Solid heat storage electric boiler coupled salt manufacturing system and power grid peak load and frequency regulation method

A technology of solid heat storage, peak regulation and frequency regulation, which is applied in the direction of heat storage equipment, steam boilers, steam boiler accessories, etc., can solve the problems that the steam parameters or flow rate of the power plant cannot meet the requirements of the salt production process, and the surplus power of peak regulation and frequency regulation increases. Achieve the effects of high quality hot air or steam, lower energy consumption, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

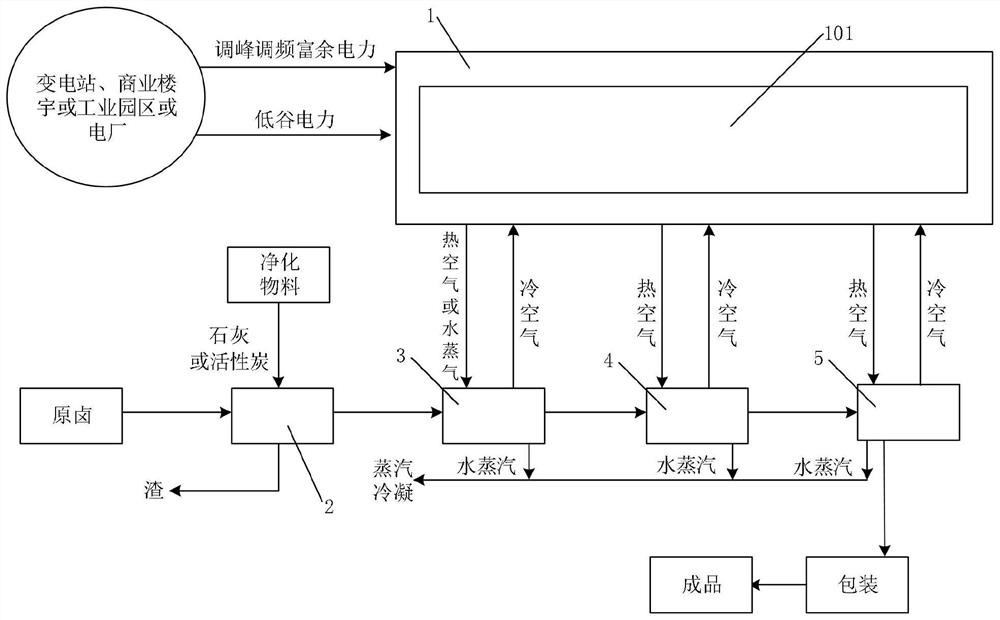

[0050] This embodiment provides a solid heat storage electric boiler coupled salt production system, such as figure 1 As shown, it includes a solid heat storage electric boiler 1 and a salt making device, the salt making device includes a purification unit 2, an evaporation unit 3, a dehydration unit 4 and a drying unit 5, and the solid heat storage electric boiler 1 is connected to the salt making device Any one or combination of the evaporation unit 3, the dehydration unit 4 or the drying unit 5; use the peak-shaving and frequency-regulating surplus power of the power grid or the power plant to heat the solid heat storage body 101 to realize heat storage, and then generate hot air or hot steam to supply the The evaporation unit 3, the dehydration unit 4 or the drying unit 5 of the salt making device; in this embodiment, the purification unit 2 is connected with the lime supply unit, or is connected with the activated carbon supply unit, and utilizes lime or activated carbon a...

Embodiment 2

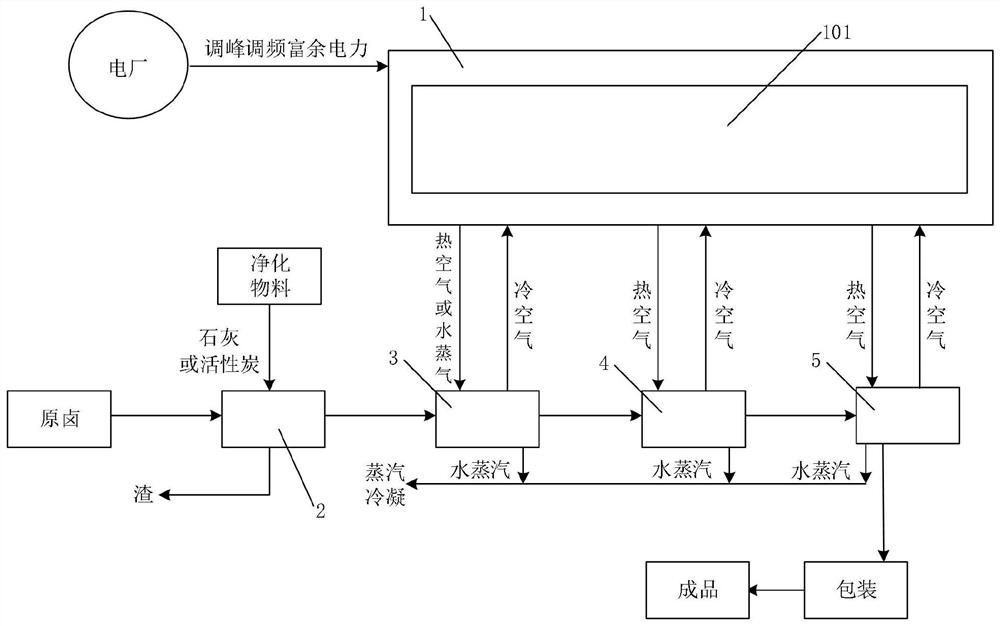

[0064] This embodiment provides a solid heat storage electric boiler coupled salt production system, such as figure 2 As shown, compared with Example 1, the solid thermal storage electric boiler 1 described in this embodiment is set in a thermal power plant or a gas-fired power plant or a nuclear power plant. 1 is connected to the salt making device. The solid heat storage electric boiler 1 can heat and store heat during the power supply period, and can continue to supply heat by relying on the residual temperature of the heated solid heat storage body 101 during the non-power supply period, so as to realize the continuous operation of the salt making device. Heat supply makes up for the problem of insufficient flue gas parameters or flow in the existing power plant coupling multi-effect vacuum evaporation salt production process, so that the salt production work can be carried out continuously and stably. At the same time, the solid heat storage electric boiler 1 can make ful...

Embodiment 3

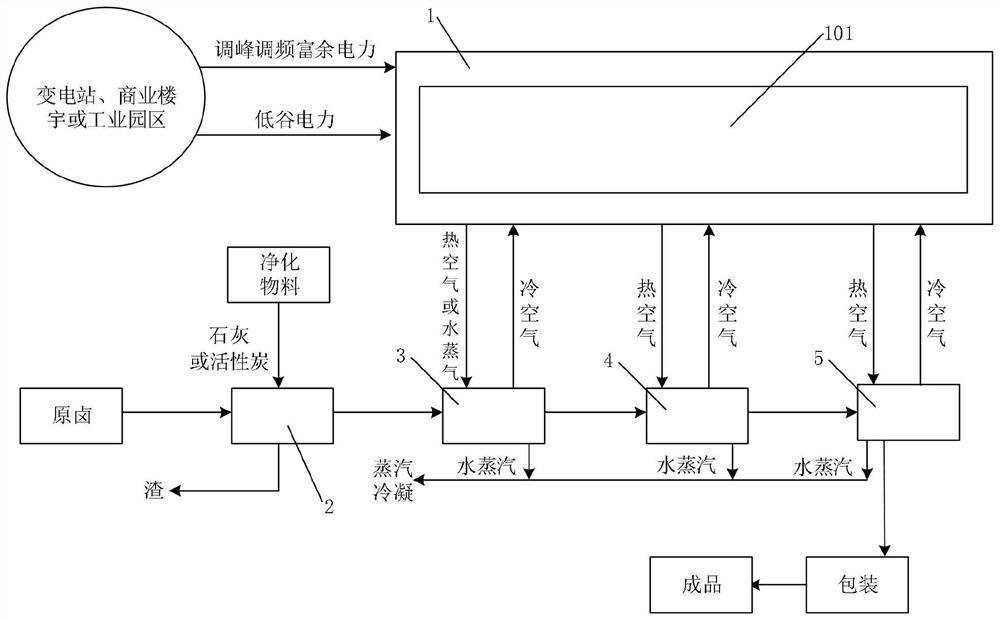

[0066] This embodiment provides a solid heat storage electric boiler coupled salt production system, such as image 3 As shown, compared with Example 1, the solid heat storage electric boiler 1 described in this embodiment is installed in a substation, a commercial building or an industrial park, and is powered by the peak-shaving and frequency-regulating surplus power in the factory. The salt device is connected, the solid heat storage electric boiler 1 can heat and store heat during the power supply period, and can continue to supply heat by relying on the residual temperature of the heated solid heat storage body 101 during the non-power supply period, so as to realize the continuous heat supply of the salt making device. It makes up for the problem of insufficient flue gas parameters or flow in the existing multi-effect vacuum evaporation salt production process, so that the salt production work can be carried out continuously and stably. At the same time, the solid heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com