4-aminobutyronitrile preparation method and device adopting pyrrolidone liquid phase method

A technology of pyrrolidone liquid and aminobutyronitrile, which is applied in the field of preparation of aminobutyronitrile, can solve the problems of less by-products, high reaction conversion rate, and low temperature of liquid phase method, so as to improve product quality, high product conversion rate, and reaction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

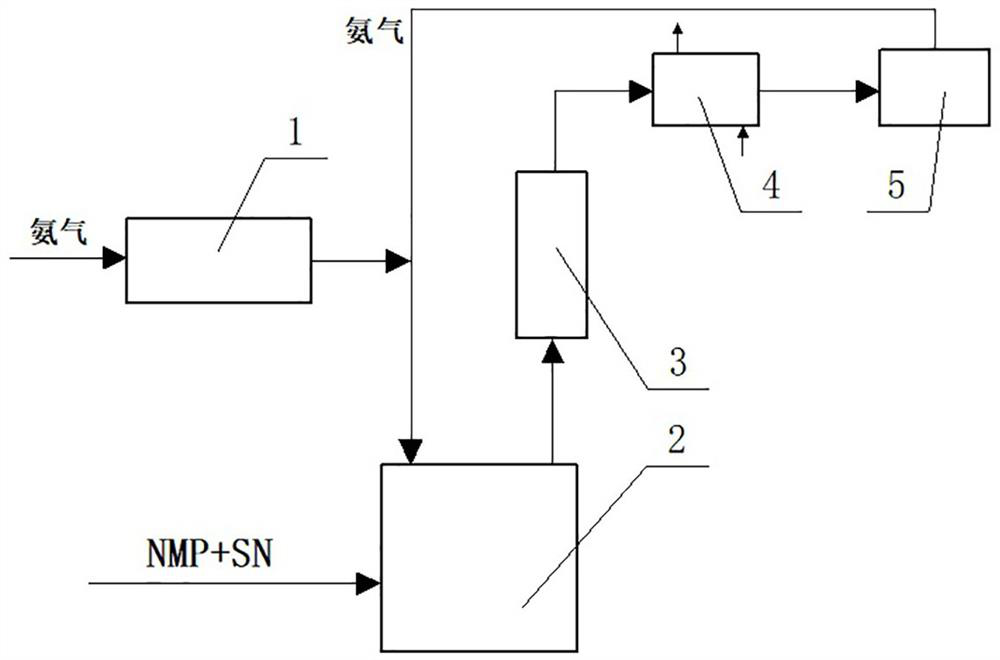

[0033] like figure 1 Shown, a kind of preparation device that utilizes pyrrolidone liquid phase method to prepare 4-aminobutyronitrile, comprises ammonia gas preprocessor 1, reactor 2, ammonia water separator 3, condenser 4 and gas-liquid separator 5; The new ammonia gas of the processor 1 and the recovered ammonia gas enter the reactor 2 in series, the gas outlet of the reactor 2 is connected with the inlet of the ammonia water separator 3, and the gas outlet of the ammonia water separator 3 is connected with the inlet of the condenser 4 The gas outlet of the condenser 4 is connected with the gas inlet of the gas-liquid separator 5, and the gas outlet of the gas-liquid separator 5 is connected with the gas inlet of the reactor 1; Shuikou, unreacted ammonia gas and new ammonia gas enter the reaction kettle 2 in series to continue the reaction.

[0034] Wherein: the ammonia water separator 3 is equipped with packing, and the circulating water in the condenser 4 is a circulatin...

Embodiment 2

[0039] Heat 100g of pyrrolidone, 1000g of succinonitrile, and 1g of boron phosphate to 100°C in a reaction kettle connected with an ammonia water separator, preheat the ammonia gas after the ammonia gas pre-treatment to 100°C, and start the stirring speed at 1000RPM, When the temperature reaches 200°C, ammonia gas is introduced, and the molar ratio of ammonia gas to pyrrolidone is 10:1 during the reaction, and the reaction lasts for 2 hours. After the reaction was completed, the upper tower was distilled under reduced pressure, the temperature of the bottom of the tower was 130°C, the temperature of the top of the tower was 110°C, and the negative pressure was -0.095MPA to obtain 4-aminobutyronitrile with a purity of 99.7%.

[0040] After product metering and analysis, the selectivity of pyrrolidone in this example was 98.50%, and the conversion rate was 65.00%.

[0041] The technical indicators of ammonia gas before and after activated carbon adsorption are shown in the table...

Embodiment 3

[0046] Heat 100g of pyrrolidone, 800g of succinonitrile, and 2g of boron phosphate in a reaction kettle with an ammonia water separator to 110°C, preheat the ammonia gas after ammonia pretreatment to 110°C, and start the stirring speed at 1200RPM. When the temperature reaches 230°C, ammonia gas is introduced, and the molar ratio of ammonia gas to pyrrolidone is 20:1 during the reaction, and the reaction lasts for 2 hours. After the reaction was completed, the upper tower was distilled under reduced pressure, the temperature of the bottom of the tower was 150°C, the temperature of the top of the tower was 125°C, and the negative pressure was -0.085MPA to obtain 4-aminobutyronitrile with a purity of 99.6%.

[0047] After product measurement and analysis, the selectivity of pyrrolidone in this example was 98.80%, and the conversion rate was 68.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com