An electric heating method for making shredded tobacco with bamboo leaf raw materials

A kind of tobacco-like, electric heating technology, applied in the fields of tobacco, application, food science, etc., can solve the problems of application, and achieve the effect of saving electricity, simple structure, and reducing harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

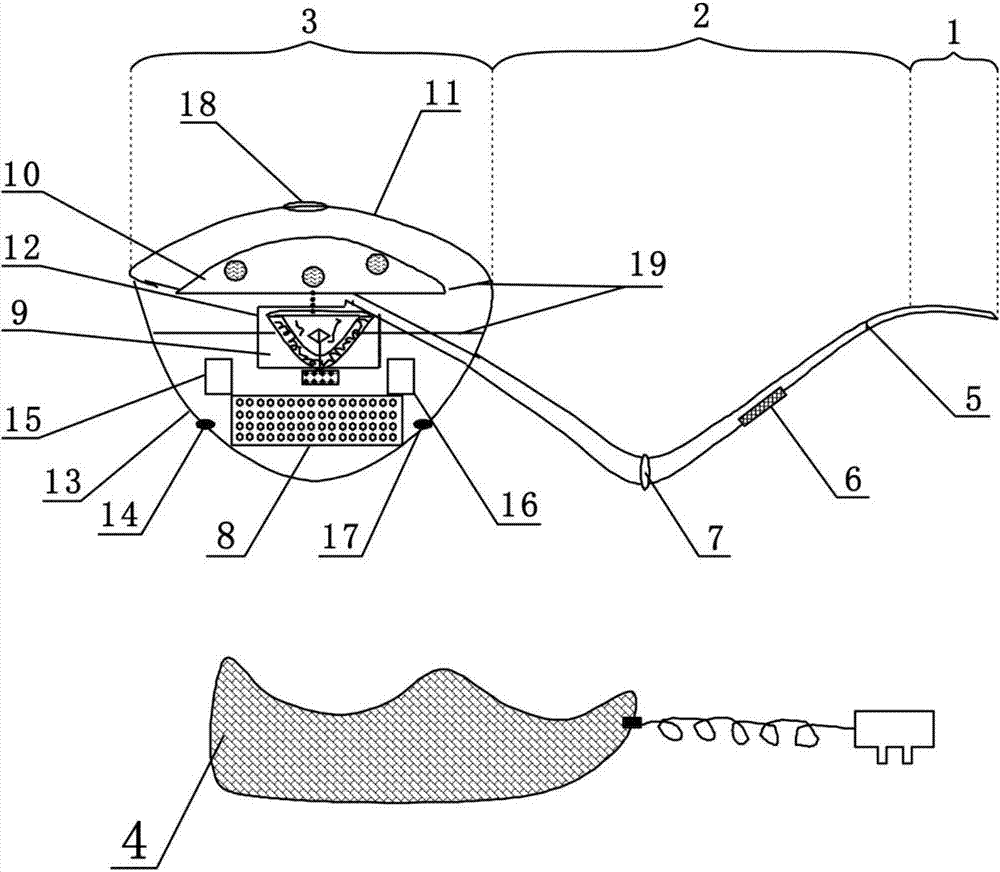

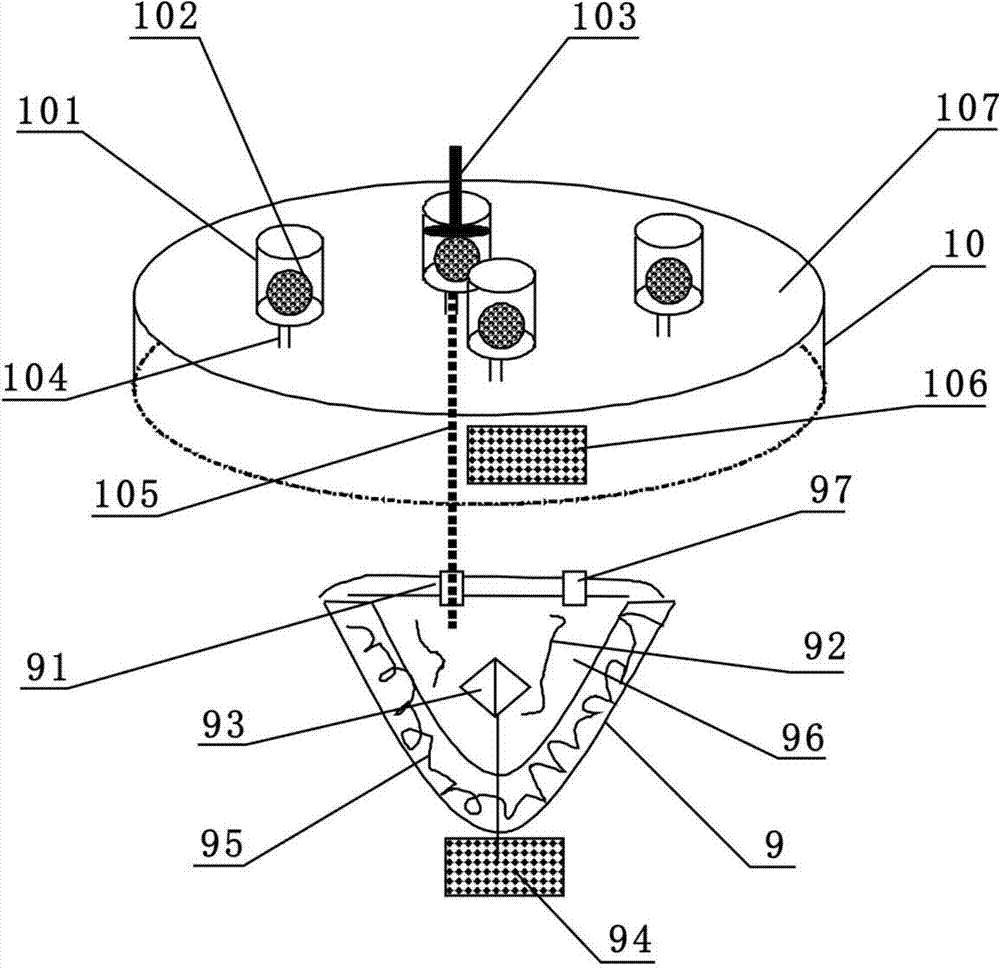

Method used

Image

Examples

Embodiment

[0038] A shredded tobacco-like object made of bamboo leaf raw material, the shredded tobacco-like object made of bamboo leaf raw material (hereinafter referred to as the shredded tobacco-like object of bamboo leaf) includes essence for tobacco, nicotine solution and shredded tobacco-like object of bamboo leaf, which are in the following parts by weight The number ratio is evenly mixed: the tobacco flavor is 0.03-0.06, the nicotine solution is 3-8, and the nicotine solution is a nicotine aqueous solution or a nicotine ethanol solution, and the parts by weight of the nicotine release amount are 0.4-1.2 (the parts by weight is the number of shares in the total weight of bamboo-leaf shredded tobacco), bamboo-leaf shredded tobacco is 55 to 120; tobacco flavors are composed of vanillin or benzyl acetate or jasmine absolute or menthol or cocoa tincture or pineapple aldehyde or anise One or more combinations of aldehydes or 10% furanone or coffee tincture or raspberry ketone.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com