An electric heating method for making shredded tobacco with edible mushroom raw materials

A technology of edible fungus and shredded tobacco, applied in food science, tobacco, application, etc., can solve the problems of no resistance to tracheal smooth muscle contraction and no application, etc., and achieve the effect of simple structure, energy saving, and comfortable suction experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

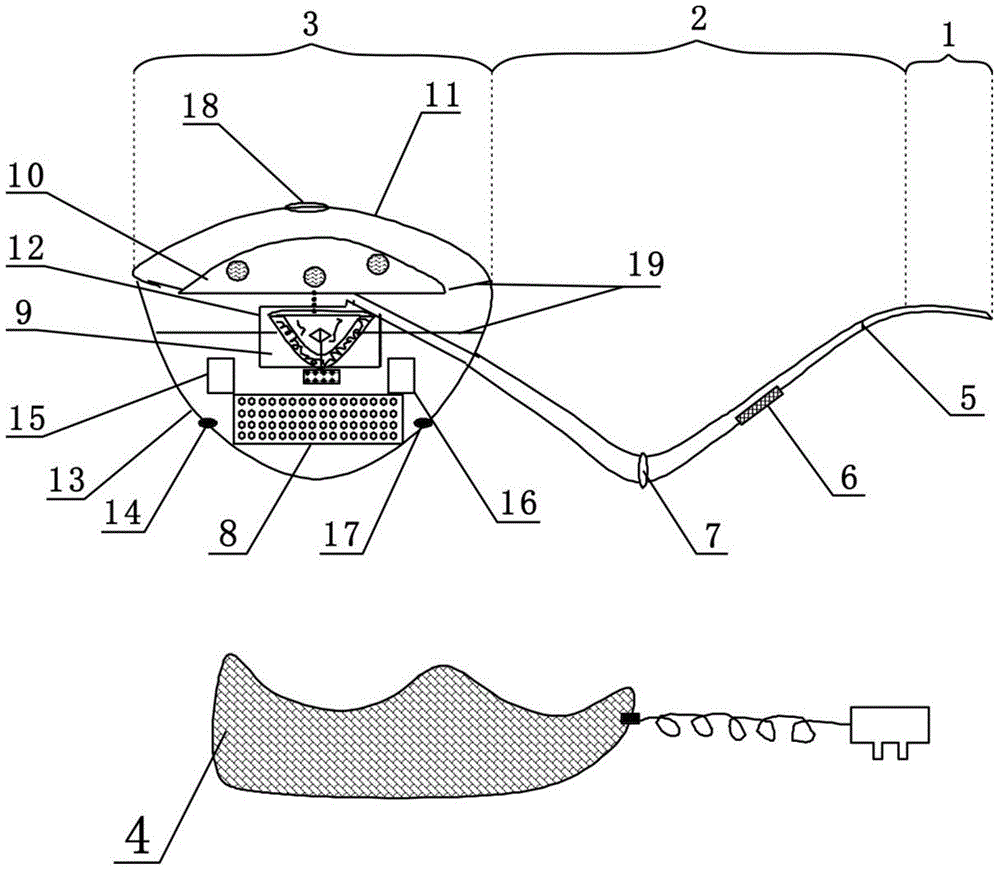

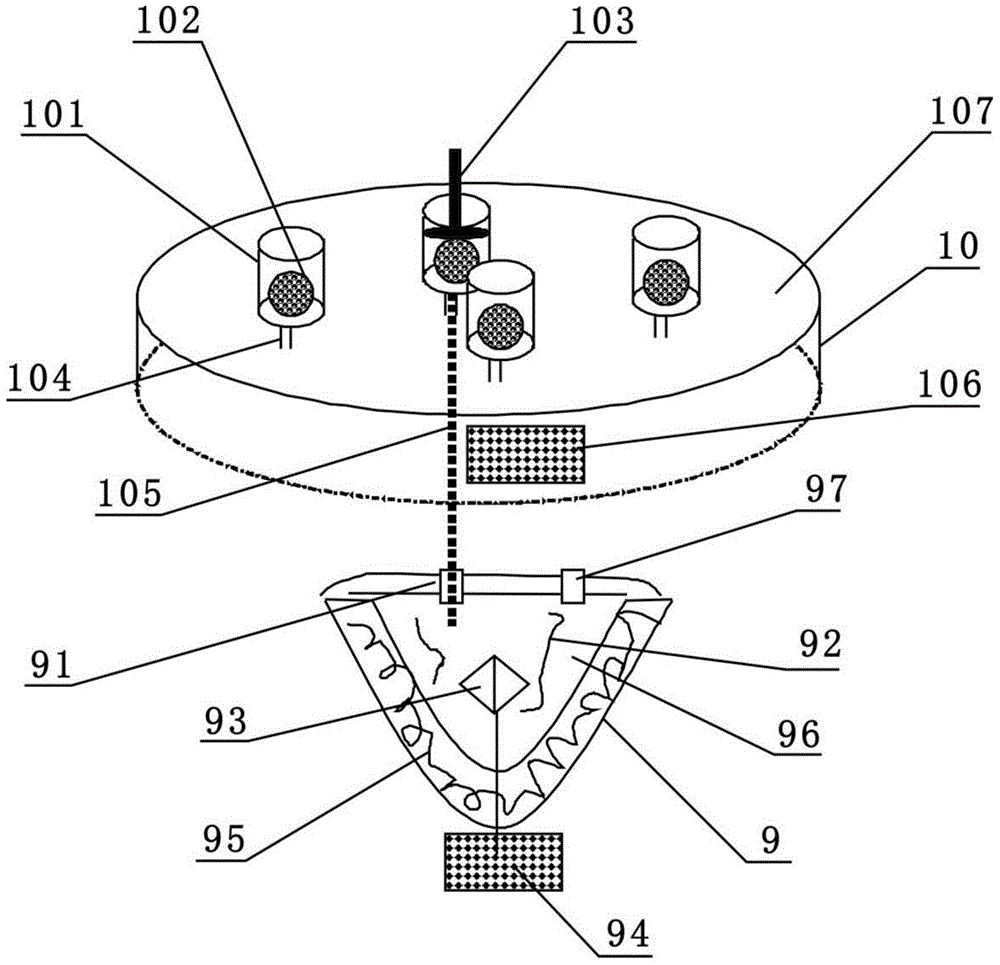

[0045] An electric heating method for making shredded tobacco from edible fungi raw materials. The shredded tobacco made from edible fungi raw materials (hereinafter referred to as shredded tobacco from edible fungi) includes tobacco essence, nicotine solution and shredded tobacco from edible fungi. The following parts by weight ratio are uniformly mixed: tobacco essence is 0.03-0.06, and nicotine solution is 3-8. Parts by weight are the parts that account for the total weight of edible fungi shredded tobacco), and the shredded tobacco of edible fungi is 55 to 120; the tobacco essence is composed of vanillin or benzyl acetate or jasmine absolute or menthol or cocoa tincture or pineapple aldehyde Or one or more combinations of anisaldehyde or 10% furanone or coffee tincture or raspberry ketone.

[0046] According to an embodiment of the preferred shredded tobacco of edible fungi in the present invention, the shredded tobacco of edible fungi is processed by shredding process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com