Reaction system and method for preparing lactide from lactic acid

A reaction system, lactide technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problem of reducing lactide product yield, low lactide separation system efficiency, and long residence time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

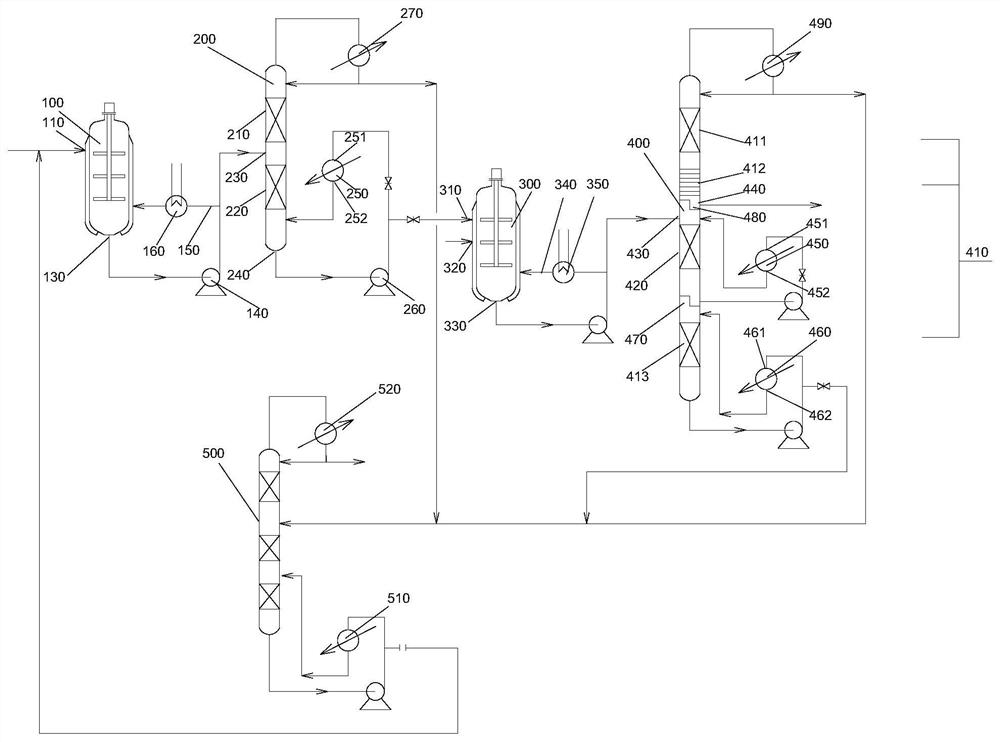

[0099] refer to figure 1 Shown is a reaction system for preparing lactide from lactic acid in an embodiment of the present invention, which includes a lactic acid oligomerization reactor 100, a first reactive distillation column 200, a lactide synthesis reactor 300, and a second reaction refiner connected in sequence. The distillation tower 400 has two major equipment bodies, and the second reactive distillation tower 400 includes a rectification section 410 and a lactide deep synthesis section 420 .

[0100] The first reactive distillation column 200 includes a first column reboiler 250, a first overhead condenser 270, a purification section 210 and a deep oligomerization dehydration reaction section 220 arranged from top to bottom;

[0101] Wherein, the lactic acid oligomerization reactor 100 is provided with a raw material inlet and a first reaction product outlet 130 , and the raw material inlet is a lactic acid inlet 110 .

[0102] The bottom of the first reactive distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com