Method for preparing metallic complex film

A technology of metal composite and composite bottom, applied in the direction of metal material coating process, superimposed layer plating, liquid chemical plating, etc., can solve the problem of easy formation of pinholes and cracks, low selectivity, and unsuitable for practical requirements etc. to achieve the effect of improving the pore structure and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

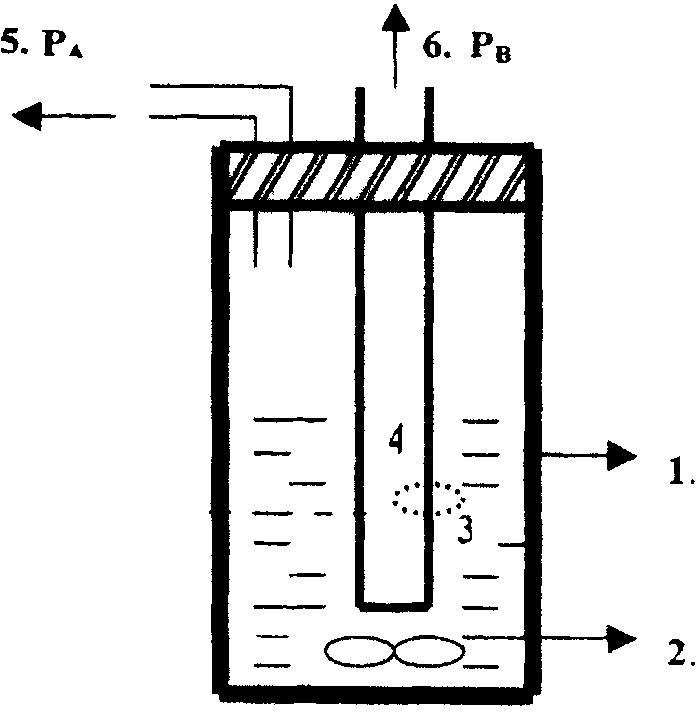

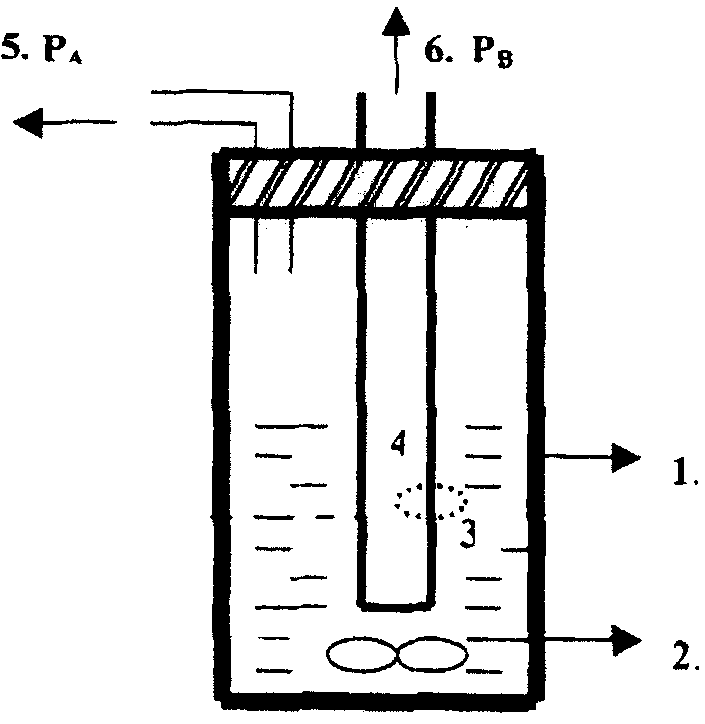

Method used

Image

Examples

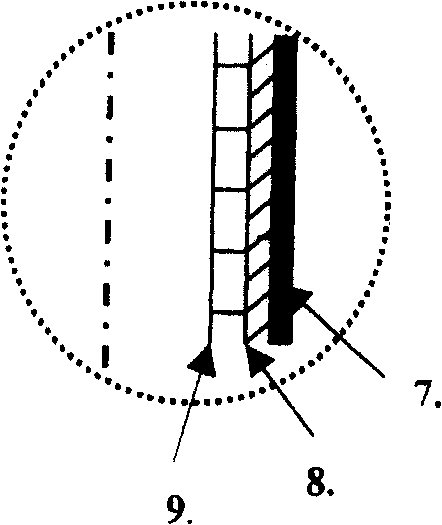

Embodiment 1

[0031] Take PURAL SB powder (a kind of commercial pseudo-boehmite for industrial use produced by Germany Condea company) as raw material to prepare 0.5mol / L γ-AlOOH sol, add 1.2wt%PVA and 0.6wt%PVA in γ-AlOOH sol PEG to adjust the viscosity of the sol, mixed evenly to form a dip-coating sol. Immerse the cleaned porous ceramic bottom film tube (bottom film thickness 5mm, average pore diameter 0.3μm, porosity about 40%) in the above-mentioned dip coating sol, dip coating for 15 seconds, dry at room temperature for two days, and place in a muffle furnace Calcined at 500-600°C for 3 hours, the surface pre-modified porous asymmetric bottom membrane can be obtained, the thickness of the top layer is about 3 μm, and the average pore diameter is 7.5nm. Subsequently, EDTA and PdCl 2 (1:1 molar ratio) made into solution so that Pd 2+ Chelation with EDTA to produce [PdEDTA] 2- , take the above solution and add it to 0.5mol / L gamma-AlOOH sol (Pd / Al=4.8 / 1000 molar ratio), and add 1.6wt%...

Embodiment 3

[0038] As described in Example 1, first carry out vacuum chemical palladium plating on the reduced film tube, change the plating solution after rinsing and carry out vacuum chemical copper plating, while maintaining a certain vacuum degree (P A =91KPa, P B =3KPa, absolute pressure), the composition of electroless copper plating solution is: CuCl 2 .2H 2 O (8.6g / L), Na 2 EDTA.2H 2 O (19.2g / L), KNaC 4 h 4 o 6 (11.3g / L), NaOH (18.0g / L), K 4 Fe(CN) 6 .3H 2 O (mg grade), 2,2-bipyridine (mg grade), N, N, N', N'-tetramethylethylenediamine (mg grade), HCHO (≥36wt%) (14ml / L), The pH value is 13.5, the constant temperature is 30°C, and the vacuum electroless plating is carried out with stirring. Control the vacuum electroless plating time, palladium plating 15-30min, copper plating 10-30min (palladium, copper are different in deposition rate in vacuum electroless plating, therefore provide the time frame of a vacuum electroless plating here. And the palladium-copper alloy film...

Embodiment 4

[0040] As described in Example 3, the vacuum chemical plating time is controlled, palladium plating is 30-60min, copper plating is 10-50min, and the vacuum chemical plating has prepared a Pd-Cu alloy film with a thickness of about 8 μm. When the pressure difference is 1bar at 500°C, hydrogen Maximum penetration is 15m 3 / m 2 .h, H 2 / Ar selectivity is greater than 3000, in the temperature range of 500-200 ° C in different proportions of H 2 / Ar mixed gas atmosphere for 30 days, the gas permeability remains stable, which indicates that the alloy membrane can overcome the hydrogen embrittlement of pure palladium membrane, and expand the temperature range of the hydrogen separation application of the membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com