Method for removing crystalline salt as well as design method and application thereof

A crystallized salt removal technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, mechanical equipment, etc., can solve the problems of incomplete flushing of clogged objects, clogging, and unreasonable planning of crystallized salt treatment methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

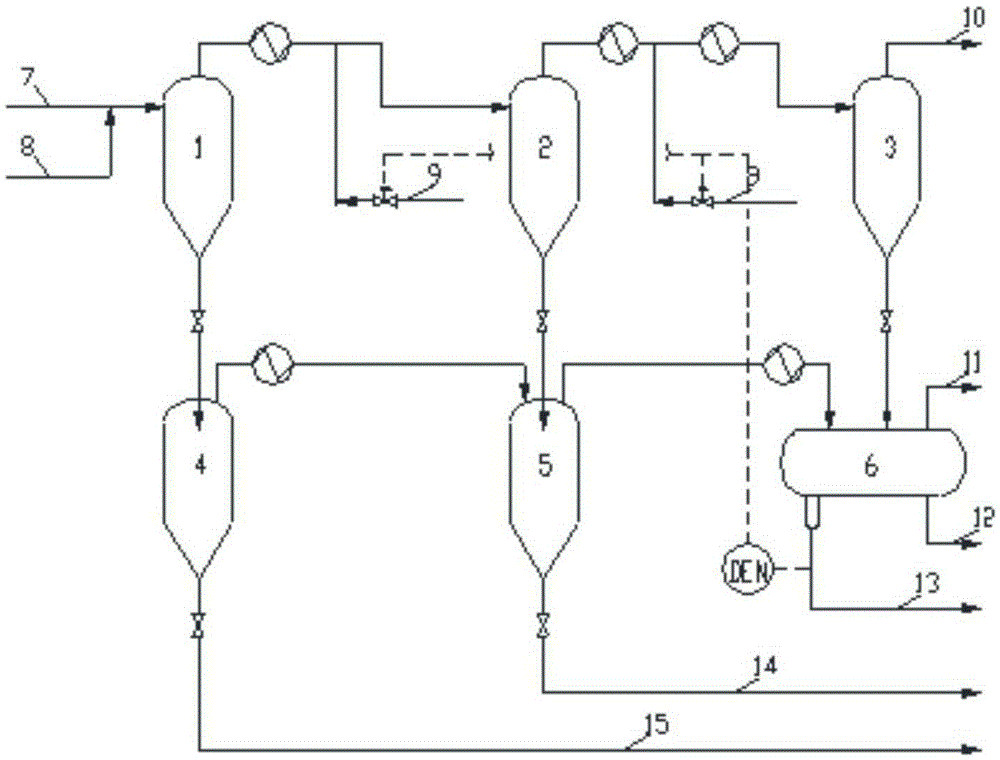

[0025] In order to further illustrate the technical content of the present invention, it will be described in conjunction with the accompanying drawings and specific embodiments.

[0026] like figure 1 As shown, this embodiment is a method for removing blockages in the high-pressure separation system, and the separation system belongs to the separation process in the slurry bed hydrogenation reaction process. The high-pressure separation system consists of six different separators, which are high-temperature and high-pressure separator 1, medium-temperature and high-pressure separator 2, normal-temperature and high-pressure separator 3, low-pressure and high-temperature separator 4, low-pressure and medium-temperature separator 5, and low-pressure normal-temperature separator 6. The normal temperature and low pressure separator 6 is placed horizontally, and the remaining separators are placed vertically. In order to remove blockages such as crystalline salt in slurry bed reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com