Mite-killing processing method for heat-moisture comfortable bio-based fiber cloth

A processing method and bio-based technology, applied in biochemical fiber treatment, fiber type, fiber treatment, etc., can solve the problems of breeding many bacteria and mites, affecting life and health, redness and swelling, etc., achieve long-lasting and efficient antibacterial effect, and speed up manufacturing High speed, good antibacterial and mite removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A heat and humidity comfortable bio-based fiber cloth mite removal processing method, including the preparation of antibacterial agents, the preparation of bio-based fiber antibacterial fabrics, and the secondary antibacterial treatment of the cloth;

[0032] The specific process is as follows:

[0033] S1, the preparation of antibacterial agent comprises selecting carrier to use zinc sulfate and silver nitrate solution as exchange liquid, adopts adsorption method to prepare antibacterial agent;

[0034] S2, the preparation of bio-based fiber antibacterial fabrics includes, at the same time, adding antibacterial agents for melt spinning, winding, warping, sizing, drawing in and weaving into bio-based fabrics during the spinning process to prepare antibacterial fabrics;

[0035] S3, the second antibacterial treatment of the cloth is to dilute the prepared antibacterial agent with water at a ratio of 1:50, then place the cloth in the soaking device for multiple soaks, and...

Embodiment 2

[0044] The antibacterial performance test of the antibacterial and anti-mite second that embodiment 1 makes;

[0045] In the experimental group, the prepared antibacterial and anti-mite fabrics were used, and colonies of Escherichia coli were used;

[0046] Control group, using common fabrics, colonies of Escherichia coli;

[0047] Experimental results, Table 1 is as follows:

[0048]

[0049] Table I

[0050] It can be seen from Table 1 that the number of surviving colonies before and after shaking in the antibacterial fabric is far less than that of ordinary fabrics. It can be seen that the antibacterial and anti-mite effect of the antibacterial and anti-mite fabric prepared in the present invention has been greatly improved.

Embodiment 3

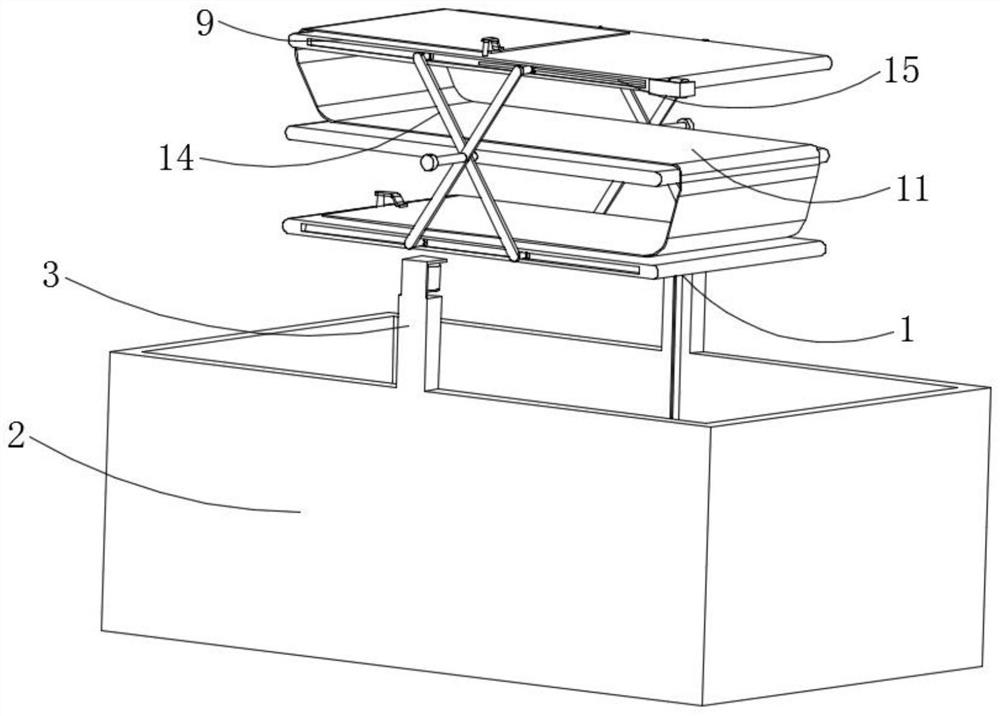

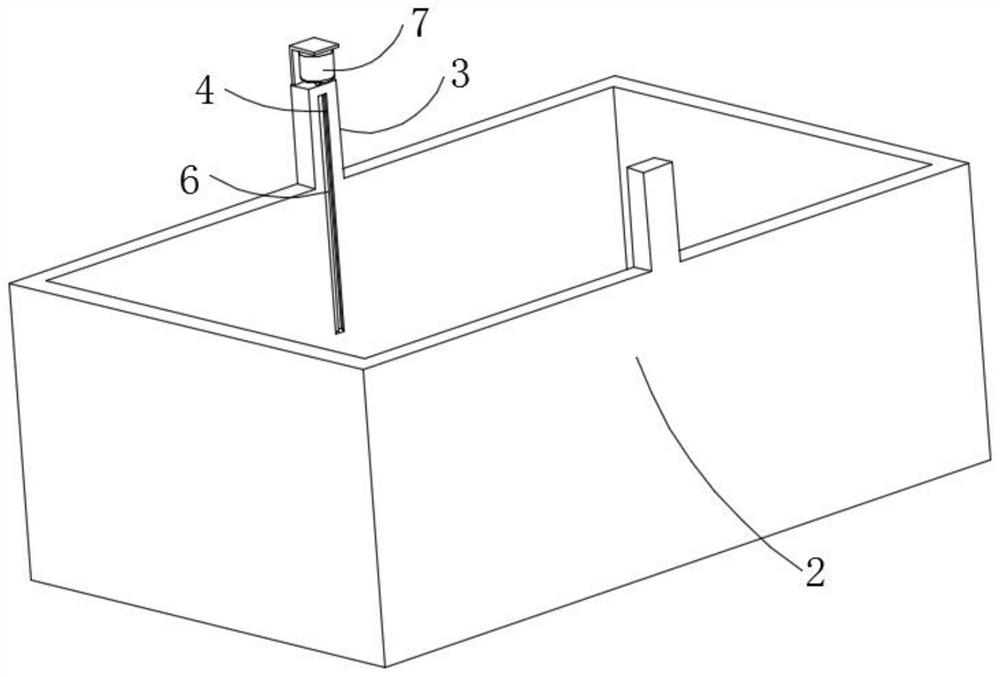

[0052] see Figure 1-4 The soaking device 1 in the illustration includes a soaking tank 2, and a slide plate 3 is fixed at the upper end of the two sides of the soaking tank 2 at the axis, and a first chute 4 is provided on the inner wall of the slide plate 3 and the soaking tank 2, and the In the first chute 4, a square slider 5 is slidably connected, and a connecting rod 8 is fixed between the square sliders 5. The first chute 4 is provided with a first threaded rod 6, and the first screw thread Rod 6 and square slide block 5 are threaded, and the slide plate 3 that screw thread runs through the upper end is connected with first motor 7, and described first motor 7 is fixed on slide plate 3 upper end by fixing plate, and described connecting rod 8 is provided with for cloth 11 Winding device 9 for placing and removing water;

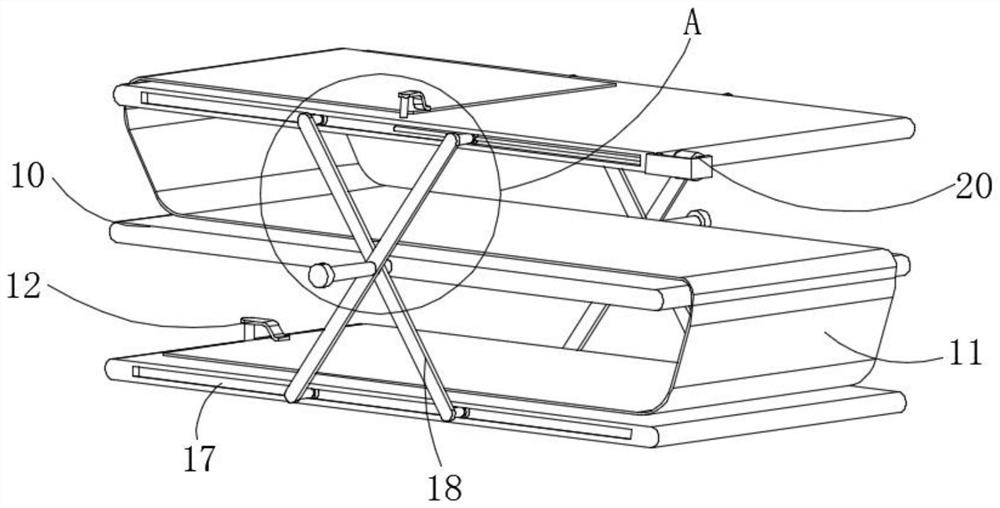

[0053]Wherein, the winding device 9 includes three placement boards 10, the placement board 10 in the middle is fixed to the connecting rod 8, cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com