External heating reaction system and method for preparing ethylene

A technology of external heating and ethylene, which is applied in chemical instruments and methods, hydrogenation hydrocarbon production, purification/separation of hydrocarbons, etc. It can solve the problems of more green oil, low catalyst utilization rate, and difficult internal heat, etc., to achieve easy heat transfer, The effect of simple and easy operation of the reaction system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

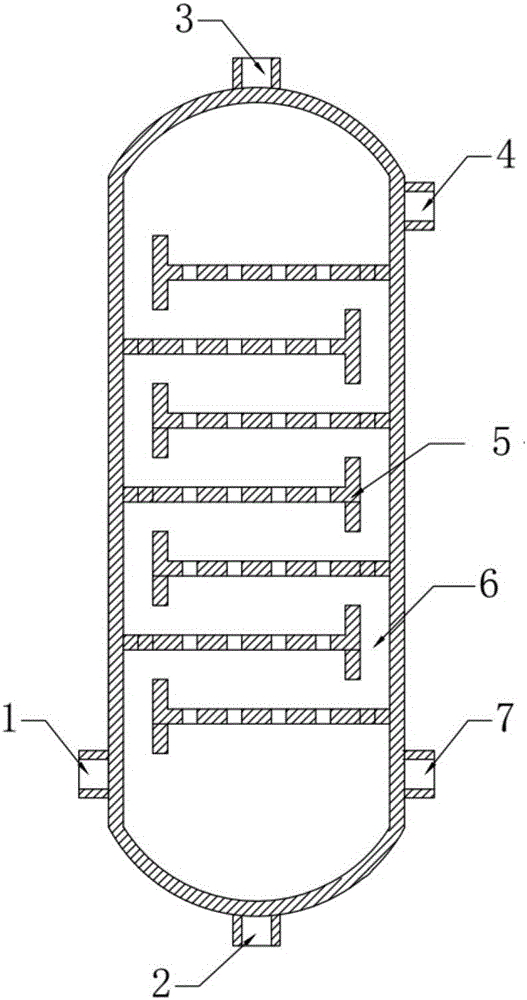

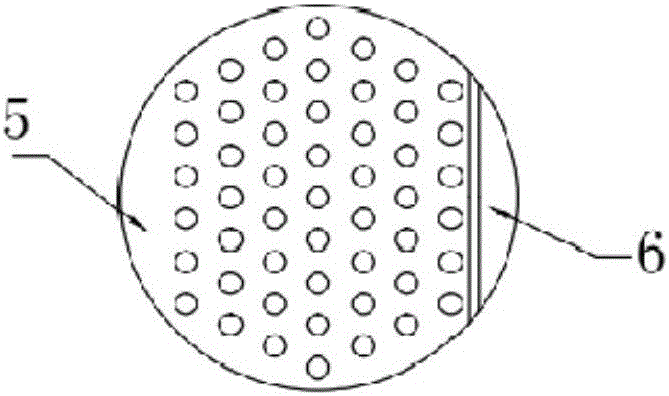

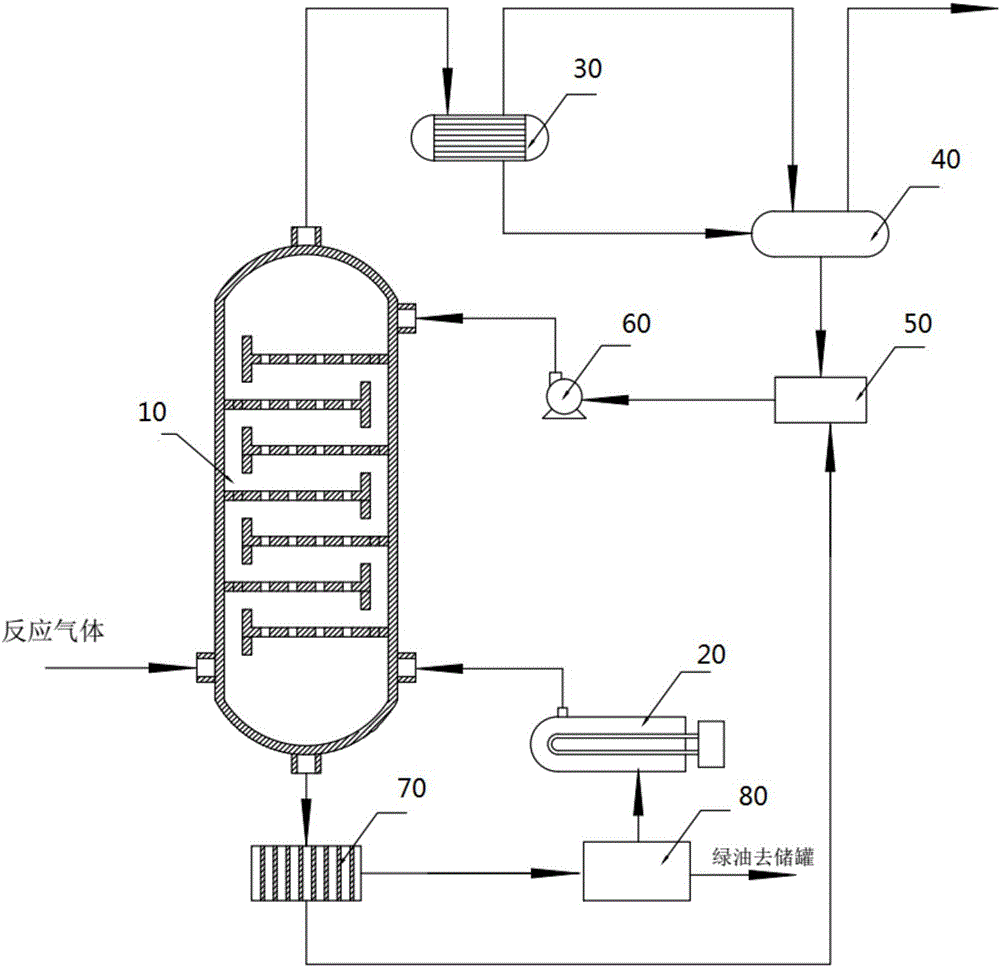

[0036] like image 3 Shown is an externally heated reaction system for preparing ethylene, which includes: the slurry bed reactor 10 mentioned in the above description, a solvent heater 20, a condenser 30, a condensation separator 40, a condensate storage tank 50, and a solvent pump 60. Filtration equipment 70 and green oil removal system 80. The solvent heater 20 communicates with the slurry bed reactor 10 through the solvent vapor inlet, the filter device 70 communicates with the slurry bed reactor 10 through the liquid outlet, and the condenser 30 communicates with the slurry bed reactor 10 through the liquid outlet. The gas outlet is communicated with the slurry bed reactor 10, and the solvent pump 60 is communicated with the slurry bed reactor 10 through the liquid inlet; the condenser 30, the condensation separator 40, the condensation The liquid storage tank 50 and the solvent pump 60 are connected in sequence; the filtering device 70 , the green oil removal system 80 ...

Embodiment 1

[0055] Adopt the system for the selective hydrogenation of acetylene to produce ethylene in the embodiment such as image 3 shown. The system structure is in the form introduced in the above-mentioned embodiment. The operating pressure of the system is 0.25MPa and the temperature is 130°C. Nitrogen can be used as the gas source to establish a gas-liquid flow with the catalyst-containing solvent in the slurry bed reactor; then, gradually turn on the solvent heater (the pressure in the solvent heater is 0.27MPa) to establish a steam updraft. When the steam rises to the top of the reactor to cool and reflux, and the temperature is stable, nitrogen can be gradually converted into a mixture of hydrogen and acetylene and fed into the reactor. In the reactor, acetylene and hydrogen are catalyzed by the catalyst to generate ethylene; the reacted gas passes through the condenser 30 and the condensation separator 40 to condense the solvent in the gas, and then sends it out of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com