Method for capturing carbon dioxide by utilizing electrical desorption technology

A carbon dioxide and technology technology, applied in the field of greenhouse gas carbon dioxide emission reduction, can solve the problems of low purity, high adsorption and capture costs, high energy consumption, and rising costs, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following provides a specific embodiment of a method for capturing carbon dioxide by electrolysis technology in the present invention.

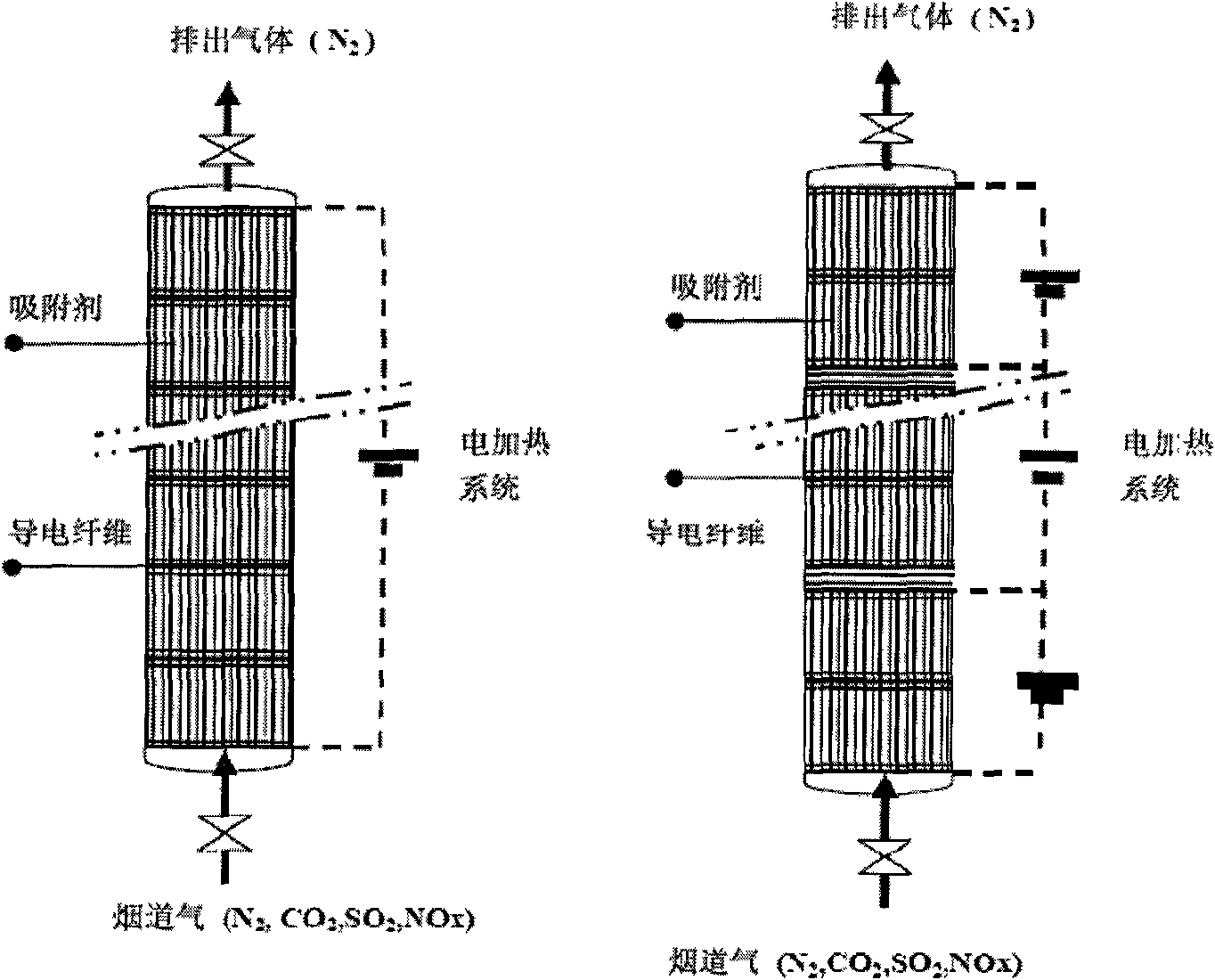

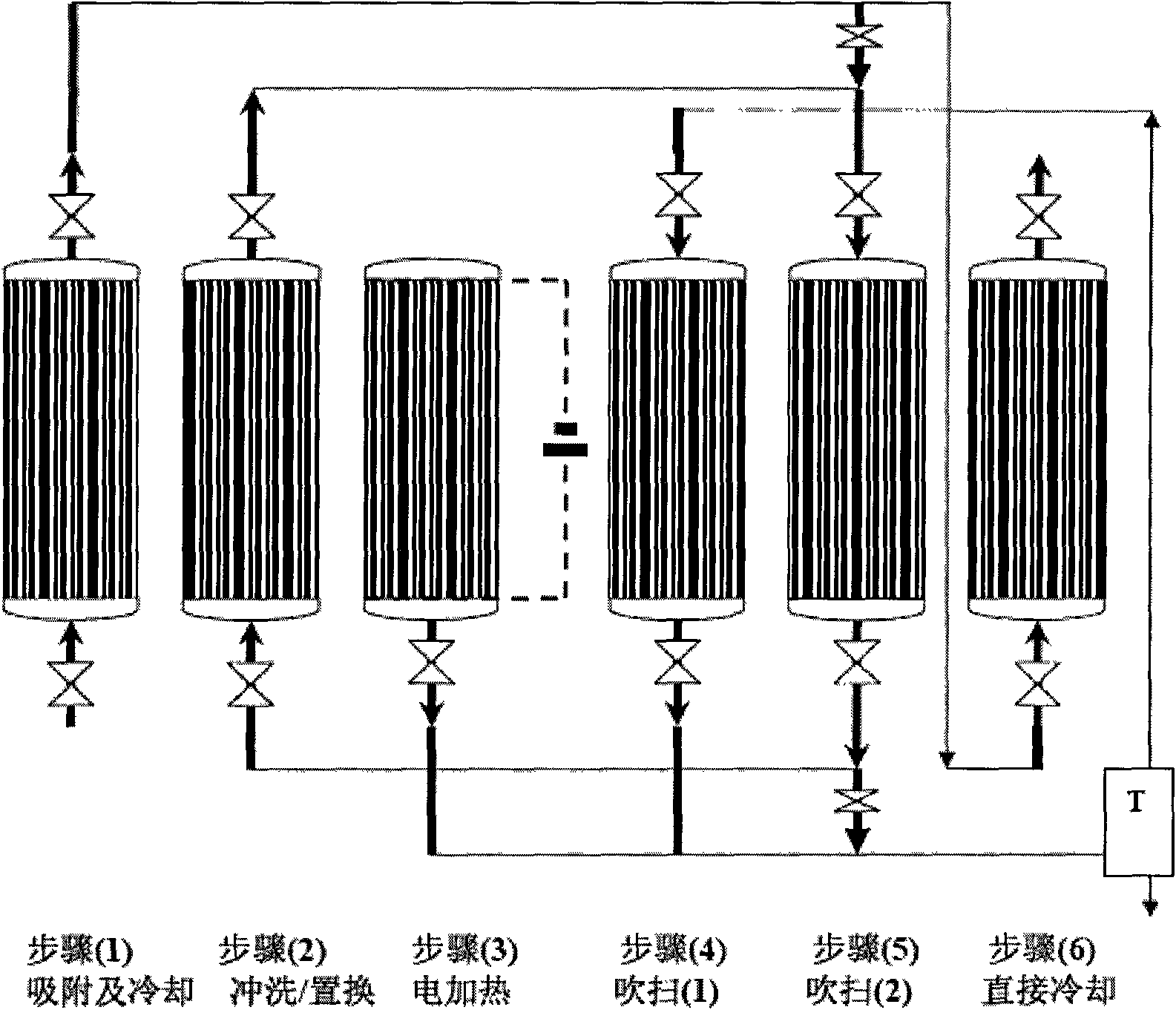

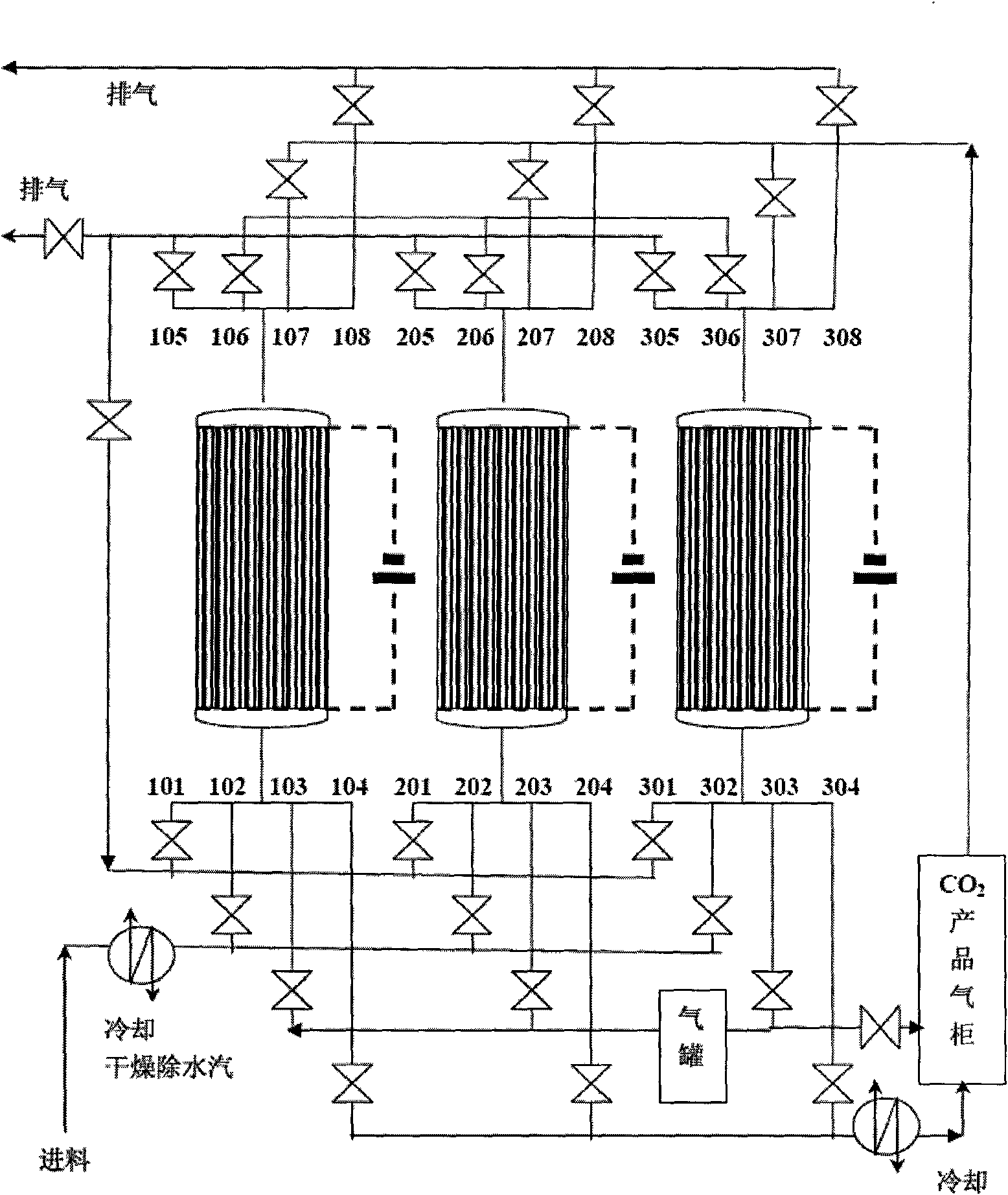

[0035] The following provides a multi-tower cycle adsorption and electrolysis method for concentrating carbon dioxide of the present invention, which is embodied in the use of adsorption materials with small pressure drop and good electrical and thermal conductivity to form an adsorption bed with a height of 10 meters or higher. Multiple adsorption towers (such as three towers) go through six cyclic adsorption and electrolysis steps to continuously capture carbon dioxide in flue gas and industrial tail gas. Please see attached figure 1 , 2 and 3, the six cycle adsorption and electrolysis operation steps are as follows:

[0036]Step (1) adsorption:

[0037] At a temperature of 10°C-50°C and a pressure of 1.1atm-5atm, it can absorb and capture carbon dioxide in flue gas and industrial tail gas. 2 The concentration is 3v / v%~30v / v%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com