A kind of production technology of anti-mildew and anti-fouling polyester fabric

A production process and fabric technology, applied in the field of fabric production, can solve problems such as inability to obtain antibacterial, mildew and stain resistance, affect personal life and environmental hygiene, and unfavorable use, so as to reduce bacterial growth, reduce manual labor, and improve use. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

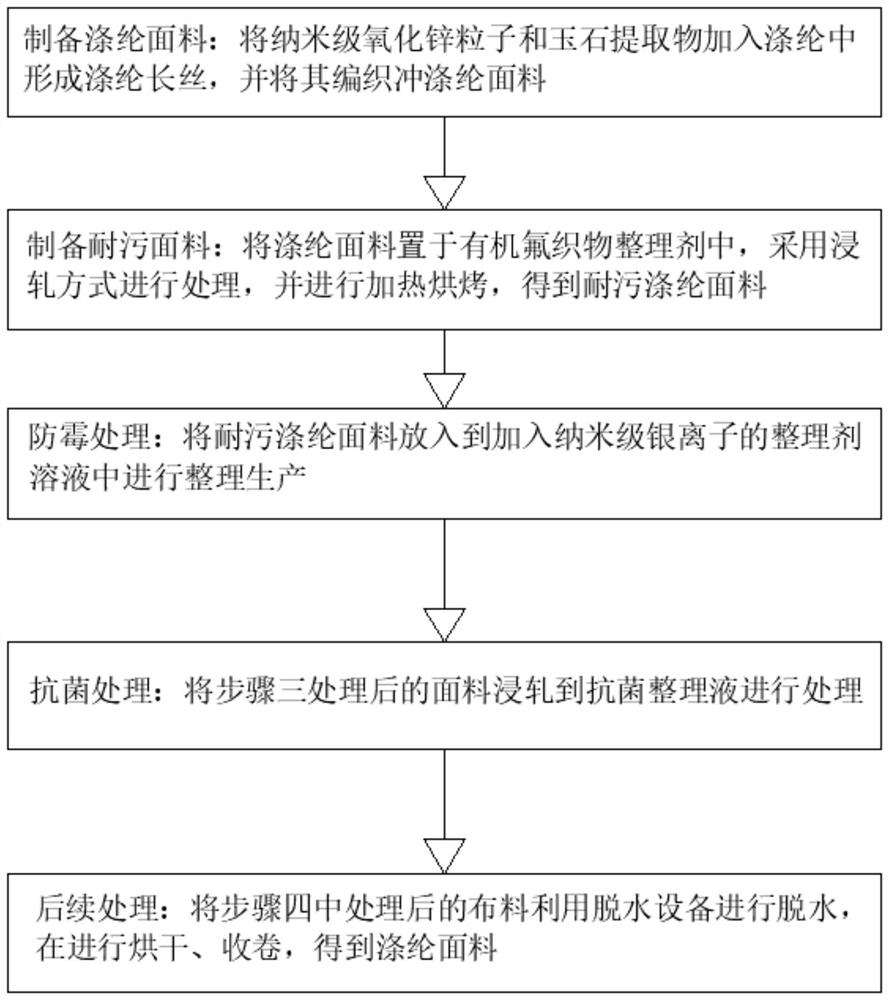

[0040] see Figure 1-8 , the present invention provides a technical solution: a production process of a mildew-resistant and anti-fouling polyester fabric, which is composed of the following steps:

[0041] Step 1. Preparation of polyester fabric: adding nano-scale zinc oxide particles and jade extract into polyester to form polyester filament, and weaving it into polyester fabric;

[0042] Step 2, preparing a stain-resistant fabric: placing the polyester fabric in an organic fluorine fabric finishing agent, processing by padding, and heating and baking to obtain a stain-resistant polyester fabric;

[0043] Step 3. Anti-mildew treatment: put the stain-resistant polyester fabric into the finishing agent solution added with nano-level silver ions for finishing and production;

[0044] Step 4, antibacterial treatment: padding the fabric treated in step 3 into an antibacterial finishing solution for treatment;

[0045] Step 5. Follow-up treatment: dehydrate the fabric treated in...

Embodiment example 2

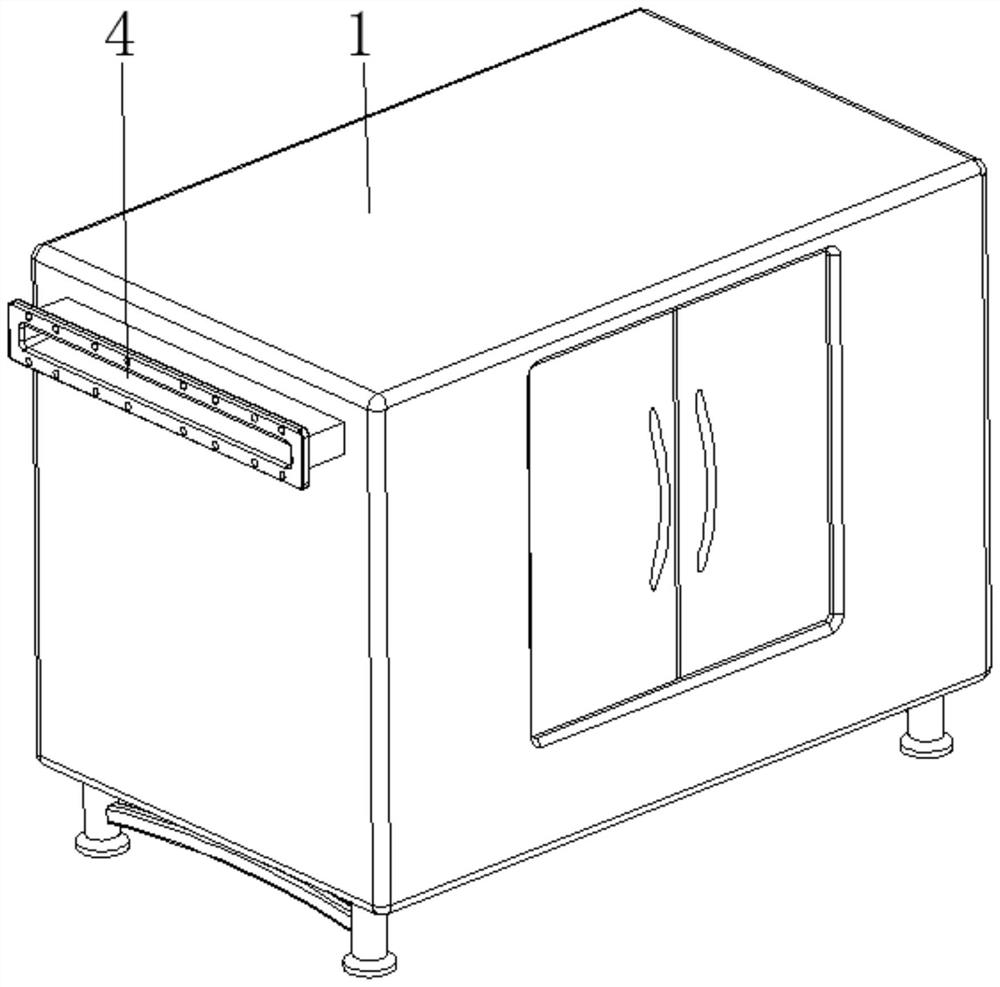

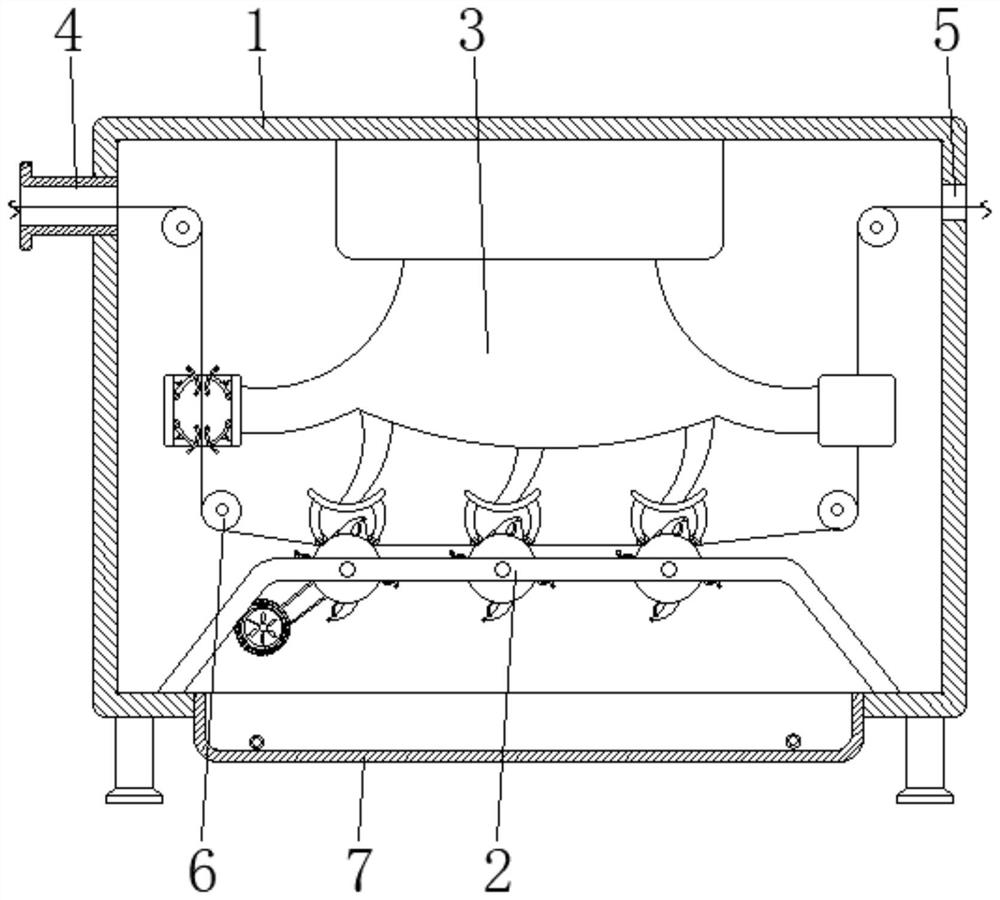

[0047] The dehydration equipment includes a body 1, a driving device 2, and a water removing device 3. The driving device 2 is arranged at the bottom center of the inner wall of the body 1, and the water removing device 3 is arranged at the top of the inner wall of the body 1;

[0048] The top surface of the body 1 is provided with a feeding port 4 and a discharging port 5. Inside the body 1 and located on both sides of the driving device 2 and the water removing device 3, there are guide rollers 6. The bottom center of the body 1 is provided with a In the water tank 7, the cloth is input from the feeding port 4, and is set between the driving device 2 and the water removing device 3 through the guide drum 6, and is output from the discharging port 5. The whole device can dewater the cloth step by step, so that the dehydration Fast and convenient, it is helpful for subsequent drying, and drying is carried out in time, realizing the integration of dehydration and drying.

Embodiment example 3

[0050] The driving device 2 is provided with a bracket 21, a power mechanism 22, and a driving roller device 23. The bottom of the bracket 21 is fixedly connected to the bottom of the inner wall of the body 1. The power mechanism 22 is arranged on the bottom side of the bracket 21, and the driving roller device 23 is rotatably connected to the bracket. At the top of 21, the end of the driving roller device 23 is connected with the output end of the power mechanism 22 through a belt drive assembly.

[0051] The driving roller device 23 is provided with a roller body 231, an arc top moving tooth 232, and an arc support member 233. The roller body 231 and the bracket 21 are rotatably connected, and the arc top moving tooth 232 is fixed on the surface of the roller body 231. The support member 233 is fixed between the two sides corresponding to the surface of the cambered top gear 232 and the surface of the roller body 231. When the power mechanism 22 drives the drive roller device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com