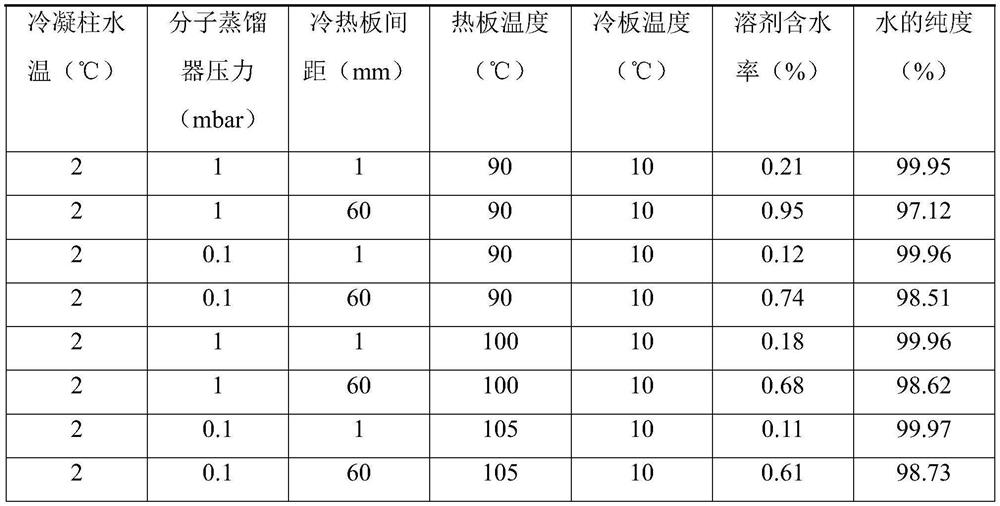

Embodiment 1

[0036] Add 9.02 kg of 4,4-dichlorodiphenyl sulfone, 6.51 kg of bisphenol A, 5.25 kg of potassium carbonate, and 65 kg of solvent dimethyl sulfoxide into a 100L polymerization reactor. All the raw materials were put into the reaction kettle, after the inside of the kettle was evacuated to ≤-0.08MPa, nitrogen gas was introduced to make the pressure inside the kettle reach ≥0.00MPa, and after nitrogen replacement three times, the reaction at normal pressure in the kettle was maintained, and the polymerization temperature rose to 189°C. The temperature of the circulating water in the condenser jacket is kept constant to 2°C by a refrigerator to ensure that the solvent and water vapor evaporated in the kettle can be quickly condensed into liquid. The cooled mixed liquid is passed into the molecular still, and the mixed liquid is scraped back and forth on the hot plate by the scraper. Reduce the internal pressure of the molecular still to 0.1mbar, the distance between the cooling pl...

Embodiment 2

[0040] Add 8.7kg of 4,4-dichlorodiphenylsulfone, 5.21kg of 4,4-dihydroxybiphenyl, 5.7kg of potassium carbonate, and 55kg of solvent dimethylacetamide into a 100L polymerization reactor. All the raw materials were put into the reaction kettle, and after the inside of the kettle was evacuated to ≤-0.08MPa, nitrogen gas was introduced to make the pressure in the kettle reach ≥0.00MPa. After three times of nitrogen replacement, the reaction at normal pressure in the kettle was maintained, and the polymerization temperature rose to 166°C. The temperature of the circulating water in the condenser jacket is kept constant to 10°C by a refrigerator to ensure that the solvent and water vapor in the kettle can be quickly condensed into liquid. The cooled mixed liquid is passed into the molecular still, and the mixed liquid is scraped back and forth on the hot plate by the scraper. Reduce the internal pressure of the molecular still to 0.1mbar, the distance between the cooling plate and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com