An organic ceramic precursor and ceramic product

A technology of organic ceramics and precursors, applied in the field of ceramic materials, can solve the problems of low conversion rate and unstable storage of ceramics, and achieve the effects of improving electrochemical performance, significant economic benefits, and small volume expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Embodiment 1: a kind of ceramic material:

[0124] This embodiment provides a ceramic material based on an organic ceramic precursor prepared by a method comprising the following steps:

[0125] S1 preparation of oligosilazane:

[0126] Under the protection of nitrogen, dissolve methylhydrogendichlorosilane in 10 times the volume of n-hexane, and react in an ice-water bath for 3 hours under the condition of passing a sufficient amount of ammonia gas. alkyl;

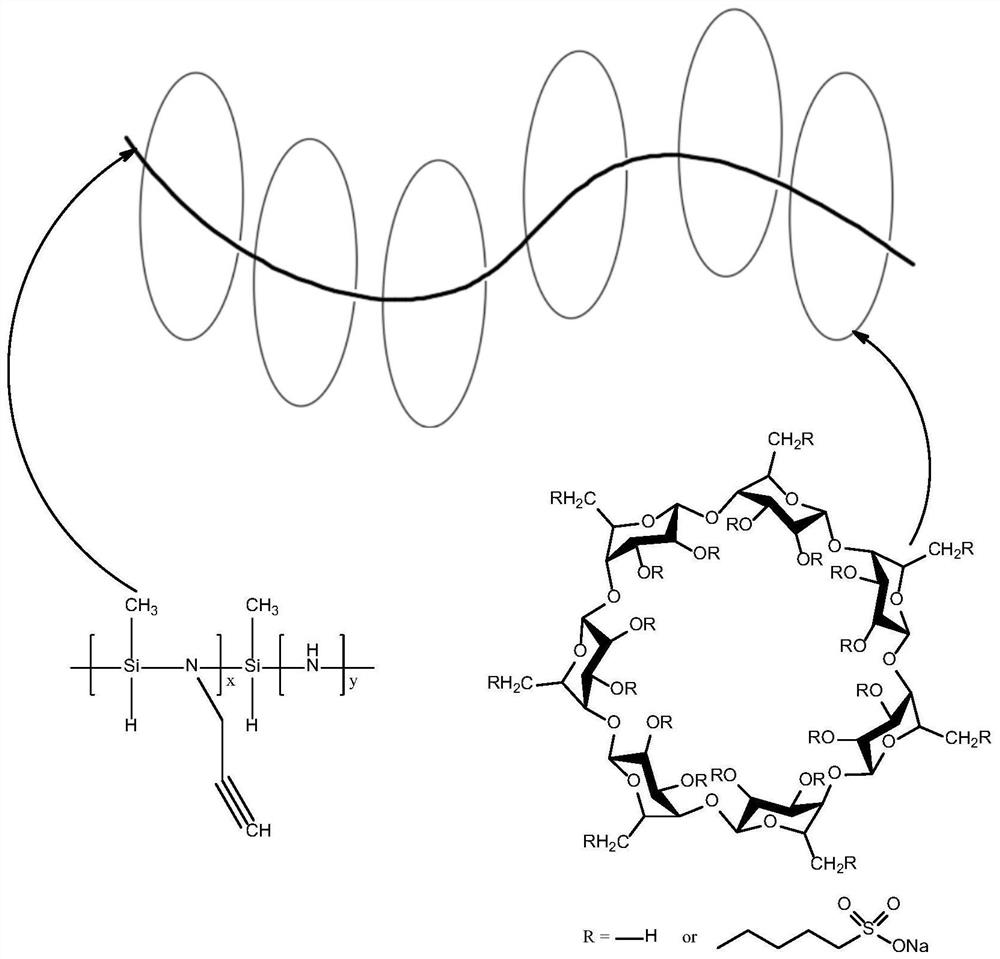

[0127] S2 prepares propargyl polysilazane:

[0128] Add pyridine and toluene to the oligosilazane, stir evenly and heat up to 60°C, add propyne bromide dropwise within 2 hours, keep warm and stir for 5 hours, and centrifuge the solution after natural cooling to obtain a yellow-brown transparent clear liquid, which is washed with toluene salt, and reclaim the washing liquid, and distill the centrifuged liquid under vacuum conditions to remove the solvent, to obtain final product;

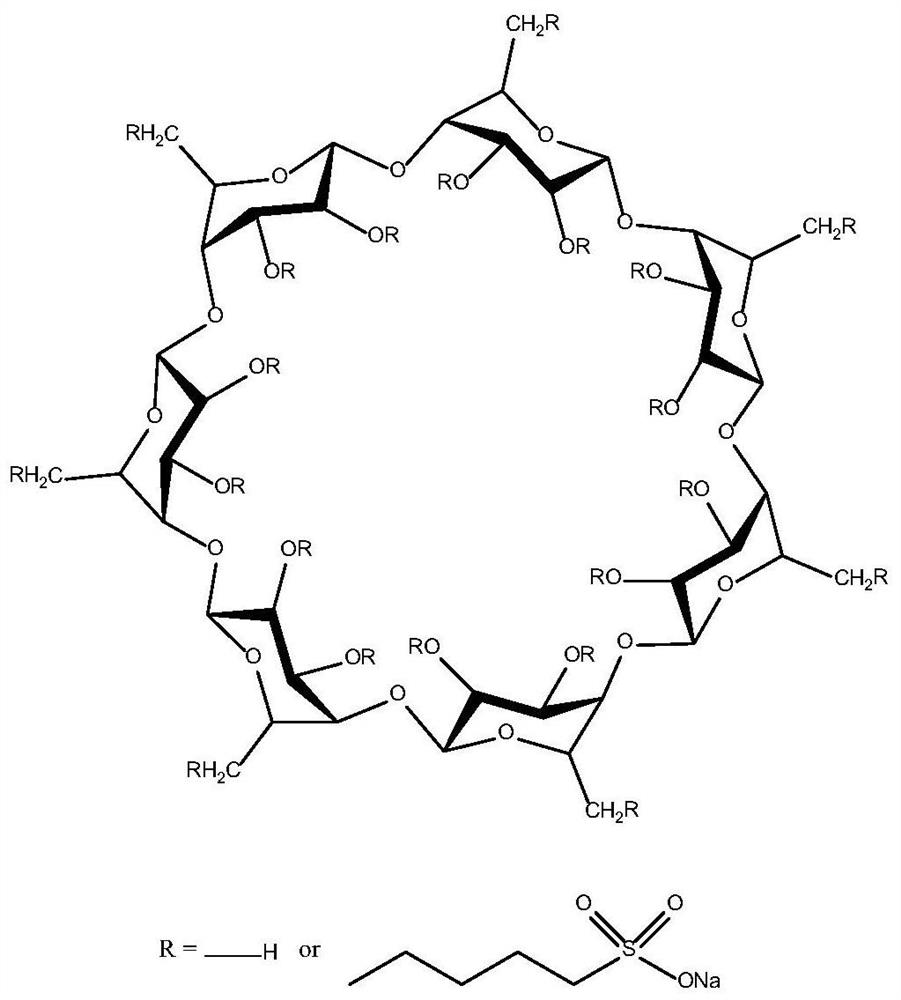

[0129] S3 Preparation of sul...

Embodiment 2

[0176] Example 2: Another ceramic material:

[0177] This embodiment provides another organic ceramic precursor and a ceramic material based on it. The formula and preparation method of the organic ceramic precursor and a ceramic material based on it are basically the same as in Example 1, except that this embodiment In this paper, the organic ceramic precursor was directly replaced by oligomeric silazane instead of propargyl polysilazane, and ceramic materials were prepared based on it.

Embodiment 3

[0178] Example 3: Another ceramic material:

[0179]This embodiment provides another organic ceramic precursor and a ceramic material based on it. The formula and preparation method of the organic ceramic precursor and a ceramic material based on it are basically the same as in Example 1, except that this embodiment Among them, β-CD was used instead of SBE-β-CD without any modification to prepare organic ceramic precursors, and ceramic materials were prepared based on it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com