Patents

Literature

47results about How to "High electric heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

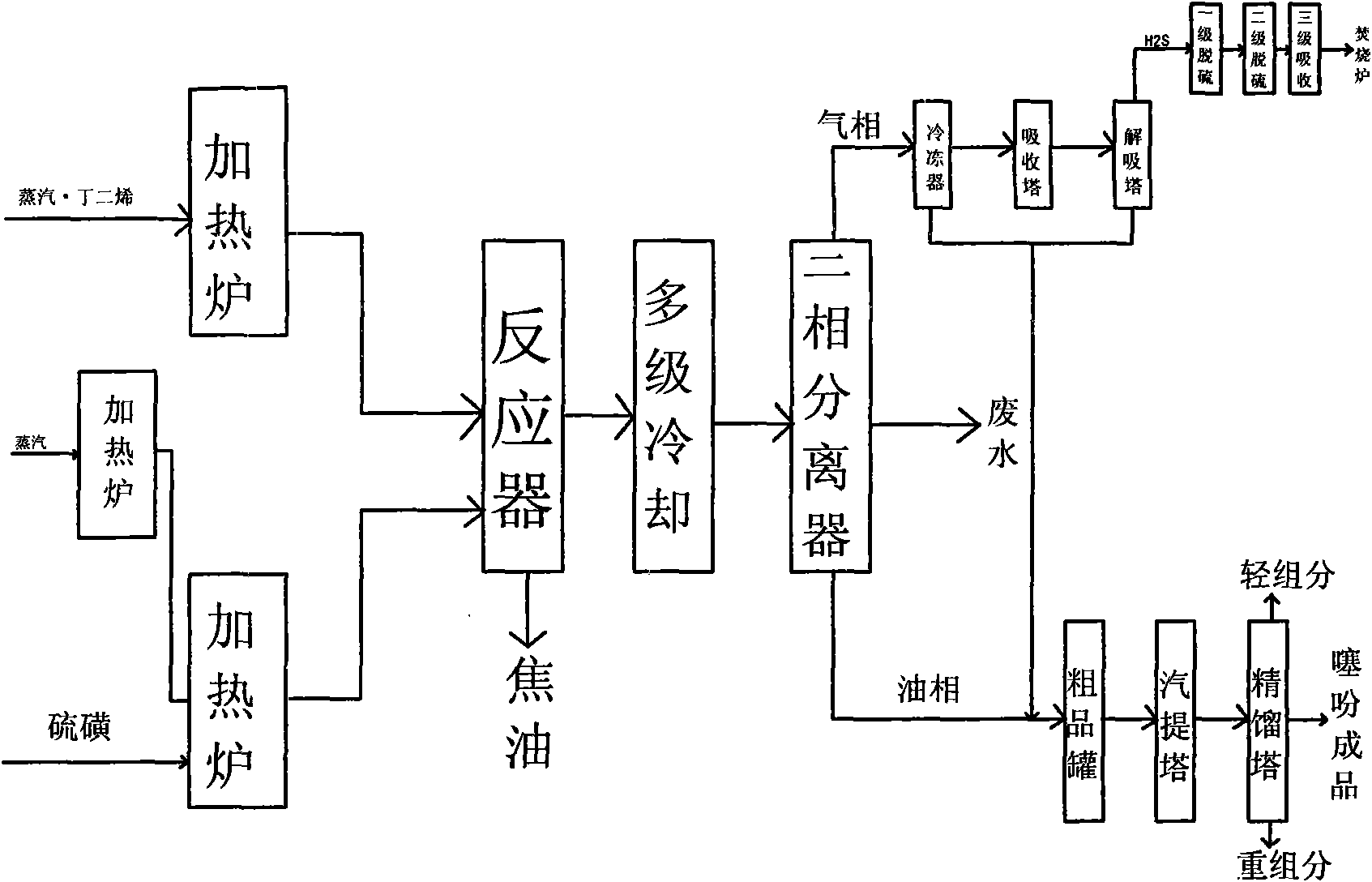

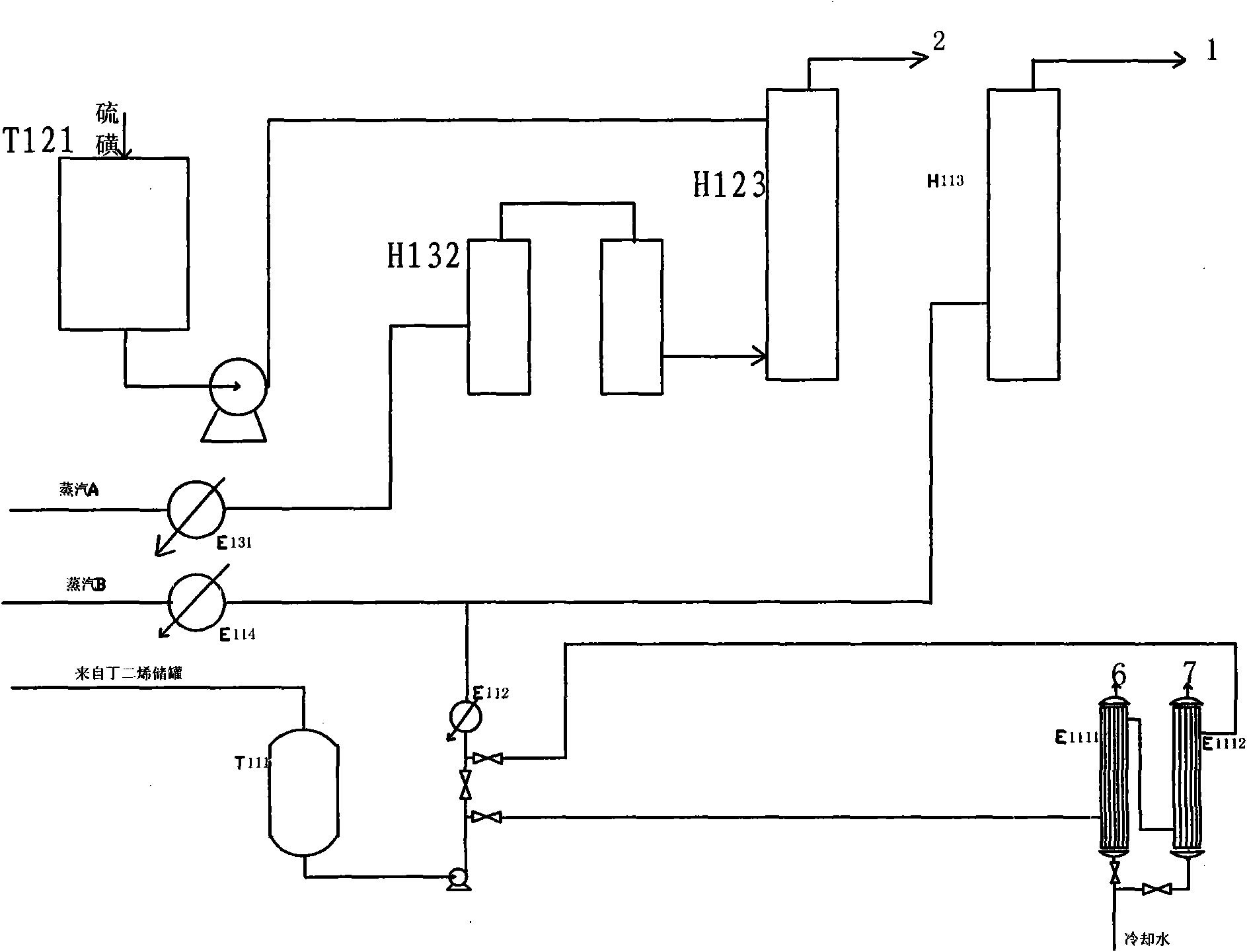

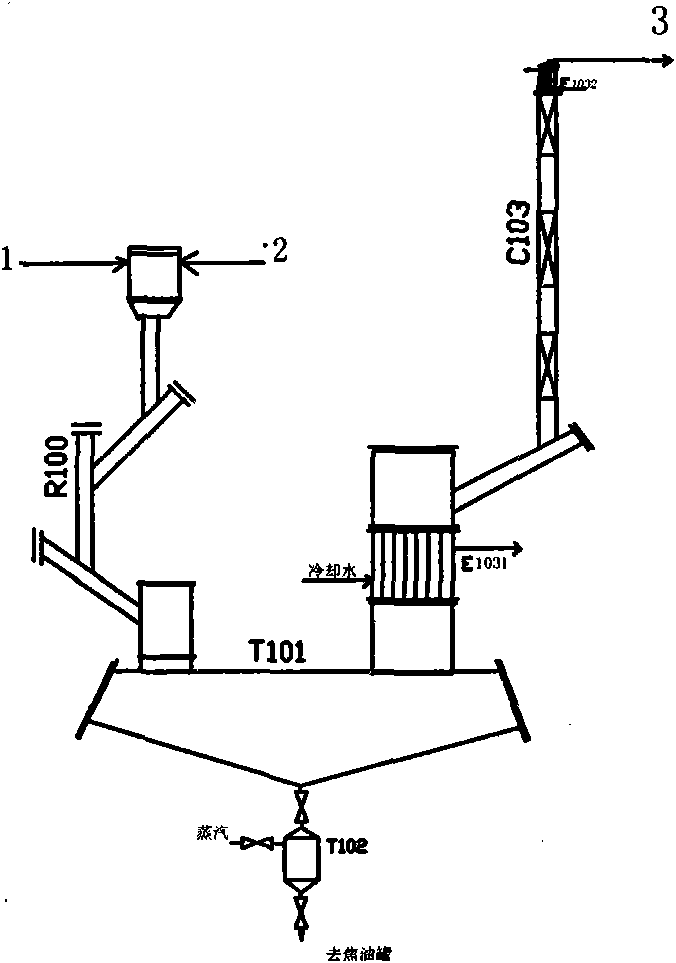

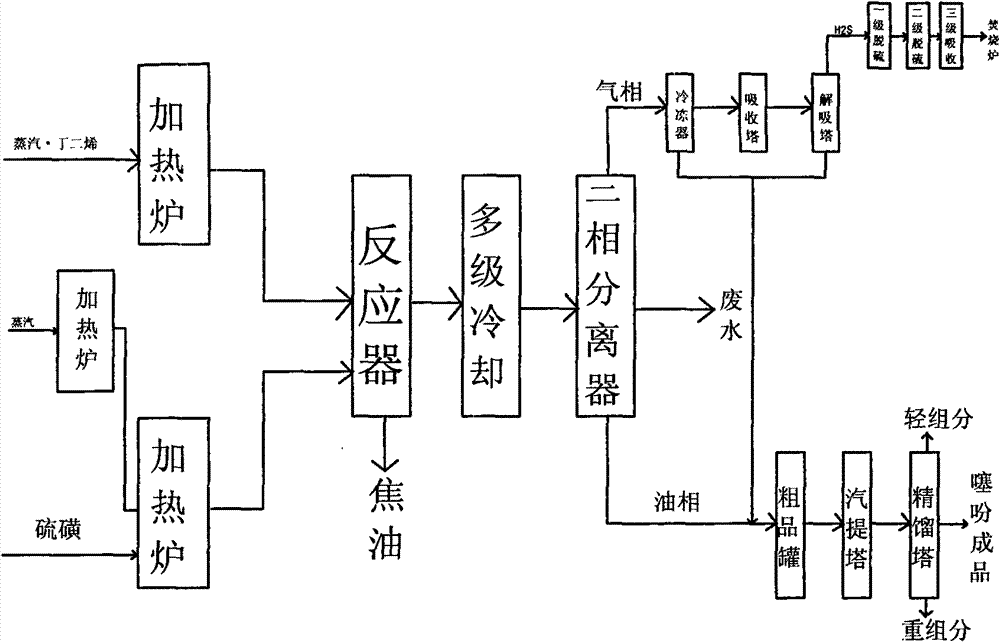

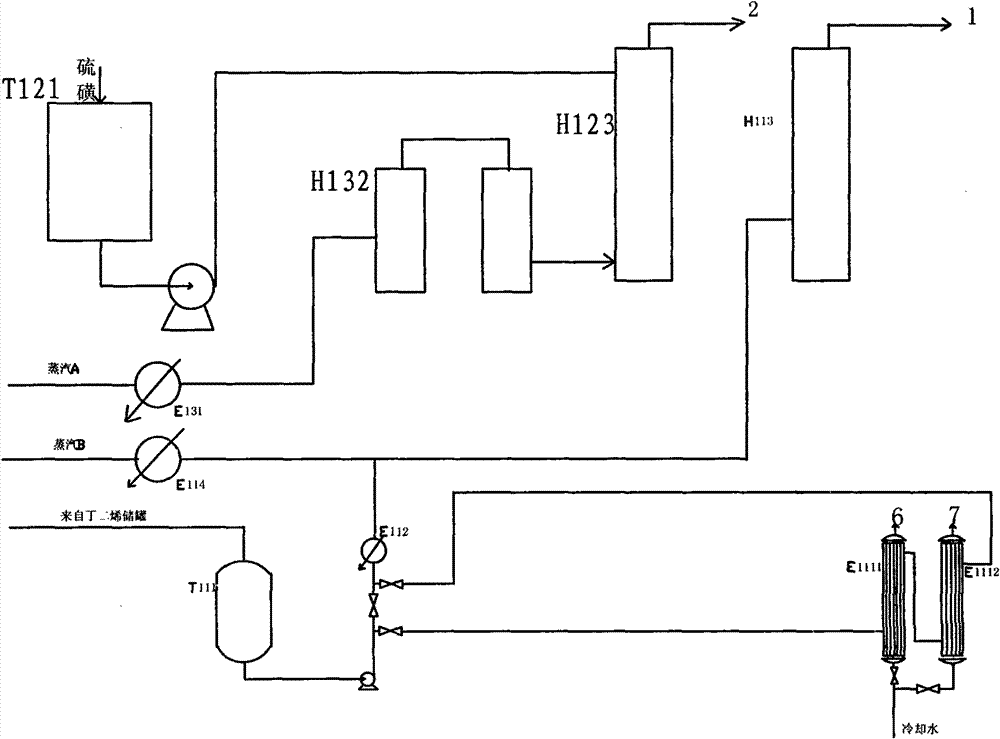

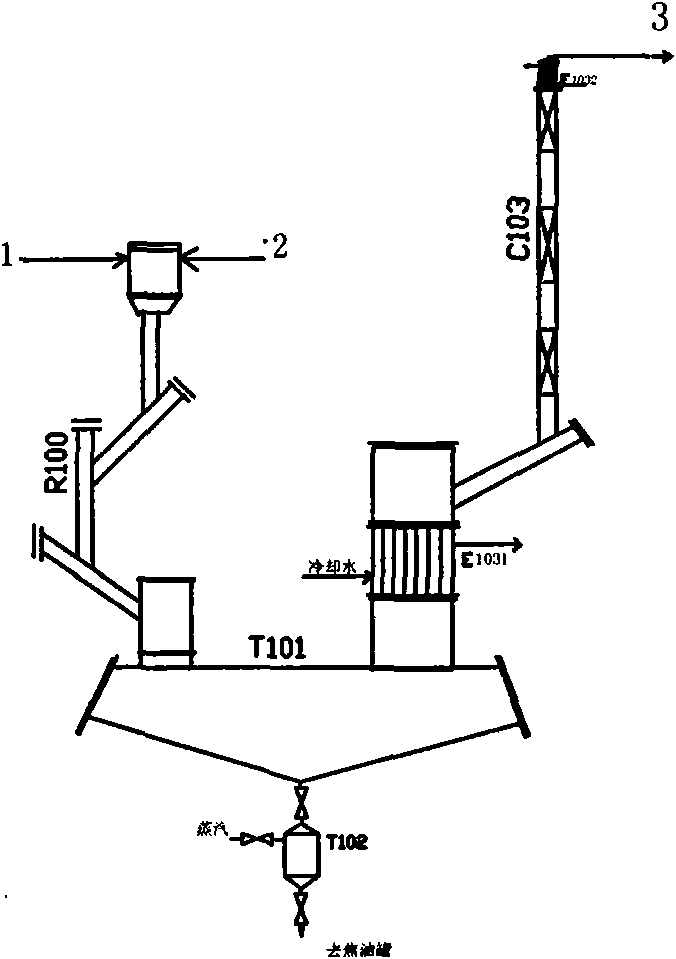

Method and device for producing thiophene and derivant thereof

ActiveCN101654449AControl inlet temperatureControl reaction temperatureOrganic chemistryDispersed particle separationRetention timeIntermediate frequency

The invention relates to method and device for producing thiophene by synthesizing butadiene and sulfur. The production method comprises the steps of reaction, separation and desulfurization. In the reaction process, raw materials are heated to initial reaction temperature by a water hose heat and intermediate frequency induction heating method, but a reactor does not need to be heated; the reaction is carried out under normal pressure at the temperature of 380-450 DEG C; the molar ratio of the sulfur to the butadiene is 1.2-1.6, the molar ratio of water to the butadiene is 1-2, and the retention time of the reaction is 1-2 seconds. A multistage cooling method is adopted to separate high boiling point tar and unreacted sulfur in a reaction product, thereby solving the problem of blockagesof pipelines and equipment. A freezing and absorbing method is adopted to recover thiophene in hydrogen sulfide which is tail gas, thereby improving the yield of the thiophene. Methods of vapor pressure sealing emptying and two-stage wet desulfurizing are adopted, thereby solving pollution problems of the tar and the hydrogen sulfide in a production process and realizing the cleaning production of the thiophene.

Owner:LIANYUNGANG DIPU CHEM

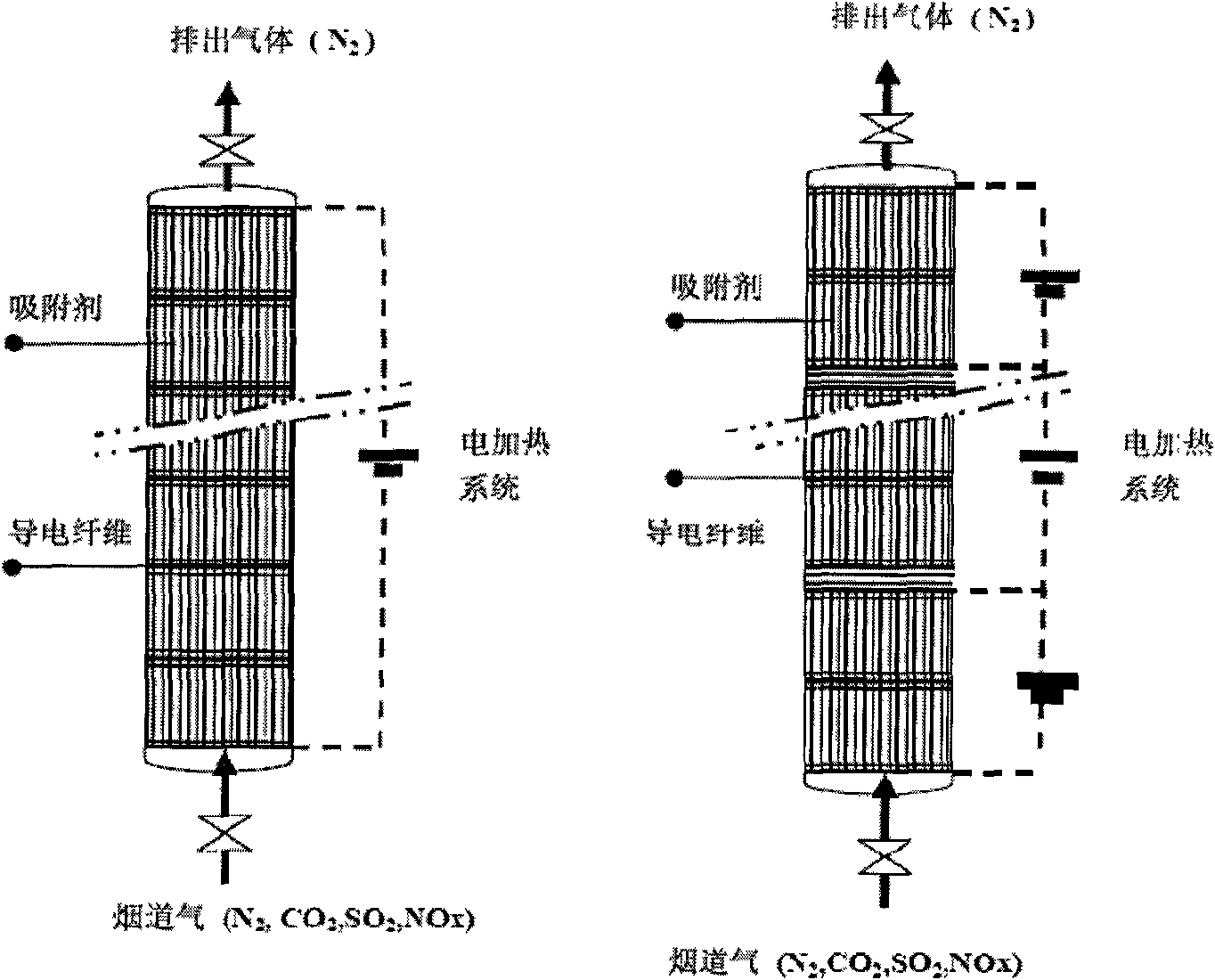

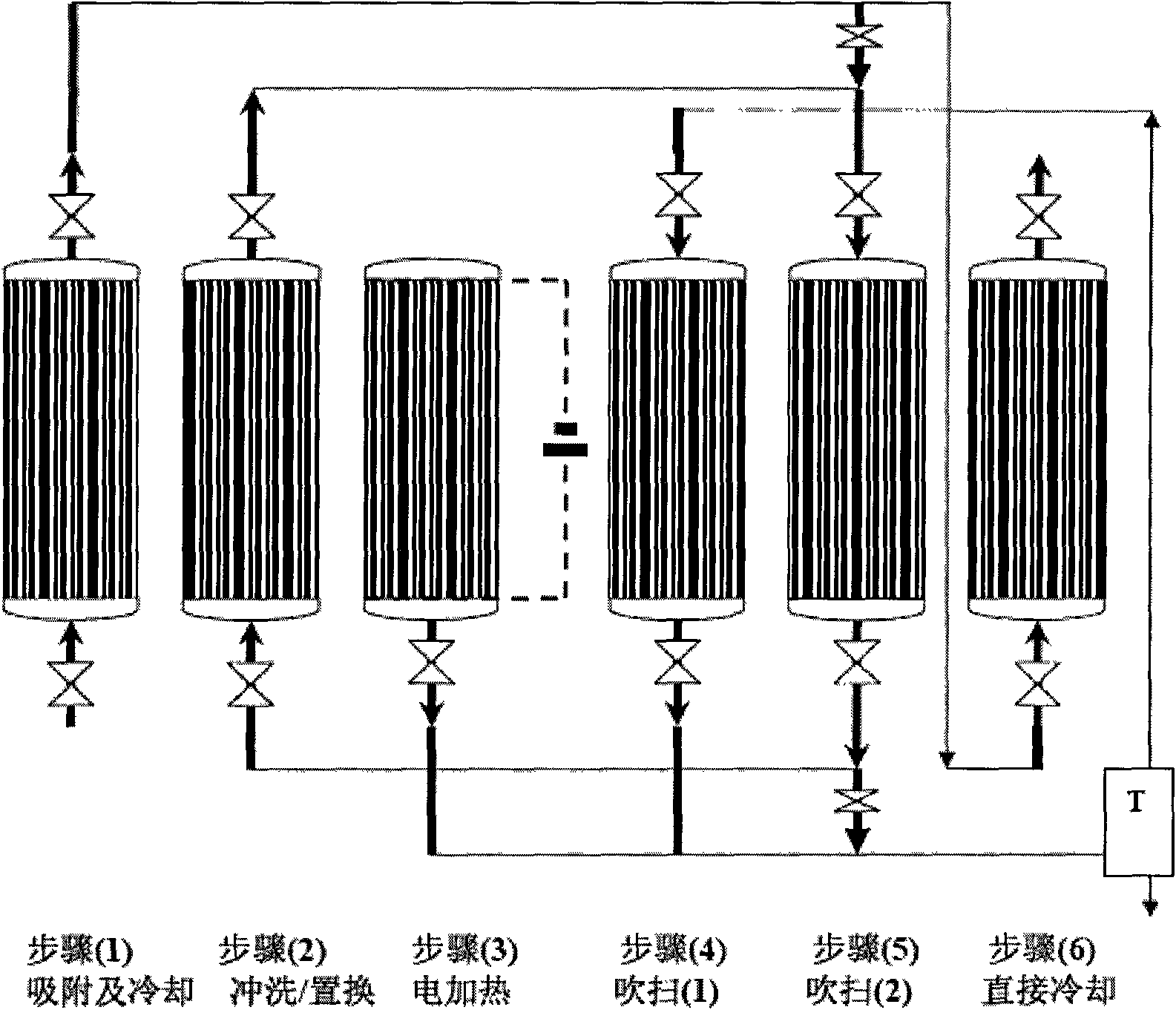

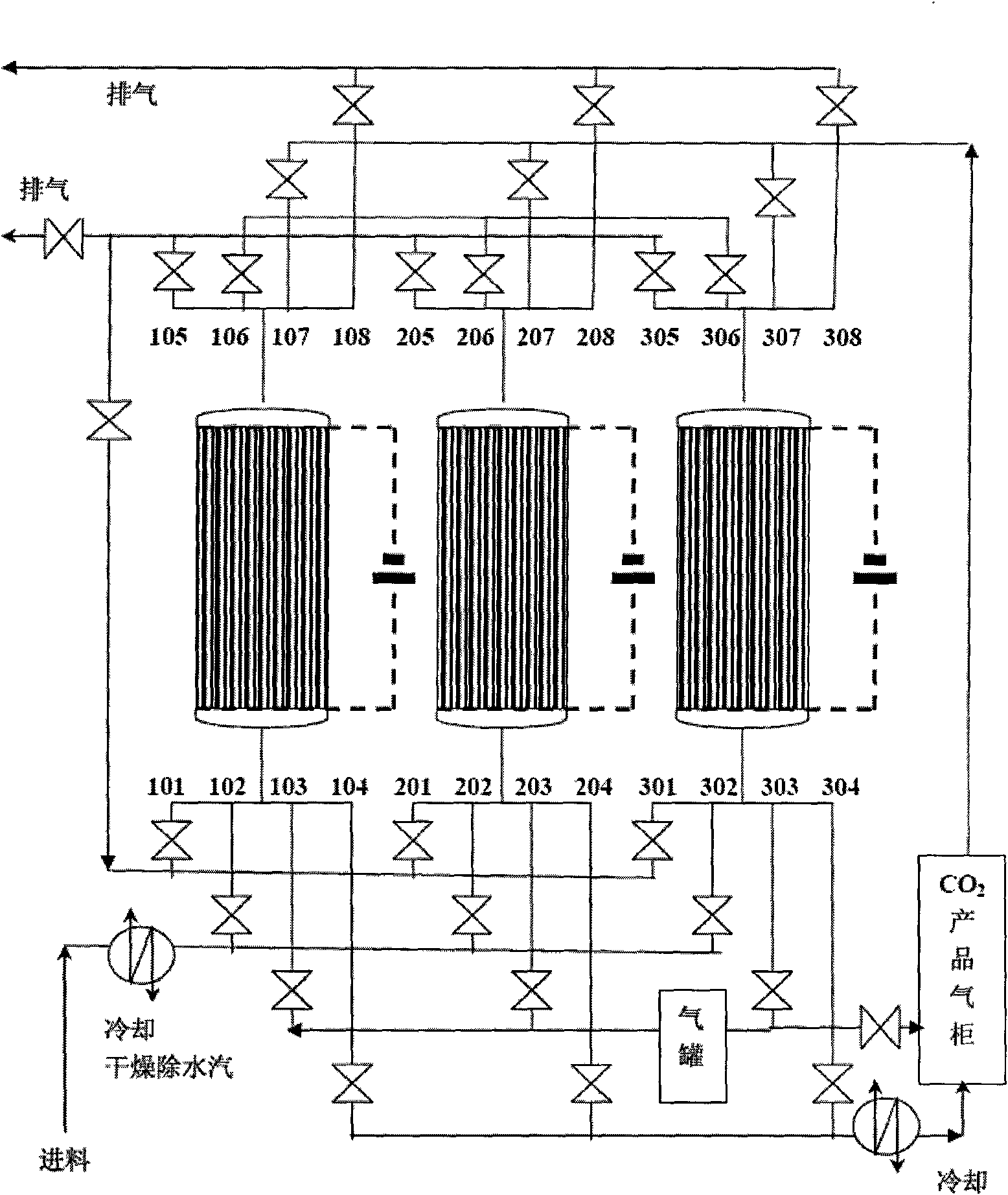

Method for capturing carbon dioxide by utilizing electrical desorption technology

The invention relates to a method for capturing carbon dioxide by utilizing an electrical desorption technology, which is a method for capturing the carbon dioxide as greenhouse gas through multi-tower type cyclic adsorption and electrical desorption technologies, and comprises the following steps: a. under the conditions that the temperature is 10 to 50 DEG C and the pressure is 1.1 to 5.0atm, capturing flue gas and the carbon dioxide in industrial tail gas by adopting an adsorbent with low pressure drop and good electricity and heat conducting performance; and b. under the condition of electrically heating the adsorbent to the temperature of 100 to 200 DEG C, desorbing the adsorbent in the step a, cooling the carbon dioxide-contained gas obtained through desorption and enabling the gas to enter a gas collector. The invention has the advantages that the adsorbent is electrically heated, thereby the temperature-rising speed is high, and the utilization ratio of electrical energy is higher; and the adsorbents with smaller pressure drop and high gas processing quantity are selected to be built into an adsorbent bed with the height of 10 meters or higher, thereby the temperature-reducing time period is shortened, the energy consumption for capturing the carbon dioxide is reduced, and the cost of capture and post processing is lowered.

Owner:EAST CHINA UNIV OF SCI & TECH

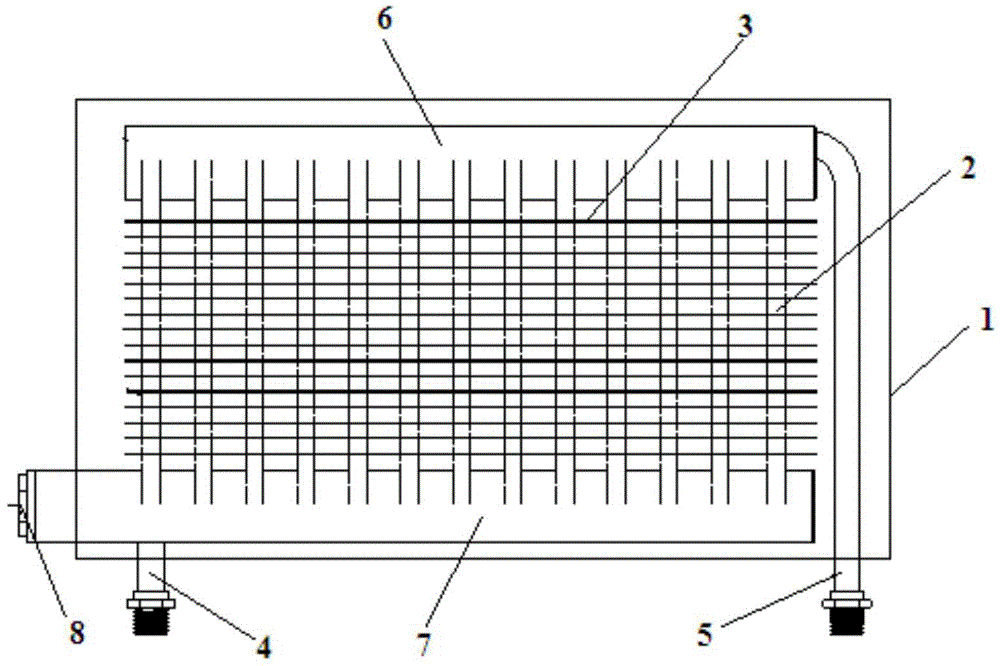

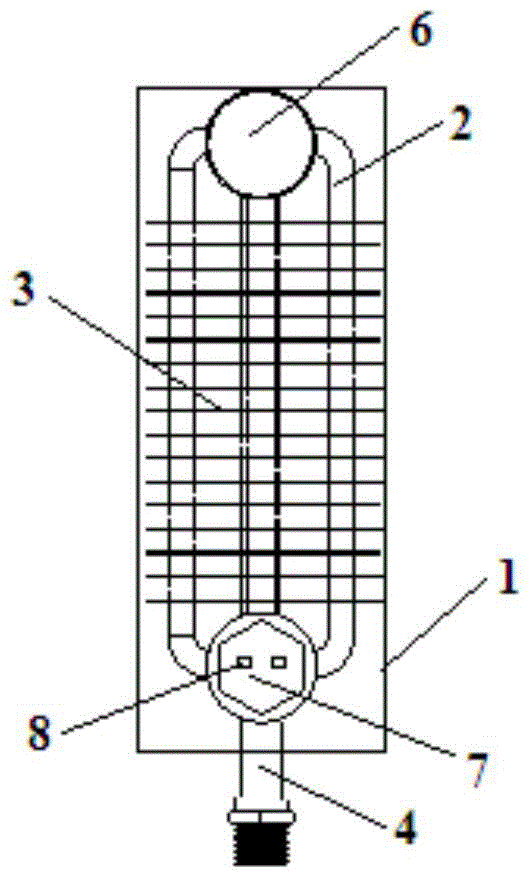

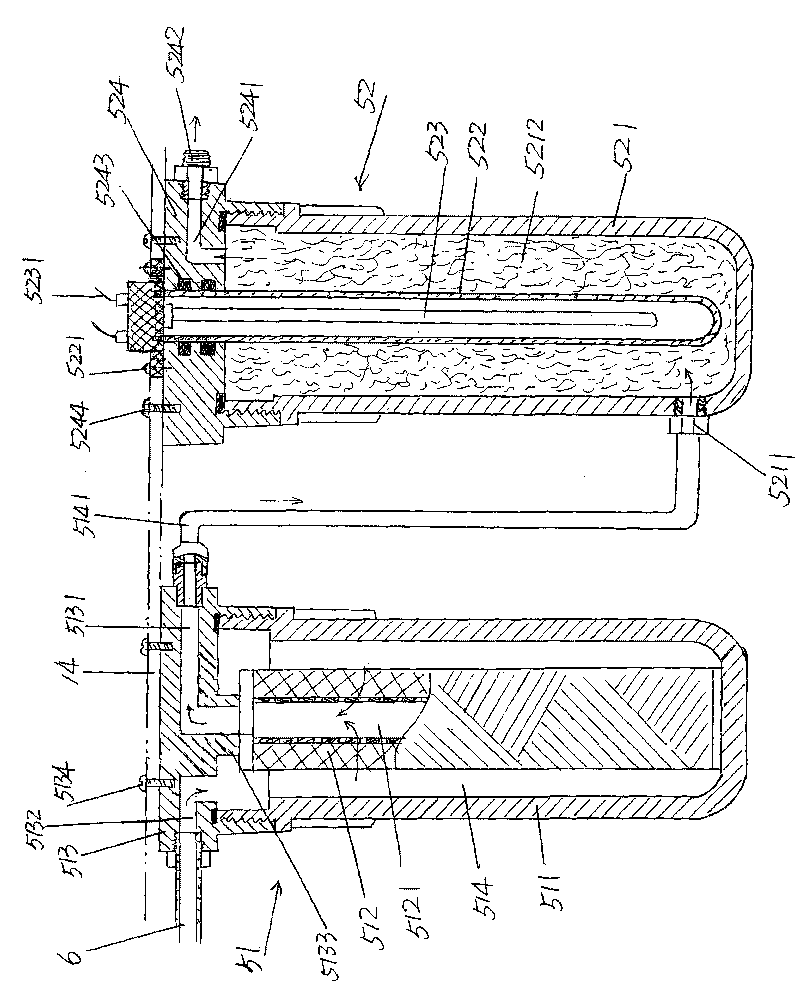

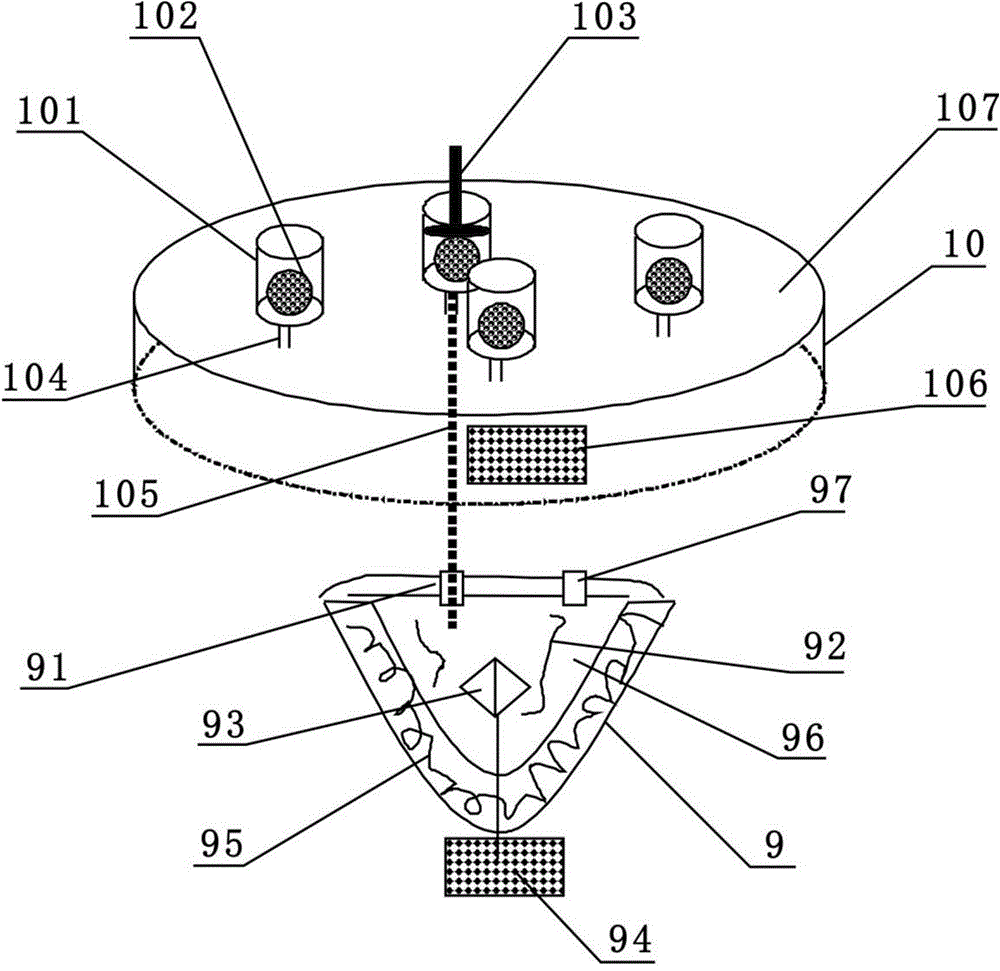

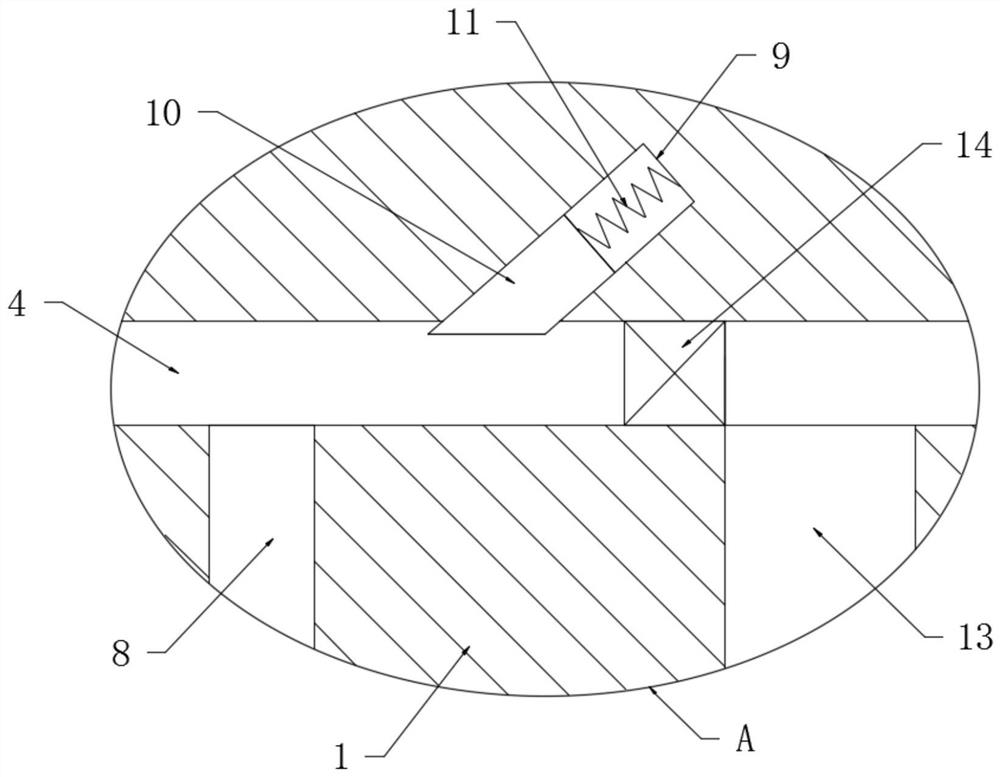

Heat exchange device for phase-change heat storage type water heater and water heater

The invention discloses a heat exchange device for a phase-change heat storage type water heater and relates to the technical field of water heaters. The heat exchange device comprises a phase-change heat storage shell, a heating device, heat exchange pipes and heat conduction fins, wherein the heating device, the heat exchange pipes and the heat conduction fins are arranged in the shell. The shell is filled with a phase-change material. A temperature sensor is arranged in the phase-change material. The heat conduction fins are mounted on the heat exchange pipes. The two ends of each heat exchange pipe correspondingly communicate with a water inlet pipe and a water outlet pipe. The heating device is arranged at the joint of the water inlet pipe and the heat exchange pipes and electrically connected with a temperature controller and is used for heating tap water flowing into the heat exchange pipes from the water inlet pipe. The invention further discloses the water heater with the heat exchange device. According to the heat exchange device and the water heater, heat storage and heat release of the phase-change material can share one heat exchange pipeline, the heating device is built-in, and no connecting accessory parts such as a circulation pump and a check valve need to be additionally arranged; and the structure is simple, the pipeline and space are saved, the electric heating efficiency is improved, the cost is saved, the failure rate and the heat loss are lowered, and user experience is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

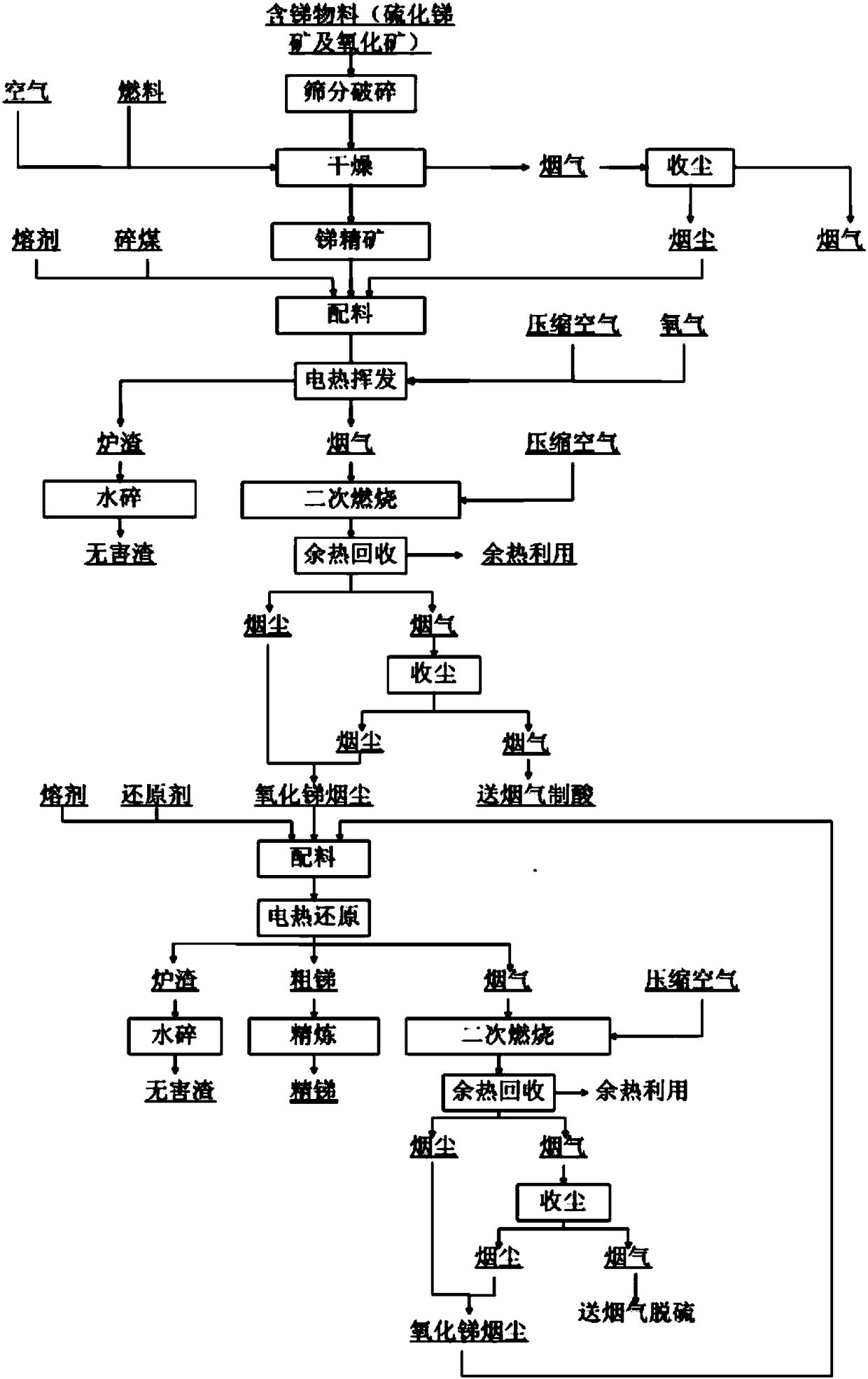

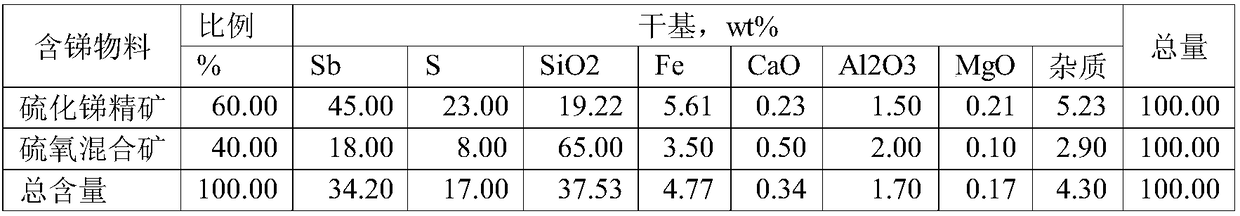

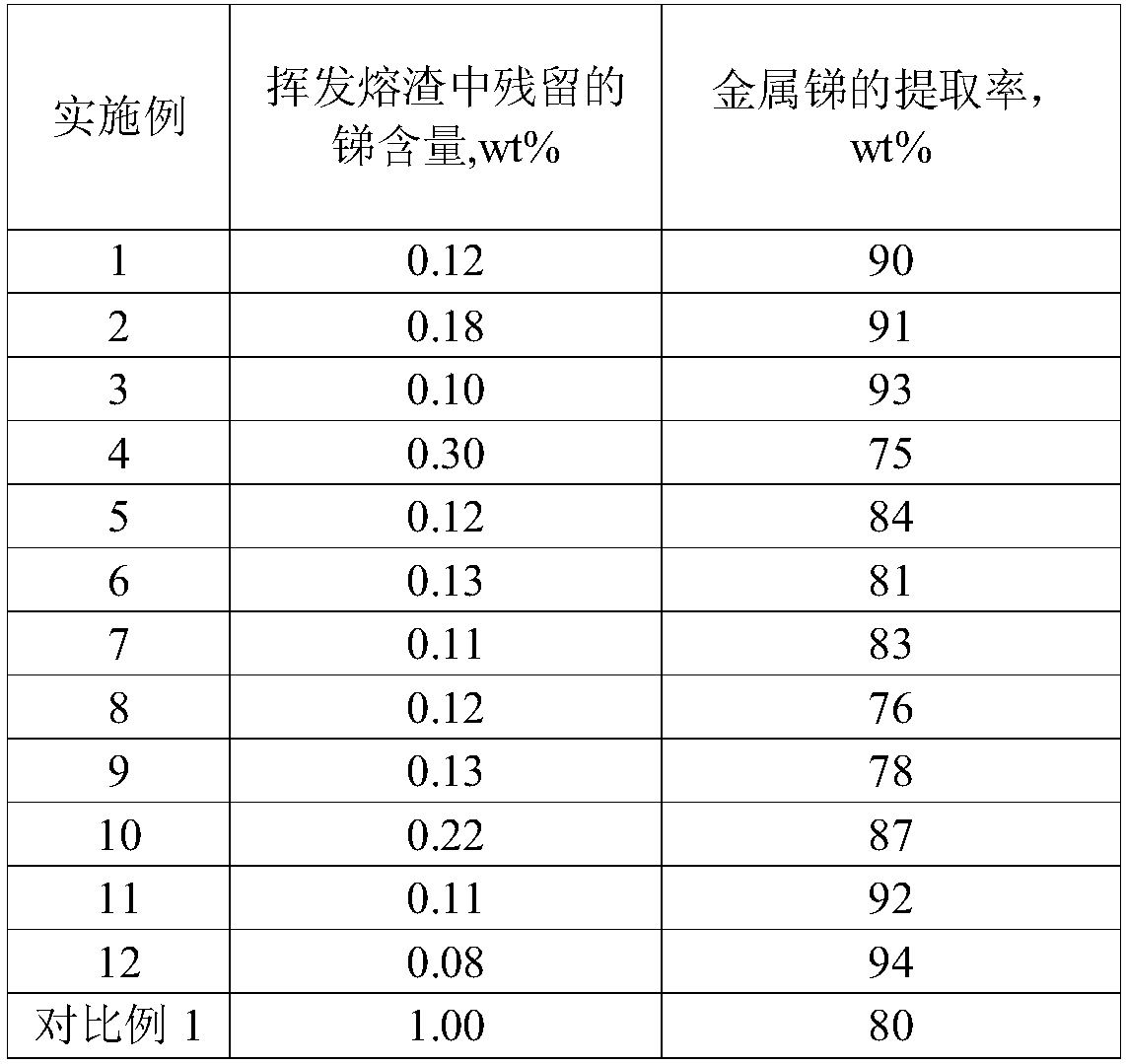

Method for extracting antimony metal

ActiveCN108456789AIncrease concentrationIncrease relative volatilityProcess efficiency improvementSulfideMaterials science

The invention provides a method for extracting an antimony metal. A device adopted by the method for extracting the antimony metal comprises an electrothermal volatilization device, a first dust collection device and an electrothermal reduction device which are connected in sequence. The method comprises the following steps: performing volatilization smelting on an antimony-containing material inthe electrothermal volatilization device so as to obtain an antimony-containing flue gas, wherein the antimony-containing material comprises antimony sulfide; collecting the antimony-containing flue gas from the first dust collection device so as to obtain antimony oxide dust; performing reduction smelting on the antimony oxide dust in the electrothermal reduction device, so as to obtain the antimony metal. The antimony-containing material is subjected to volatilization smelting through electric heating, and the whole volatilization smelting process needs no air blown combustion fuel, so thatthe flue gas quantity can be greatly reduced, and the concentration of SO2 in the flue gas can be increased. High electric heating efficiency can be achieved, not only is the amount of a fluxing agentreduced, but also residues can be reduced, and comprehensive benefits of environment protection, energy conservation, recycling rate increase, and the like, can be achieved. Due to electrothermal reduction, the heat efficiency can be greatly improved, the energy consumption can be reduced, the smelting intensity can be greatly improved, and the number of reduction devices can be greatly reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Method and device for producing thiophene and derivant thereof

ActiveCN101654449BHigh yieldExtended run timeOrganic chemistryDispersed particle separationButadiene DioxideReaction temperature

The invention relates to method and device for producing thiophene by synthesizing butadiene and sulfur. The production method comprises the steps of reaction, separation and desulfurization. In the reaction process, raw materials are heated to initial reaction temperature by a water hose heat and intermediate frequency induction heating method, but a reactor does not need to be heated; the reaction is carried out under normal pressure at the temperature of 380-450 DEG C; the molar ratio of the sulfur to the butadiene is 1.2-1.6, the molar ratio of water to the butadiene is 1-2, and the retention time of the reaction is 1-2 seconds. A multistage cooling method is adopted to separate high boiling point tar and unreacted sulfur in a reaction product, thereby solving the problem of blockagesof pipelines and equipment. A freezing and absorbing method is adopted to recover thiophene in hydrogen sulfide which is tail gas, thereby improving the yield of the thiophene. Methods of vapor pressure sealing emptying and two-stage wet desulfurizing are adopted, thereby solving pollution problems of the tar and the hydrogen sulfide in a production process and realizing the cleaning production ofthe thiophene.

Owner:LIANYUNGANG DIPU CHEM

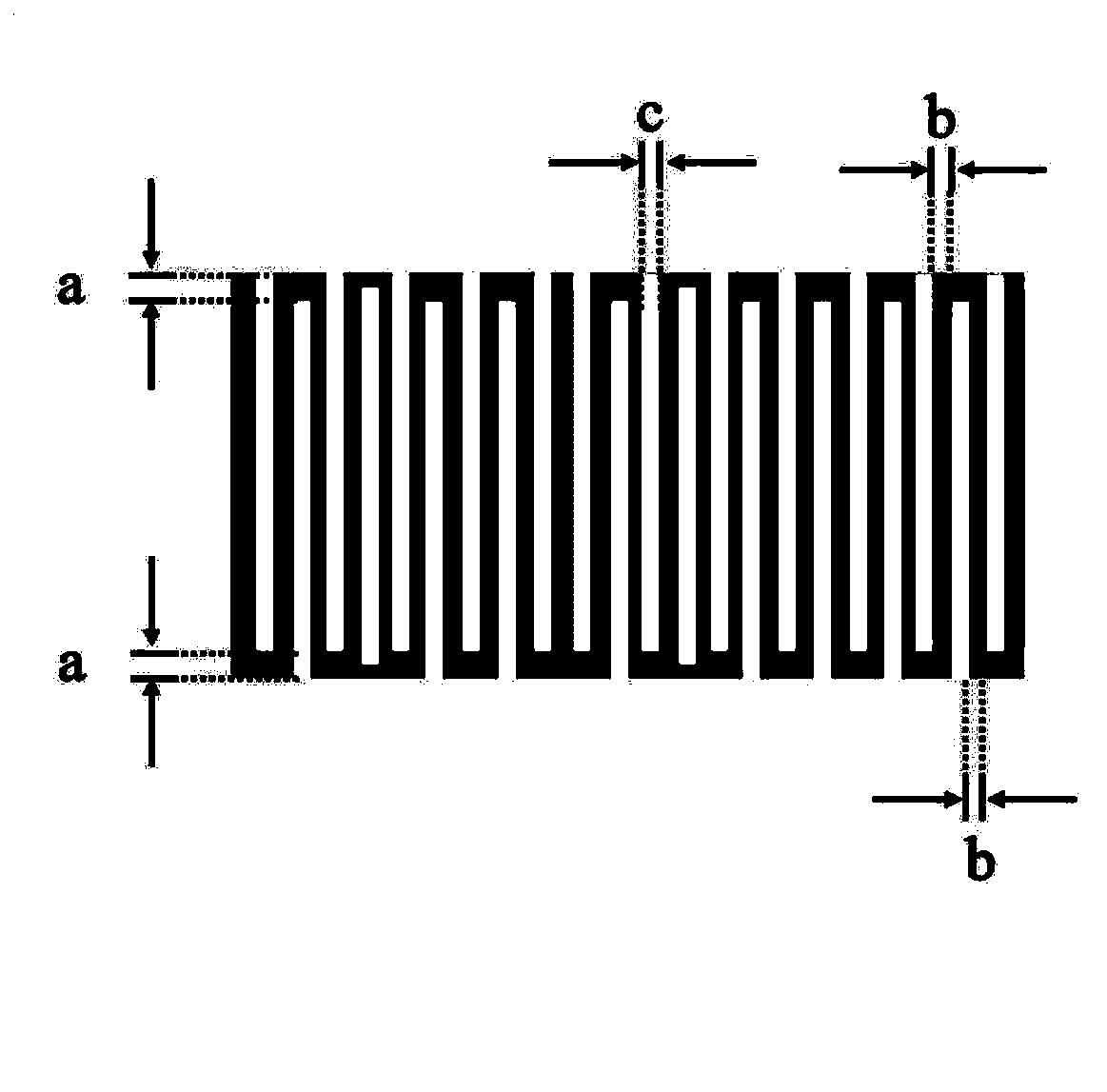

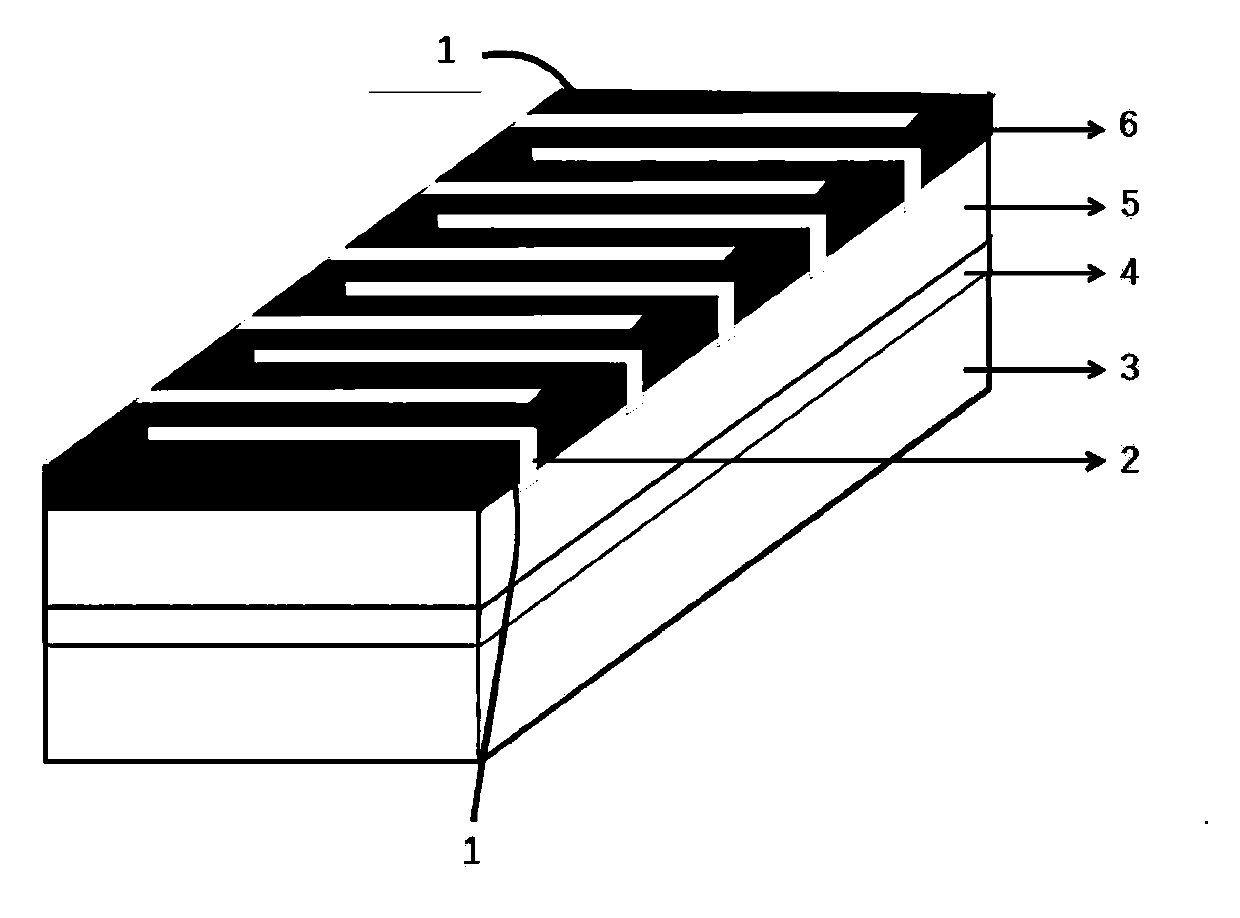

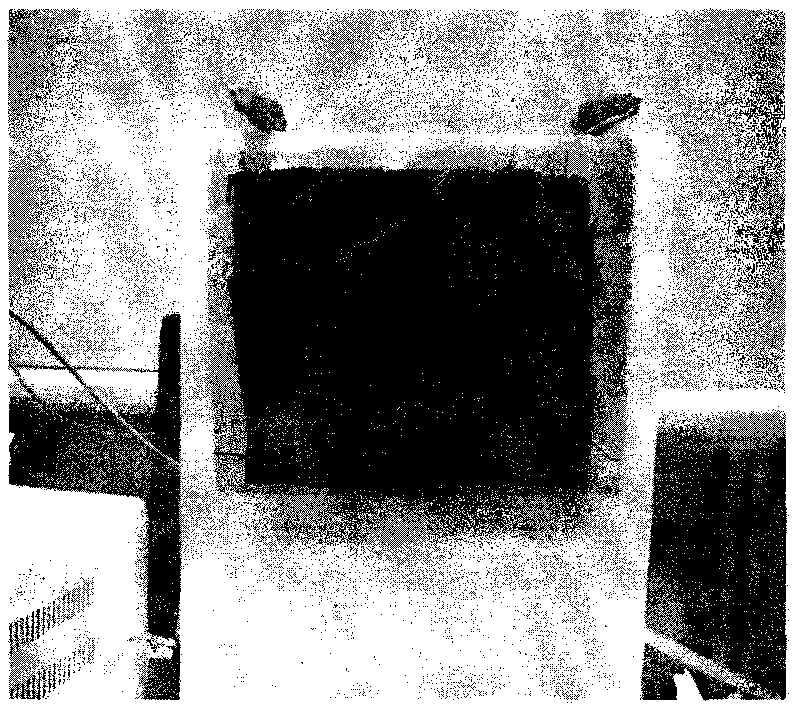

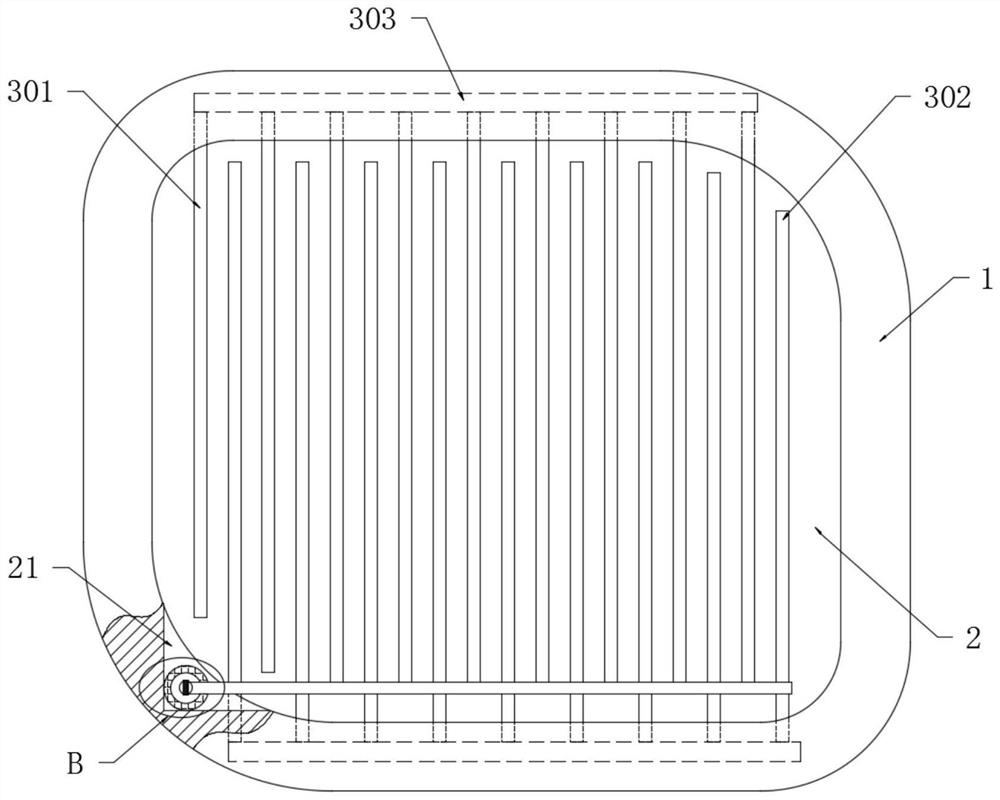

Novel electrical heating coating and preparation method thereof

InactiveCN110629151AImprove heating efficiencyIncrease varietyMolten spray coatingThermal sprayingCoating system

The invention relates to a novel electrical heating coating and a preparation method thereof, in particular used for ice-prevention and removal purposes in the fields of vehicles, aerospace and the like, and relates to the technical field of thermal spraying and laser engraving. The preparation method comprises the main preparation steps: a) A1 base plate test; b) A1 base plate surface pre-treatment; c) spraying the electrical heating coating to the surface of an A1 base plate by a thermal spraying technology; and d) laser engraving the surface of the electrical heating coating. The novel electrical heating coating has the advantages that 1) an electrical heating coating system of a three-layered structure is prepared by thermal spraying; and 2) a novel laser engraving process map is designed, and a discontinuous line groove is formed in the surface of the coating as a result of interaction of laser and the coating, so that a heat conducting area of the electrical heating coating becomes a continuous line shape, and therefore, the electrical heating efficiency is improved. Compared with an existing electrical heating coating structure, for example, an electrode layer and the like are needed to prepare, the thermal spraying and rapid proto-typing technological (laser engraving) processes are combined, the preparation process is simplified, and the novel electrical heating coating is the novel electrical heating coating structure.

Owner:GUANGDONG INST OF NEW MATERIALS

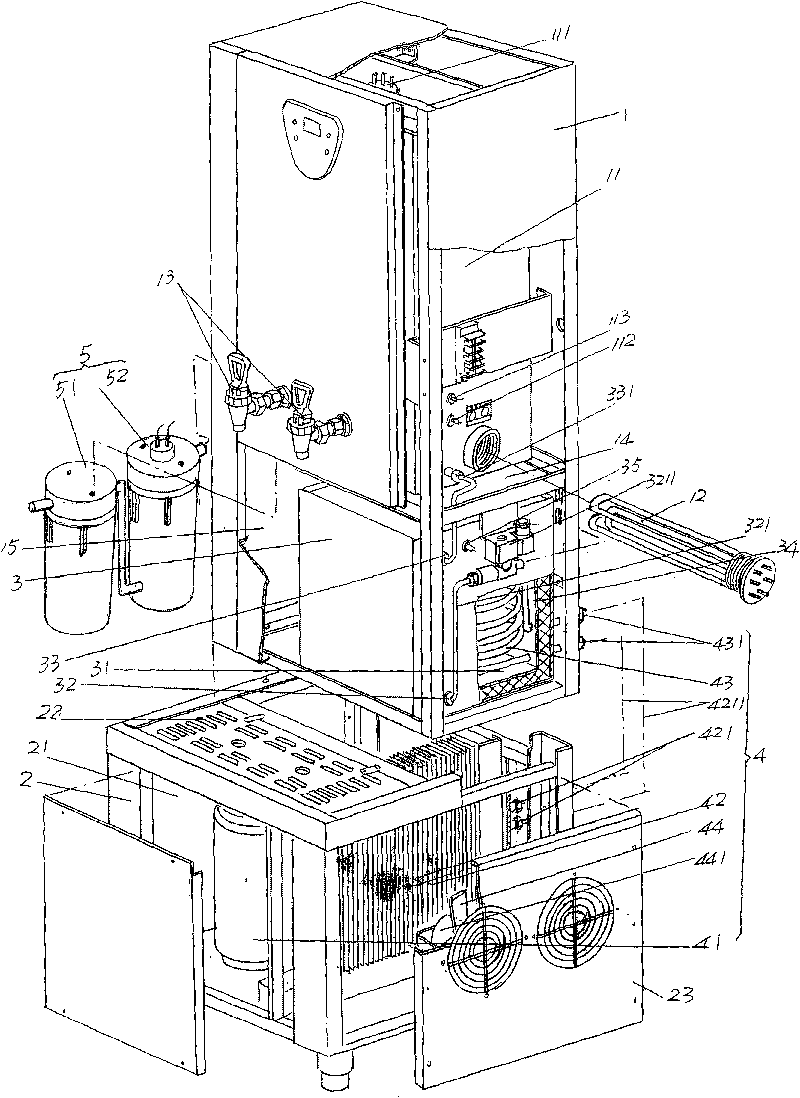

Heat pump type electric water boiler with purifying and sterilizing functions

InactiveCN101699182AShorten heating timeExtended service lifeWater/sewage treatment by irradiationMultistage water/sewage treatmentElectricityWater source

The invention discloses a heat pump type electric water boiler with purifying and sterilizing functions, and belongs to the technical fields of air source heat pumps and electric heaters. The heat pump type electric water boiler comprises a boiler body and a base with a base cavity, wherein the boiler body comprises an electric heating boiling water tank, an electric heating element and a hot water tap; the lower part of the electric heating boiling water tank is provided with a heat pump type water tank cavity separated by a bottom plate of the boiler body; the inside of the heat pump type water tank cavity is provided with a heat pump type water tank and a purifying and sterilizing mechanism; the purifying and sterilizing mechanism is connected in series between a water source pipe and a water inlet pipe of the heat pump type water tank, and is fixed with the bottom plate; a water outlet pipe of the heat pump type water tank is communicated with the electric heating boiling water tank; and the inside of the base cavity is provided with a heat pump heating mechanism used for heating water in the heat pump type water tank cavity of the heat pump type water tank. The technical scheme not only can save energy, reduce network load and prolong the service life of the electric heating element, but also can guarantee the cleanness of water.

Owner:CHANGSHU HIBRIGHT ELECTRIC APPLIANCES

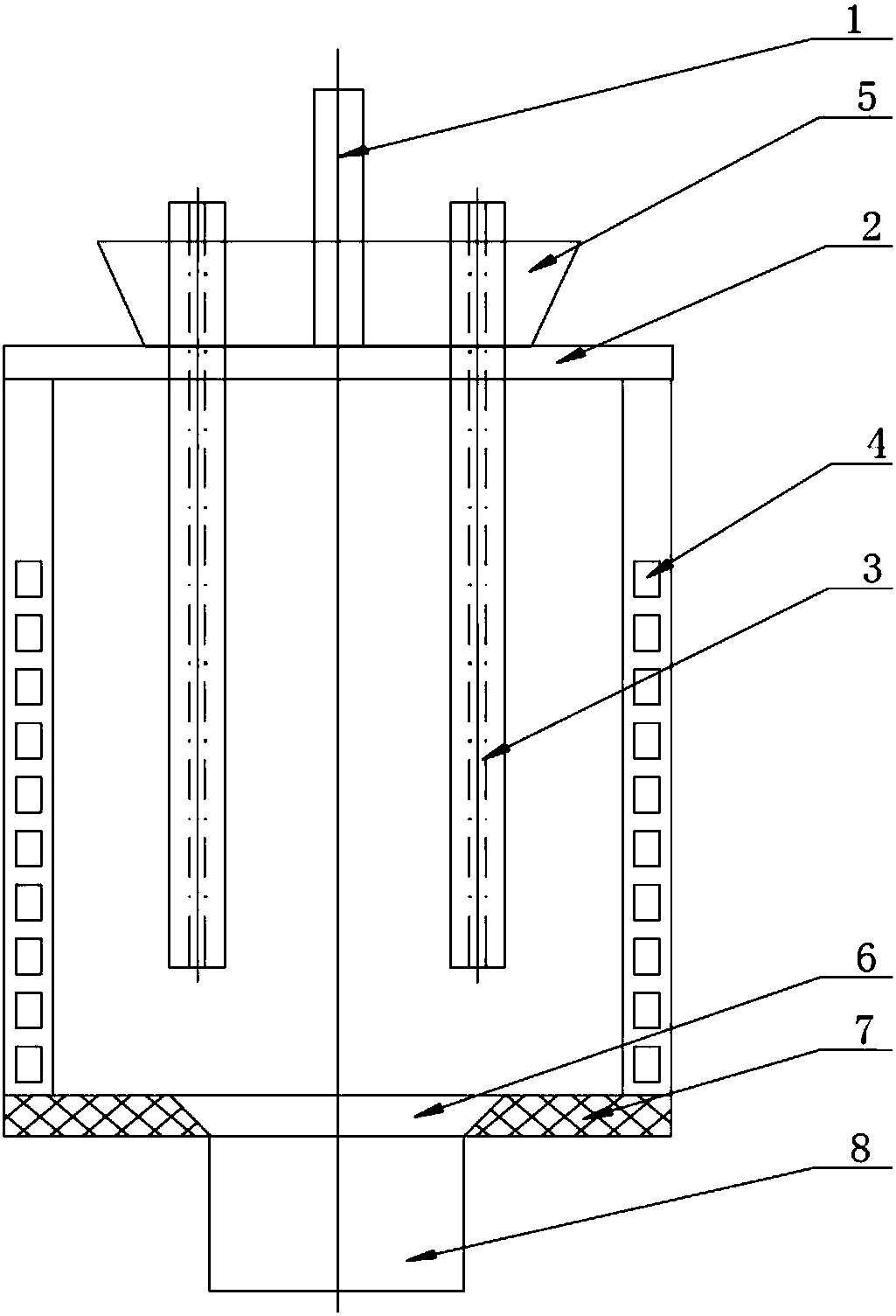

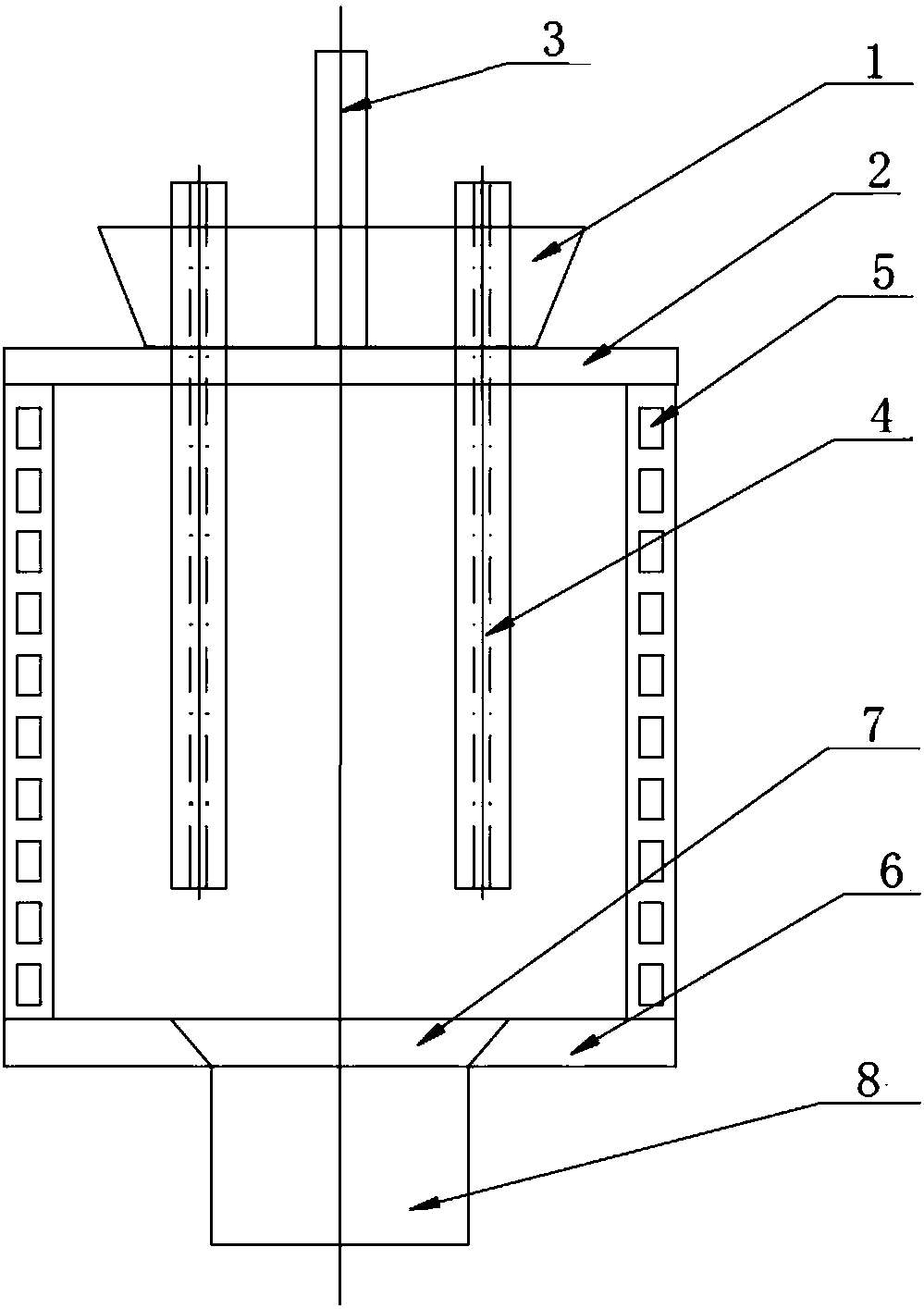

Composite heating type heat treatment furnace

PendingCN107655333AImprove uniformityImprove heating efficiencyFurnaces without endless coreCoil arrangementsGraphiteHeating effect

The invention discloses a composite heating type heat treatment furnace. The composite heating type heat treatment furnace comprises an induction coil arranged on the outer side of a furnace body andused for sensing a heated material and an electrode pair arranged in the furnace body as a secondary heating element, and the induction coil arranged at the outermost layer of a graphitizing furnace is used as a furnace shell. According to the composite heating type heat treatment furnace, by combining induction heating and electrode pair direct current heating, the heating effect is obviously improved, and meanwhile, the uniformity degree of material heating is improved.

Owner:ZHUZHOU CHENXIN INDUCTION EQUIP CO LTD

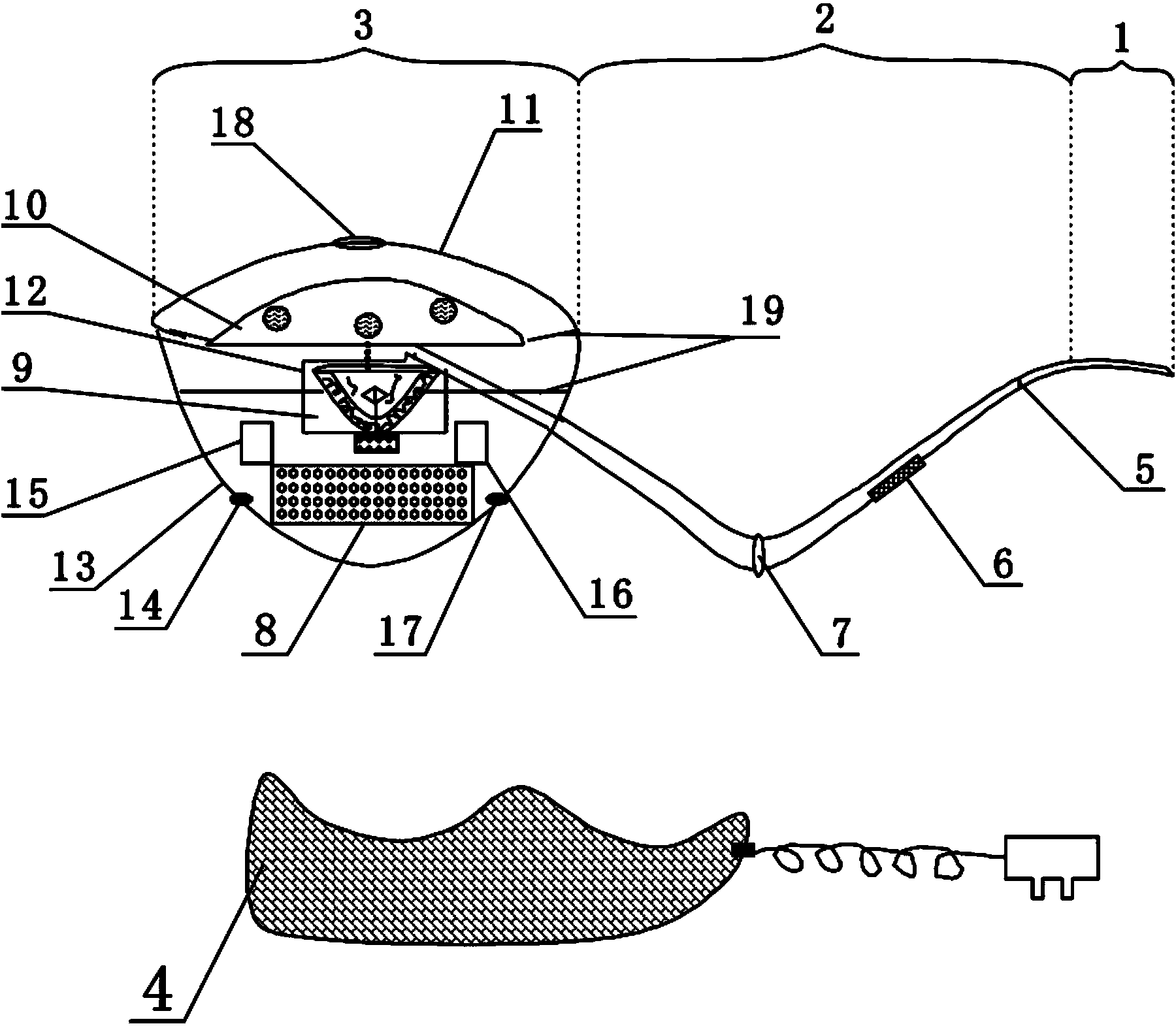

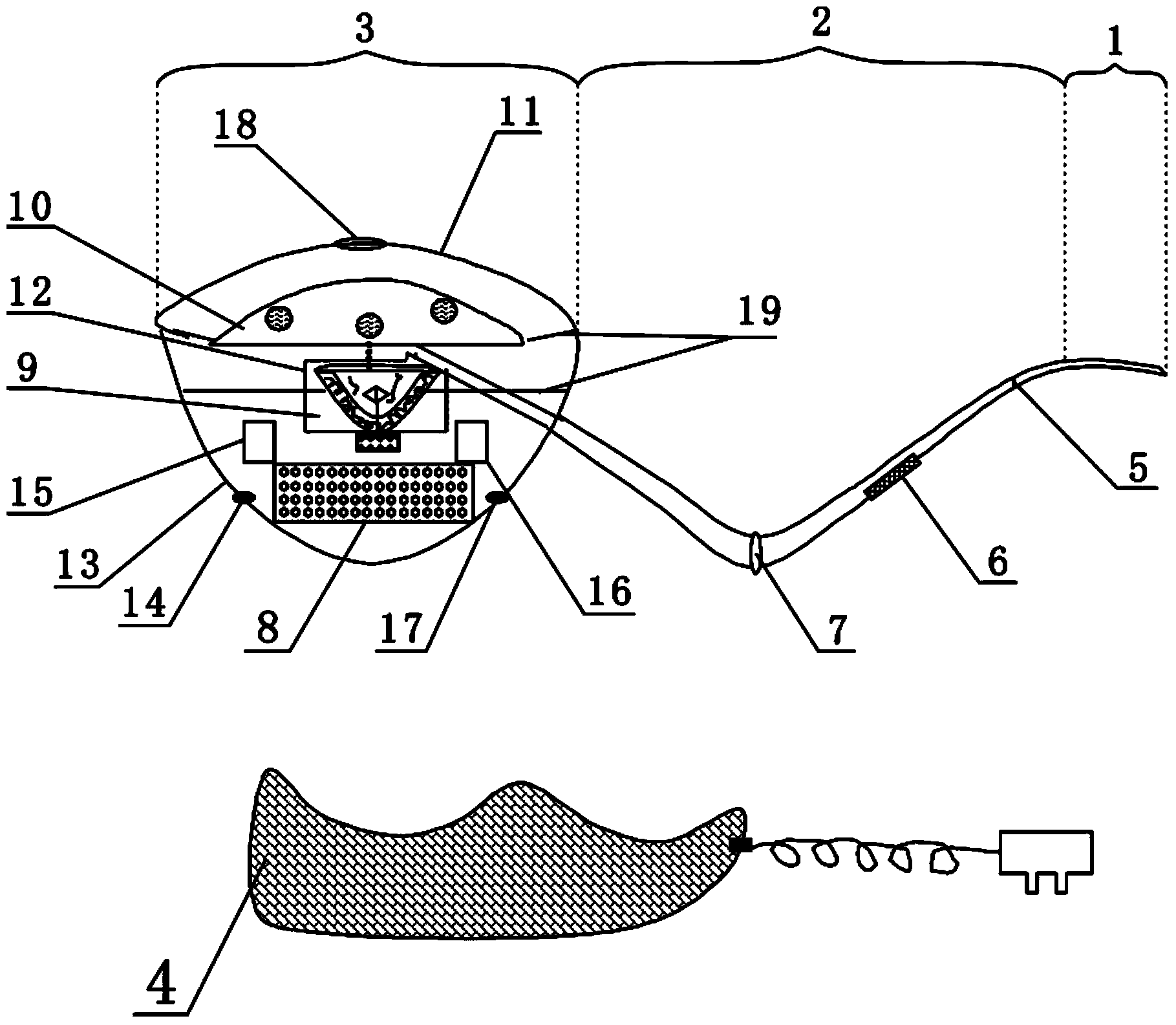

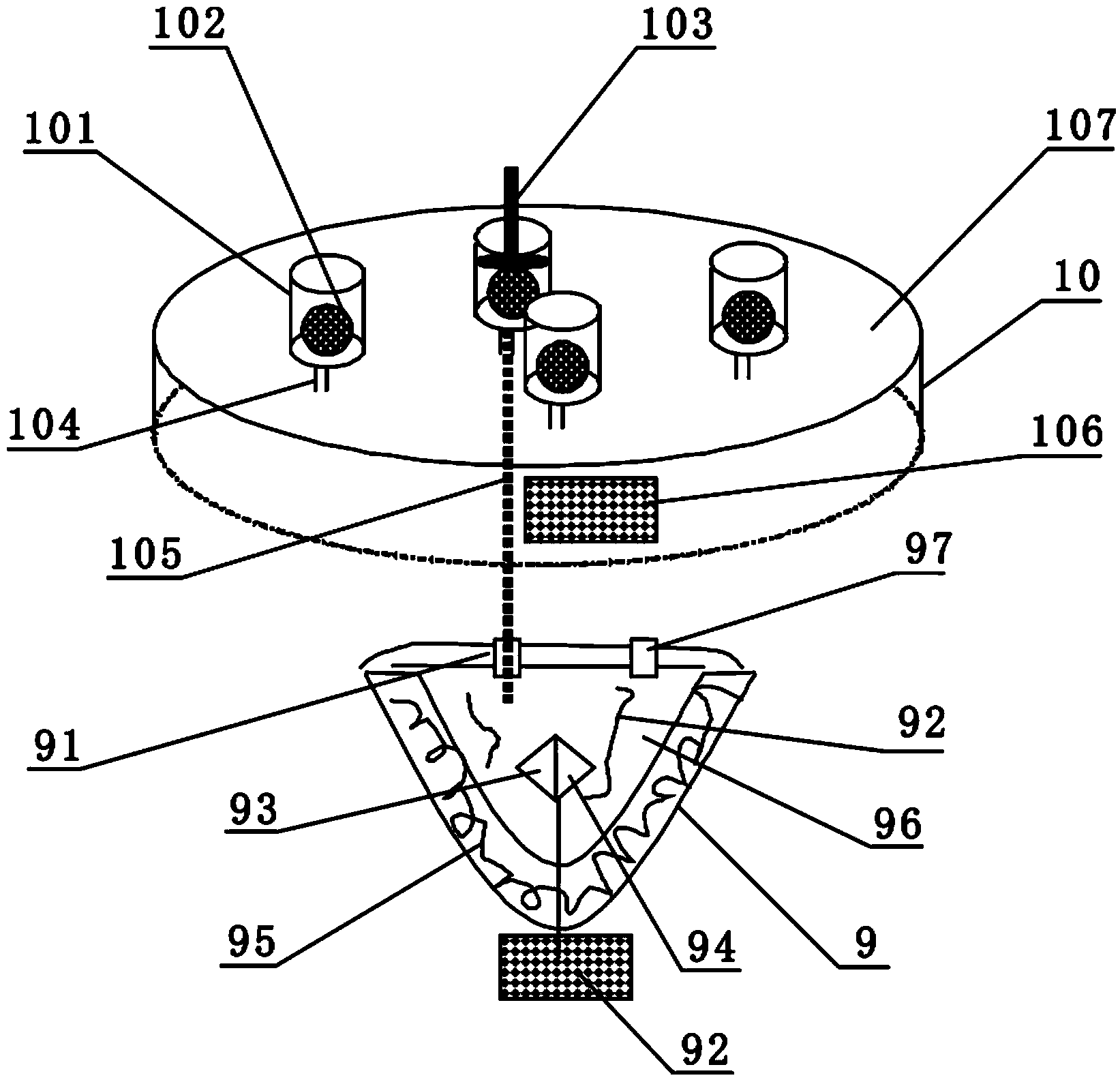

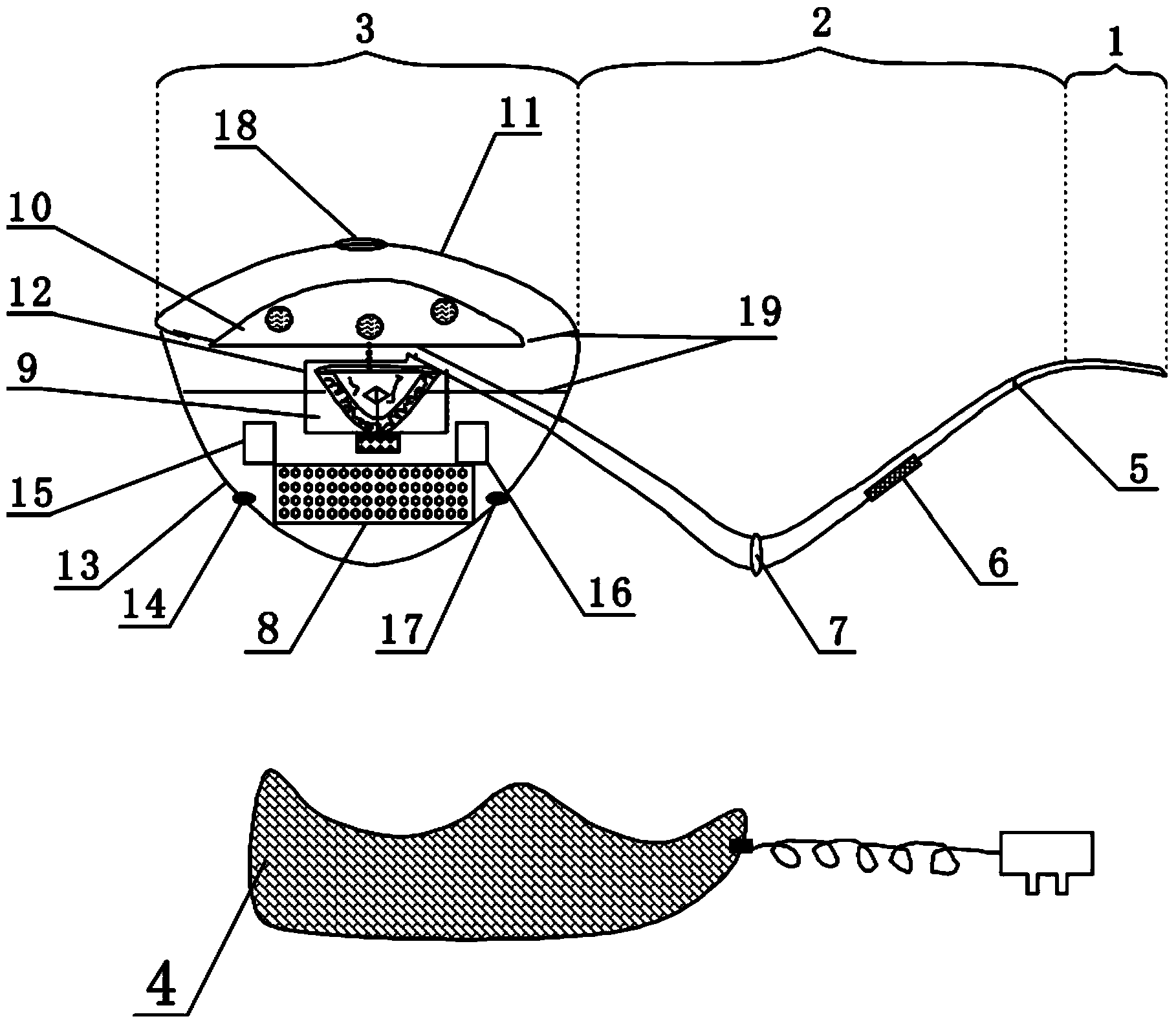

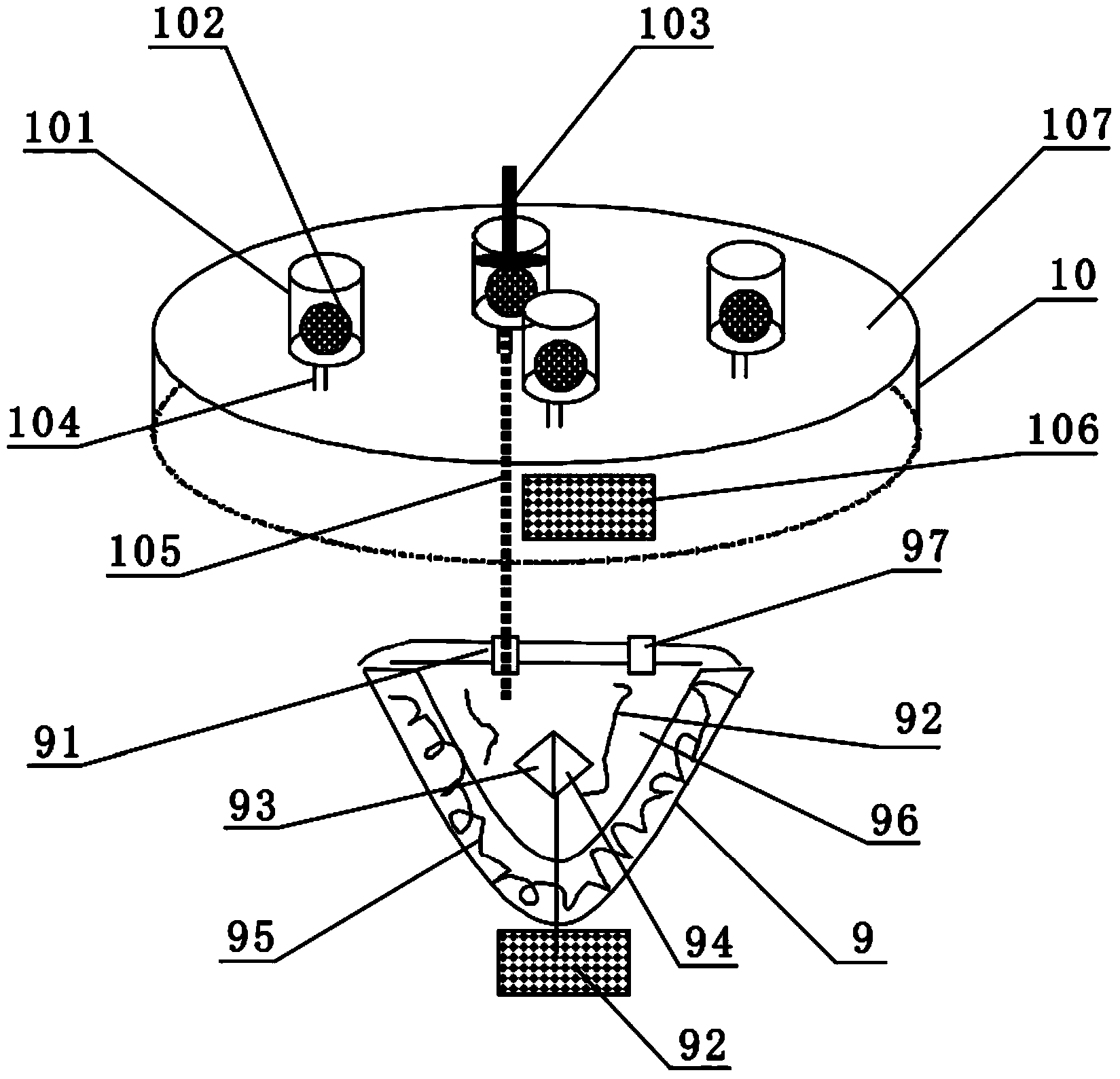

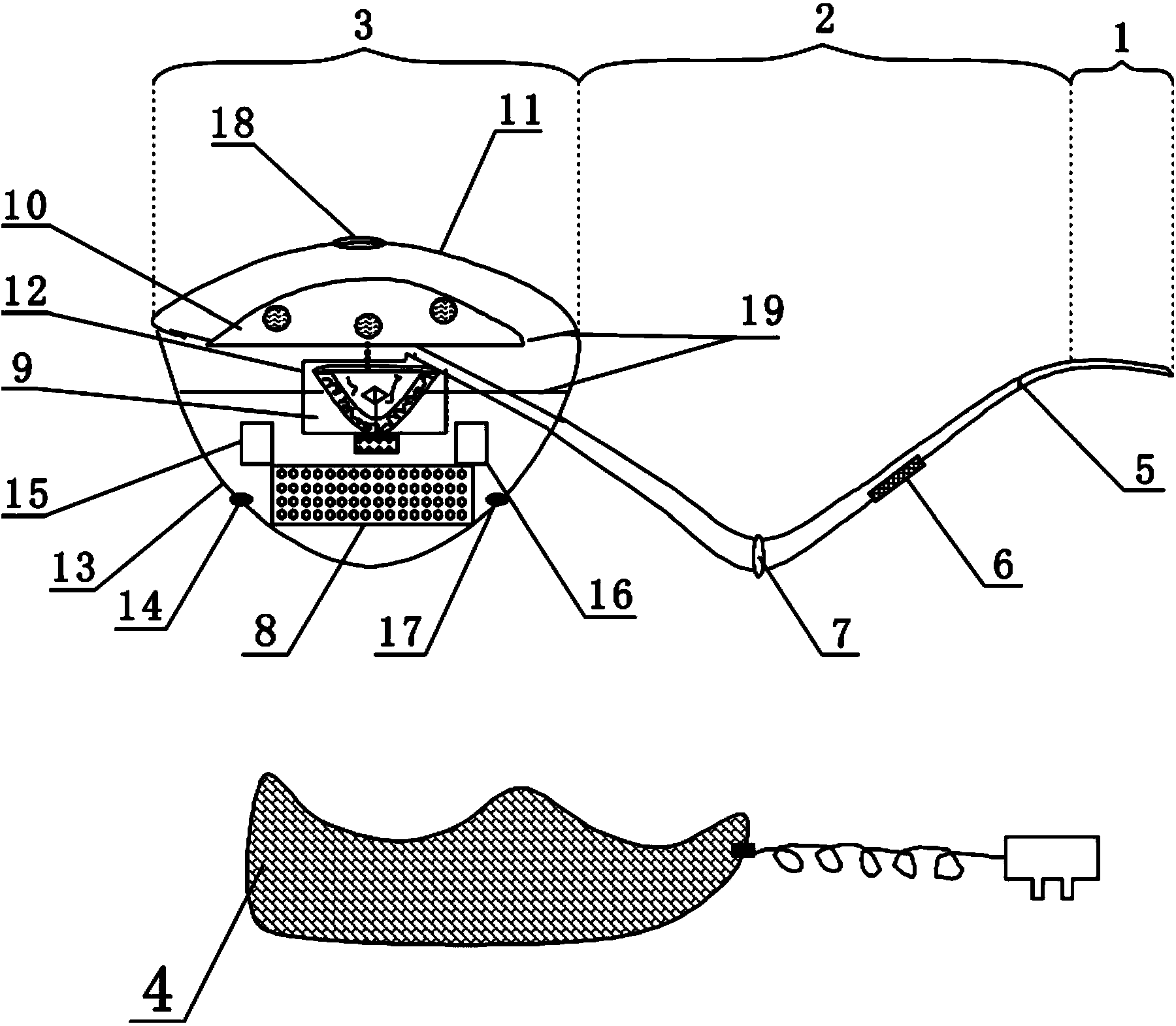

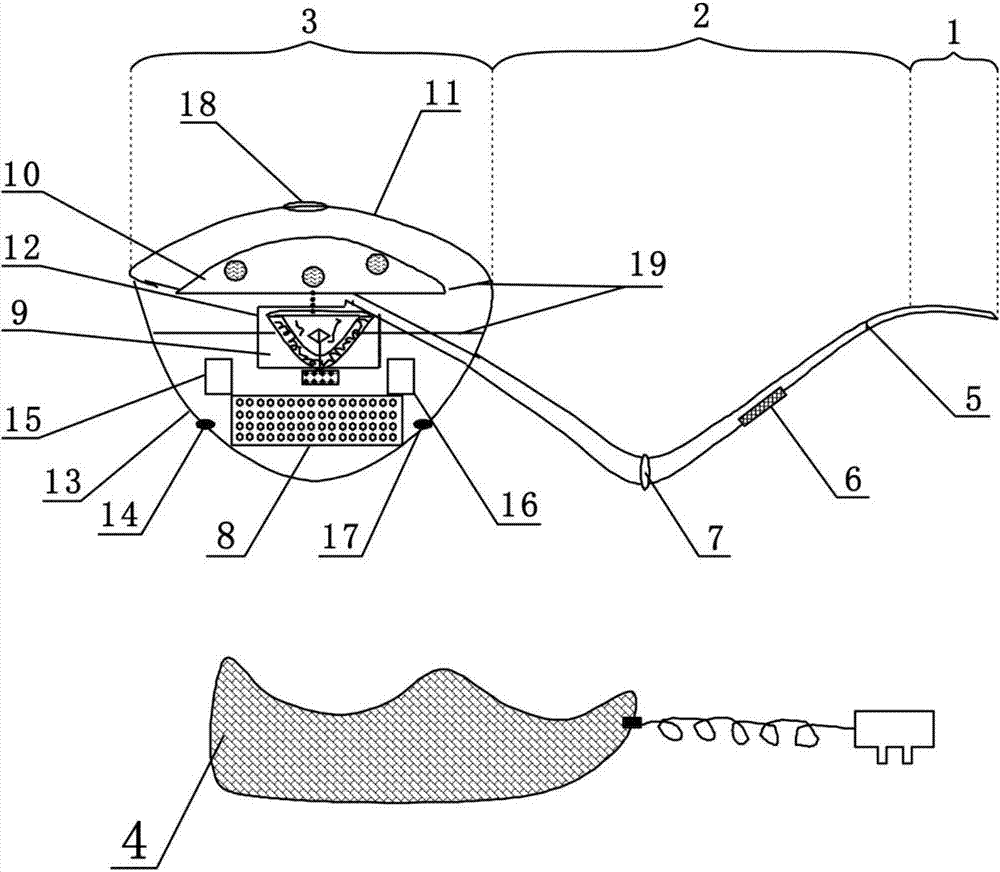

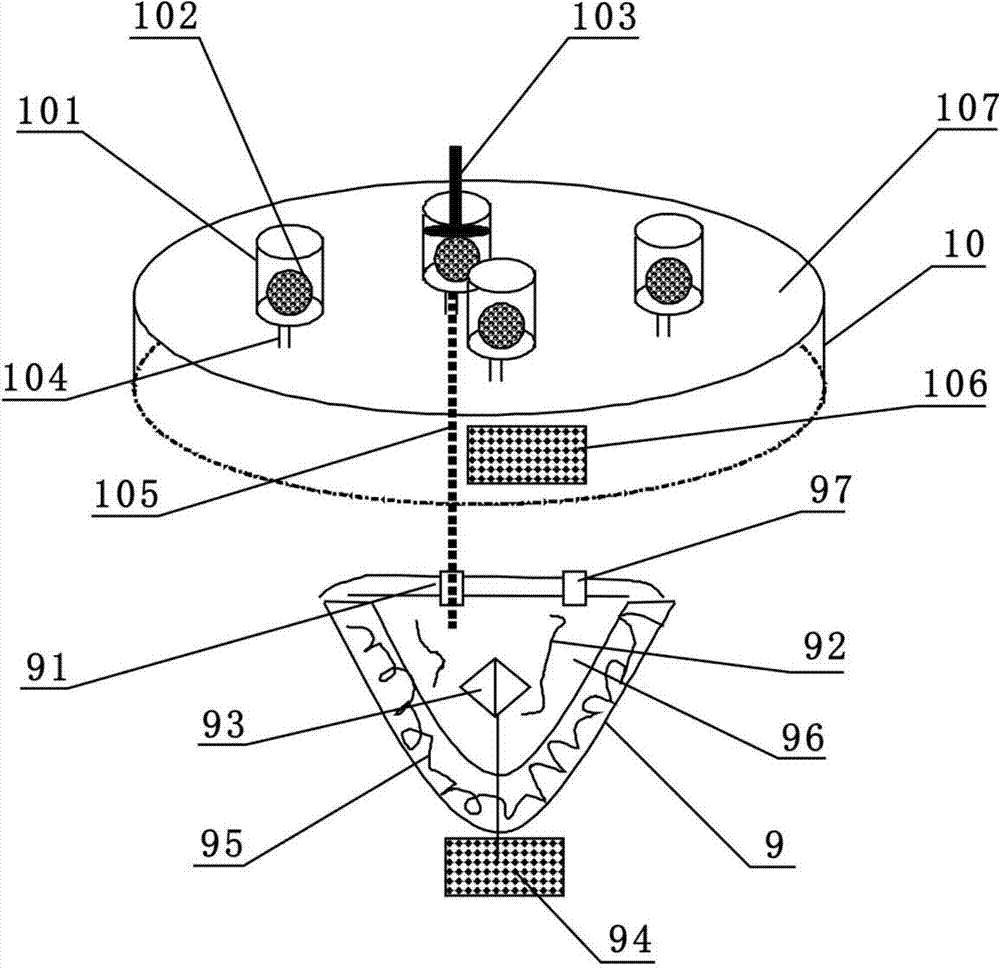

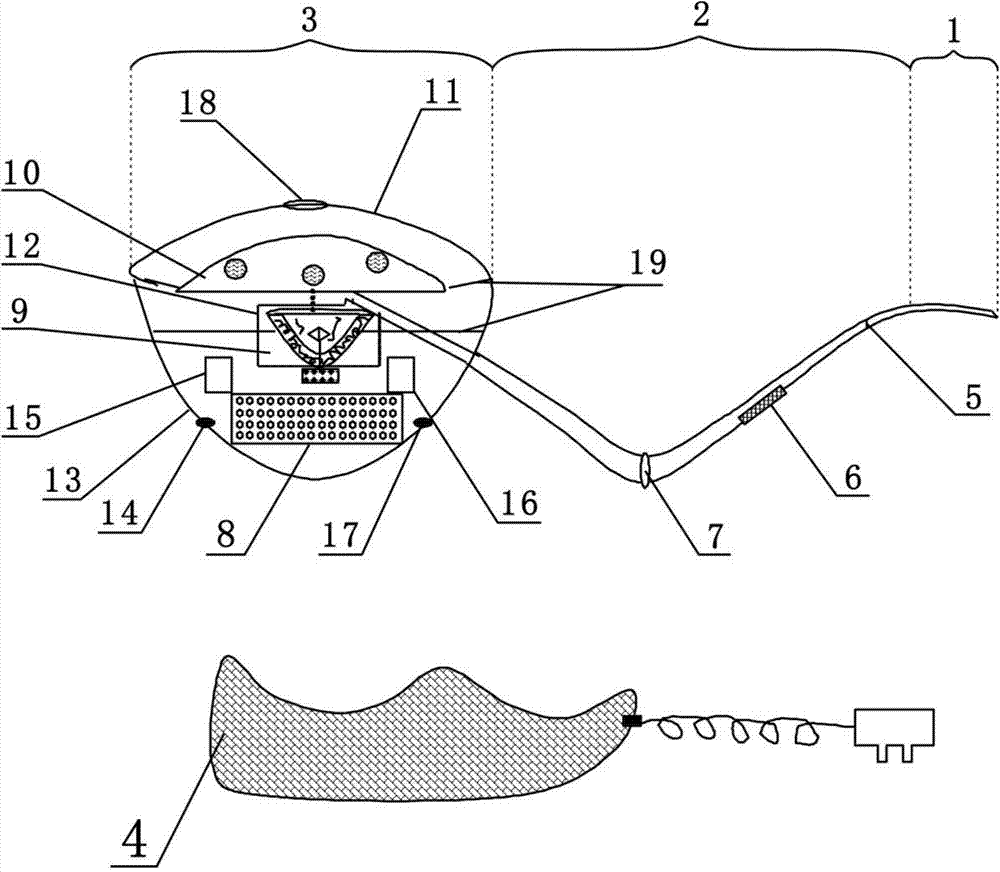

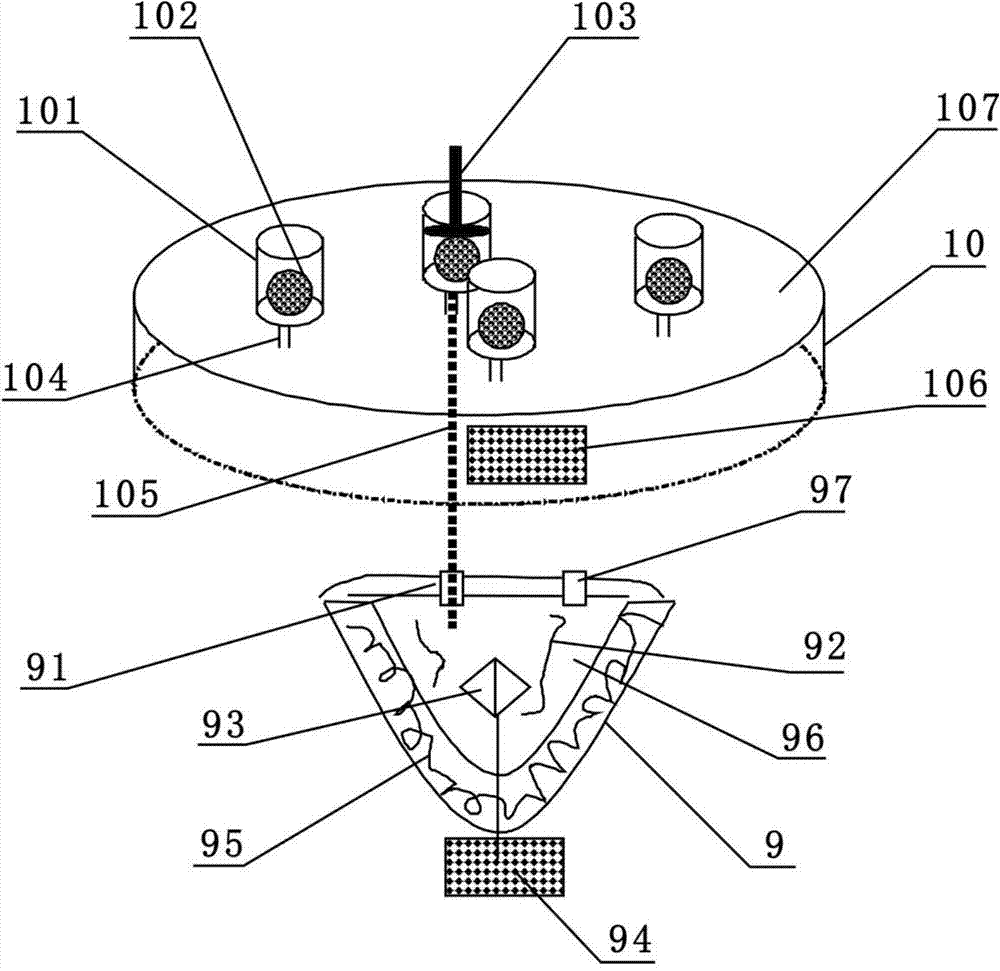

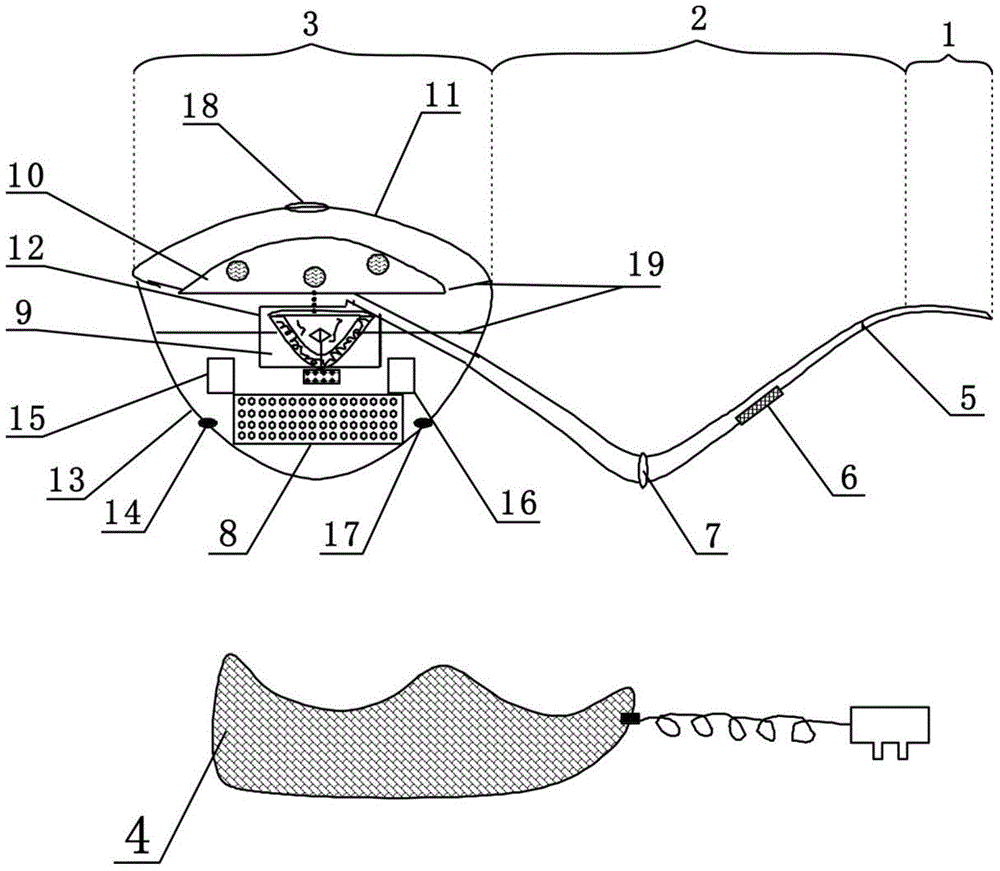

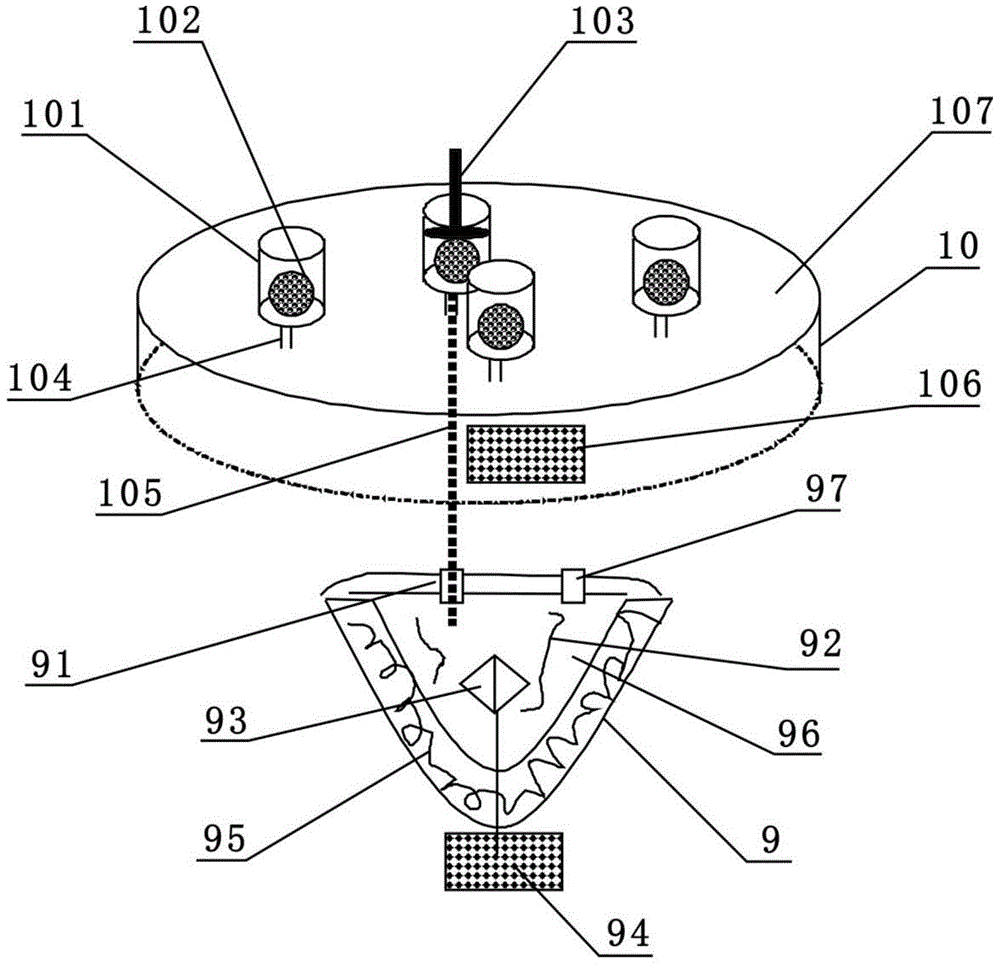

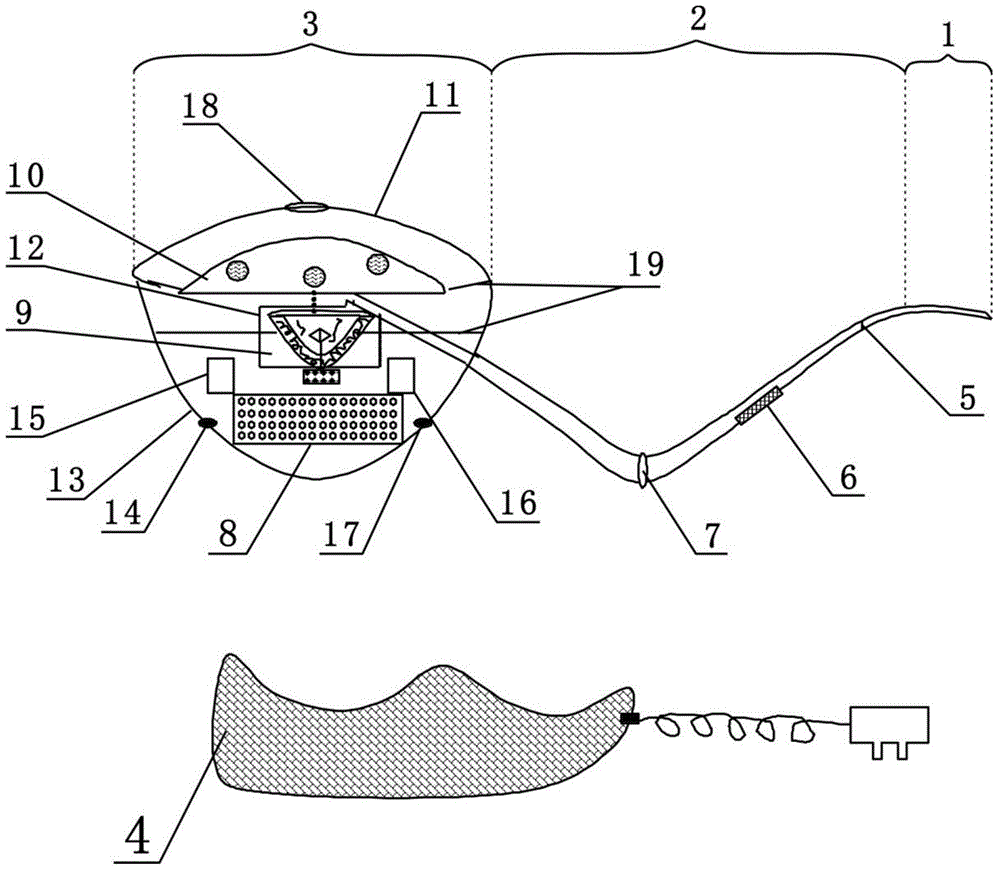

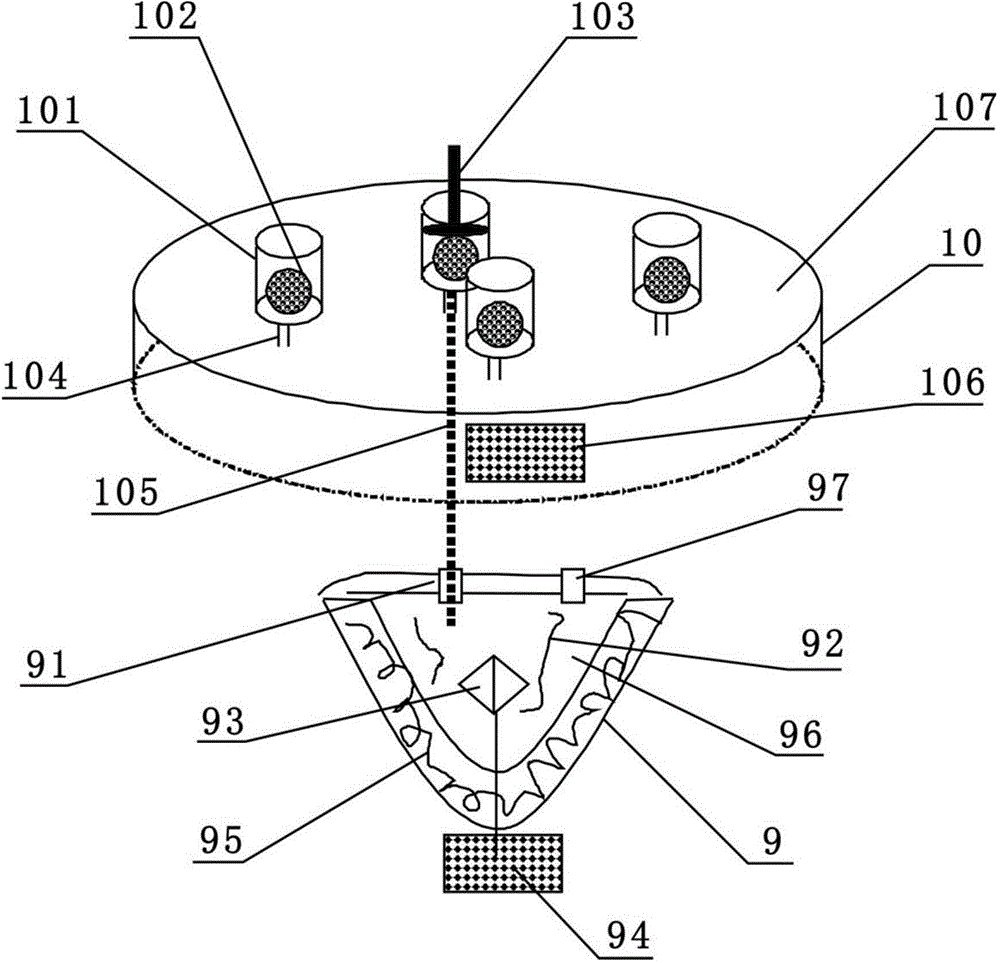

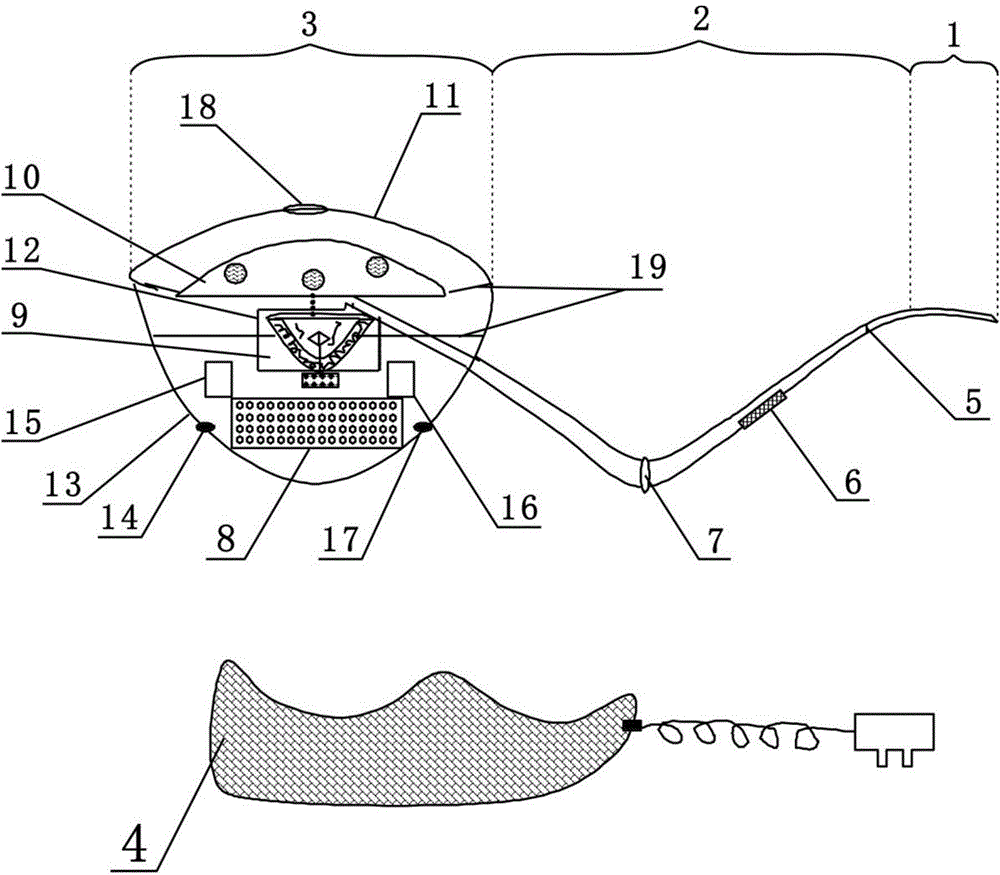

Tobacco-shred-similar substance made of Chinese-date raw materials and electric heating method of tobacco-shred-similar substance

ActiveCN103892452AComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesElectricityFlavor

The invention discloses a tobacco-shred-similar substance made of Chinese-date raw materials and an electric heating method of the tobacco-shred-similar substance. The tobacco-shred-similar substance made of the Chinese-date raw materials comprises tobacco flavors, nicotine solution and a Chinese-date tobacco-shred-shaped substance body, 0.03-0.06 part by weight of the tobacco flavors and 3-8 parts by weight of the nicotine solution are evenly mixed, the nicotine solution is nicotine aqueous solution or nicotine ethanol solution, and released substances are composed of 0.4-1.2 parts by weight of nicotine and 55-120 parts by weight of the Chinese-date tobacco-shred-shaped substance body. According to the tobacco-shred-similar substance and the electric heating method, the Chinese-date raw materials, the tobacco flavors and the nicotine solution are used for manufacturing the tobacco-shred-similar substance, the tobacco-shred-similar substance will generate smoke by being electrically heated, a smoker can have a smoke, environment pollution can be reduced, harm to the human body caused by harmful substance generated by combustion of traditional cigarettes is reduced, the health-care, edible and medical effects of Chinese dates are fully used, and smoking experience is more comfortable compared with the traditional cigarettes.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

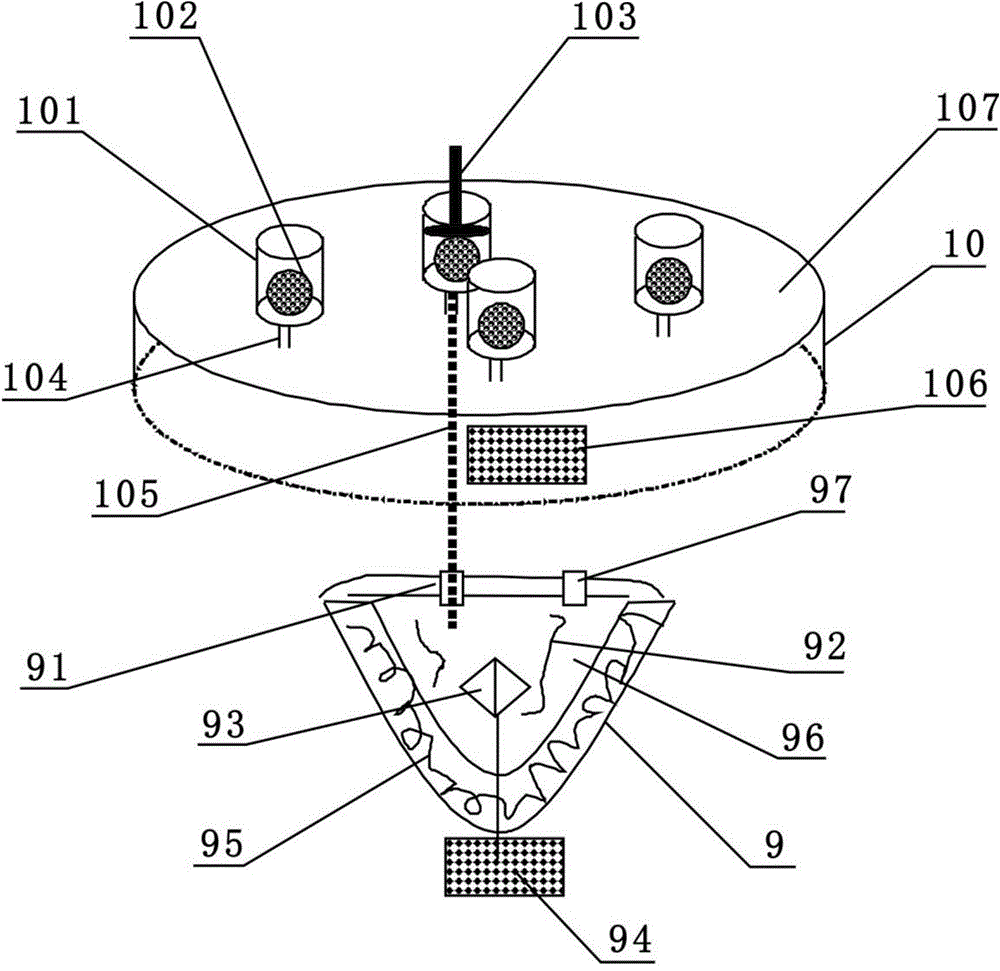

Graphitization furnace

PendingCN107651679AReduce volumeSave manufacturing costCarbon compoundsChemical industryInsulation layerHeat treated

The invention discloses a graphitization furnace. The graphitization furnace comprises an induction coil located at the outer side a furnace body and used for inducing a heating material, and the induction coil is an encapsulated induction coil; and the graphitization furnace is a graphitization furnace without metal furnace shells, and the induction coil arranged at the outermost layer of the graphitization furnace also serves as a furnace shell. The graphitization furnace provided by the invention has no furnace shells or heat insulation layers, so that the volume of the furnace body is unlimited, and the maintenance costs after the furnace is used at one time are extremely low, and the graphitization furnace is especially suitable for batched continuous production of heat treatment of materials.

Owner:ZHUZHOU CHENXIN INDUCTION EQUIP CO LTD

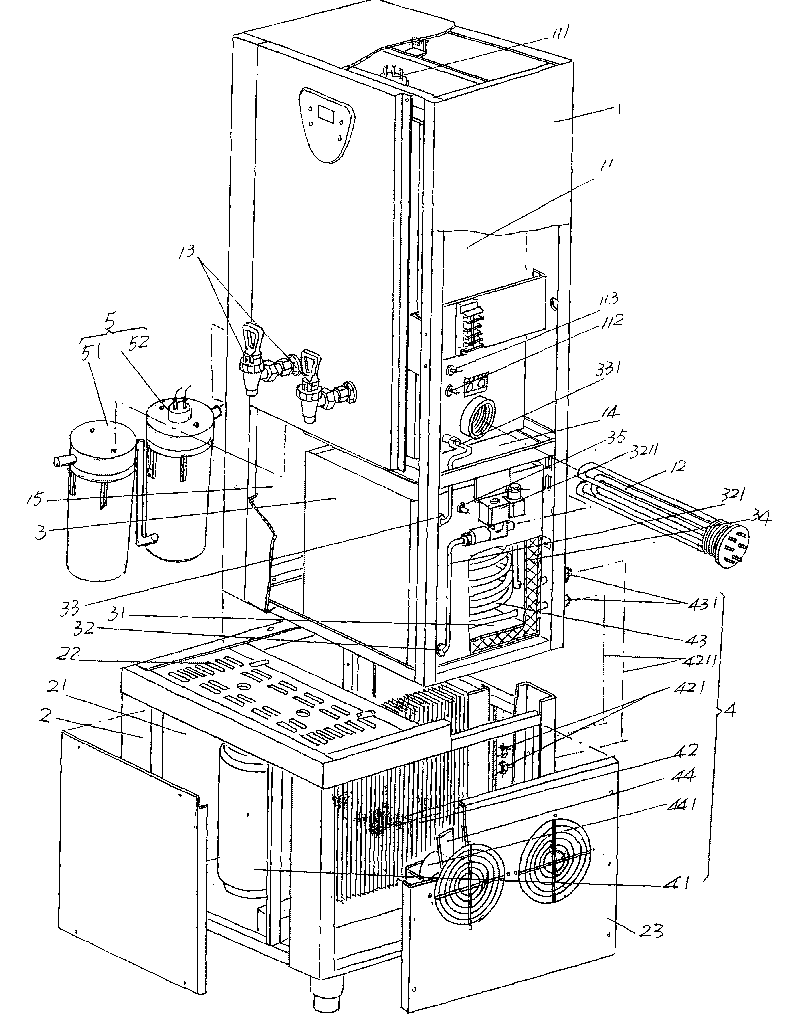

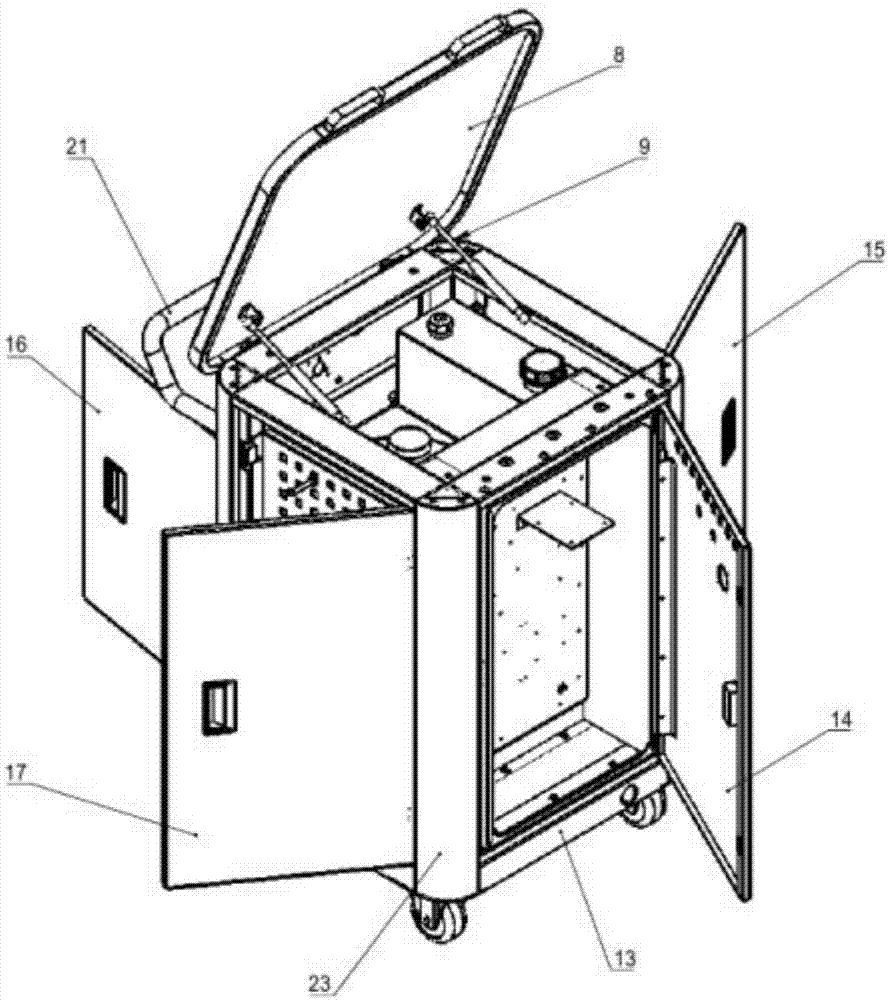

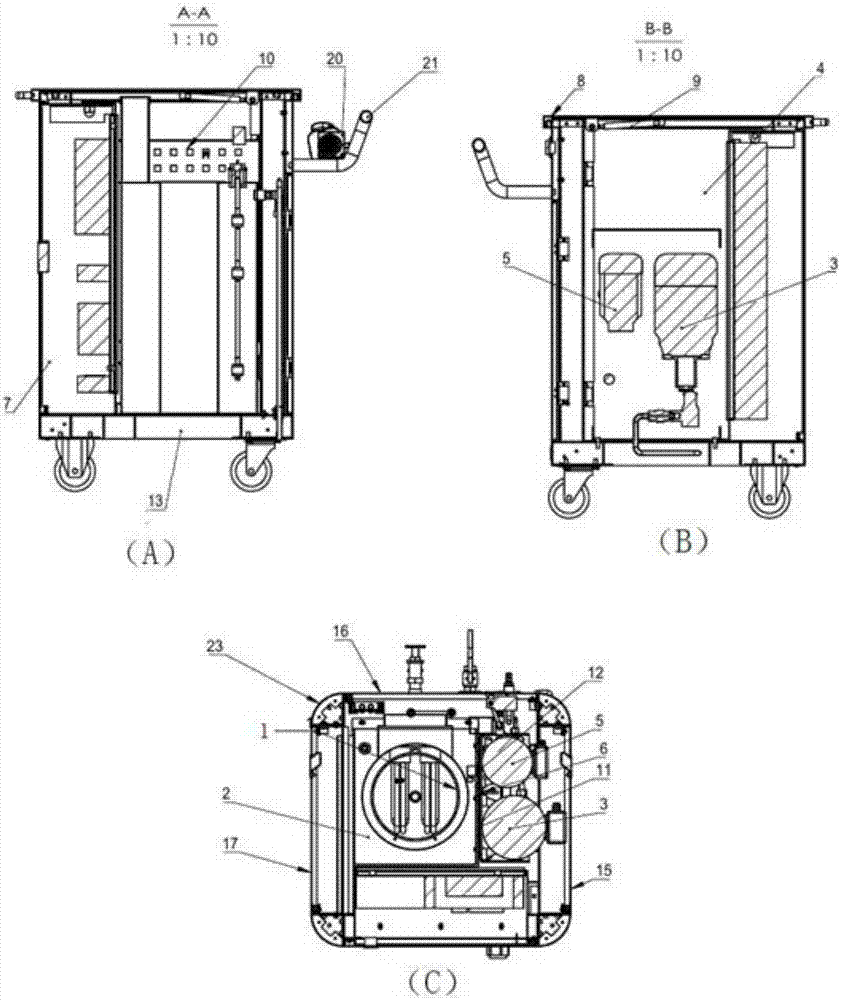

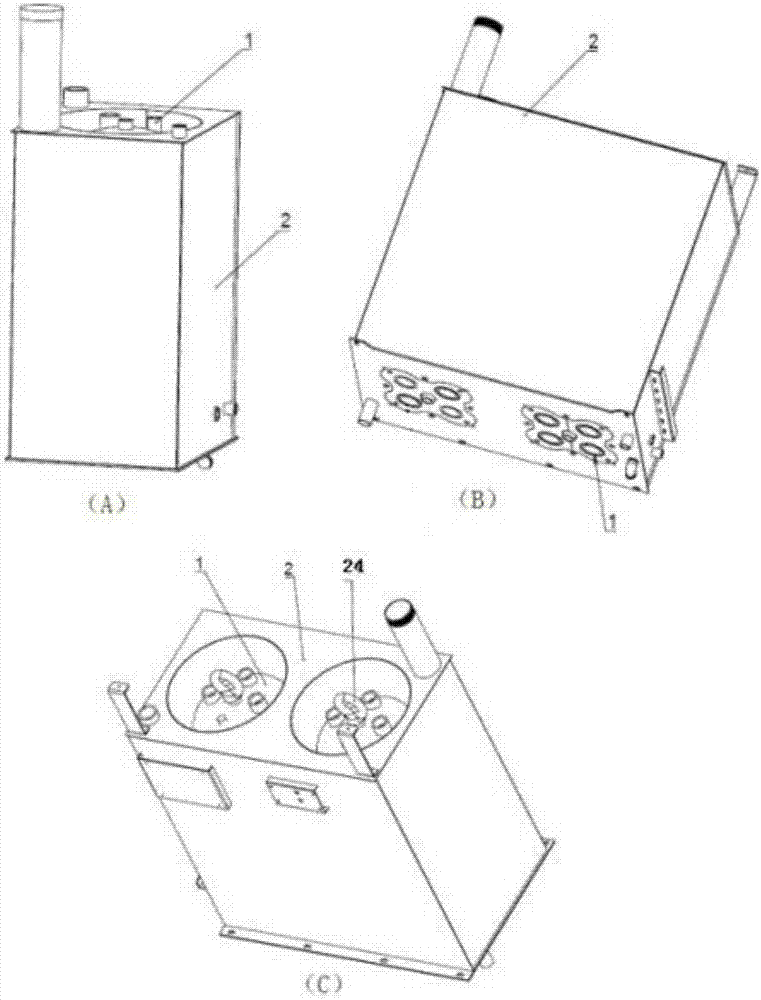

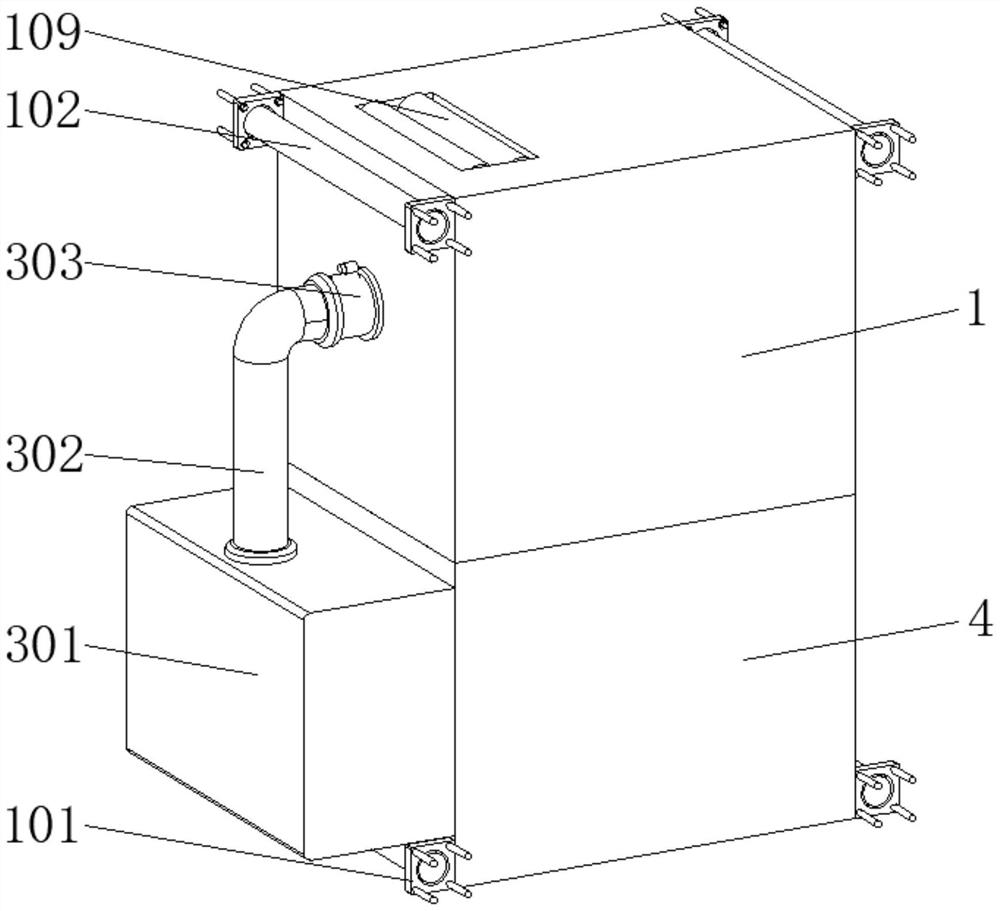

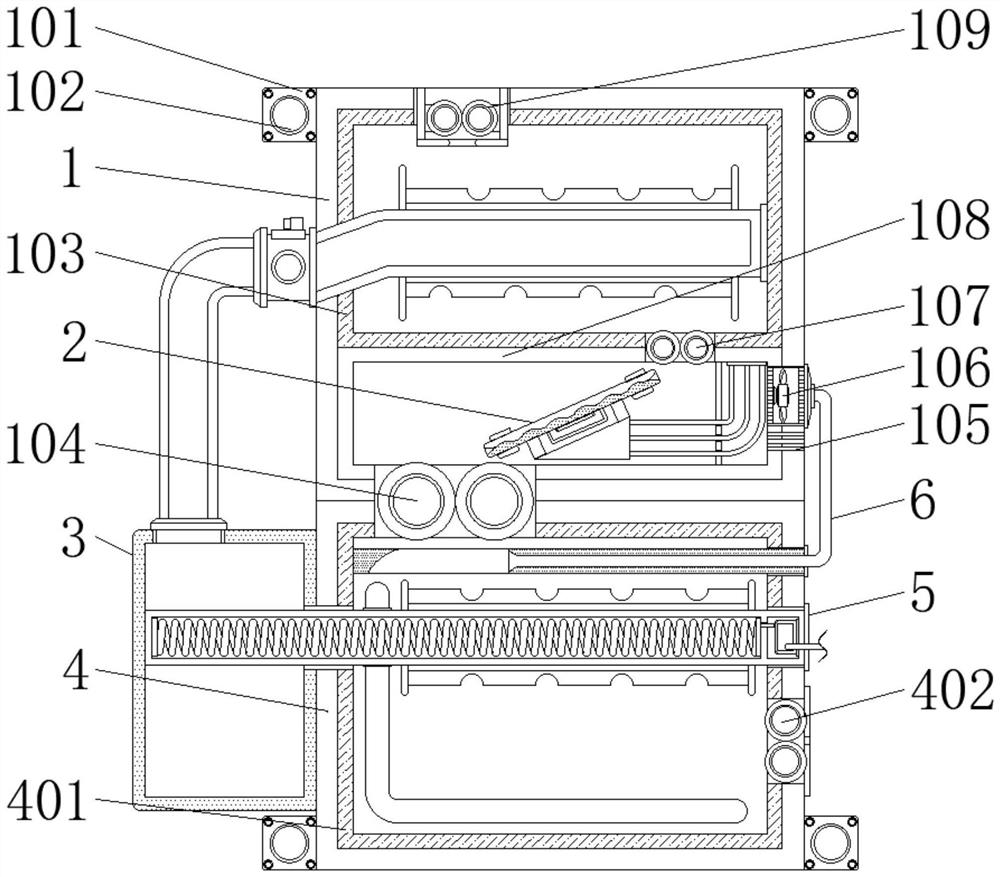

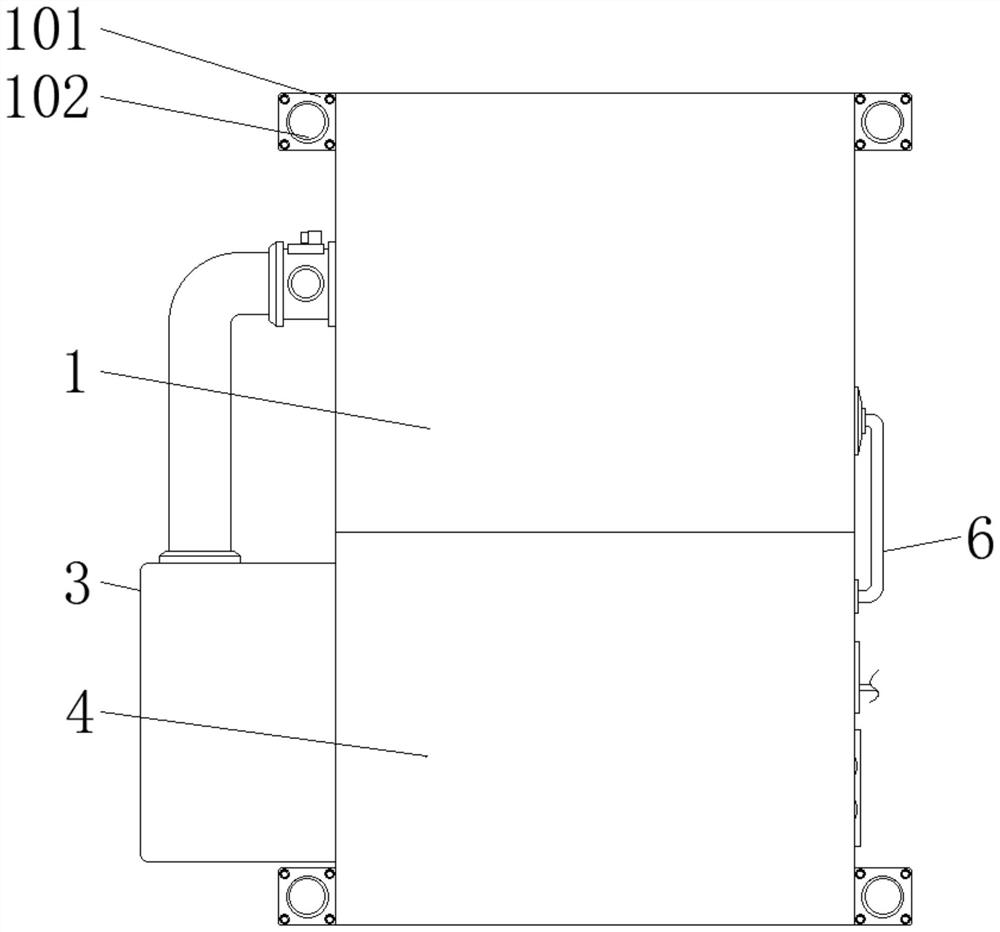

Efficient modular saturated steam washing equipment

The invention discloses efficient modular saturated steam washing equipment. The efficient modular saturated steam washing equipment comprises an equipment underframe, steam generators, a water tank, a water pump, a liquid box, a liquid pump and a washing gun head. The equipment underframe is of a stereoscopic inner hollow structure, and the four side faces and the top of the equipment underframe are each of an open structure. An electric box door, a water pump maintenance door, a heater maintenance door and a tool box door are mounted on the four side faces of the equipment underframe correspondingly. A top cover capable of being opened is mounted at the top of the equipment underframe. The water tank is an inner hollow type, and the steam generators are located in the water tank. A water storage area is defined by the outer wall and the inner wall of the water tank, and meanwhile the steam generators are wrapped by the inner wall of the water tank. Heat energy of the steam generators is transmitted to the inner wall of the water tank, and water in the water tank is preheated and then conveyed into the steam generators. According to the efficient modular saturated steam washing equipment, the modular design concept is adopted, meanwhile, the steam generators are arranged in the water tank, the inner space layout of the equipment is more reasonable, and electrical use safety and the energy utilization rate are increased.

Owner:微一绿色环保科技(海盐)有限公司

Tobacco shred analogue made of bamboo leaves and electric heating method thereof

InactiveCN103892453AComfortable suction experienceRich suction experienceTobacco treatmentTobacco devicesElectricityEngineering

The invention discloses a tobacco shred analogue made of bamboo leaves and an electric heating method of the tobacco shred analogue. The tobacco shred analogue made of the bamboo leaves is formed by evenly mixing, by weight, tobacco essence 0.03-0.06, a nicotine solution 3-8 and tobacco-shred-like materials made of the bamboo leaves 155-120, wherein the nicotine solution is the nicotine and water solution or the nicotine and ethanol solution, the part by weight of the release amount of nicotine is 0.4-1.2. According to the tobacco shred analogue made of the bamboo leaves, the bamboo leaves, the tobacco essence and the nicotine solution are utilized to manufacture the tobacco shred analogue, the health care, edible and medical effects of the bamboo leaves are fully utilized, and compared with a traditional cigarette, smoking experience is more comfortable and richer. With regard to the smoking mode, the electric heating method is adopted, the tobacco shred analogue can produce smoke gas through electric heating, which is beneficial to smoking of a smoker, environmental pollution is reduced, and harm to a human body by harmful substances produced in the combustion process of the traditional cigarette is reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Tobacco-shred-similar object produced with mint raw materials and electric heating method of tobacco-shred-similar object produced with mint raw materials

ActiveCN103892447AComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesMentha spicataProcess engineering

The invention discloses a tobacco-shred-similar object produced with mint raw materials and an electric heating method of the tobacco-shred-similar object produced with the mint raw materials. The tobacco-shred-similar object produced with the mint raw materials comprises tobacco flavors, nicotine solutions and mint tobacco-shred-shaped objects, the raw materials which comprise, by weight, 0.03-0.06 parts of the tobacco flavors, 3-8 parts of the nicotine solutions and 55-120 parts of the mint tobacco-shred-shaped objects are evenly mixed, the nicotine solutions are nicotine aqueous solutions or nicotine ethanol solutions, and the nicotine release amount is 0.4-1.2 parts by weight. By means of the tobacco-shred-similar object and the electric heating method, the tobacco-shred-similar object is produced by the tobacco flavors, the nicotine solutions and the mint tobacco-shred-shaped objects, and the health care effect and the medical effect of mint are sufficiently used by the tobacco-shred-similar object; compared with a traditional cigarette, the smoking experience of the tobacco-shred-similar object is comfortable and abundant. In the smoking mode, the electric heating method is adopted, smoke can be generated by electrically heating the tobacco-shred-similar object, a smoker can conveniently have a smoke, pollution to the environment is reduced, and harms of hazardous substance burning of the traditional cigarette on the human body are reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Efficient polyamide yarn elasticizing processing device and production process

The invention relates to the technical field of elasticizers, in particular to an efficient polyamide yarn elasticizing processing device. According to the technical scheme, the device comprises a shell, a steam assembly, an electric heating assembly and a backflow assembly, a heating chamber is mounted at the top in the shell, a cooling chamber is mounted at the bottom of the heating chamber, a bottom shell is welded to the bottom of the shell, the electric heating assembly is mounted in the bottom shell, the backflow assembly is mounted on the electric heating assembly, a mounting plate is mounted in the backflow assembly, and an air guide groove is formed in one side of the mounting plate. The air guide groove is formed in one side of the mounting plate, and air flow in the pressurizing pipe can be guided through the air guide groove to blow biphenyl steam downwards, so that the biphenyl steam can circularly flow in the bottom shell, and the air flow forms an air curtain in the horizontal direction; on the premise of ensuring normal transmission of the nylon yarns, biphenyl steam leakage is avoided, and the safety of the device is improved when the nylon yarns are plasticized and heated by using biphenyl steam.

Owner:四川润厚特种纤维有限公司

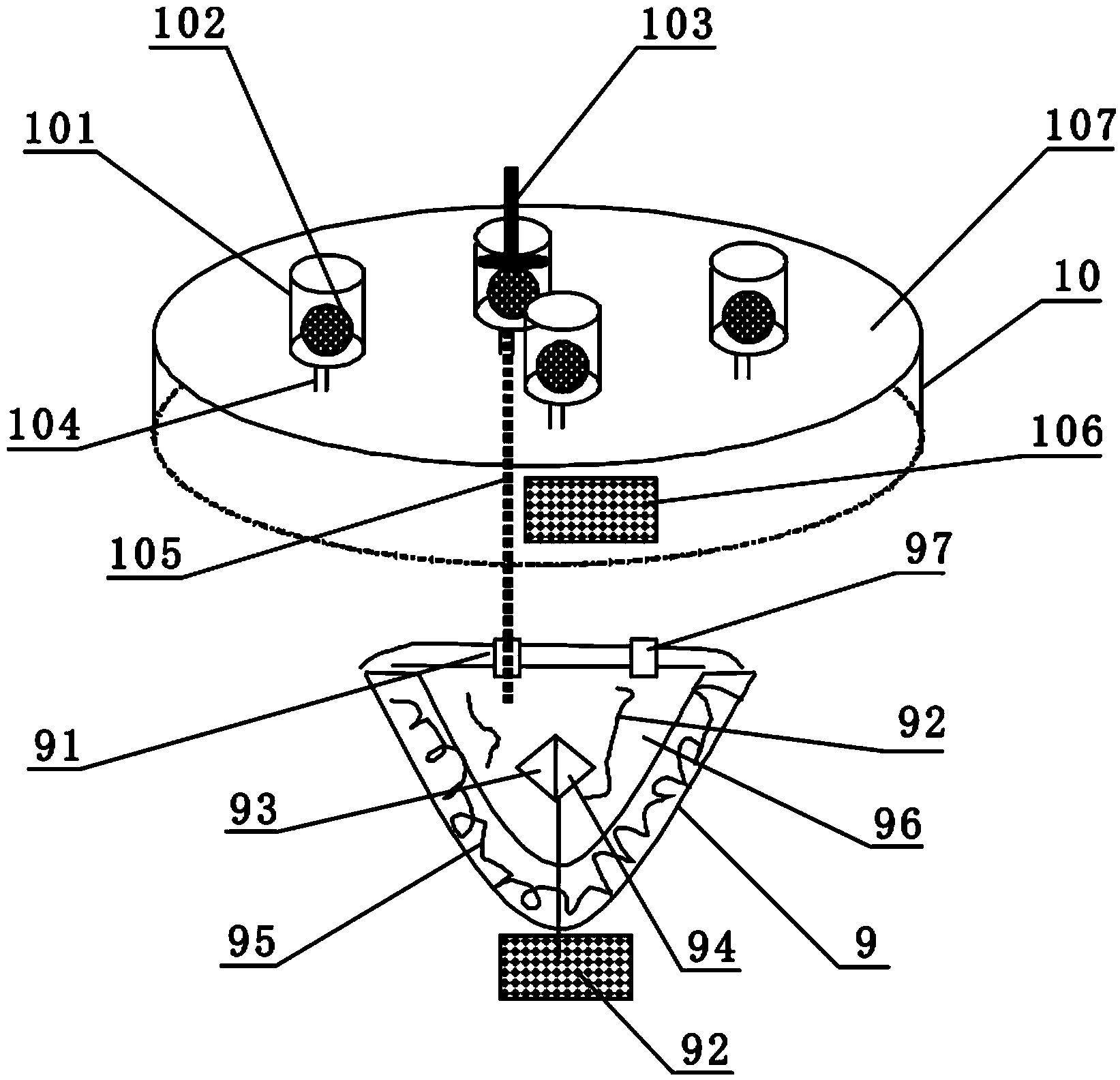

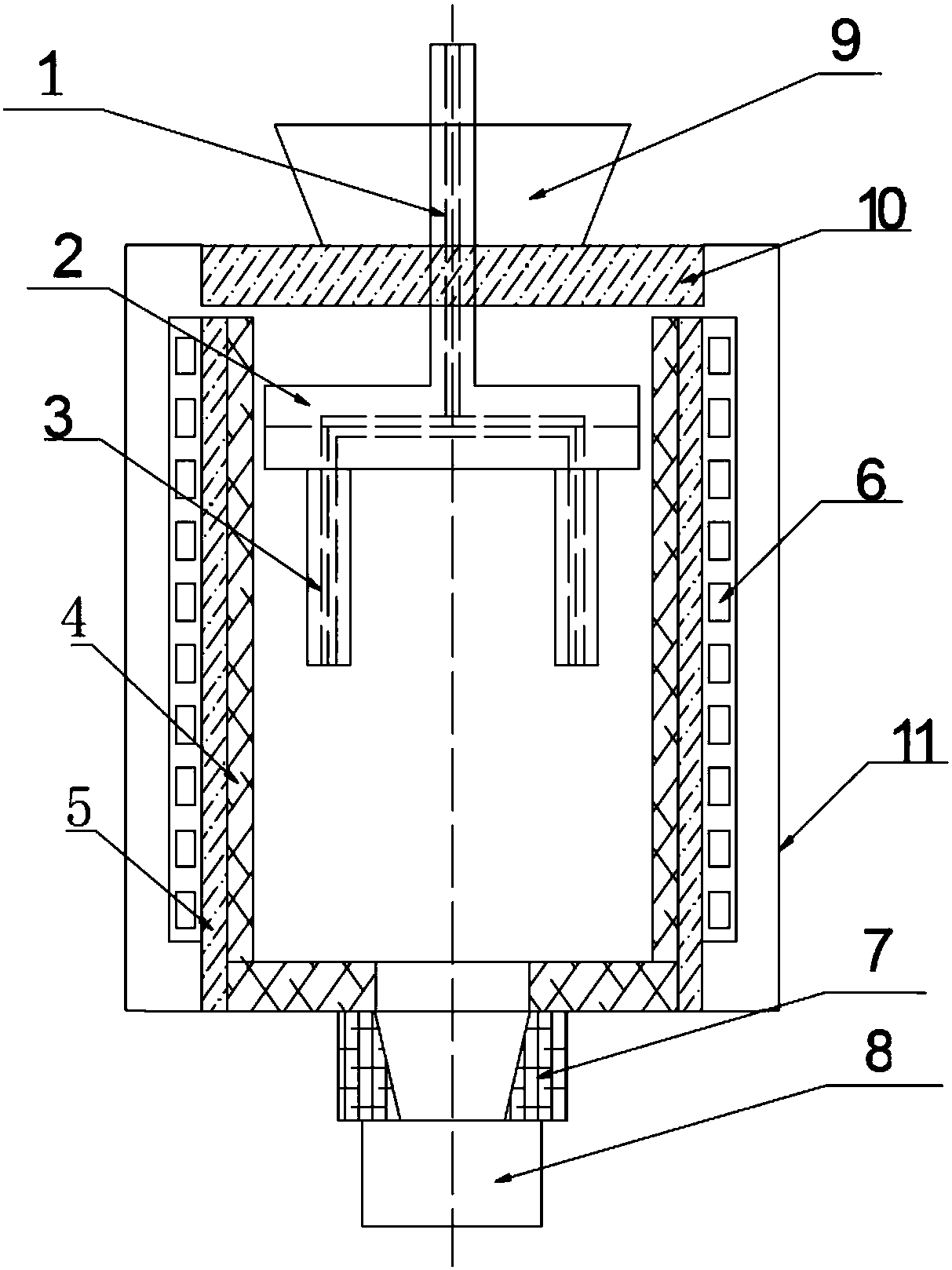

Heat-treatment furnace of powder

ActiveCN107651678AImprove temperature uniformityLong time in high temperature zoneCarbon compoundsChemical industryCrucibleHearth

The invention discloses a heat-treatment furnace of powder. The heat-treatment furnace of the powder comprises a furnace shell with a closed furnace hearth, a crucible arranged in the closed furnace hearth and a heat-preserving cover arranged at the top end of the furnace shell; a charging opening is formed in the heat-preserving cover, and a discharging opening is formed in the bottom end of thefurnace shell; an induction coil is arranged between the external wall of the crucible and the internal wall of the furnace shell; and a rotating disk and a rotating shaft, which penetrates through the heat-preserving cover and is fixedly connected with the rotating disk, are arranged at the internal upper part of the crucible. According to the heat-treatment furnace of the powder, the continuousproduction of powder materials is achieved, the energy saving effect is good, and the heating efficiency is high.

Owner:ZHUZHOU CHENXIN INDUCTION EQUIP CO LTD

Tobacco-shred-similar object produced with chrysanthemums and lonicera japonica as raw materials and electric heating method of tobacco-shred-similar object produced with chrysanthemums and lonicera japonica as raw materials

InactiveCN103892451AComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesFlavorHazardous substance

The invention discloses a tobacco-shred-similar object produced with chrysanthemums and lonicera japonica as raw materials and an electric heating method of the tobacco-shred-similar object produced with the chrysanthemums and the lonicera japonica as the raw materials. The tobacco-shred-similar object produced with the chrysanthemums and the lonicera japonica as the raw materials comprises tobacco flavors, nicotine solutions and a mixture of the smashed chrysanthemums and the smashed lonicera japonica, the raw materials which comprise, by weight, 0.03-0.06 parts of the tobacco flavors, 3-8 parts of the nicotine solutions and 55-120 parts of the mixture of the smashed chrysanthemums and the smashed lonicera japonica are evenly mixed, the nicotine solutions are nicotine aqueous solutions or nicotine ethanol solutions, and the nicotine release amount is 0.4-1.2 parts by weight. By means of the tobacco-shred-similar object and the electric heating method, the health care effect and the medical effect of the chrysanthemums and the lonicera japonica are sufficiently used; compared with a traditional cigarette, the smoking experience of the tobacco-shred-similar object is comfortable and abundant. In the smoking mode, the electric heating method is adopted, smoke can be generated by electrically heating the tobacco-shred-similar object, a smoker can conveniently have a smoke, pollution to the environment is reduced, and harms of hazardous substance burning of the traditional cigarette on the human body are reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

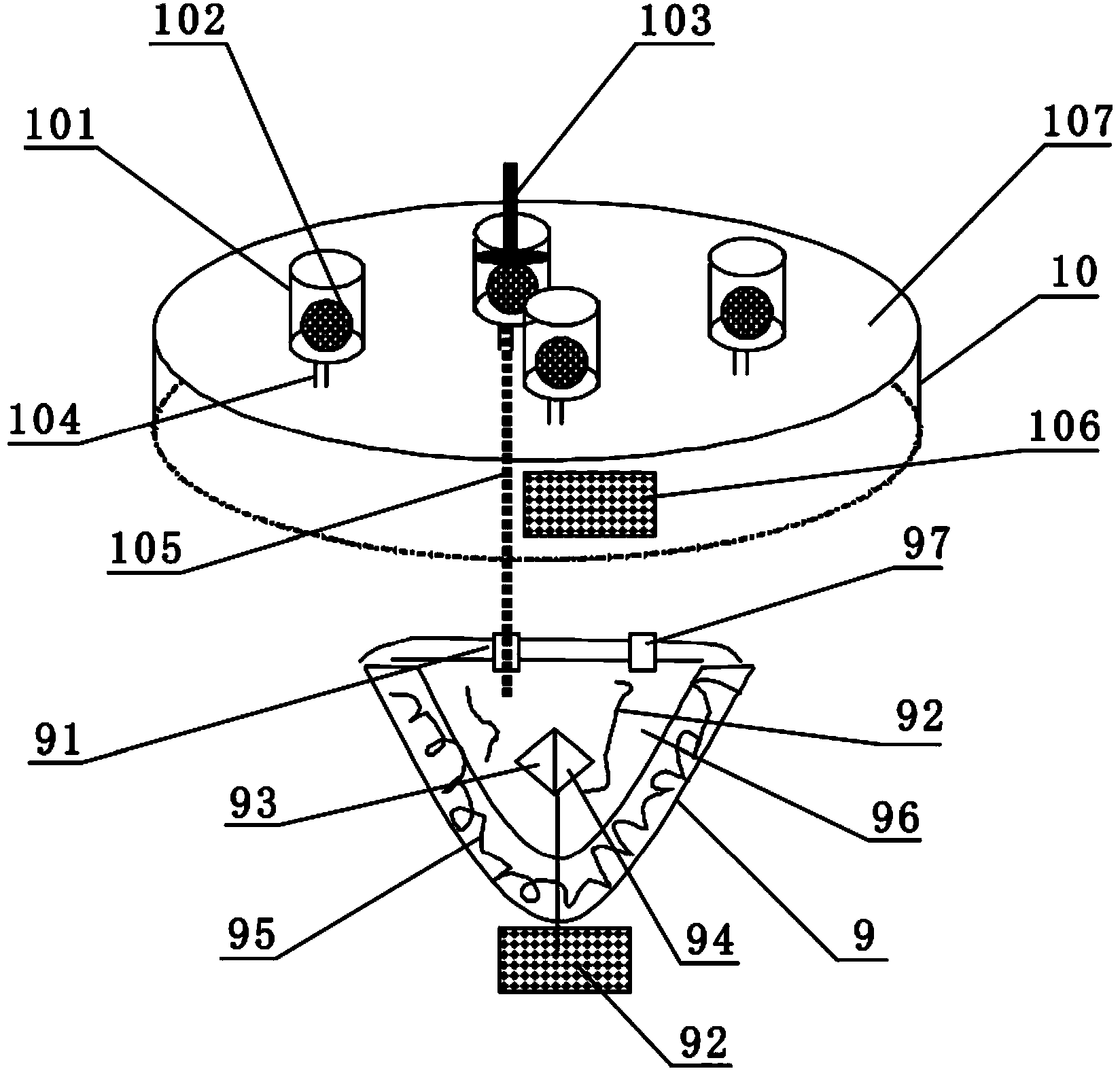

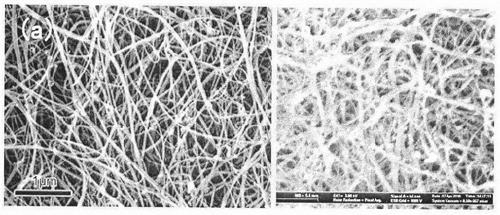

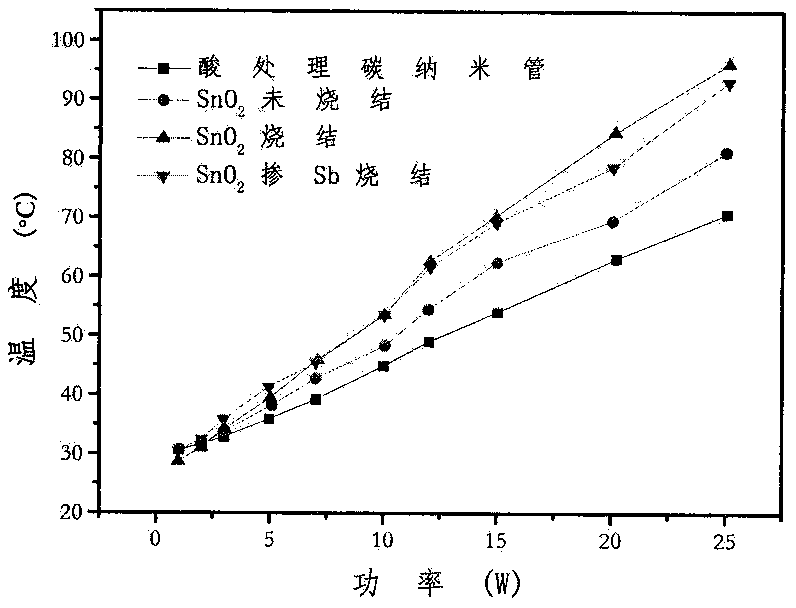

Preparation method of Sb-doped SnO2 @ carbon nanotube composite electrothermal film

ActiveCN110395714AHigh electric heating efficiencyGood electrothermal characteristicsCarbon compoundsChemical industryElectrical resistance and conductanceComposite film

It is disclosed that the advantages of two types of electric heating materials are combined to prepare a Sb-doped SnO2 @ carbon nanotube composite electric heating film. In the method, Sb-doped SnO2 is loaded on a carbon nanotube film by adopting a hydrothermal method; therefore, compared with a pure carbon nanotube film, the material has the advantages that the electric heating performance is remarkably improved, the electric resistance is reduced, the required power is lower when the temperature is increased to the same temperature, and the heating rate is higher. The composite film in the invention is a novel flexible electric heating material which is convenient to use, energy-saving and environment-friendly, and has a wide application prospect.

Owner:南京智融纳米新材料科技有限公司

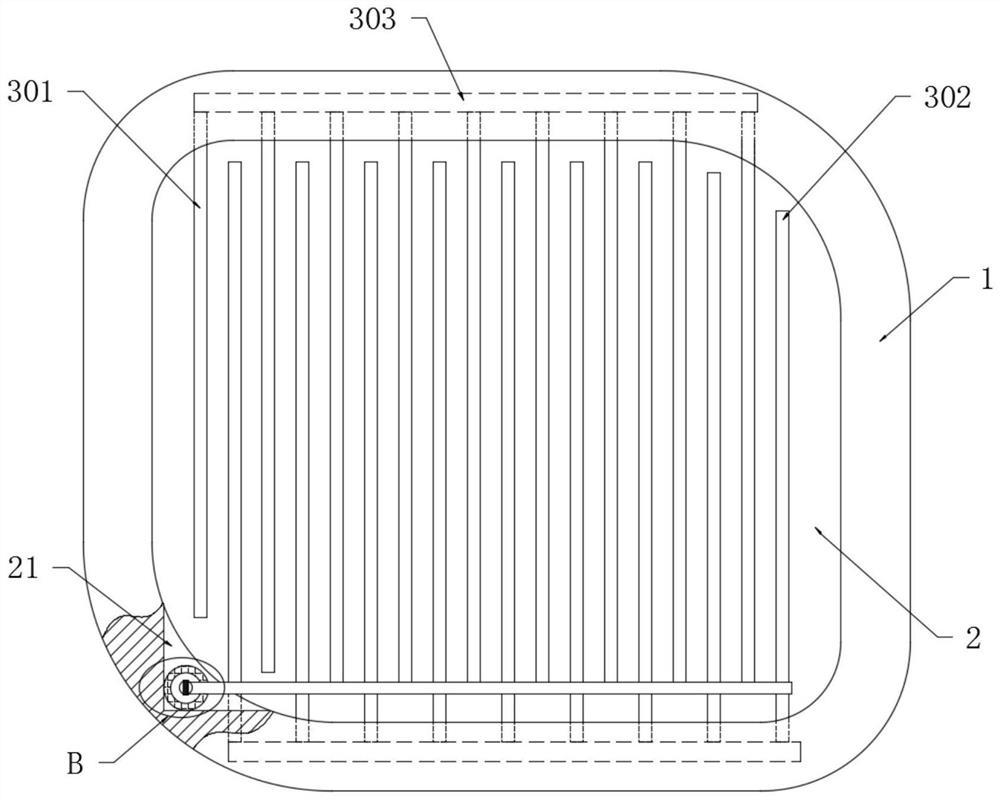

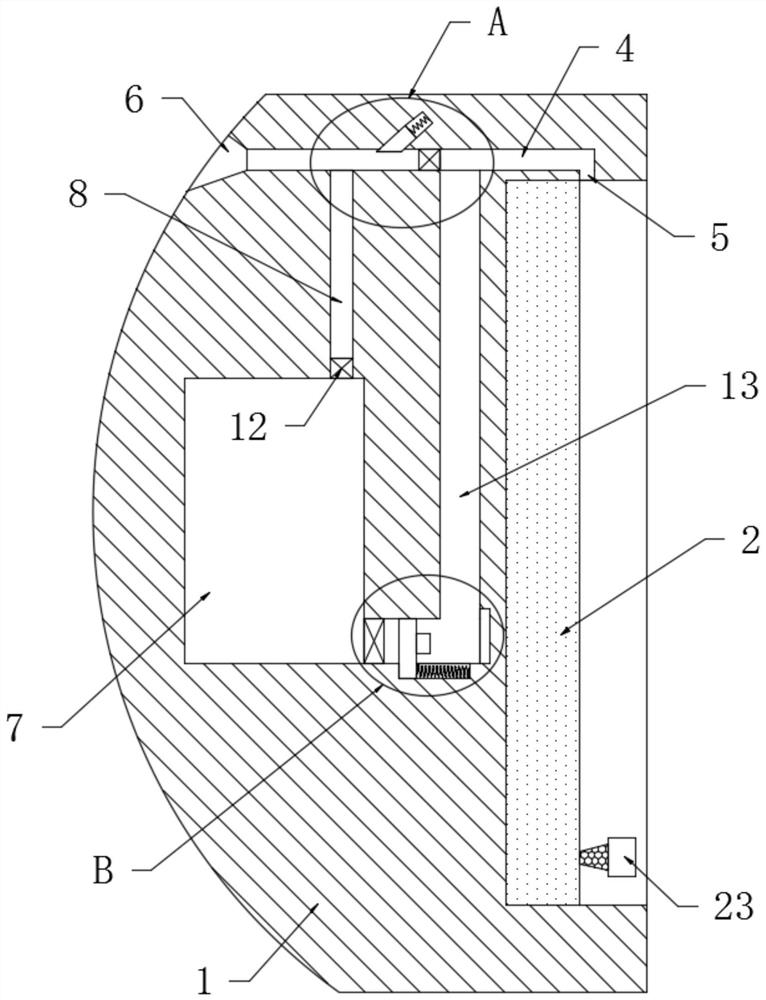

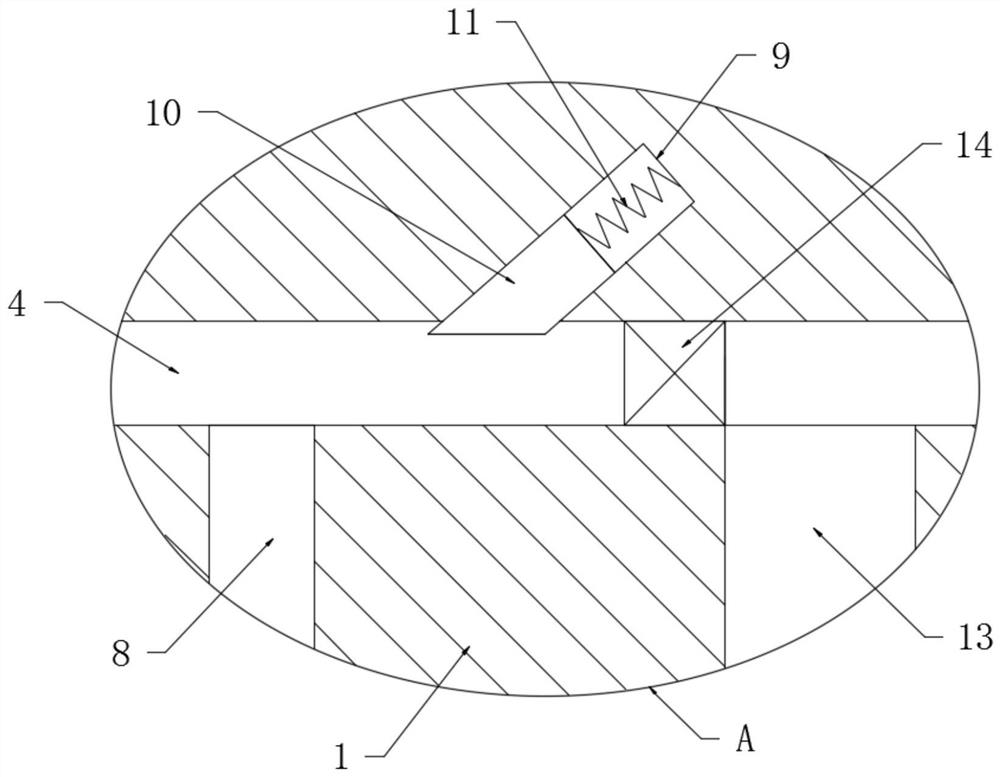

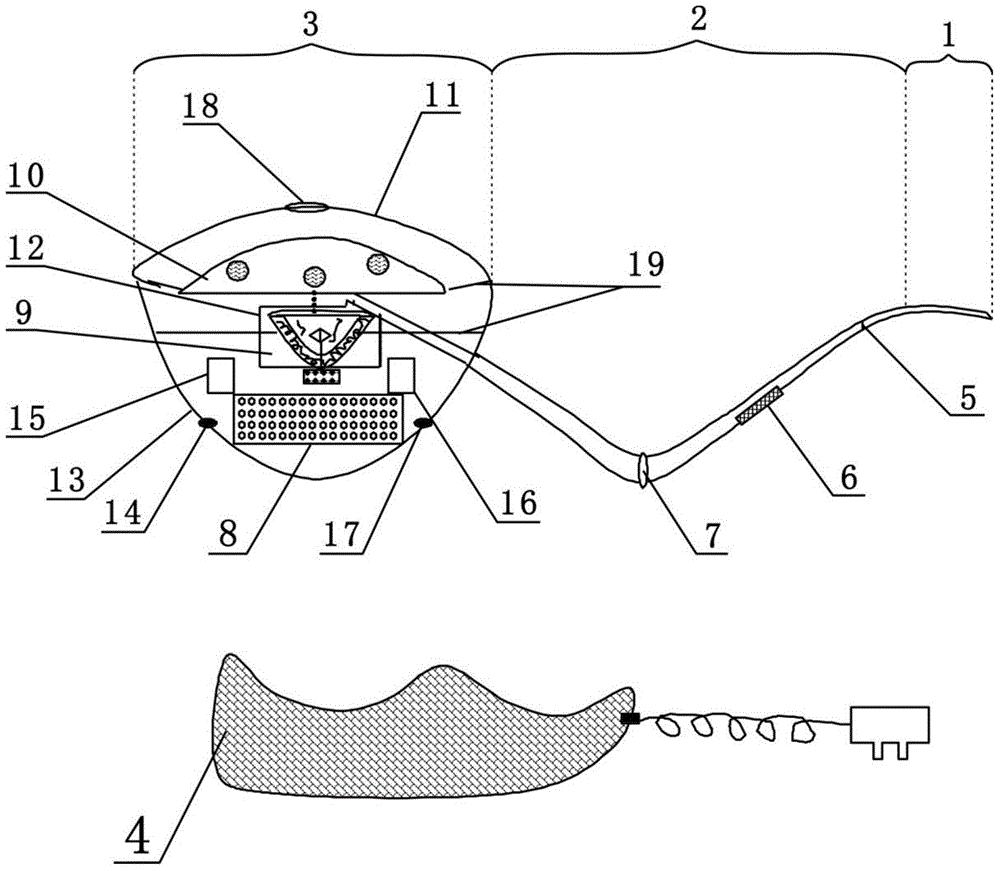

Quick water removal rearview mirror of new energy automobile

ActiveCN112172678APlay a dust-proof effectHigh electric heating efficiencyVehicle cleaningOptical viewingNew energyProcess engineering

The invention discloses a quick water removal rearview mirror of a new energy automobile, which comprises a rearview mirror body and a mirror surface embedded on the rearview mirror body, a heating device is arranged on the mirror surface, a breather pipe is embedded at the top of the rearview mirror body, a horn-shaped air inlet is formed in the outer wall of the side, away from the mirror surface, of the rearview mirror body, one end of the ventilation pipe is communicated with an air inlet, a row of uniform air outlet holes are formed in a mirror frame, located above the mirror surface, ofthe rearview mirror body, and the end, away from the air inlet, of the ventilation pipe is communicated with the multiple air outlet holes. The quick water removal rearview mirror has the advantages that when an automobile travels, stored energy of gas is used for generating electricity, external power supply is not needed, energy conservation and environmental protection are achieved, mirror surface heating, mechanical rainwater wiping and gas storage water blowing are used in cooperation for water removal of the rearview mirror, and the water removal effect is improved while the water removal efficiency is improved.

Owner:湖州力卓机械设备技术开发有限公司

An electric heating method for making shredded tobacco with bamboo leaf raw materials

InactiveCN103892453BComfortable suction experienceRich suction experienceTobacco treatmentTobacco devicesElectricityEngineering

The invention discloses a tobacco shred analogue made of bamboo leaves and an electric heating method of the tobacco shred analogue. The tobacco shred analogue made of the bamboo leaves is formed by evenly mixing, by weight, tobacco essence 0.03-0.06, a nicotine solution 3-8 and tobacco-shred-like materials made of the bamboo leaves 155-120, wherein the nicotine solution is the nicotine and water solution or the nicotine and ethanol solution, the part by weight of the release amount of nicotine is 0.4-1.2. According to the tobacco shred analogue made of the bamboo leaves, the bamboo leaves, the tobacco essence and the nicotine solution are utilized to manufacture the tobacco shred analogue, the health care, edible and medical effects of the bamboo leaves are fully utilized, and compared with a traditional cigarette, smoking experience is more comfortable and richer. With regard to the smoking mode, the electric heating method is adopted, the tobacco shred analogue can produce smoke gas through electric heating, which is beneficial to smoking of a smoker, environmental pollution is reduced, and harm to a human body by harmful substances produced in the combustion process of the traditional cigarette is reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

A shredded tobacco-like object made from citrus substances and its electric heating method

ActiveCN103908012BComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesBiotechnologyHazardous substance

The invention discloses a tobacco material class produced by taking citrus materials as raw materials and an electric heating method of the tobacco material class. The tobacco material class produced by evenly blending the raw materials including, by weight, 0.03-0.06 parts of tobacco essence, 3-8 parts of a nicotine solution and 55-120 parts of citrus tobacco materials, wherein the nicotine solution is a nicotine water solution or a nicotine ethanol solution, and the releasing amount of nicotine accounts for 0.4-1.2 parts by weight. Produced by the citrus materials, the tobacco essence and the nicotine solution and fully utilizing healthcare, edible and medical effects of citrus, the tobacco material class compared with conventional cigarettes has the advantages that smoking experience is more comfortable and richer; by means of the electric heating method, the tobacco materials class can produce smoke which can be conveniently sucked by a smoker, pollution to the environment is lowered, and damages of burning hazardous substances of the conventional cigarettes to human body can be reduced.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

An electric heating method for making cut tobacco-like objects with chrysanthemum and honeysuckle as raw materials

InactiveCN103892451BComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesBiotechnologyHazardous substance

The invention discloses a tobacco-shred-similar object produced with chrysanthemums and lonicera japonica as raw materials and an electric heating method of the tobacco-shred-similar object produced with the chrysanthemums and the lonicera japonica as the raw materials. The tobacco-shred-similar object produced with the chrysanthemums and the lonicera japonica as the raw materials comprises tobacco flavors, nicotine solutions and a mixture of the smashed chrysanthemums and the smashed lonicera japonica, the raw materials which comprise, by weight, 0.03-0.06 parts of the tobacco flavors, 3-8 parts of the nicotine solutions and 55-120 parts of the mixture of the smashed chrysanthemums and the smashed lonicera japonica are evenly mixed, the nicotine solutions are nicotine aqueous solutions or nicotine ethanol solutions, and the nicotine release amount is 0.4-1.2 parts by weight. By means of the tobacco-shred-similar object and the electric heating method, the health care effect and the medical effect of the chrysanthemums and the lonicera japonica are sufficiently used; compared with a traditional cigarette, the smoking experience of the tobacco-shred-similar object is comfortable and abundant. In the smoking mode, the electric heating method is adopted, smoke can be generated by electrically heating the tobacco-shred-similar object, a smoker can conveniently have a smoke, pollution to the environment is reduced, and harms of hazardous substance burning of the traditional cigarette on the human body are reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

An electric heating method for making shredded tobacco with mint raw materials

ActiveCN103892447BComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesHazardous substancePollution

The invention discloses a tobacco-shred-similar object produced with mint raw materials and an electric heating method of the tobacco-shred-similar object produced with the mint raw materials. The tobacco-shred-similar object produced with the mint raw materials comprises tobacco flavors, nicotine solutions and mint tobacco-shred-shaped objects, the raw materials which comprise, by weight, 0.03-0.06 parts of the tobacco flavors, 3-8 parts of the nicotine solutions and 55-120 parts of the mint tobacco-shred-shaped objects are evenly mixed, the nicotine solutions are nicotine aqueous solutions or nicotine ethanol solutions, and the nicotine release amount is 0.4-1.2 parts by weight. By means of the tobacco-shred-similar object and the electric heating method, the tobacco-shred-similar object is produced by the tobacco flavors, the nicotine solutions and the mint tobacco-shred-shaped objects, and the health care effect and the medical effect of mint are sufficiently used by the tobacco-shred-similar object; compared with a traditional cigarette, the smoking experience of the tobacco-shred-similar object is comfortable and abundant. In the smoking mode, the electric heating method is adopted, smoke can be generated by electrically heating the tobacco-shred-similar object, a smoker can conveniently have a smoke, pollution to the environment is reduced, and harms of hazardous substance burning of the traditional cigarette on the human body are reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

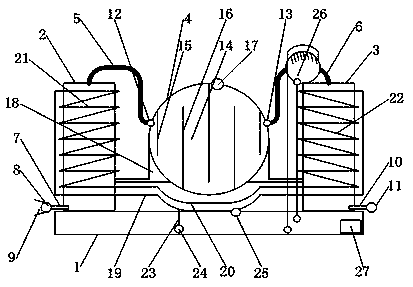

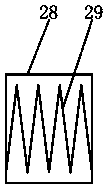

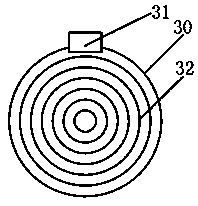

Waste gas double-cooling single-hot-drying treatment equipment

InactiveCN111298586AEasy accessImprove heat treatment efficiencyCombination devicesAir pumpEnvironmental engineering

The invention discloses waste gas double-cooling single-hot-drying treatment equipment, which comprises a bottom bin, wherein an air inlet bin is arranged on one side of the top of the bottom bin, anair outlet bin is arranged on the other side of the top of the bottom bin, a hot-drying bin is arranged in the middle of the top of the bottom bin, and is installed between the air inlet bin and the air outlet bin, the top of the air inlet bin is connected with the top of the hot-drying bin through an air inlet pipeline, the top of the air outlet bin is connected with the top of the hot-drying binthrough an air outlet pipeline, an air inlet pipe is arranged at the bottom of the air inlet bin, a main air inlet pump is arranged at the outer end of the air inlet pipe, an air outlet pipe is arranged at the bottom of the air outlet bin, an air outlet ball is arranged at the outer end of the air outlet pipe, an auxiliary air inlet pump is arranged between the air inlet pipeline and one side ofthe top of the hot-drying bin, an air outlet pump is arranged between the air outlet pipeline and the other side of the top of the hot-drying bin, and a conveying gas circuit is arranged in the hot-drying bin. According to the invention, waste gas in the bin body is subjected to electric heating treatment; and second electric heating wires arranged in a concentric circle mode and first electric heating wires arranged in a spiral mode greatly improve the waste gas heating treatment efficiency.

Owner:何英

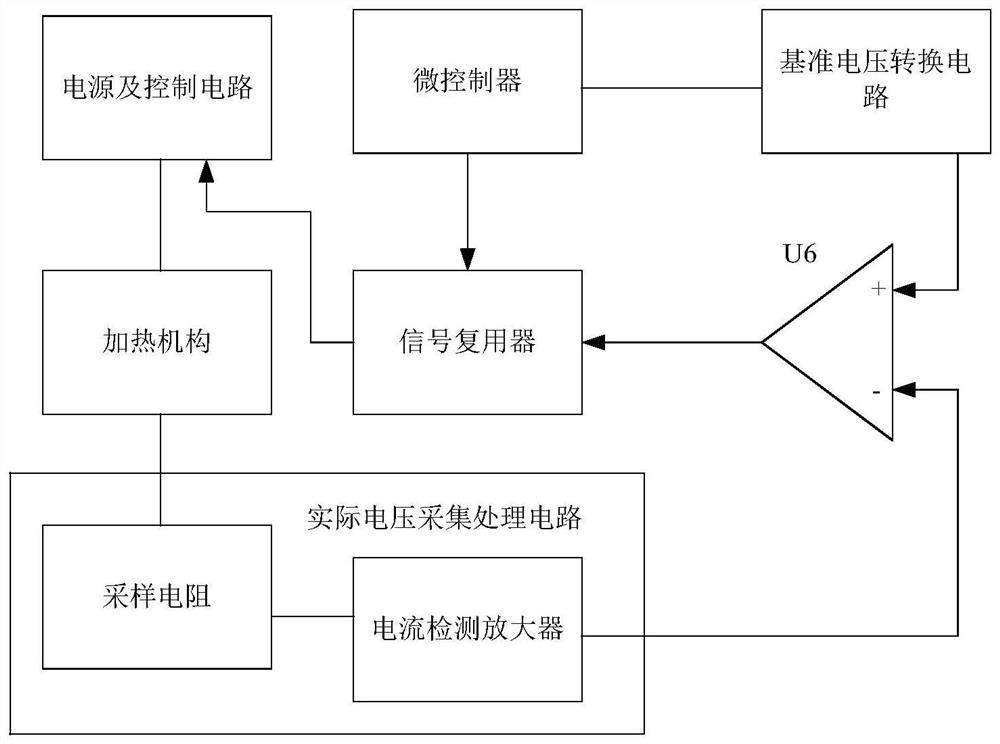

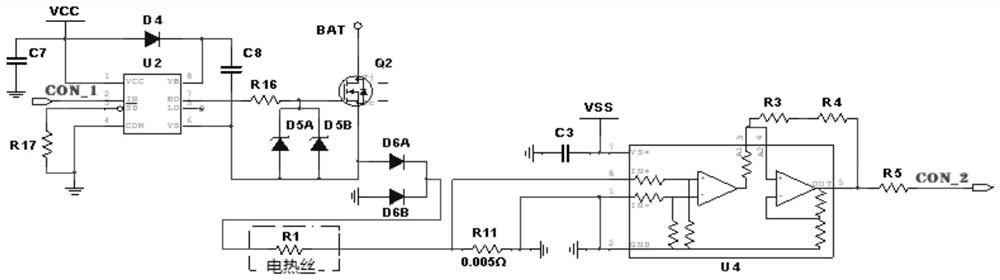

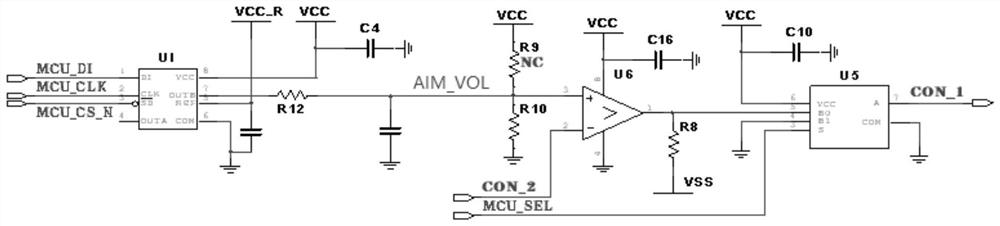

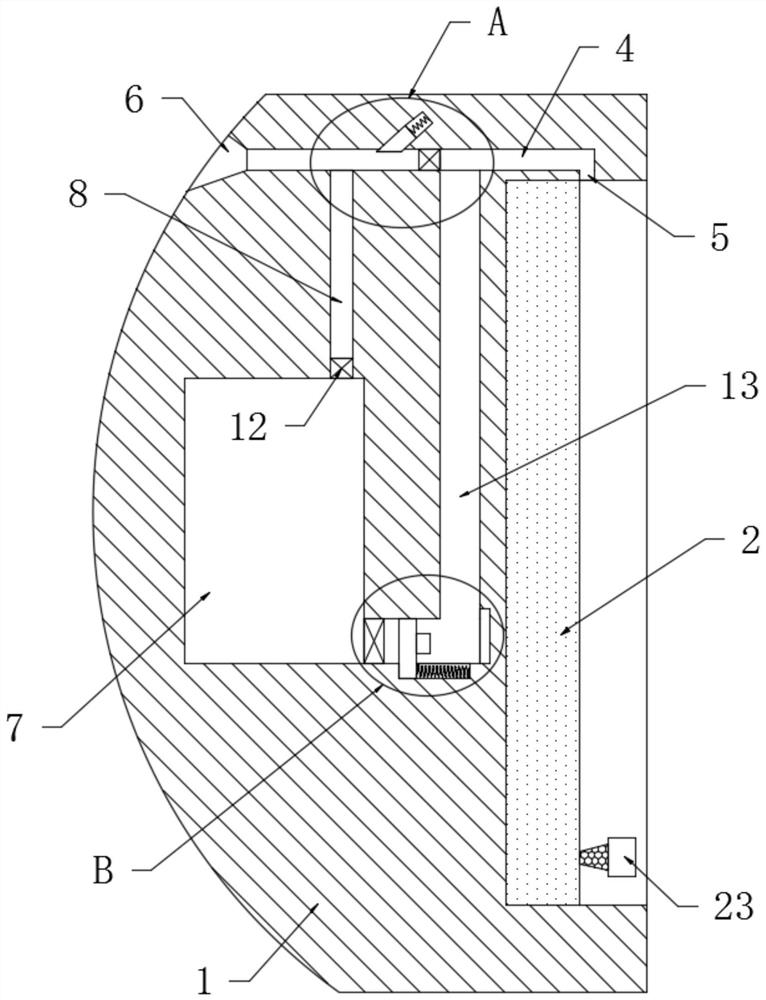

Heating circuit board based on edge server

PendingCN113543376AReduce the burden onHigh electric heating efficiencyElectric heatingEnergy efficient computingElectric heatingHeating efficiency

The invention relates to the technical field of servers, and provides a heating circuit board based on an edge server, which comprises a power supply and control circuit, a heating mechanism, a microcontroller, an actual voltage acquisition and processing circuit, a reference voltage conversion circuit, a voltage comparator U6 and a signal multiplexer U5, the power supply and control circuit is used for controlling the power-on state of the heating mechanism according to the level of an enable signal CON_1 generated by the signal multiplexer U5, and the actual voltage collecting and processing circuit and the reference voltage conversion circuit are used for obtaining actual comparison voltage CON_2 and reference voltage respectively. The voltage comparator U6 and the signal multiplexer U5 are combined with the microcontroller to realize an adjustable scheme of heating power, so that the electric heating efficiency in a low-temperature environment is improved, the control logic and code quantity are simplified, the burden of a control system is relieved, and the stability and safety of the system are improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

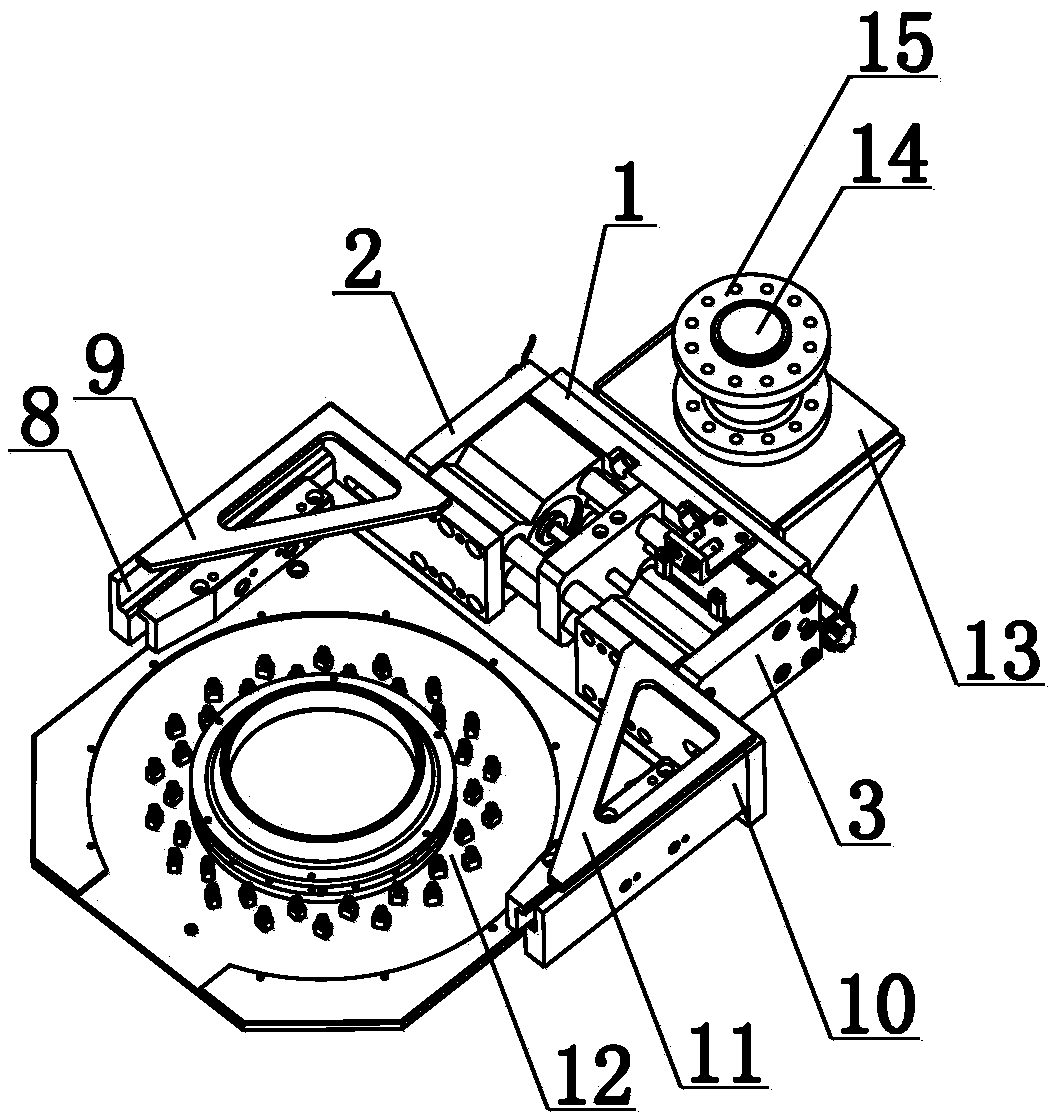

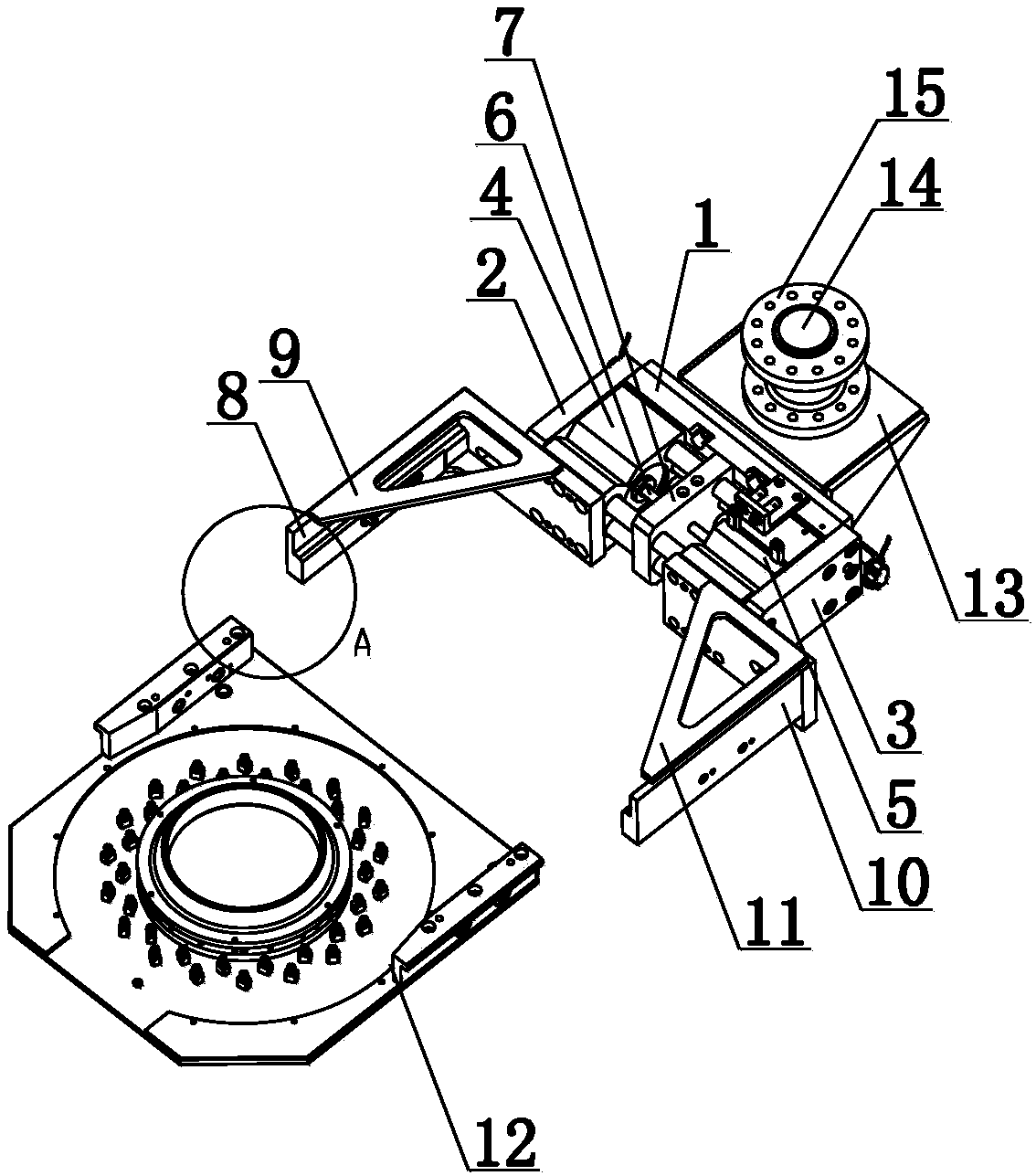

Winding device for electric heating wire of heating cylinder of plastic granulator

InactiveCN108856582AHigh electric heating efficiencyImprove the efficiency of winding to the outer peripheral surface of the heating cylinderEngineeringElectric heating

The invention discloses a winding device for an electric heating wire of a heating cylinder of a plastic granulator. The winding device comprises a fixing plate; one side of the fixing plate is provided with a first side plate; the other side of the fixing plate is provided with a second side plate; the inward surface of the first side plate is provided with a first fixing seat; the inward surfaceof the second side plate is provided with a second fixing seat; the front part of the first side plate is provided with a first limiting rail; the upper part of the first limiting rail is provided with a first protective frame; the front part of the second side plate is provided with a second limiting rail; the upper part of the second limiting rail is provided with a second protective frame; a positioning mechanism is arranged between the first limiting rail and the second limiting rail; the positioning mechanism comprises a regulating plate; the regulating plate is provided with a positioning cylinder; a rear seat is arranged at the back part of the fixing plate; the rear seat is provided with a positioning shaft; and the outer circumferential surface of the positioning shaft is sleevedwith an winding wheel. According to the winding device disclosed by the invention, the electric heating wire can be unwound by the unwinding wheel, and an operator can pull the electric heating wireby using a hand and then wind the electric heating wire on the outer circumferential surface of the heating cylinder.

Owner:徐荣春

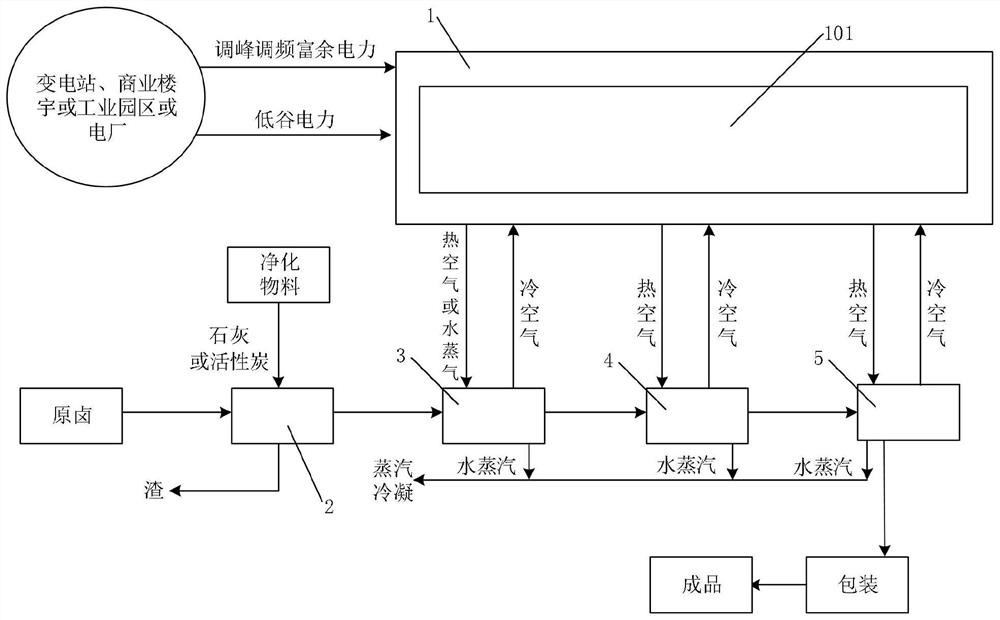

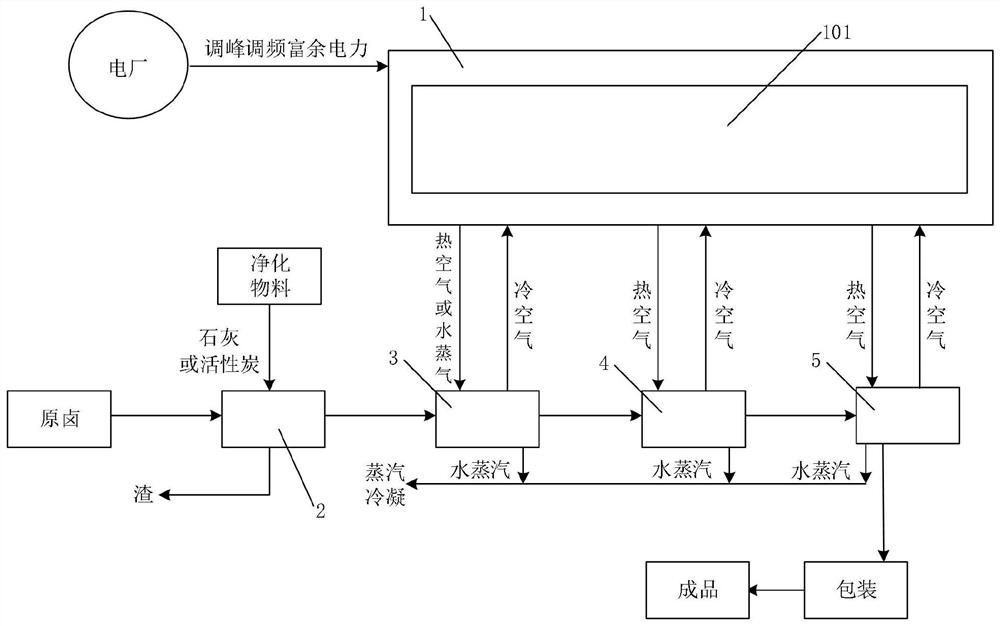

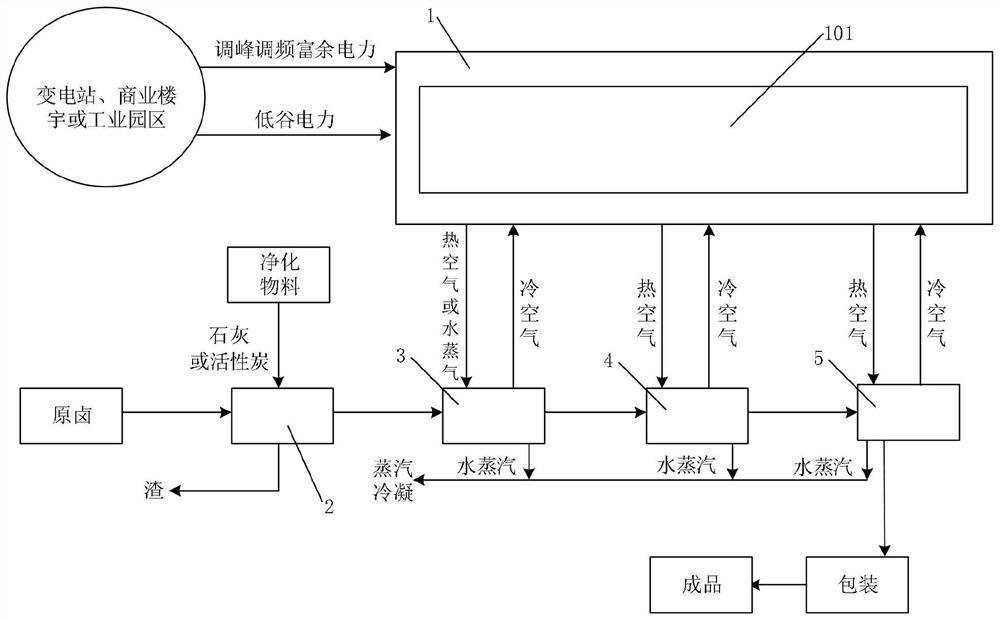

Solid heat storage electric boiler coupled salt manufacturing system and power grid peak load and frequency regulation method

PendingCN113803701AGuaranteed uptimeReduce manufacturing costSteam generation heating methodsHeat storage plantsActivated carbonThermodynamics

The invention discloses a solid heat storage electric boiler coupled salt manufacturing system and a power grid peak load and frequency regulation method. The solid heat storage electric boiler coupled salt manufacturing system comprises a solid heat storage electric boiler and a salt manufacturing device, and the solid heat storage electric boiler is connected with the salt manufacturing device; a solid heat accumulator is heated to realize heat accumulation by utilizing peak load and frequency regulation surplus electric power of a power grid or a power plant, so that hot air or hot steam is generated and supplied to an evaporation unit, a dehydration unit or a drying unit of the salt manufacturing device; a purification unit is connected with a lime supply unit or an activated carbon supply unit, and lime or activated carbon is used as a purifying agent to purify raw brine; and the salt manufacturing device uses hot air or steam generated by the solid heat storage electric boiler as a heat source for evaporation, dehydration or drying. The system is simple in structure, power is supplied to the solid heat storage electric boiler through peak load and frequency regulation surplus power, a heat source is provided for the salt manufacturing device through the solid heat storage electric boiler, the consumption amount of the peak load and frequency regulation surplus power is increased, and the production cost of salt manufacturing is also reduced.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

A shredded tobacco substance made from hawthorn raw material and its electric heating method

InactiveCN103908014BComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesHazardous substanceEngineering

The invention discloses a tobacco material class produced by taking hawthorn raw materials as raw materials and an electric heating method of the tobacco material class. The tobacco material class produced by evenly blending the hawthorn raw materials including, by weight, 0.03-0.06 parts of tobacco essence, 3-8 parts of a nicotine solution and 55-120 parts of hawthorn tobacco materials, wherein the nicotine solution is a nicotine water solution or a nicotine ethanol solution, and the releasing amount of nicotine accounts for 0.4-1.2 parts by weight. Produced by the hawthorn raw materials, the tobacco essence and the nicotine solution and fully utilizing healthcare, edible and medical effects of hawthorns, the tobacco material class compared with conventional cigarettes has the advantages that smoking experience is more comfortable and richer; by means of the electric heating method, the tobacco materials class can produce smoke which can be conveniently sucked by a smoker, pollution to the environment is lowered, and damages of burning hazardous substances of the conventional cigarettes to human body can be reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

A fast water-removing rearview mirror for new energy vehicles

ActiveCN112172678BPlay a dust-proof effectHigh electric heating efficiencyVehicle cleaningOptical viewingNew energyRear-view mirror

The invention discloses a fast water-removing rearview mirror for a new energy vehicle, which comprises a rearview mirror body and a mirror surface embedded on the rearview mirror body, a heating device is provided on the mirror surface, and a rearview mirror body has a A ventilation pipe is buried in the top position, and a trumpet-shaped air inlet is provided on the outer wall of the rearview mirror body away from the side of the mirror surface. One end of the ventilation pipe communicates with the air inlet, and the rearview mirror body is located at A row of uniform air outlets is provided on the frame above the mirror surface, and the end of the ventilation pipe away from the air inlet is connected with a plurality of air outlets. The advantage is that the present invention utilizes the energy storage of the gas to generate electricity when the vehicle is running, without external power supply, energy saving and environmental protection, and the combination of mirror surface heating, mechanical rain scraping and gas storage blowing is used to remove water from the rearview mirror, improving Improve the water removal efficiency while improving the water removal effect.

Owner:湖州力卓机械设备技术开发有限公司

A kind of tobacco-like material made by using tobacco waste and electric heating method thereof

ActiveCN103908010BComfortable suction experienceRich suction experienceTobacco treatmentTobacco pipesFlavorHazardous substance

The utility model discloses a similar cut tobacco prepared by tobacco waste and an electrical heating method of the similar cut tobacco. The similar cut tobacco prepared by the tobacco waste comprises a tobacco flavor, a nicotine solution and a tobacco waste cut tobacco type object, the tobacco flavor, the nicotine solution and the tobacco waste cut tobacco type object are uniformly mixed in parts by weight: 0.03-0.06 parts of tobacco flavor, 3-8 parts of nicotine solution and 55-120 parts of tobacco waste cut tobacco type object, wherein the nicotine solution is either a nicotine water solution or a nicotine ethane solution, and the release amount of nicotine is 0.4-1.2 parts by weight. The similar cut tobacco is prepared by the tobacco flavor, the nicotine solution and the tobacco waste cut tobacco type object, and is electrically heated to generate smoke smoked by a smoker, so that the environmental pollution can be reduced, the harm on the human body caused by the harmful substances generated by burning traditional cigarettes can be reduced, the hygienical, edible and medical effects of the tobacco waste can be fully used, and the smoking experience is more comfortable in comparison with the traditional cigarettes.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

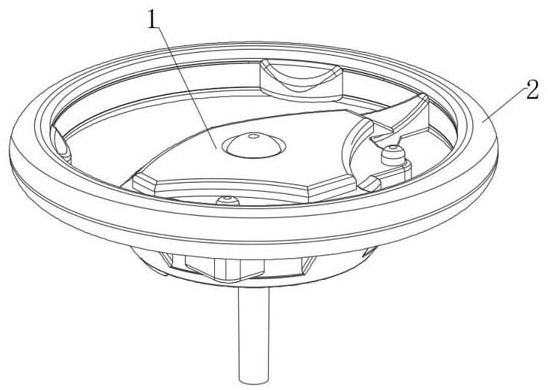

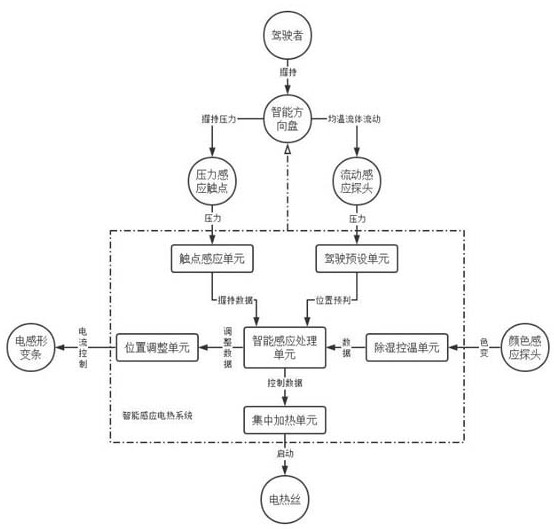

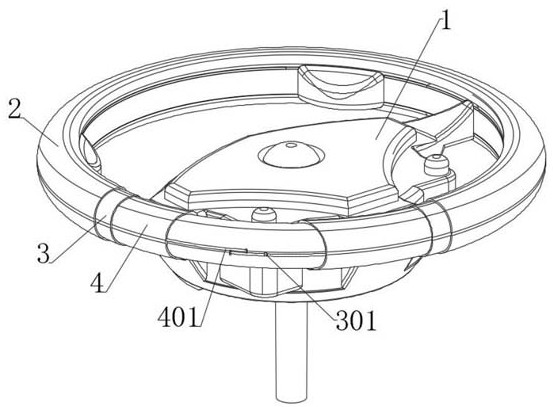

Induction electric heating device for automobile steering wheel

The invention discloses an induction electric heating device for an automobile steering wheel, which belongs to the field of electric heating. An induction electric heating device for an automobile steering wheel includes an intelligent steering wheel. The outer end of the intelligent steering wheel is fixedly connected with an induction sheath, and the inner wall of the induction sheath is fixedly connected with a The passive temperature equalizing sleeve can effectively sense the operating position of the driver's hand through the induction sheath and the heat-collecting heating arc, and centrally heat the position, effectively shortening the heating time of the smart steering wheel and reducing the temperature difference caused by the driver. Stimulation, effectively saving the driver's application time of using the smart steering wheel, effectively improving the driver's sense of experience, and after the heat-collecting heating arc is partially heated, it can conduct rapid and uniform temperature conduction to the entire smart steering wheel, improving the smart steering wheel. While improving the efficiency of electric heating, it also improves the automation and intelligence of the electric heating process of the smart steering wheel, making the electric heating effect more humane.

Owner:海安荣民汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com