Method for extracting antimony metal

An extraction method and antimony metal technology, applied in the field of antimony metal extraction, can solve the problems of poor environmental protection, low recovery rate and high energy consumption, and achieve the effects of solving poor environmental protection, improving recovery rate and improving melting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

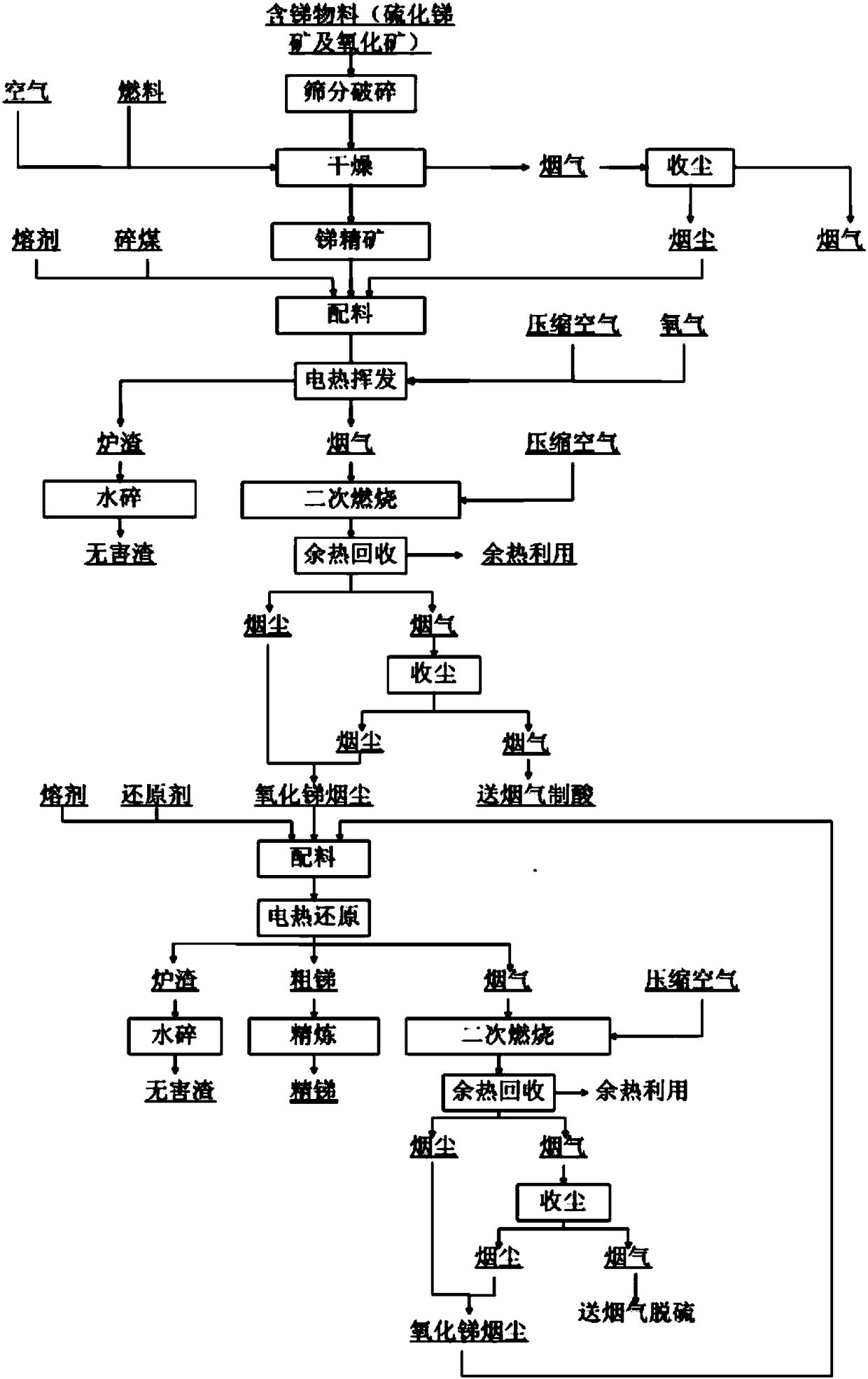

Method used

Image

Examples

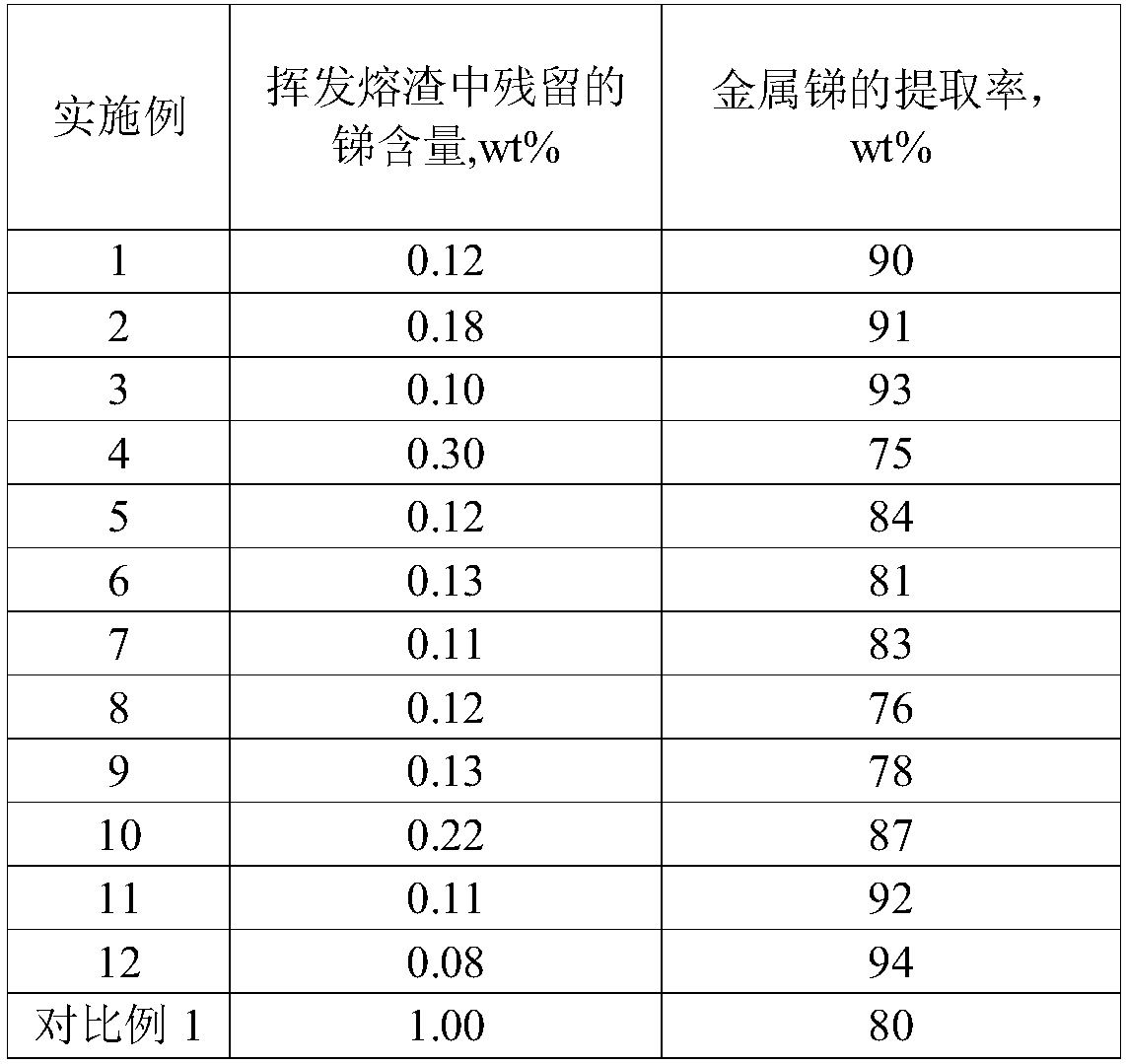

Embodiment 1

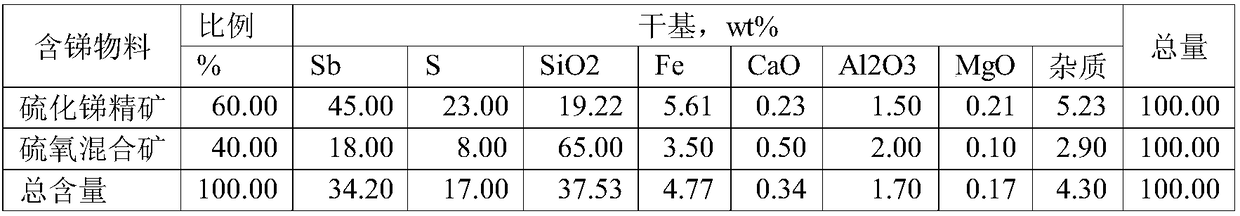

[0063] First, by analyzing the antimony-containing materials that enter the furnace, according to the preferred smelting slag type, mix in iron ore and limestone target slag type, 60wt% SiO 2 , 10wt% FeO, 15wt% CaO target slag type.

[0064] Secondly, the above-mentioned materials to be treated are volatilized and smelted in an electric heating volatilization device (the first electric furnace), so that the Sb 2 S 3 is transformed into Sb 2 o 3 , get antimony oxide flue gas and volatile slag (type is FeO-SiO 2 -CaO, composed of 60wt% SiO 2 , 10wt% FeO, 15wt% CaO, and the rest are impurities), and the volatilization melting temperature is 1250°C.

[0065] The above-mentioned antimony oxide flue gas is gathered in the waste heat recovery device, and after cooling to 800°C, it enters the dust collection device to obtain antimony oxide dust (powder Sb 2 o 3 ). After finishing, the residual antimony content in the volatilized slag is only 0.12wt%.

Embodiment 2

[0068] First, by analyzing the antimony-containing materials that enter the furnace, according to the preferred smelting slag type, mix in iron ore and limestone target slag type, 60wt% SiO 2 , 10wt% FeO, 10wt% CaO target slag type.

[0069] Secondly, the above-mentioned materials to be treated are volatilized and smelted in an electric heating volatilization device (the first electric furnace), so that the Sb 2 S 3 is transformed into Sb 2 o 3 , to obtain antimony oxide flue gas and volatile slag, and the temperature of volatile smelting is 1250°C.

[0070] The above-mentioned antimony oxide flue gas is gathered in the waste heat recovery device, and after being cooled to 800°C, it enters the dust collection device to obtain antimony oxide dust (powder Sb 2 o 3 ). At the same time, oxygen-enriched blowing (oxygen blowing) is carried out on the above-mentioned volatile slag. After the end, the residual antimony content in the volatile slag is only 0.18wt%.

[0071] Anti...

Embodiment 3

[0073] The difference from Example 1 is: the volatilization melting temperature is 1350°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com