A kind of preparation method of reactive epoxy resin diluent with low total chlorine content

A technology of total chlorine content and epoxy resin, applied in the direction of organic chemistry, etc., can solve the problem of high total chlorine, and achieve the effects of low hydrolyzed chlorine, reduced side reactions, and fewer by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

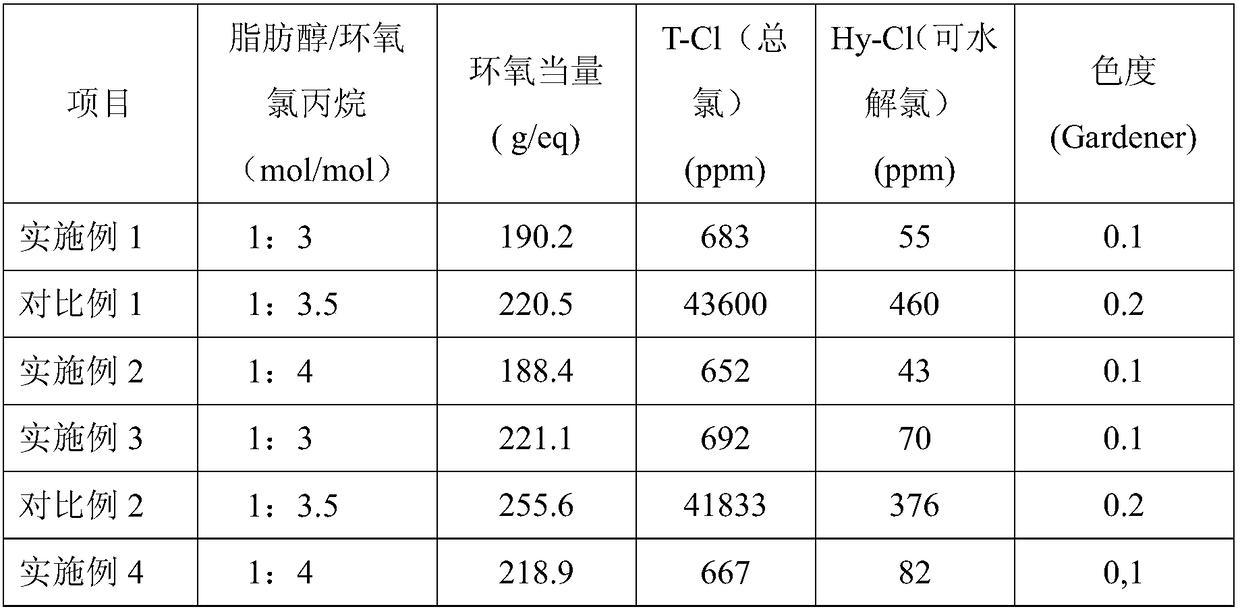

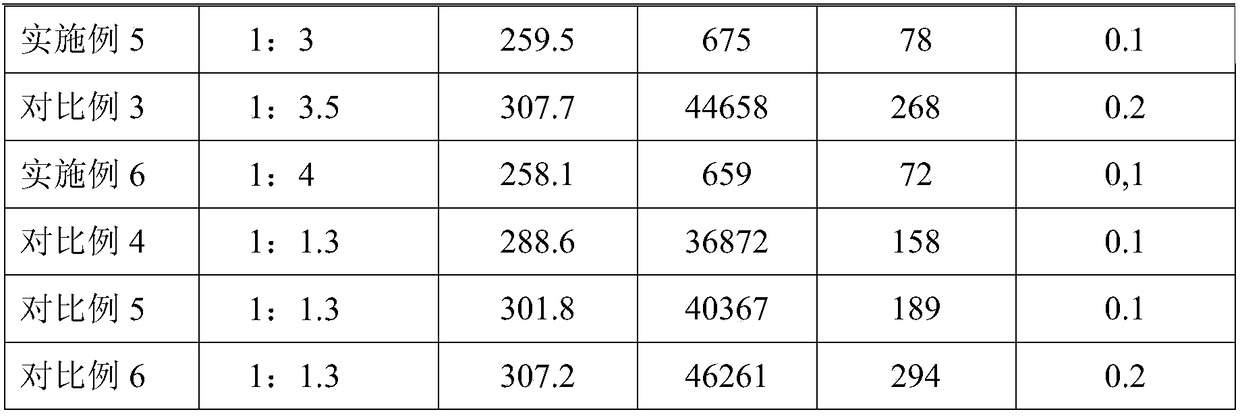

Examples

Embodiment 1

[0028] The preparation method of the active epoxy resin thinner of the low total chlorine content of the present embodiment is carried out according to the following steps:

[0029] (1) With C8 fatty alcohol and epichlorohydrin as raw materials, first the C8 fatty alcohol is pretreated, and 195g of C8 fatty alcohol is added in a 1000mL four-necked flask equipped with a stirrer, a thermometer and a condenser, and the purity of the C8 fatty alcohol is ≥ 99.0%, then heated the flask to 95°C under nitrogen protection, turned on the vacuum pump for dehydration for 60 minutes, then lowered the temperature to 90°C, added a composite catalyst to the flask: 1g of boron trifluoride ether, 2g of aluminum chloride and ferric chloride The mixture was stirred at 200rpm for 10min, kept at 100°C, and 416.3g of epichlorohydrin was added dropwise to the flask within 6h;

[0030] (2) After epichlorohydrin has been added dropwise, add 3.8g of 50% aqueous sodium hydroxide solution in the flask, st...

Embodiment 2

[0038] The preparation method of the reactive epoxy resin diluent of the low total chlorine content of this comparative example is carried out according to the following steps:

[0039] (1) With C8 fatty alcohol and epichlorohydrin as raw materials, first the C8 fatty alcohol is pretreated, and 130g of C8 fatty alcohol is added in a 1000mL four-necked flask equipped with a stirrer, thermometer and condenser. %, then heated the flask to 105°C under the protection of nitrogen, turned on the vacuum pump for dehydration for 60 minutes, then lowered the temperature to 90°C, added a composite catalyst to the flask: 0.65g boron trifluoride ether, added 1.3g aluminum chloride and chloride The iron mixture was stirred at 200rpm for 10min, kept at 100°C, and 369.6g of epichlorohydrin was added dropwise to the flask within 6h;

[0040] (2) After epichlorohydrin has been added dropwise, add 2.5g of 50% aqueous sodium hydroxide solution to the flask, stir for 10min, then add dropwise 100g ...

Embodiment 3

[0043] The preparation method of the active epoxy resin thinner of the low total chlorine content of the present embodiment is carried out according to the following steps:

[0044] (1) Take C10 fatty alcohol and epichlorohydrin as raw materials, first carry out pretreatment to C10 fatty alcohol, add 142gC10 fatty alcohol in a 1000mL four-necked flask equipped with stirrer, thermometer and condenser, C10 fatty alcohol purity ≥ 99.0%, then heated the flask to 105°C under nitrogen protection, turned on the vacuum pump for dehydration for 60 minutes, then lowered the temperature to 90°C, added a composite catalyst to the flask: 0.71g boron trifluoride ether, added 1.4g aluminum chloride and chlorine The mixture of ferric oxide was stirred at 200rpm for 10min, kept at 100°C, and 277.5g of epichlorohydrin was added dropwise to the flask within 6h;

[0045] (2) After epichlorohydrin has been added dropwise, add 4g of a 50% aqueous sodium hydroxide solution to the flask, stir for 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com