A multi-point oxygen injection and segmented mixing device for supercritical water oxidation reaction tubular reactor

A supercritical water oxidation, tubular reactor technology, applied in chemical/physical/physical-chemical stationary reactors, feeding devices, chemical instruments and methods, etc., can solve the problems of oxygen waste and reduce system economy, etc. Achieve the effect of optimizing the reaction route, improving the service life and preventing local over-temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

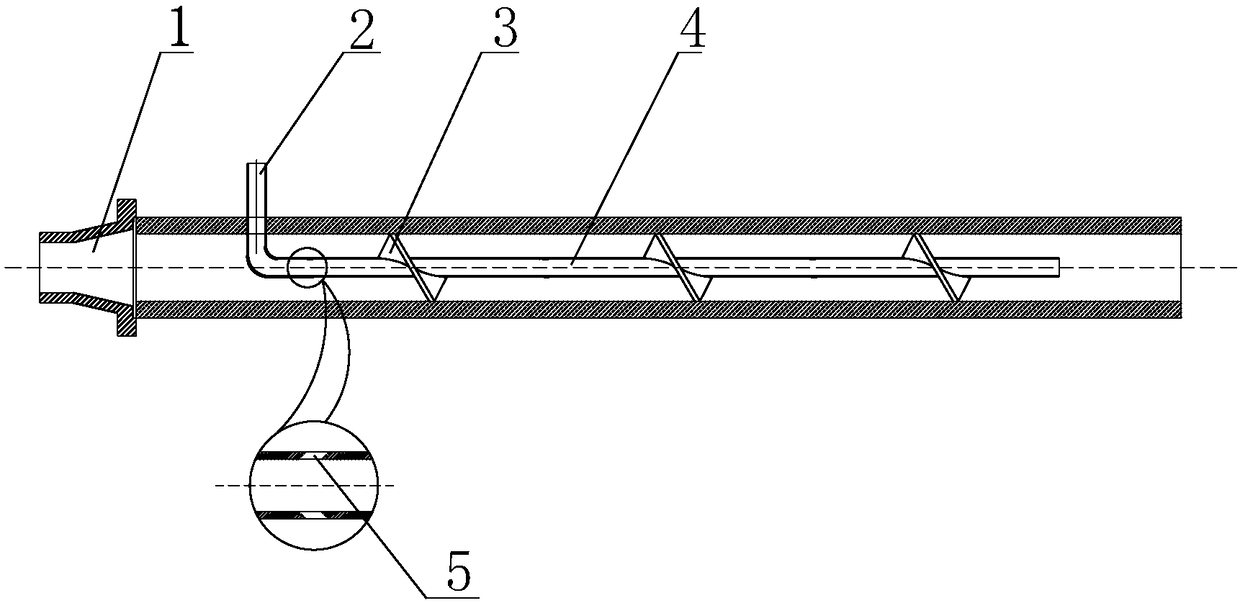

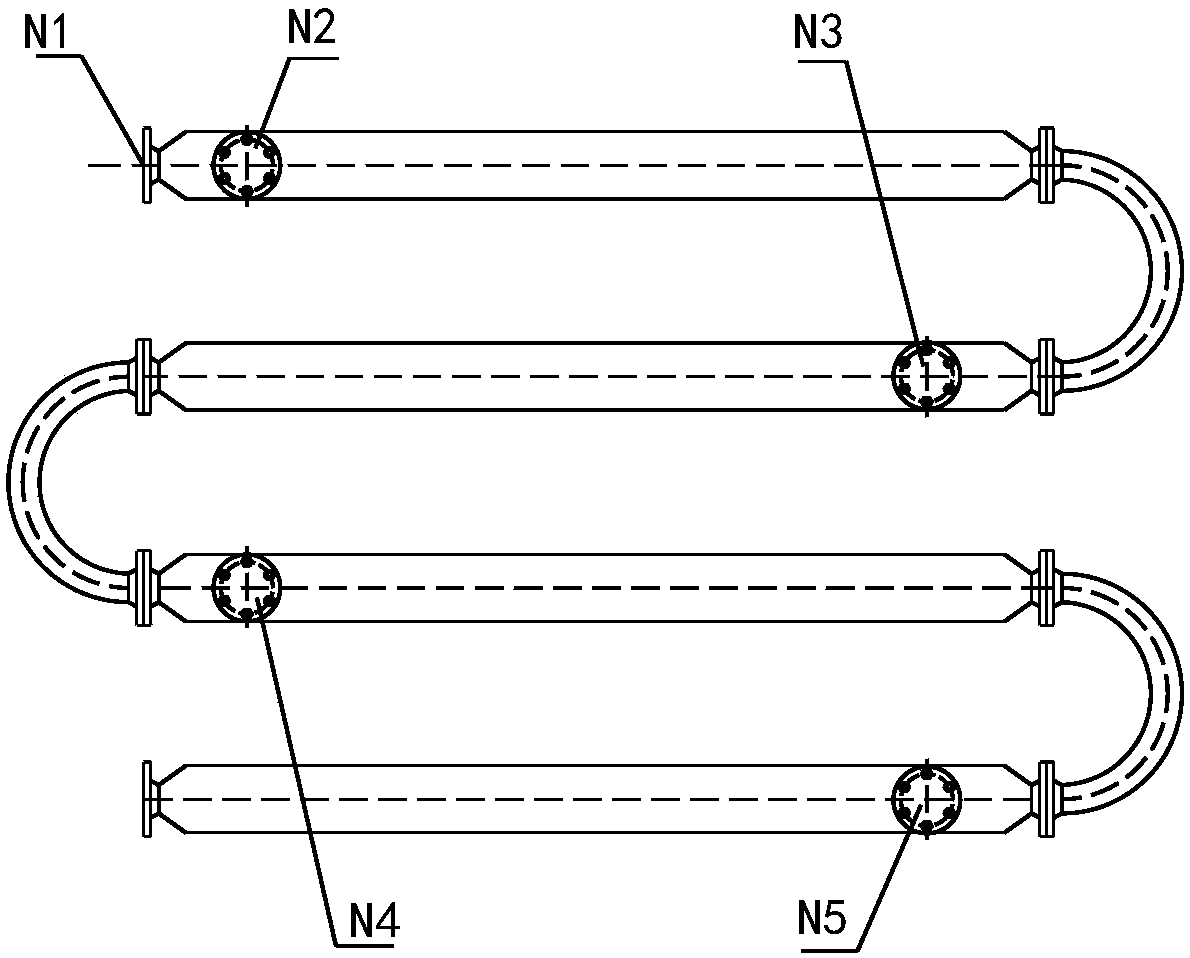

[0028] see figure 1 , the invention discloses a multi-point oxygen injection and segmented mixing device for a supercritical water oxidation reaction tubular reactor. Several reaction main pipes of the reactor are provided with an oxygen injection port 2, and each oxygen injection port 2 is provided with a core pipe 4 that can extend into the reaction main pipe, and several groups of pipes are provided on the core pipe 4 for Pores 5 for diffusion of oxygen. The core tube 4 is also sheathed with a number of helical parts 3 with stirring and supporting functions. The central part of the helical part 3 is discontinuous, and it is made into a ring structure to cover the outside of the core tube, and the top of the helical part 3 just fits the inner wall of the reaction main tube.

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com