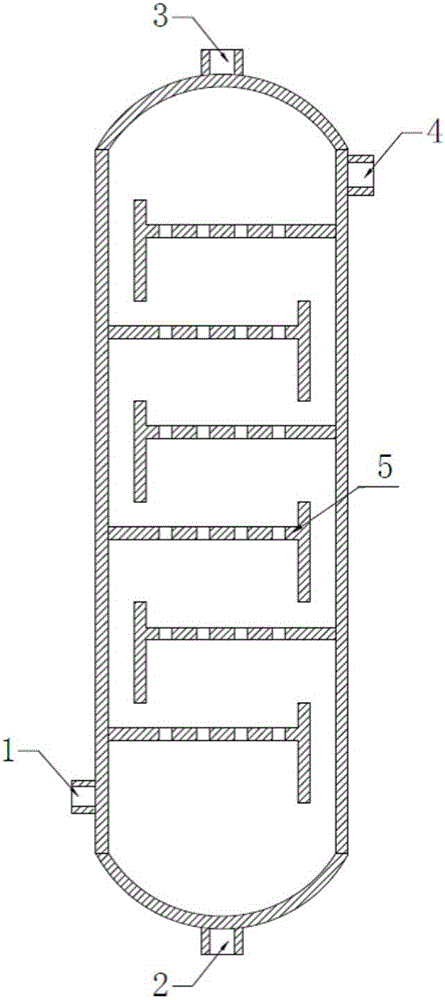

Reaction system and method for preparing ethylene by using slurry bed reactor

The technology of a reactor and a slurry bed is applied in the field of a reaction system for preparing ethylene using a slurry bed reactor, which can solve the problems of low catalyst utilization rate and difficult internal heat, etc., and achieve a reaction system and method that are simple, easy to operate, and easy to move hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

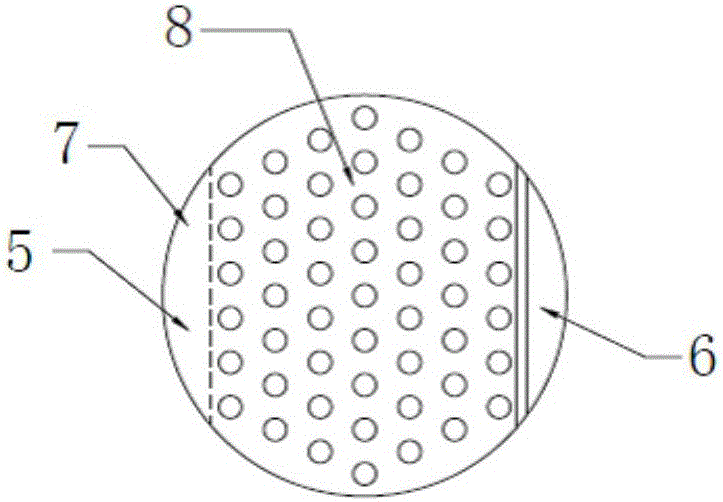

Method used

Image

Examples

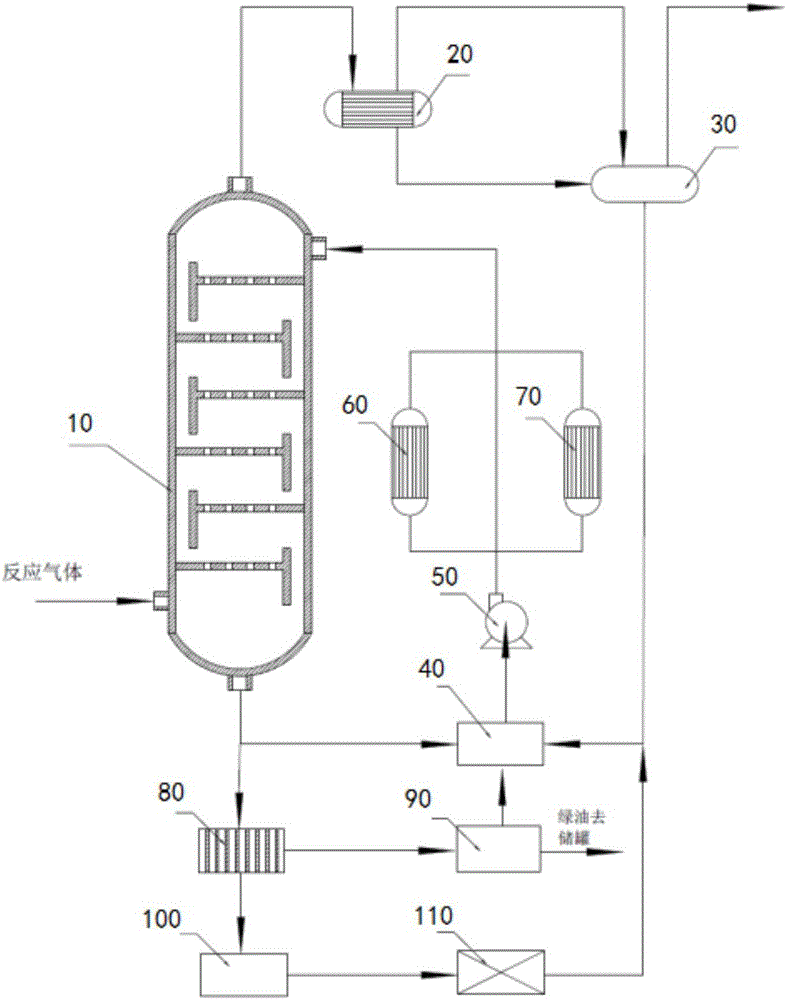

Embodiment 1

[0054] Adopt the system for the selective hydrogenation of acetylene to produce ethylene in the embodiment such as image 3 shown. The operating pressure of the reactor in this system is 0.15-0.3MPa, and the temperature is 100-180°C. First use nitrogen as a gas source to establish a gas-liquid flow with the catalyst-containing solvent in the slurry bed reactor 10 . Subsequently, the heater 60 of the temperature control system is gradually turned on to gradually increase the temperature of the solvent system. When the solvent temperature in the reactor reaches the target temperature and the system runs smoothly, acetylene and hydrogen are fed into the reactor. In the reactor, acetylene and hydrogen are catalyzed by the catalyst to produce ethylene. The reacted gas passes through the condenser 20 and the condensation separator 30 to condense the solvent in the gas, and then sends out the reaction boundary area. The solvent condensed from the reactor top condensation separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com