Water removal system of flow sensor

A flow sensor and solenoid valve technology, applied in the field of flow sensors, can solve the problems of flow sensor probe condensation, insufficient detection accuracy, and inaccurate detection of ventilators, etc., to prolong the use time and life, high detection accuracy, and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

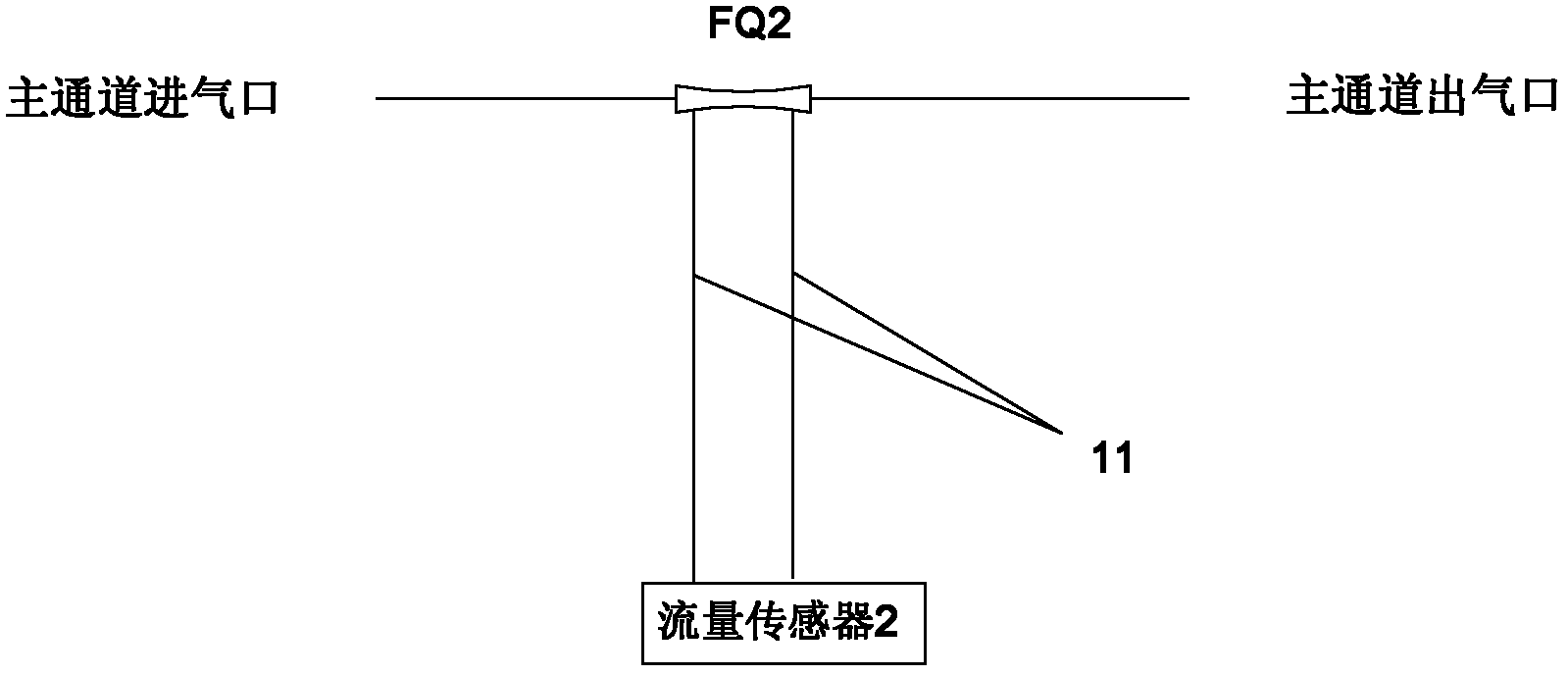

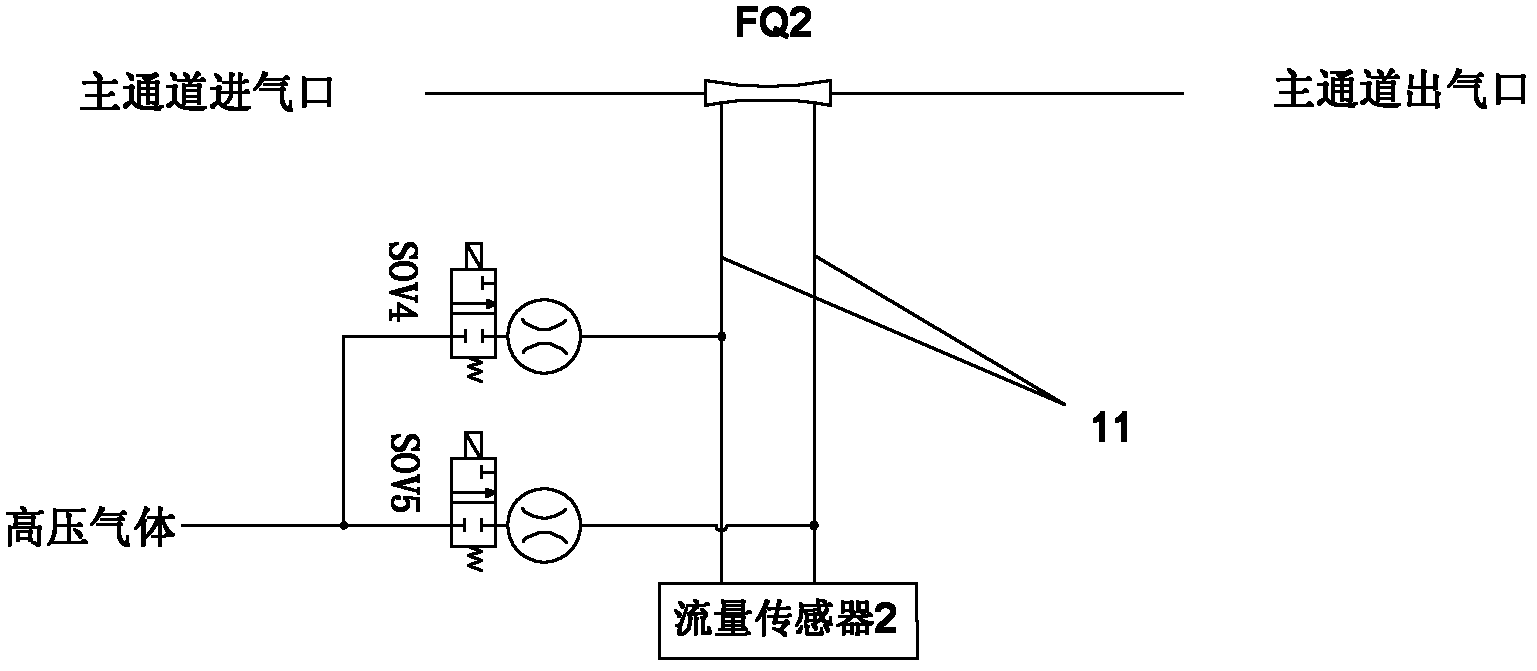

[0025] According to the first embodiment of the present invention, the flow sensor water removal system has a gas path structure such as figure 2 As shown, the gas path is connected to the flow sensor 2 and the flow sensor probe FQ2, and includes a first solenoid valve SOV4 and a second solenoid valve SOV5 respectively arranged on the bypass cross pipe of the respective linear detection branch gas path 11, and the outside is connected to high-pressure gas , This high-pressure gas can be the output gas of a decompressed oxygen cylinder.

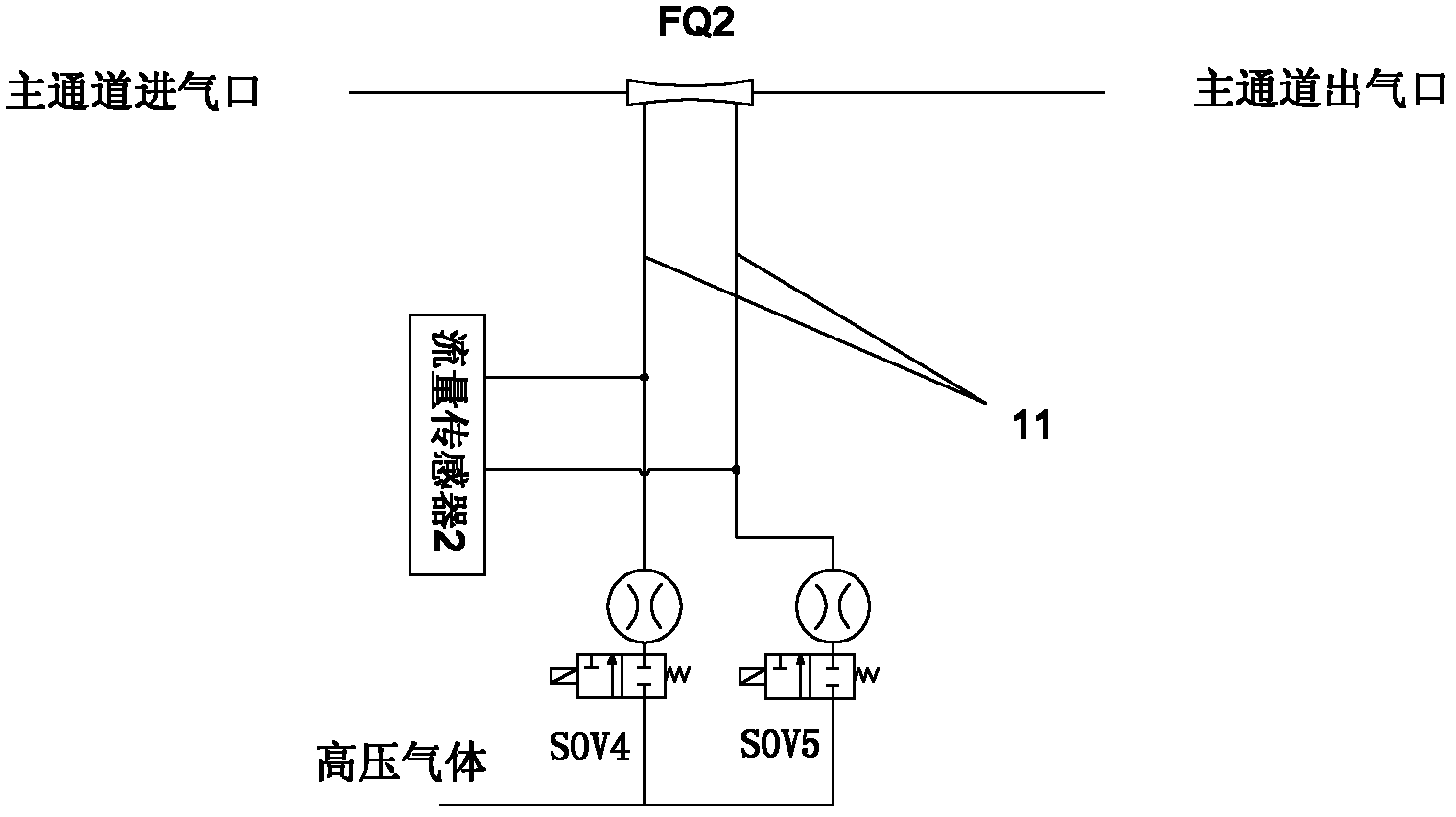

[0026] The water removal system of the flow sensor of the second embodiment of the present invention has a gas path structure such as image 3 As shown, the gas path communicates with the flow sensor 2 and the flow sensor probe FQ2, and includes a first solenoid valve SOV4 and a second solenoid valve SOV4 and a second solenoid valve SOV4 and a second solenoid valve respectively arranged on a conducting pipe which is in a straight line with one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com