Patents

Literature

52results about How to "Reduce gas load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

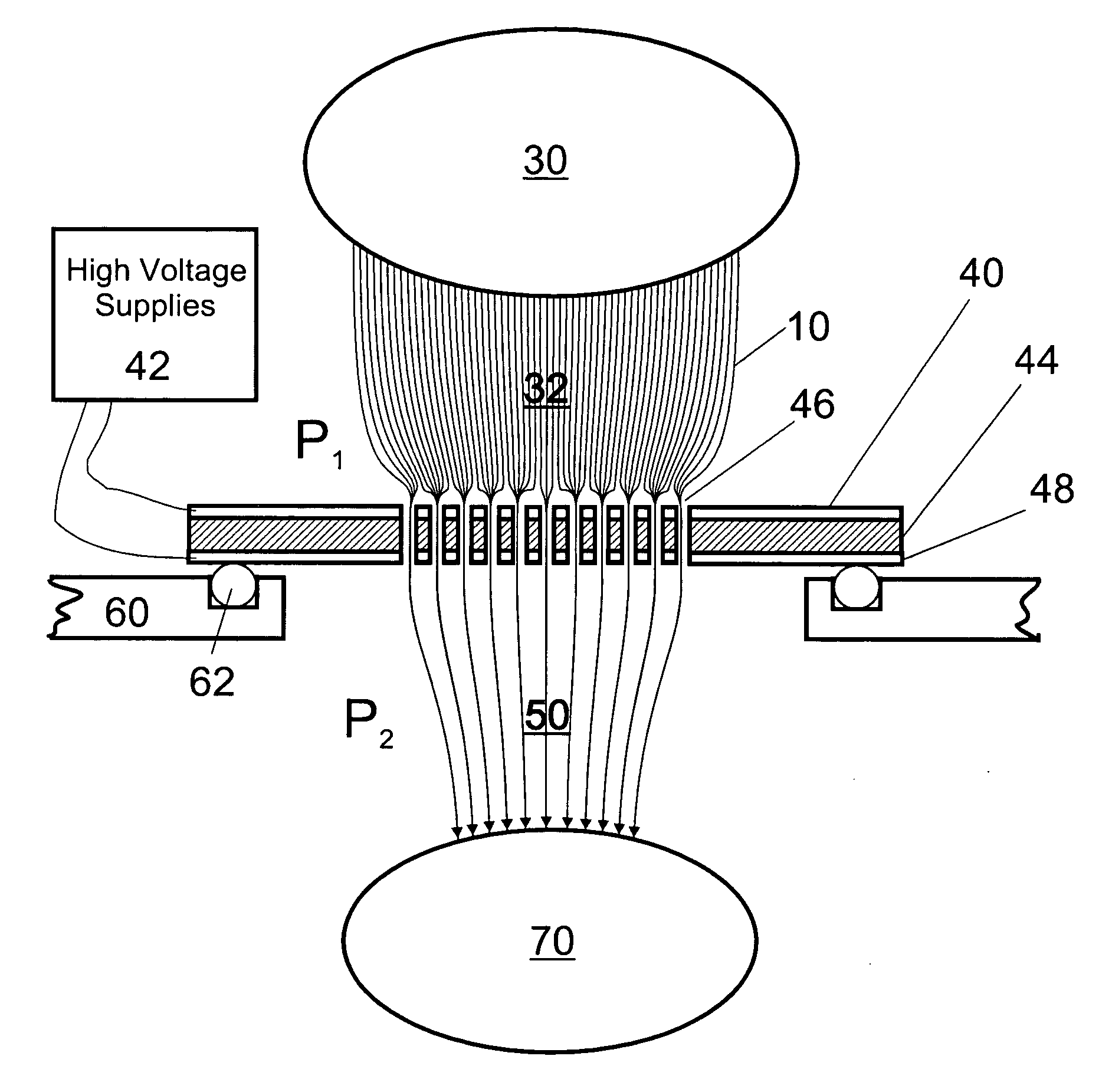

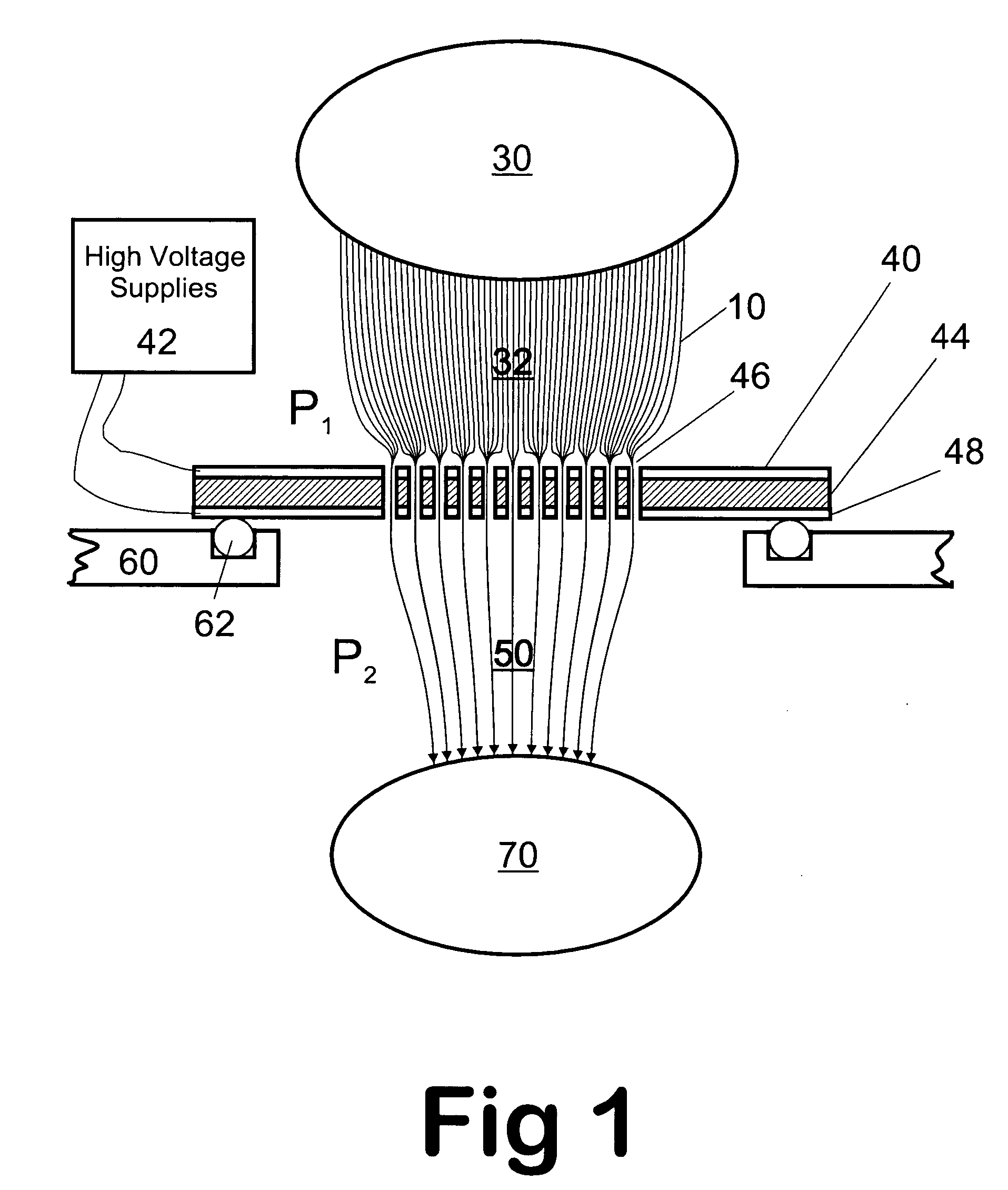

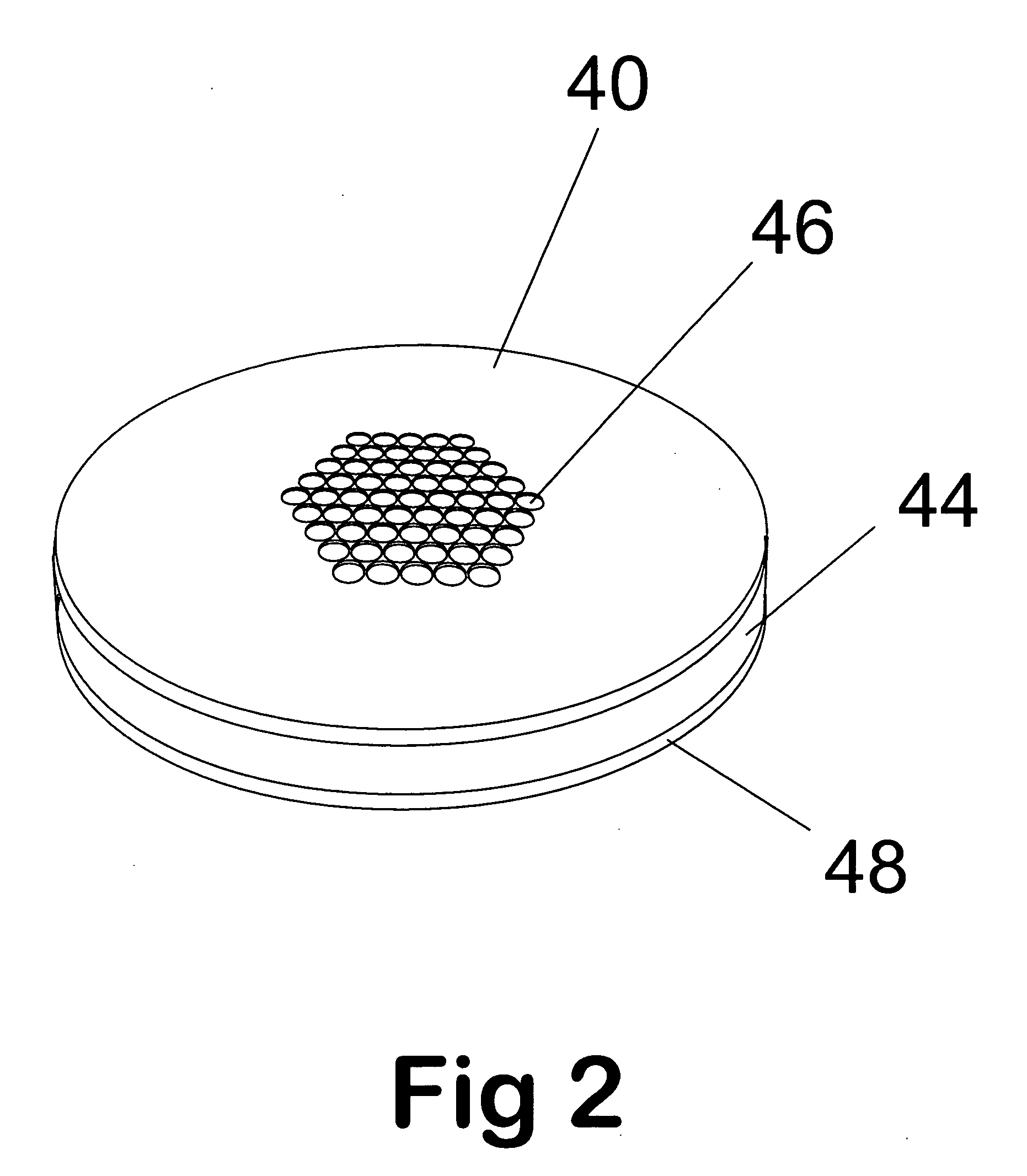

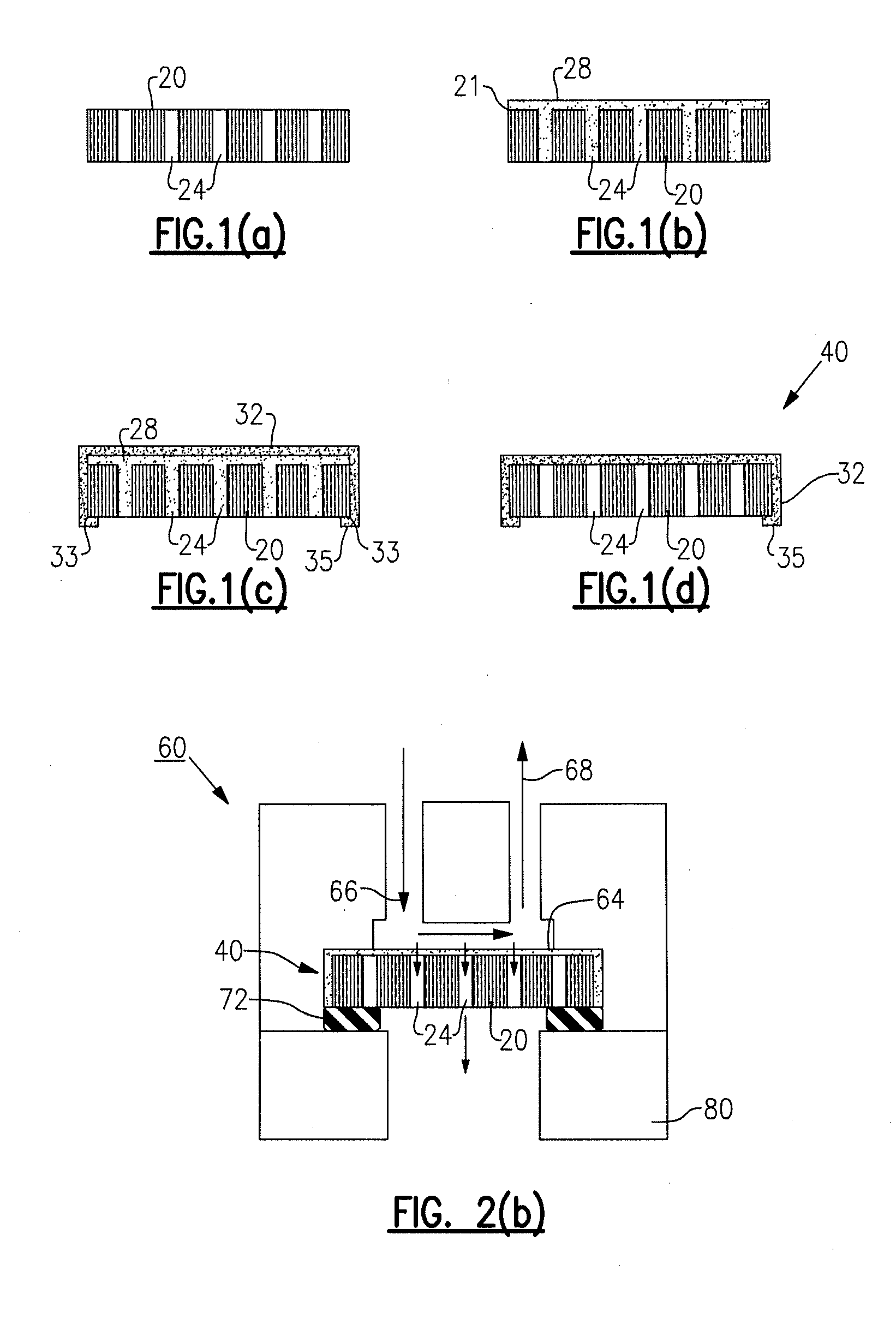

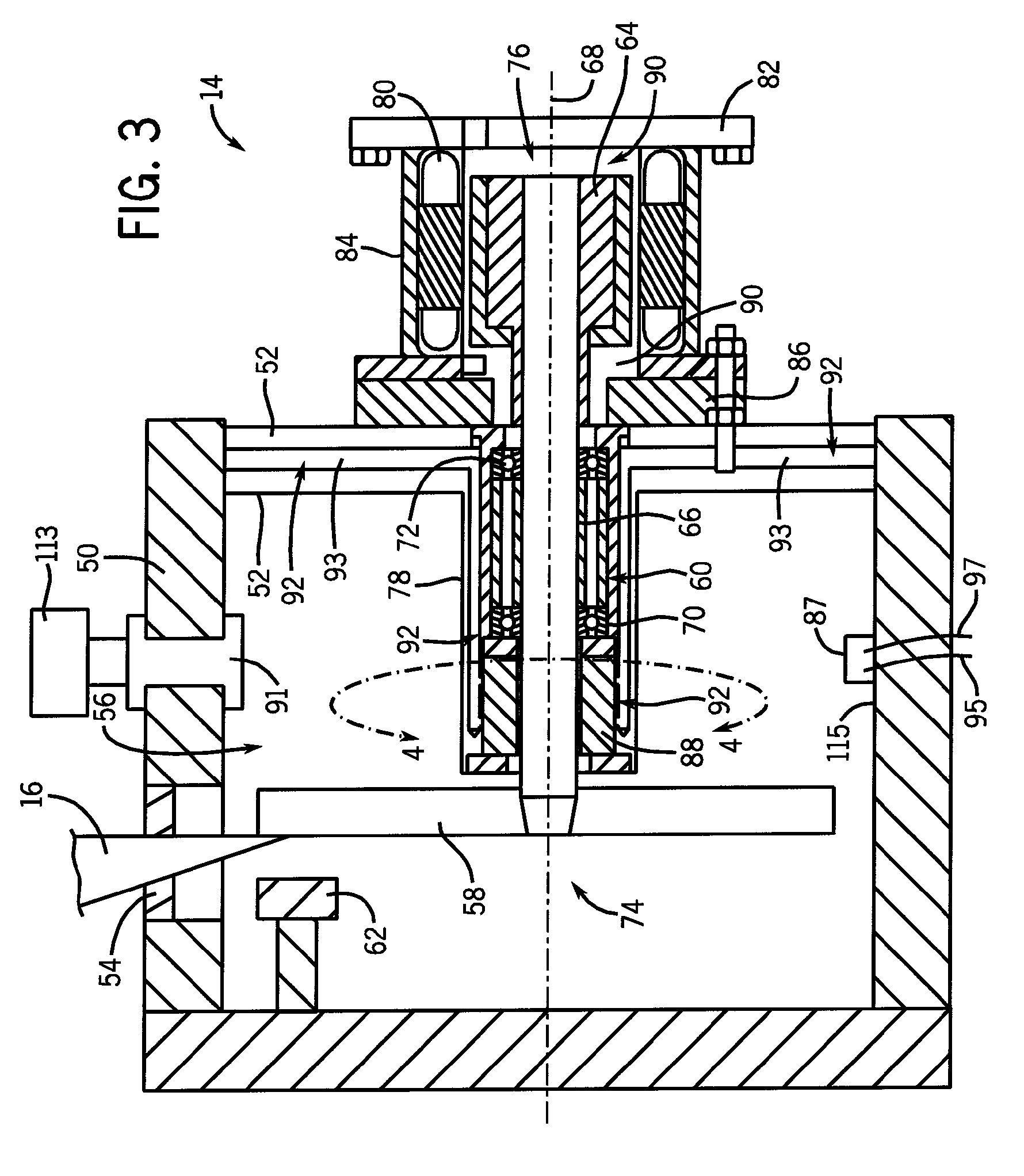

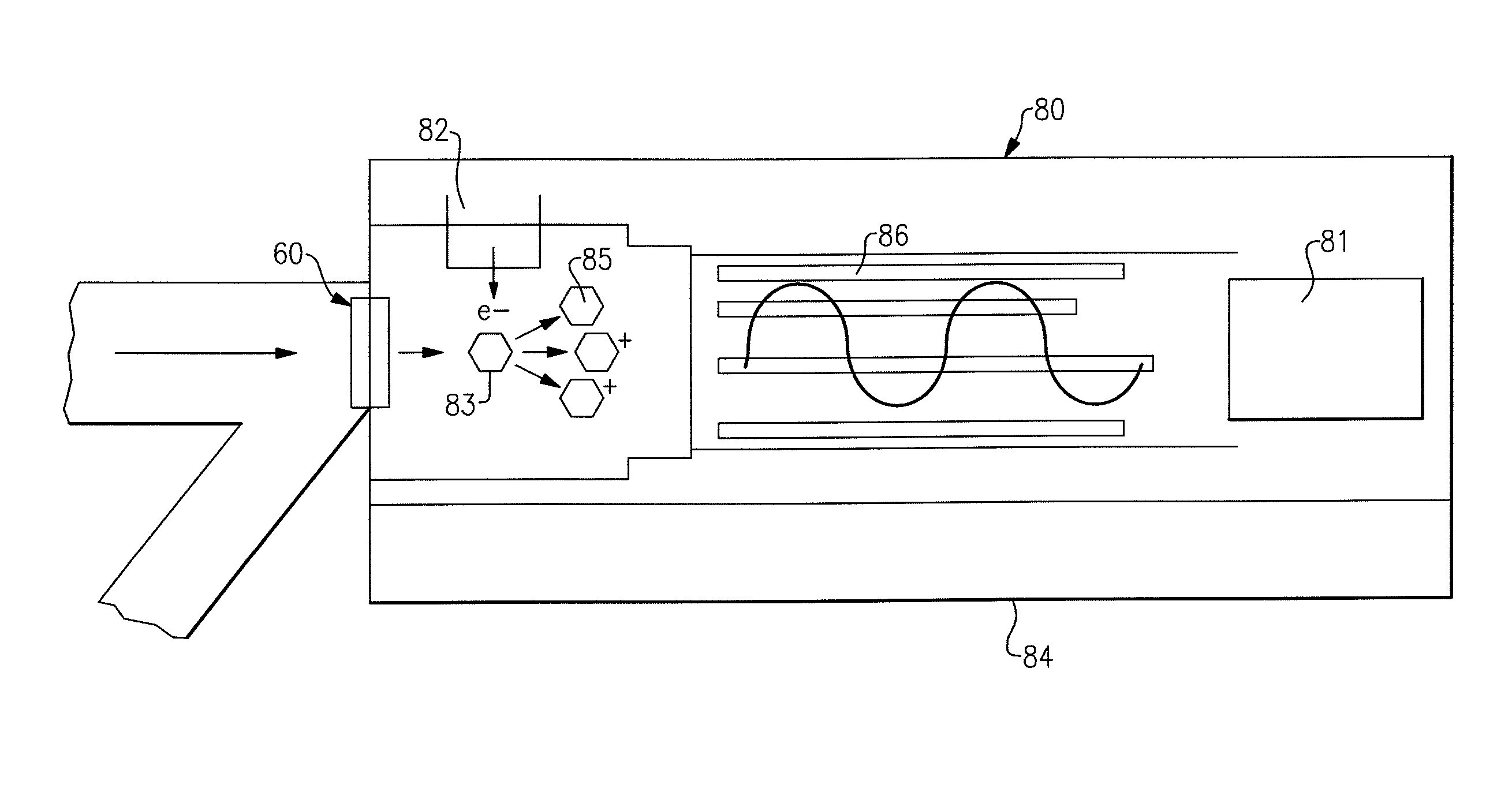

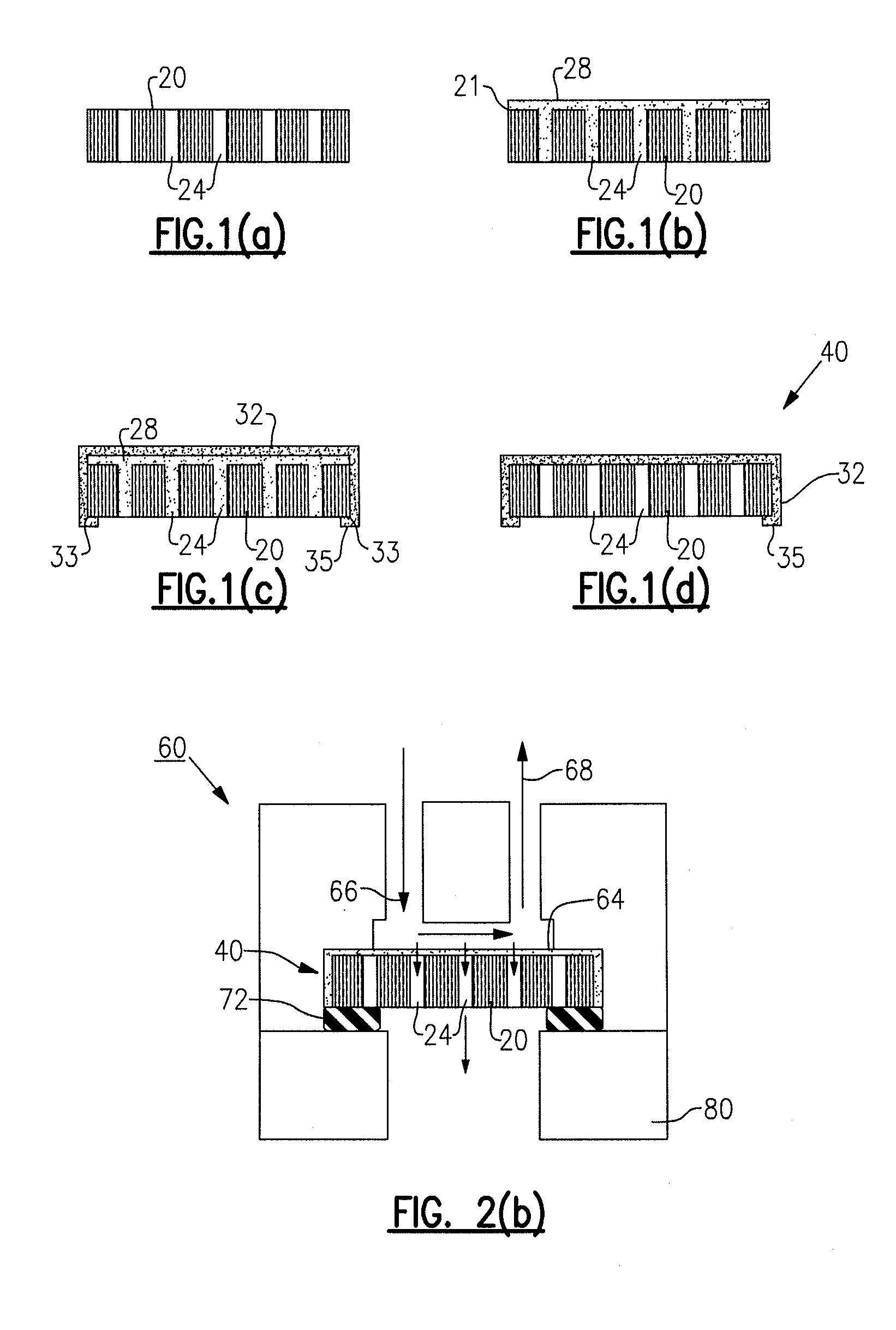

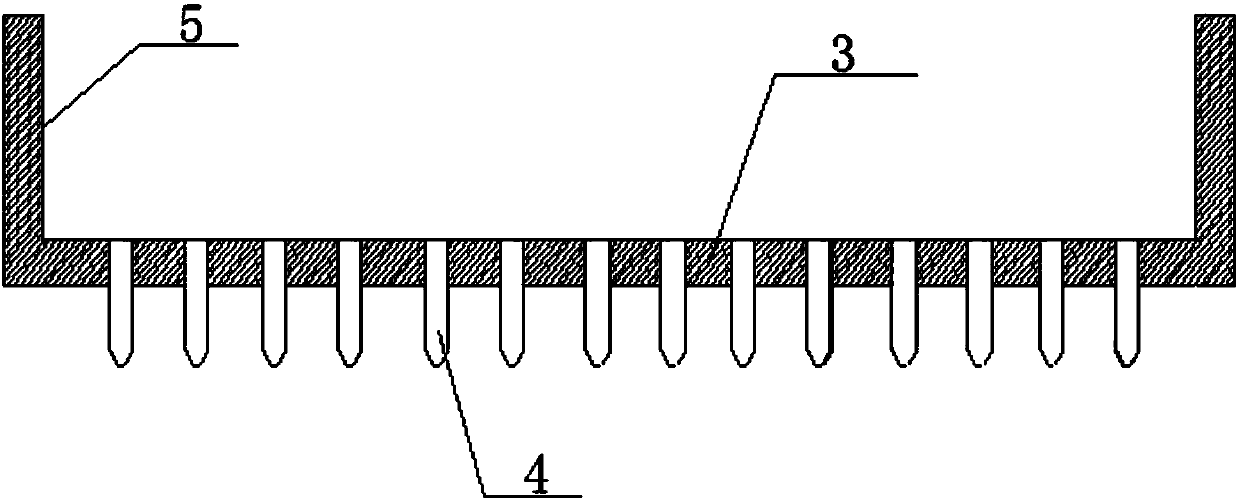

Ion enrichment aperture arrays

InactiveUS20040245458A1Maximizes transmission of ionImprove transmittanceTime-of-flight spectrometersElectron/ion optical arrangementsAtmospheric pressure dischargeInductively coupled plasma

Improvements have been made for collecting, focusing, and directing of ions and / or charged particles generated at atmospheric or near atmospheric pressure sources, such as but not limited to, electrospray; atmospheric pressure discharge ionization, chemical ionization, photoionization, and matrix assisted laser desorption ionization; and inductively coupled plasma ionization. A multiple-aperture laminated structure is place at the interface of two pressure regions. Electric fields geometries and strengths across the laminated structure and diameters of the apertures; all of which act to optimize the transfer of the ions from the higher pressure region into the lower pressure region while reducing the gas-load on the lower pressure region. Embodiments of this invention are methods and devices for improving sensitivity of mass spectrometry when coupled to atmospheric, near atmospheric, or higher pressure ionization sources by reducing the gas-load on the vacuum system.

Owner:CHEM SPACE ASSOIATES

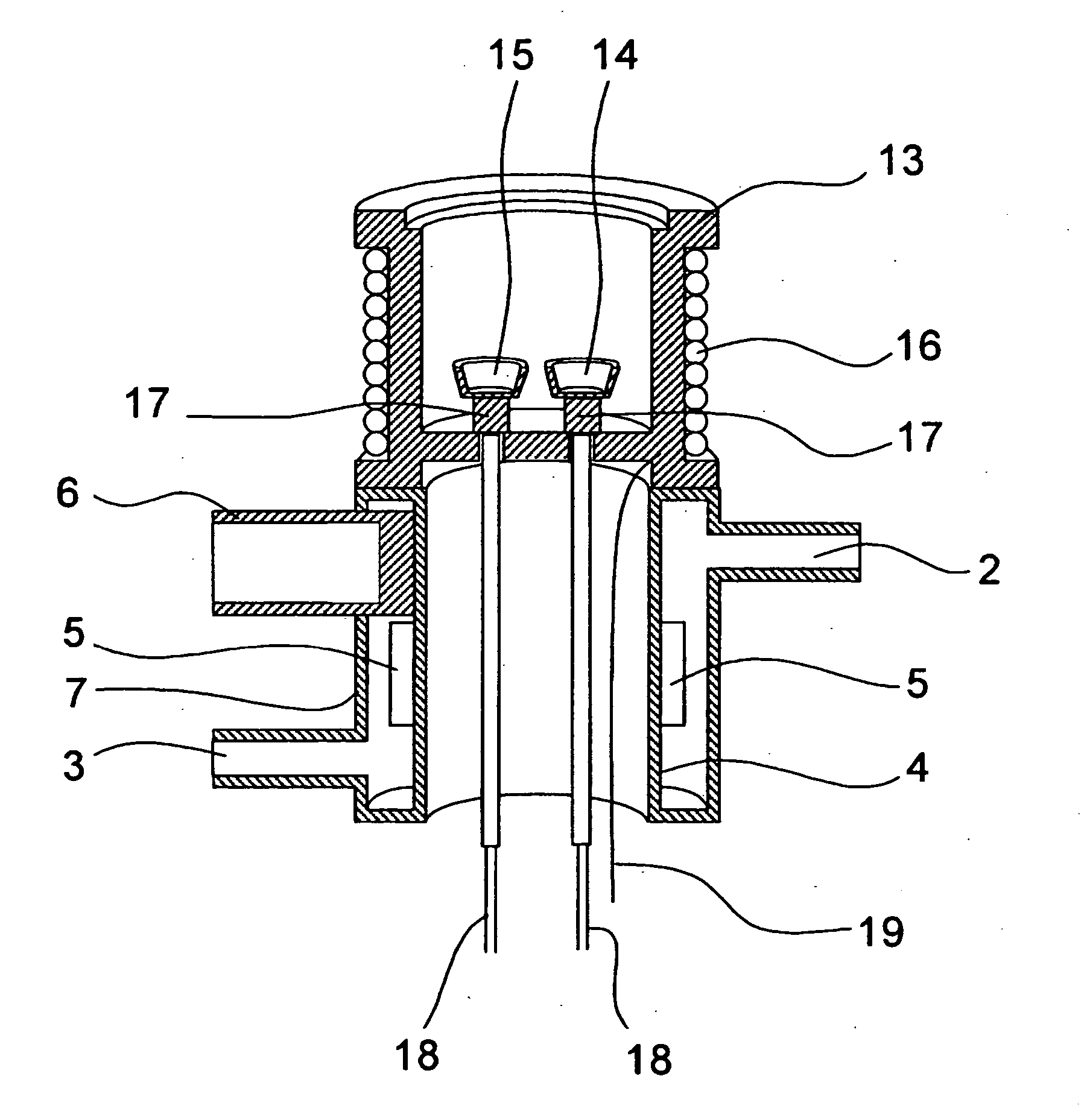

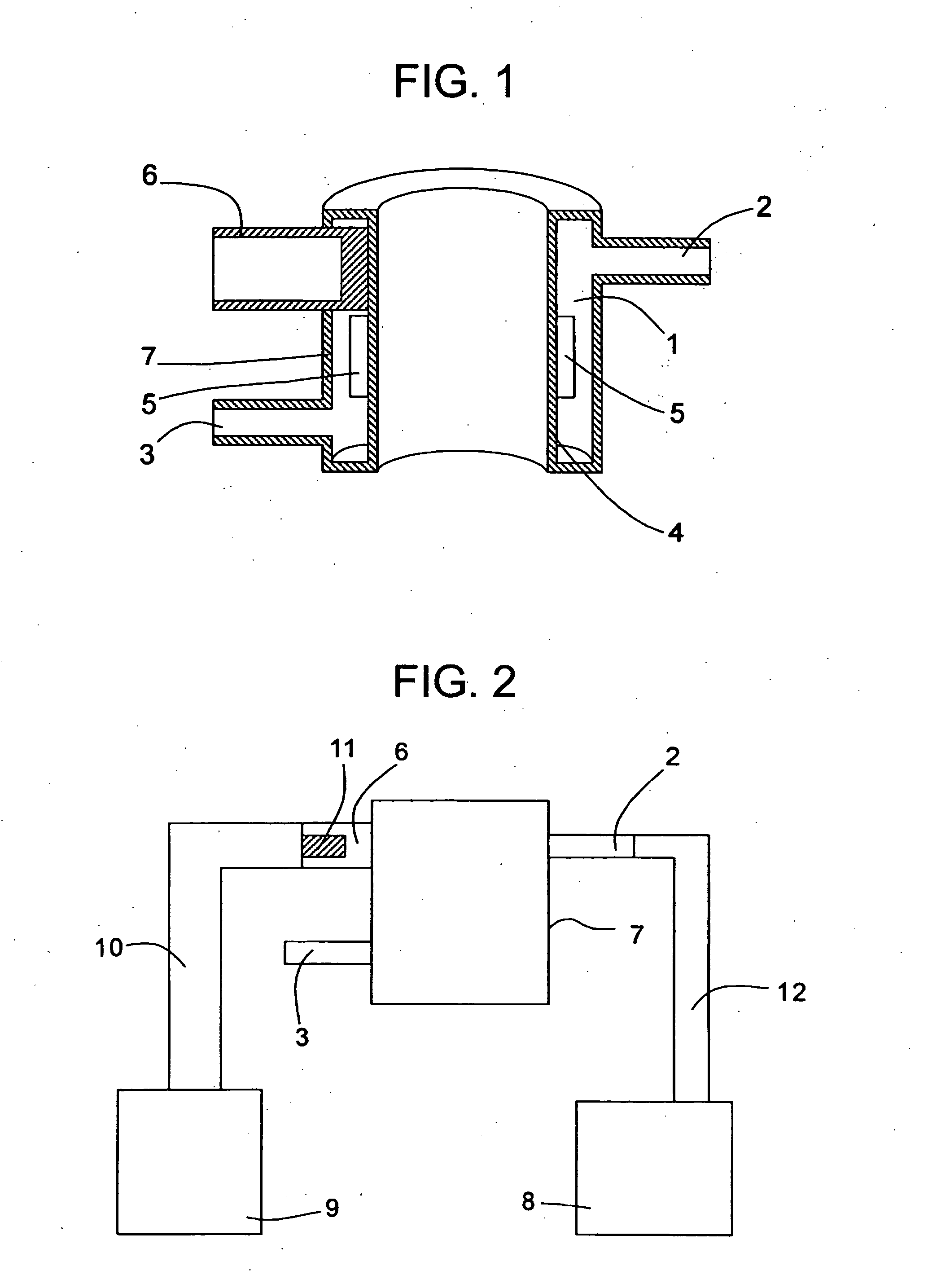

Ultra-thin membrane for chemical analyzer and related method for forming membrane

ActiveUS20120208004A1Reduce gas loadEasy to detectMembranesSemi-permeable membranesPorous substrateThin membrane

A method for forming an ultra-thin membrane for use in a chemical analyzer such as a mass spectrometer includes the step of applying a sacrificial blocking layer onto a porous substrate, applying a semi-permeable membrane layer onto the sacrificial blocking layer, and removing the sacrificial blocking layer following cure of the membrane layer. In a preferred version, at least one of the blocking layer and the membrane layer are applied to the porous support by means of spin coating, though other deposition techniques can be employed.

Owner:INFICON GMBH

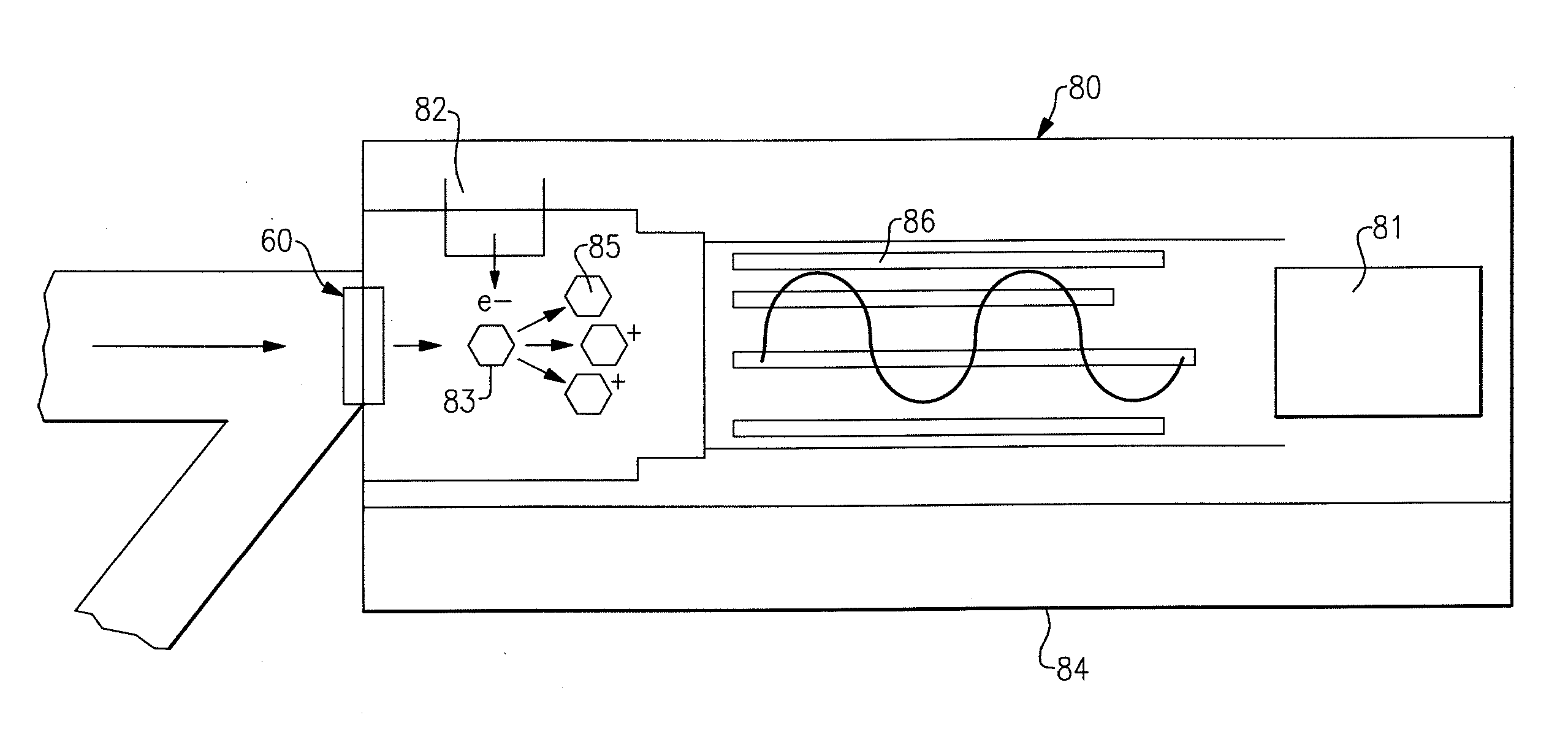

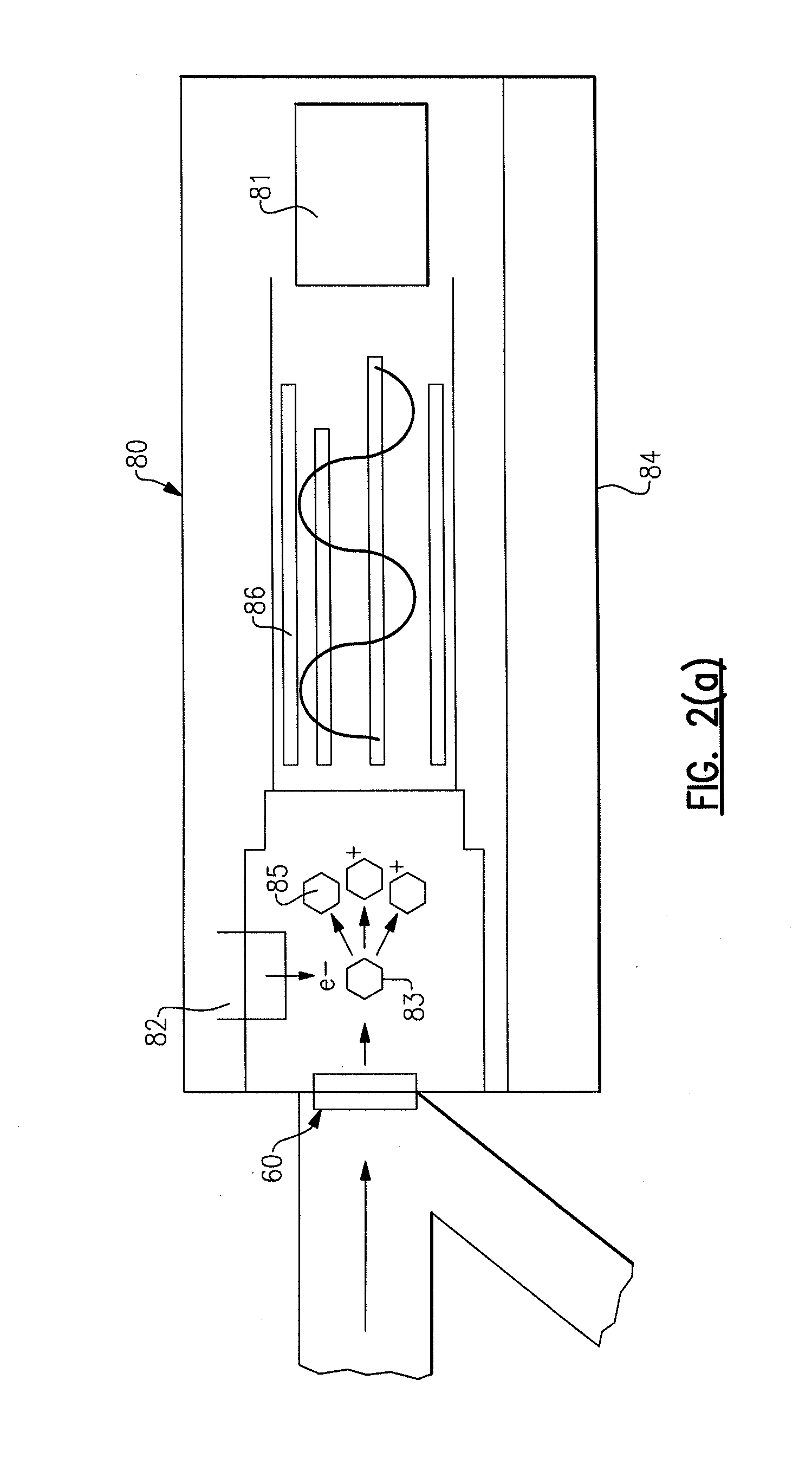

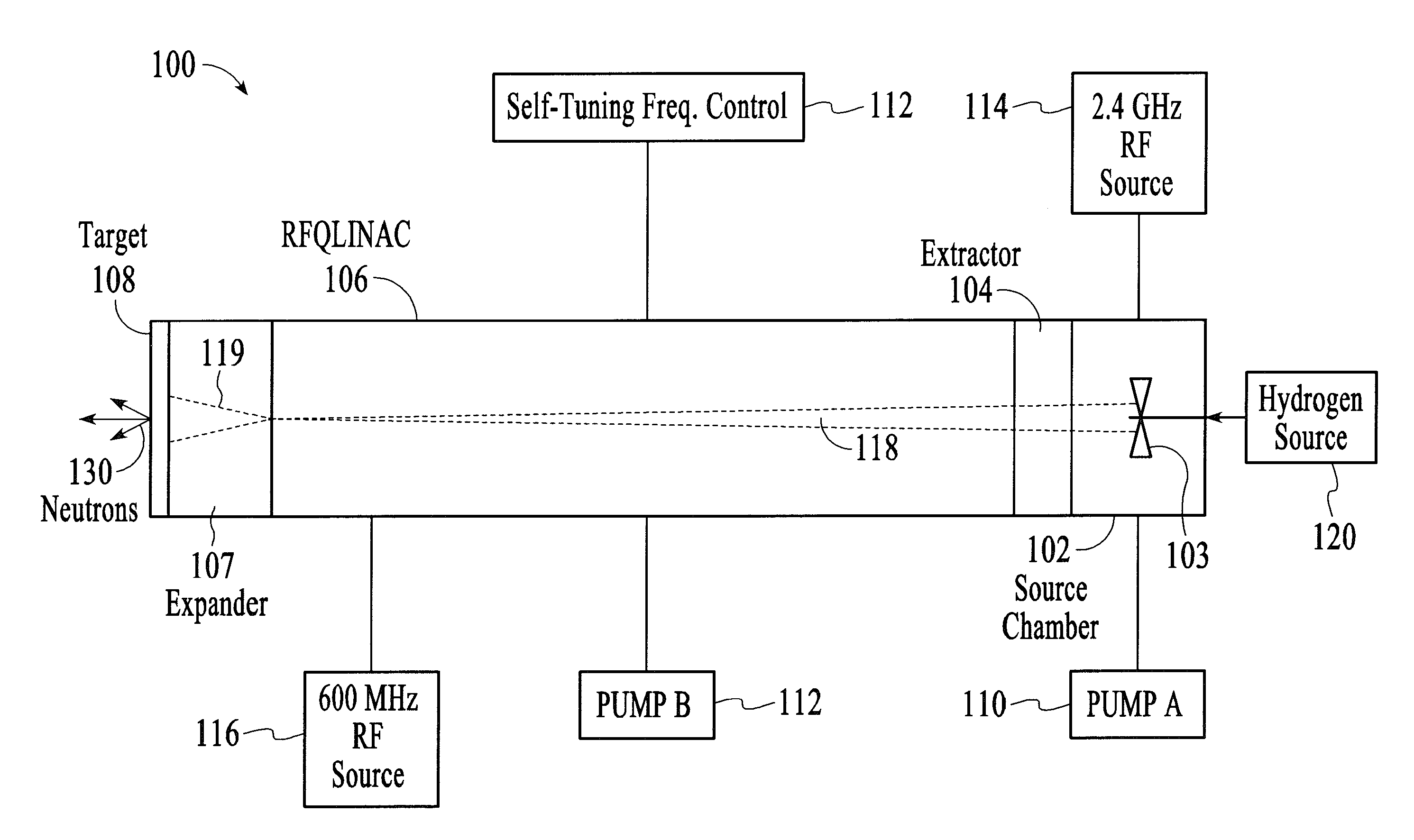

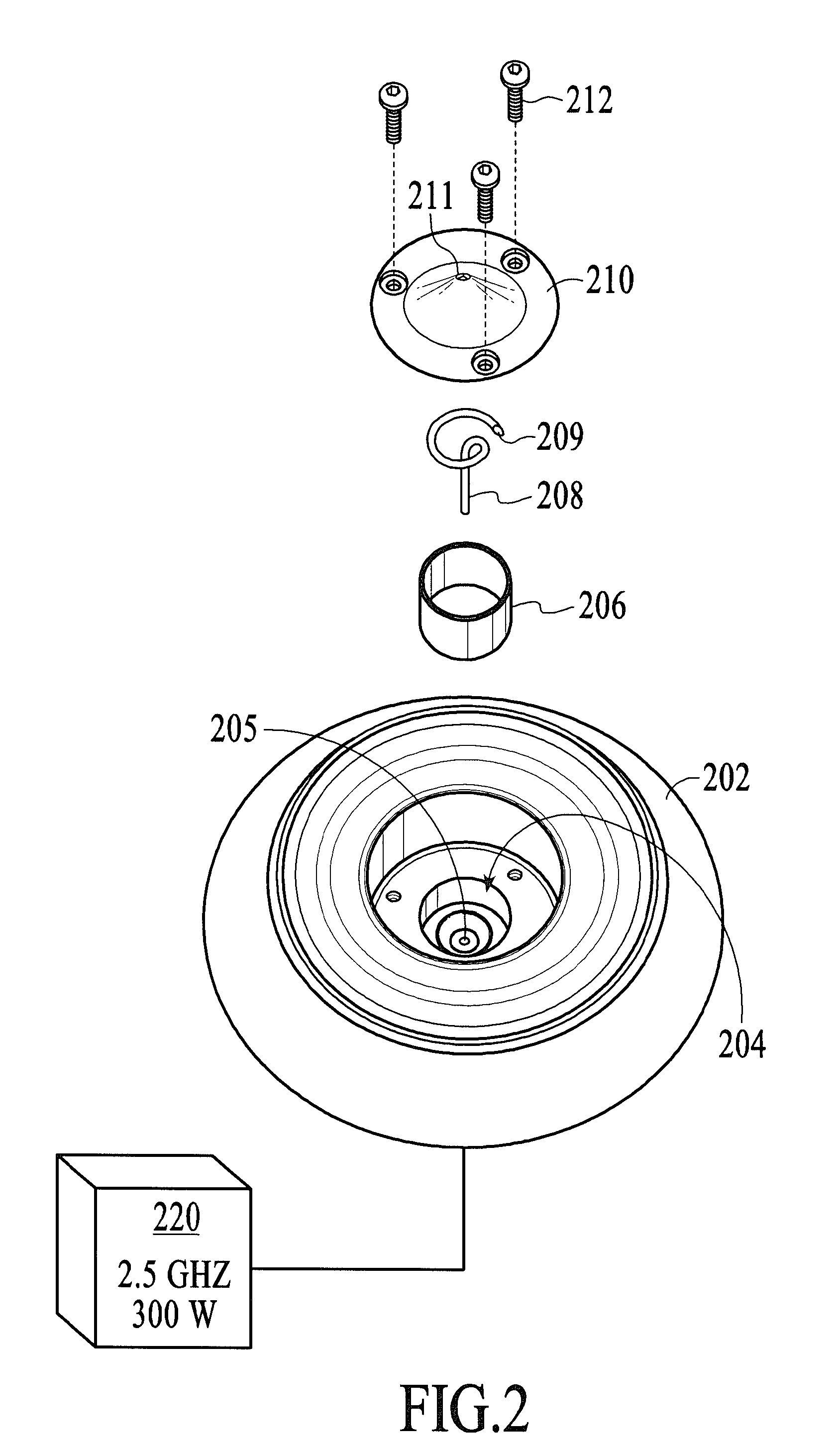

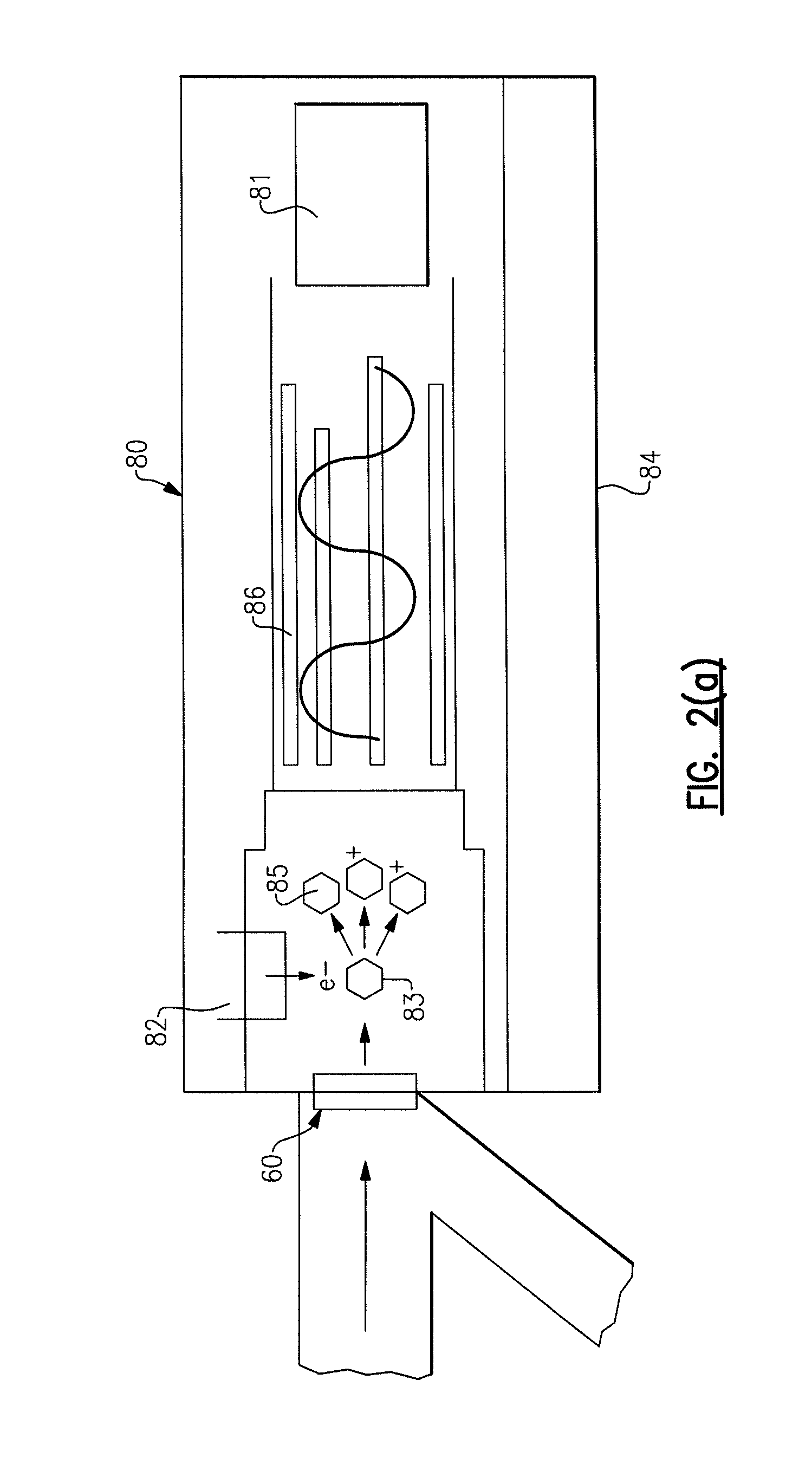

Portable low energy neutron source for high sensitivity material characterization

InactiveUS20110176648A1Suitable for useReduce gas loadConversion outside reactor/acceleratorsDirect voltage acceleratorsLithiumHydrogen

A portable neutron generator includes a Radio Frequency Quadrupole linear accelerator designed to accelerate charged particles of hydrogen (protons) to energies useful for producing neutrons with the (p,n) reaction on lithium. The ion source is driven by a coaxial feed and a spiral antenna to couple the microwave power into the plasma. The linear accelerator is driven by a 600 MHz pulsed RF power supply. A differential pumping scheme is used to balance the need for a high gas load on the ion source end and good vacuum on the accelerator end.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

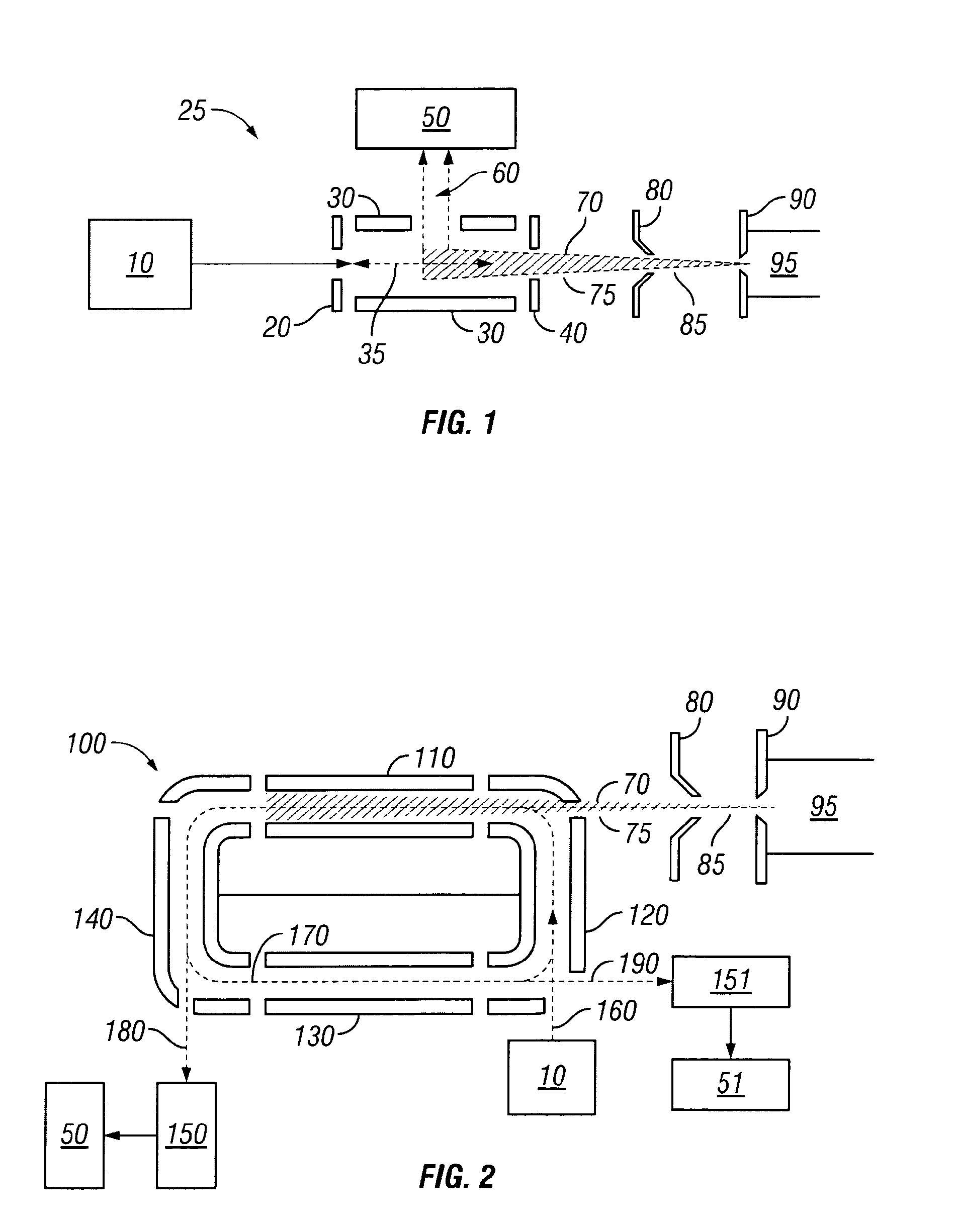

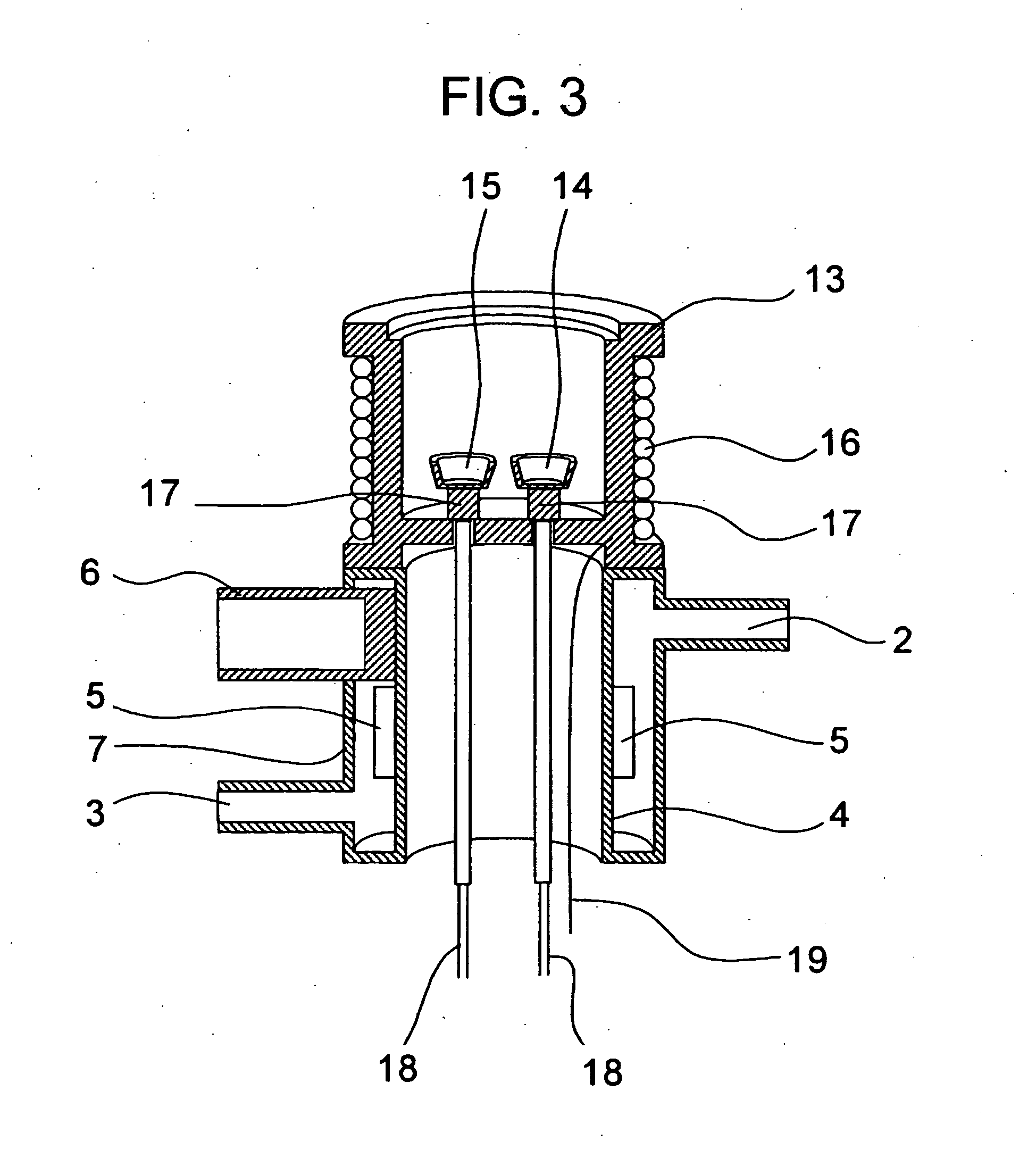

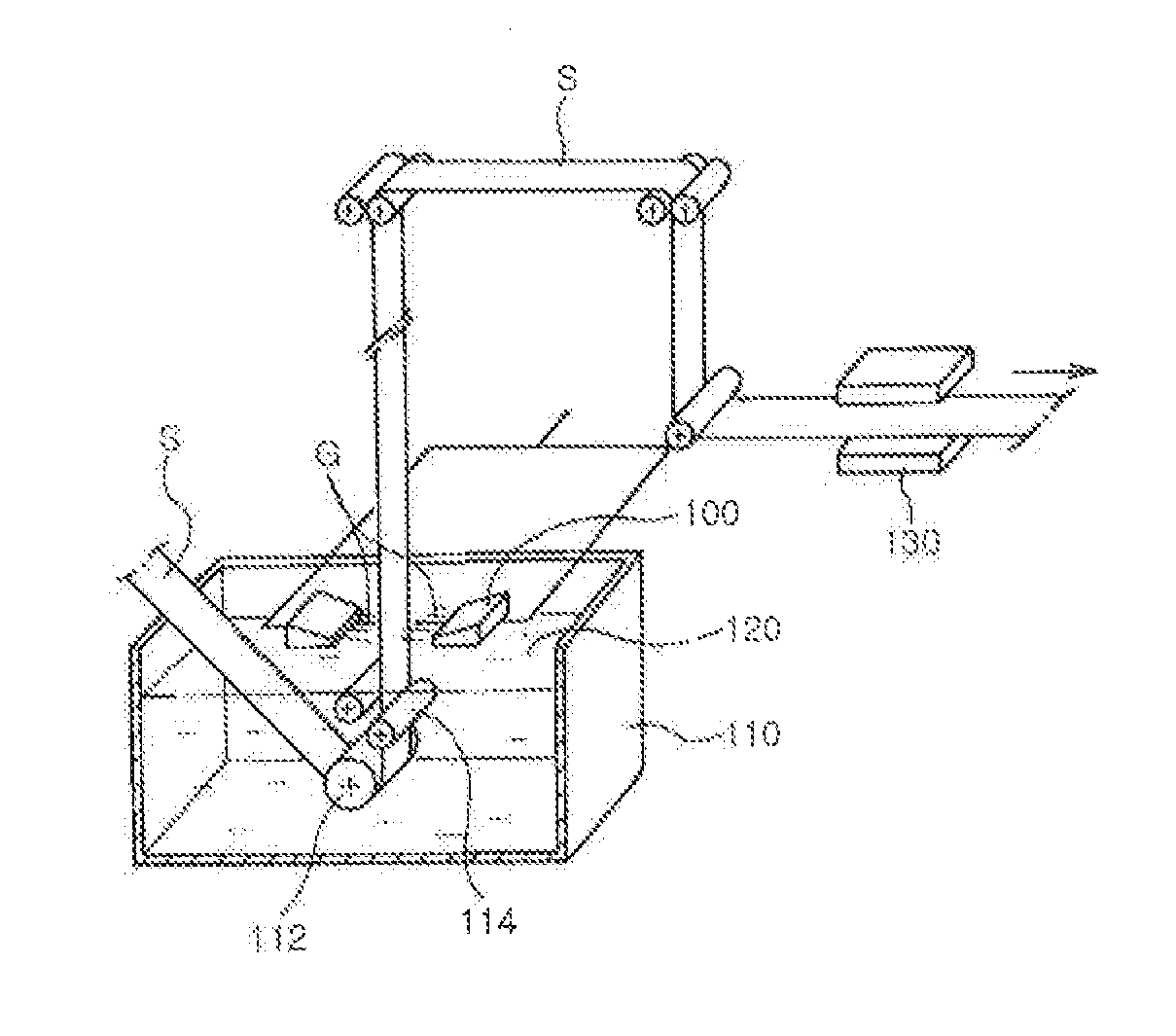

Ion trap for cooling ions

ActiveUS8642948B2Degree of flexibilityReduce divergenceMaterial analysis by electric/magnetic meansIsotope separationIon trap mass spectrometryGas passing

A method of changing the kinetic energy of ions is provided, comprising: trapping ions in a trapping region of an ion trap; and directing a beam of gas through the trapping region, so as to change the kinetic energy of the trapped ions thereby. Also provided is a method of separating ions, the method comprising: causing ions to enter a trapping region of an ion trap along a first axis of the trapping region; directing a beam of gas along the first axis and applying an electric potential in the direction of the first axis so as to cause separation of the ions based on their ion mobility. An ion trap and a mass spectrometer for performing the methods are also provided.

Owner:THERMO FISHER SCI BREMEN

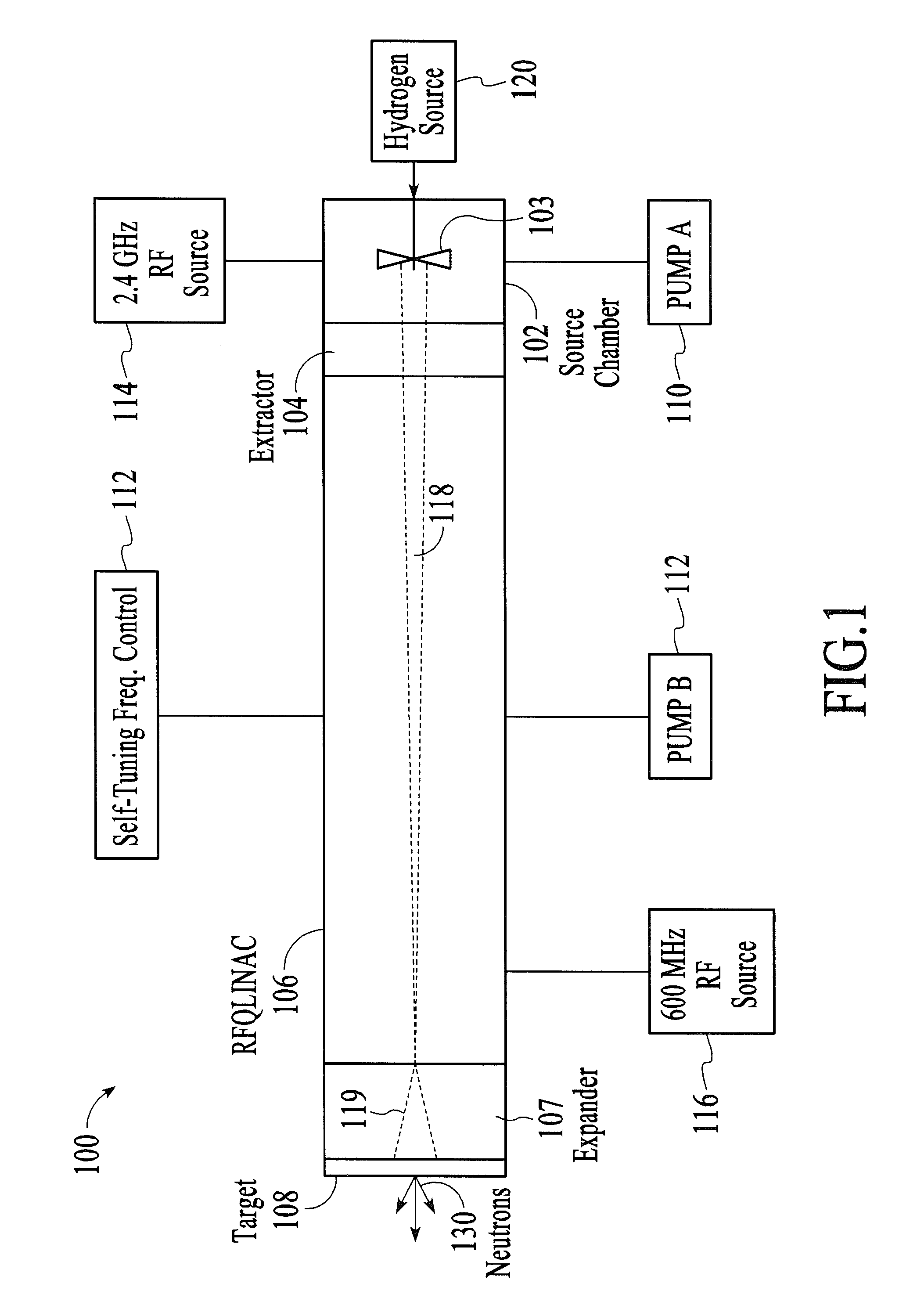

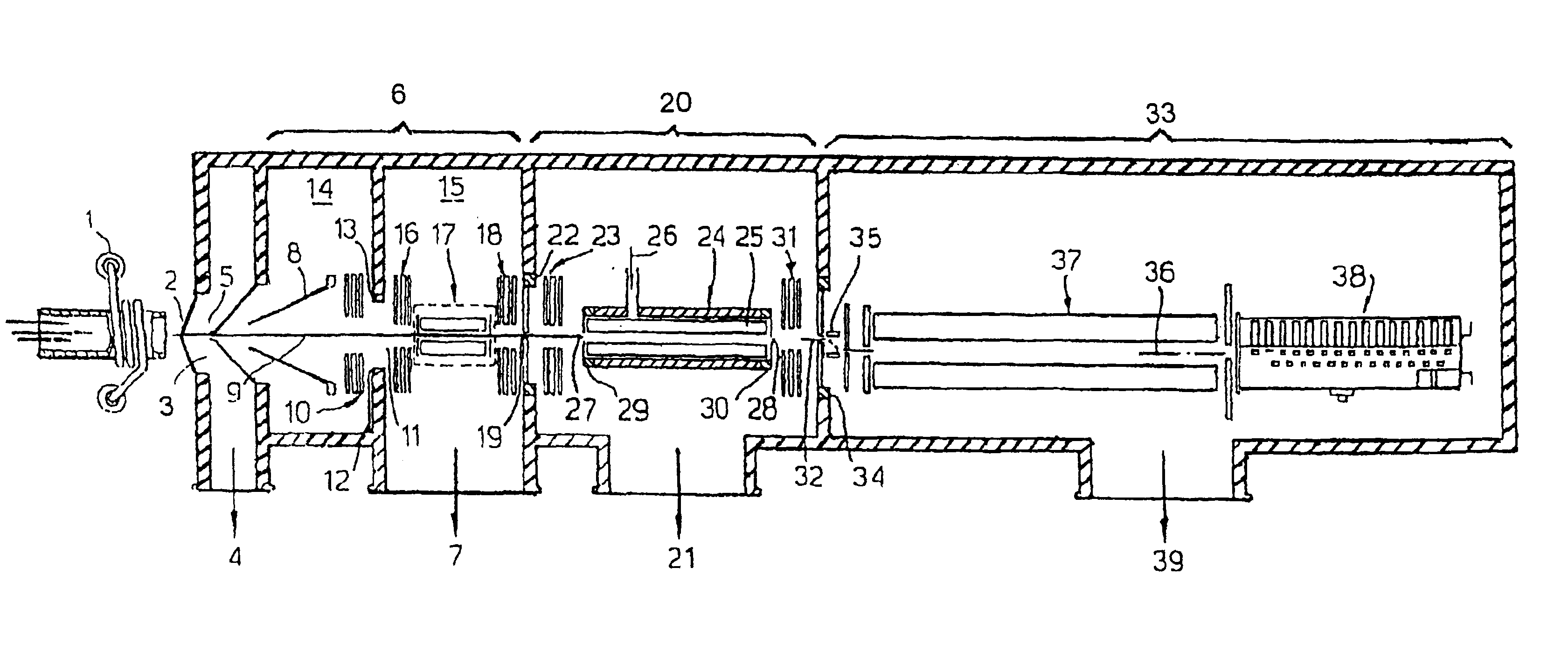

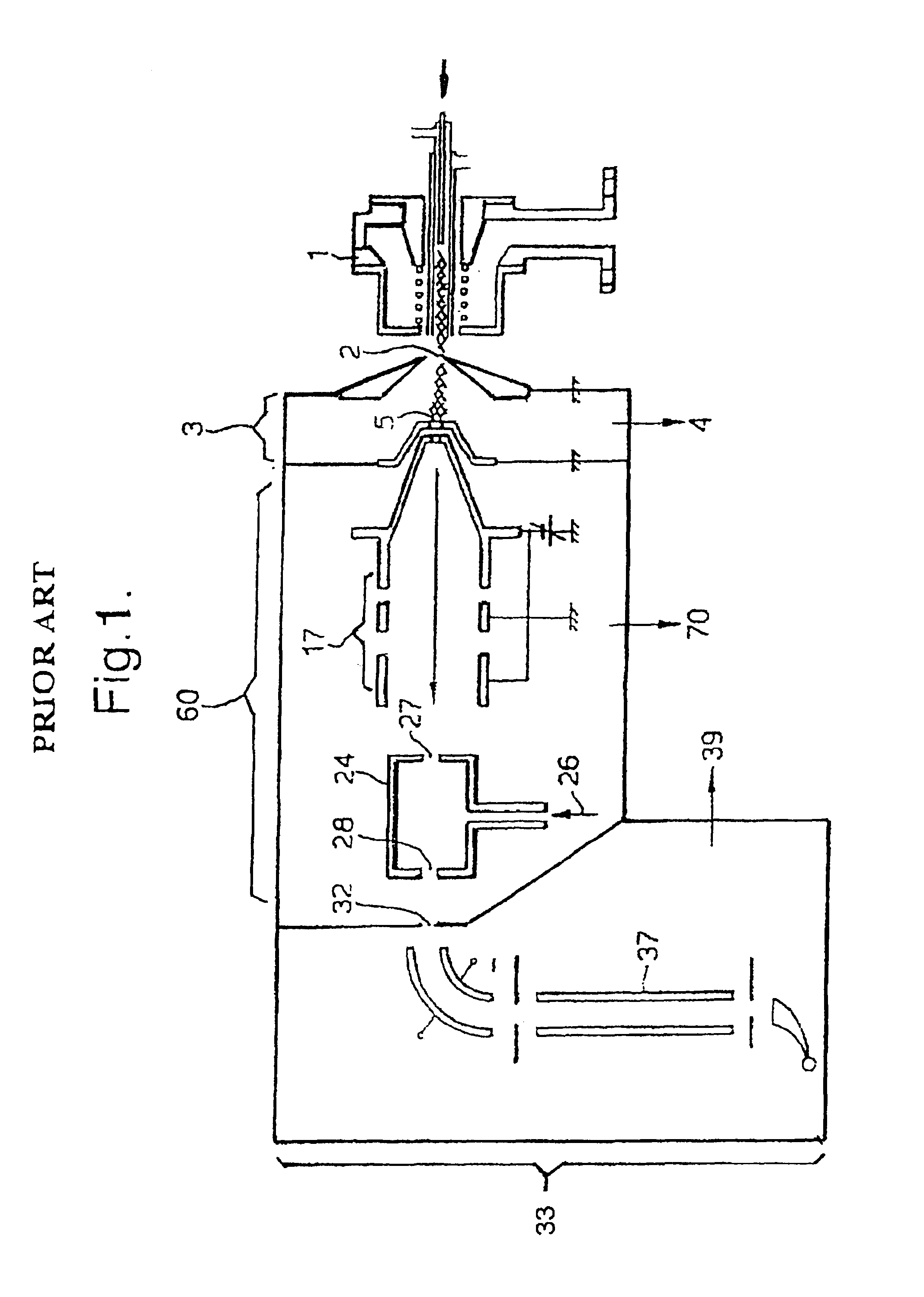

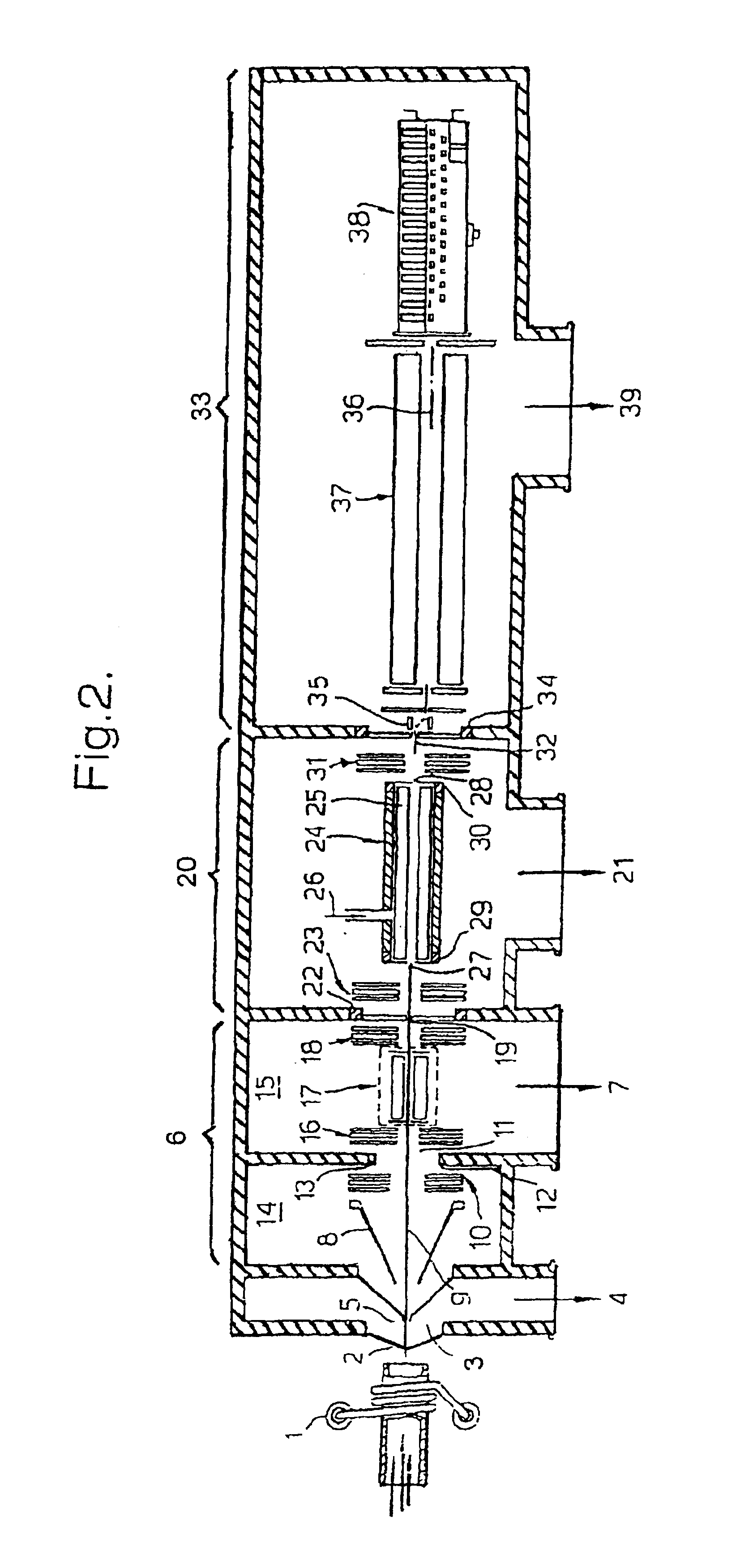

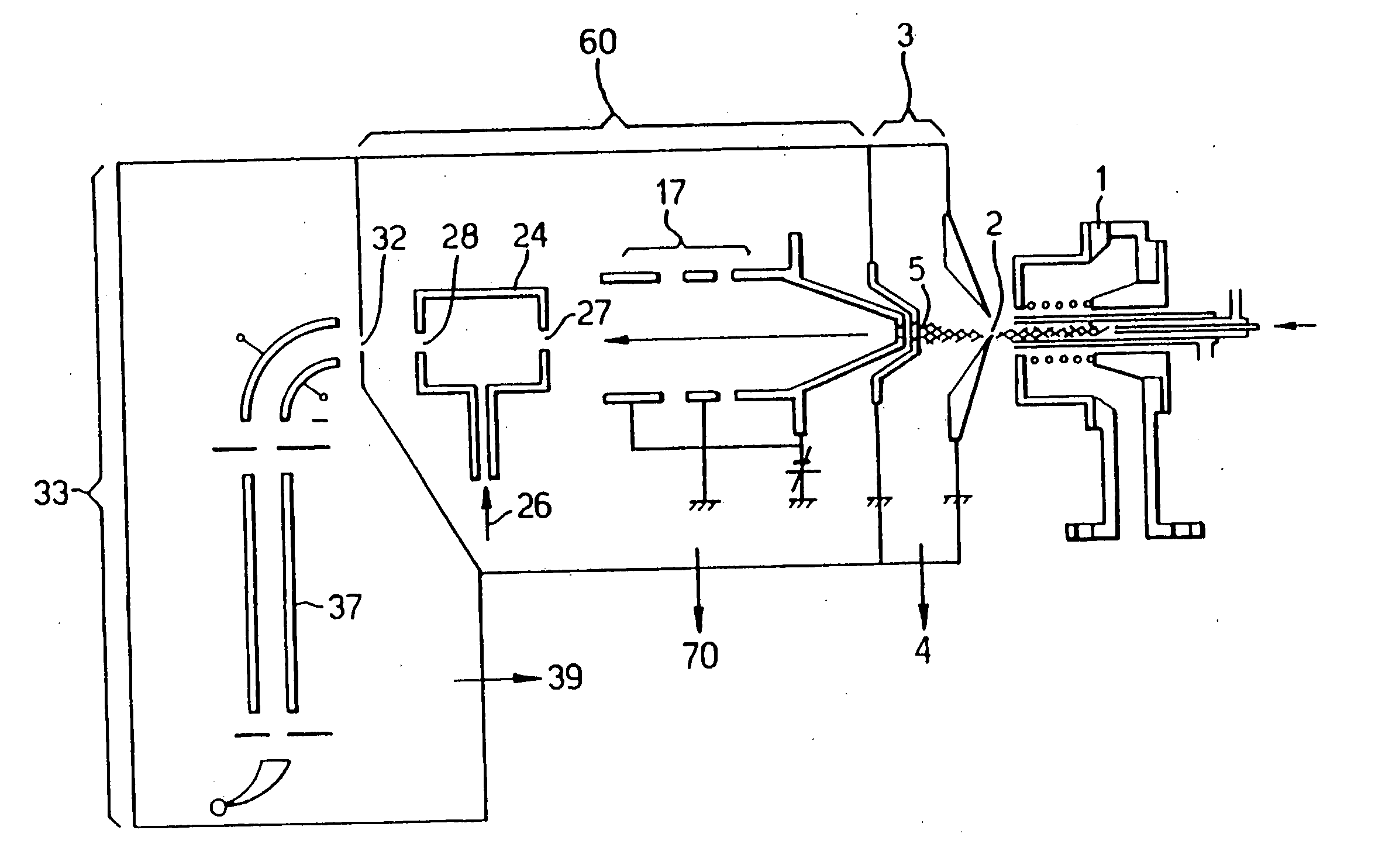

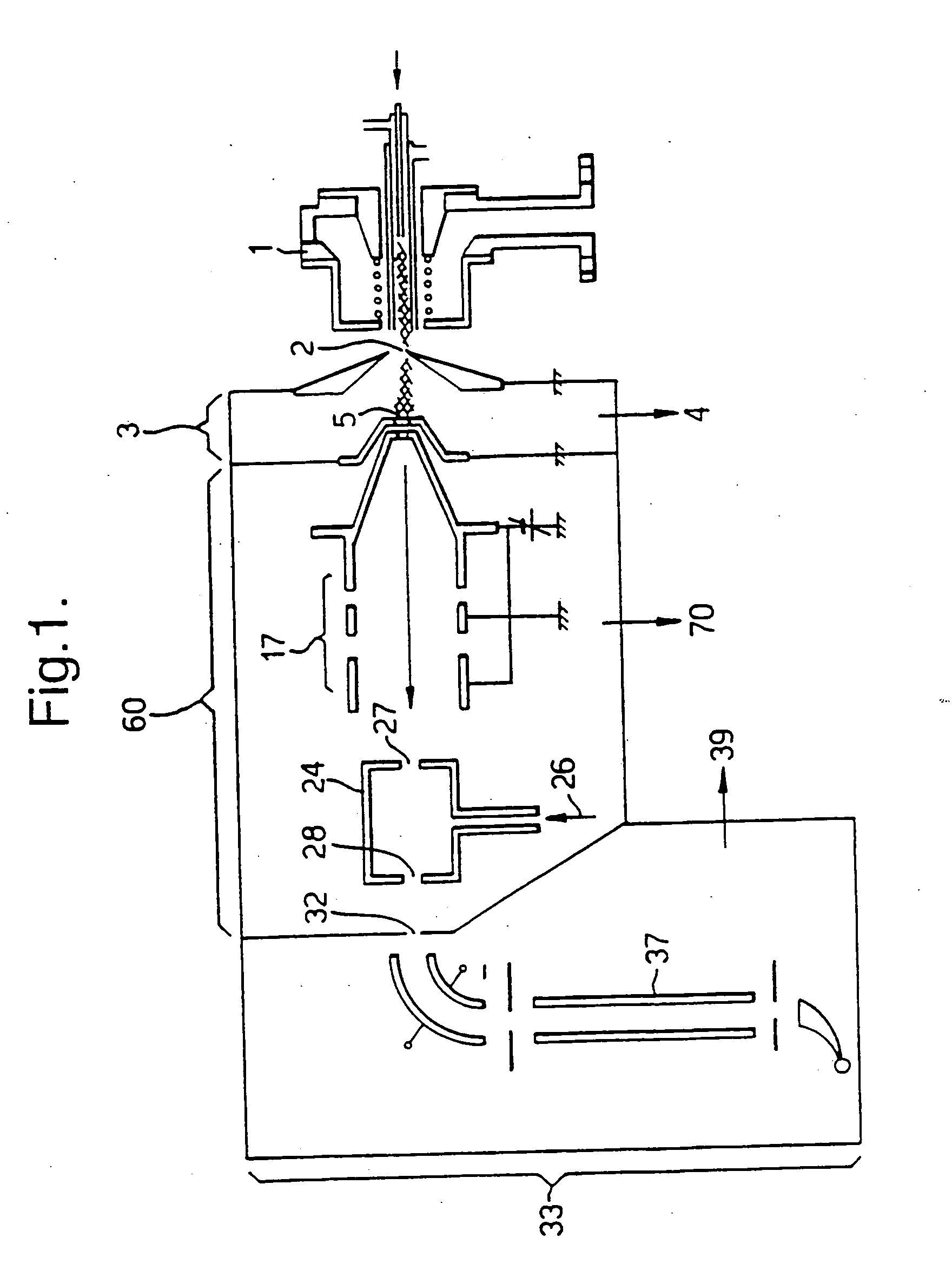

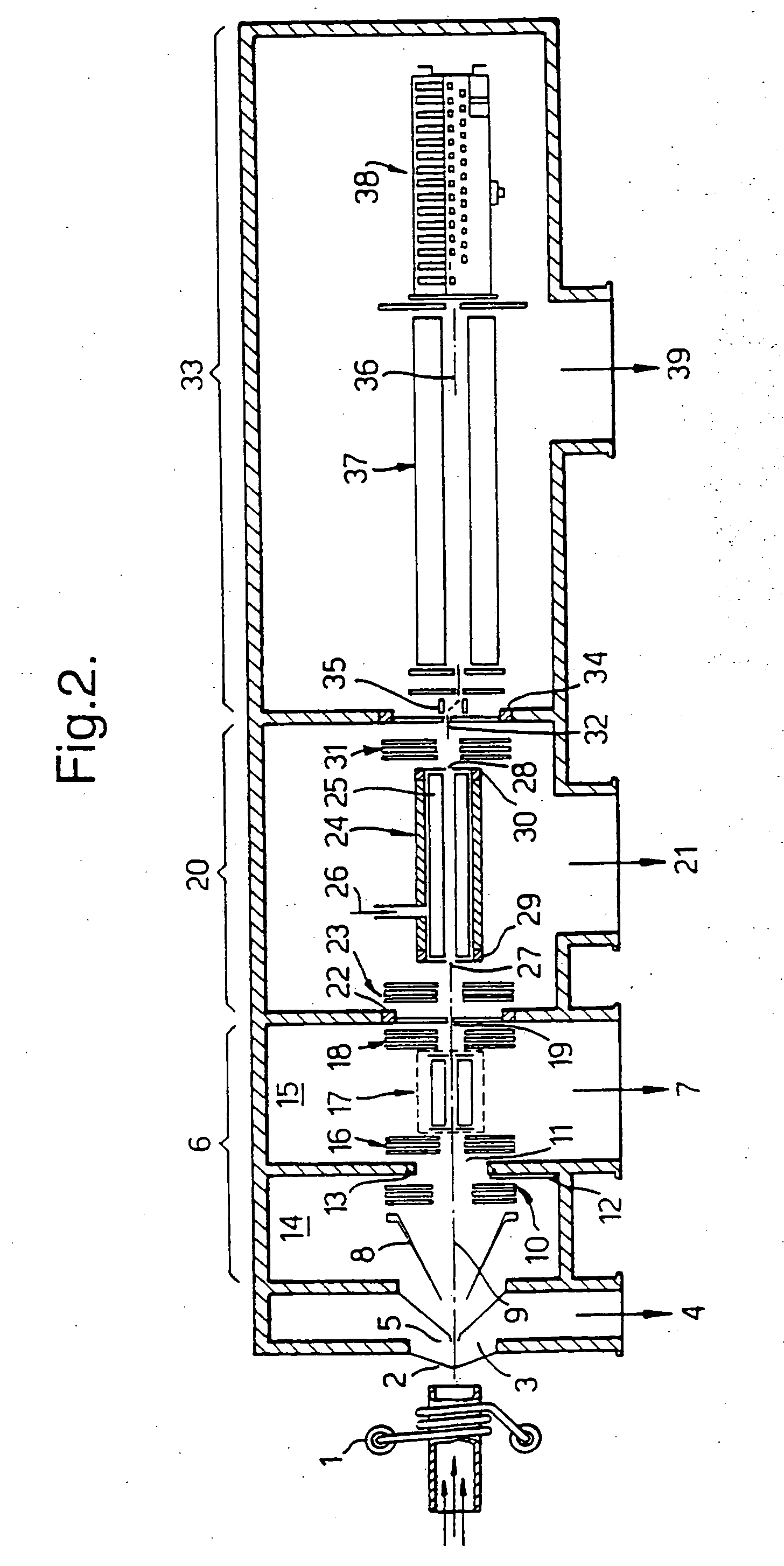

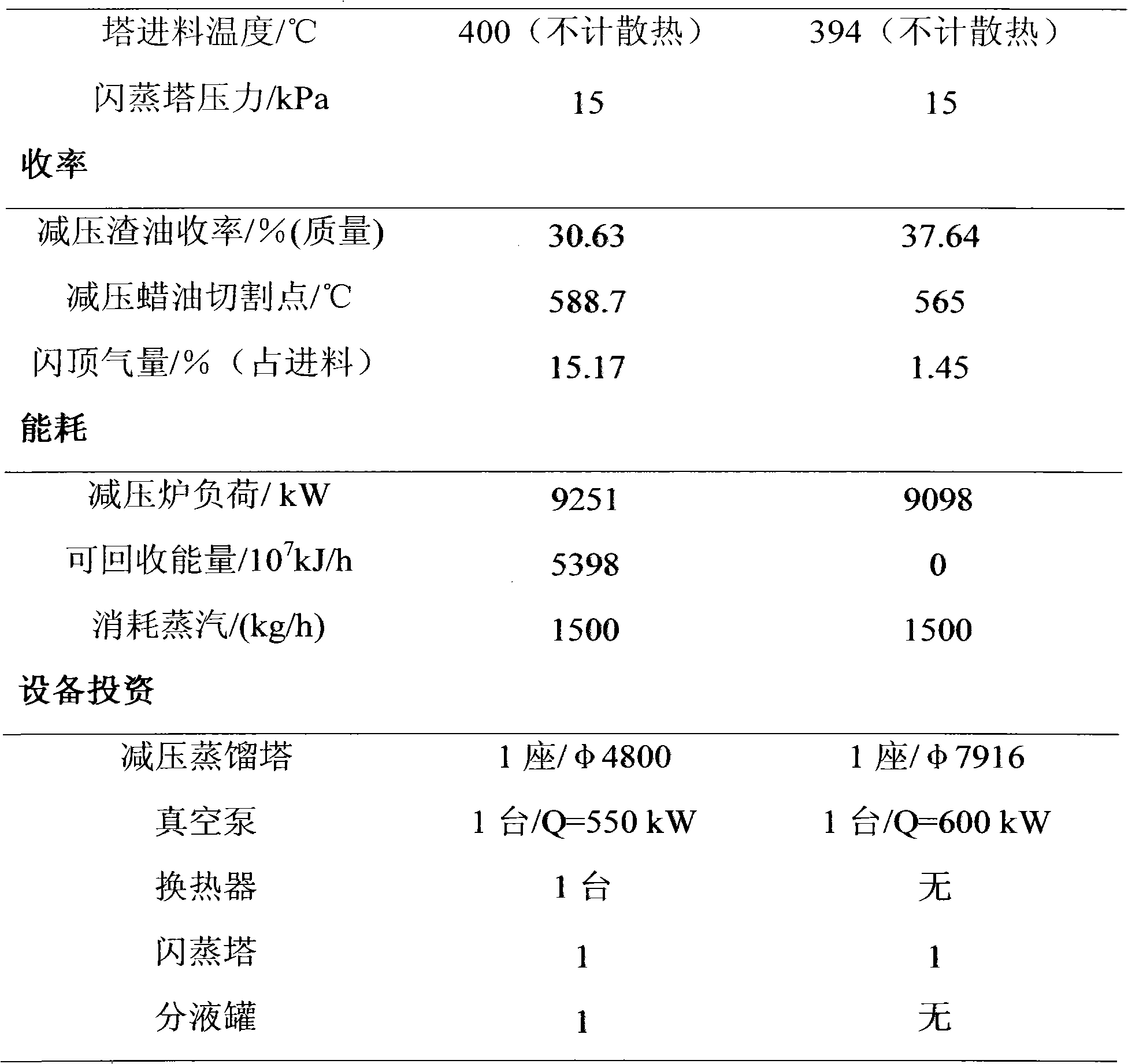

Means for removing unwanted ions from an ion transport system and mass spectrometer

InactiveUS7202470B1Reduce gas loadSufficient transmissionStability-of-path spectrometersSamples introduction/extractionTransport systemIon beam

The present invention relates to inductively coupled plasma mass spectrometry (ICPMS) in which a collision cell is employed to selectively remove unwanted artefact ions from an ion beam by causing them to interact with a reagent gas. The present invention provides a first evacuated chamber (6) at high vacuum located between an expansion chamber (3) and a second evacuated chamber (20) containing the collision cell (24). The first evacuated chamber (6) includes a first ion optical device (17). The collision cell (24) contains a second ion optical device (25). The provision of the first evacuated chamber (5) reduces the gas load on the collision cell (24), by minimising the residual pressure within the collision cell (24) that is attributable to the gas load from the plasma source (1). This serves to minimise the formation, or re-formation, of unwanted artefact ions in the collision cell (24).

Owner:THERMO FISHER SCI BREMEN +1

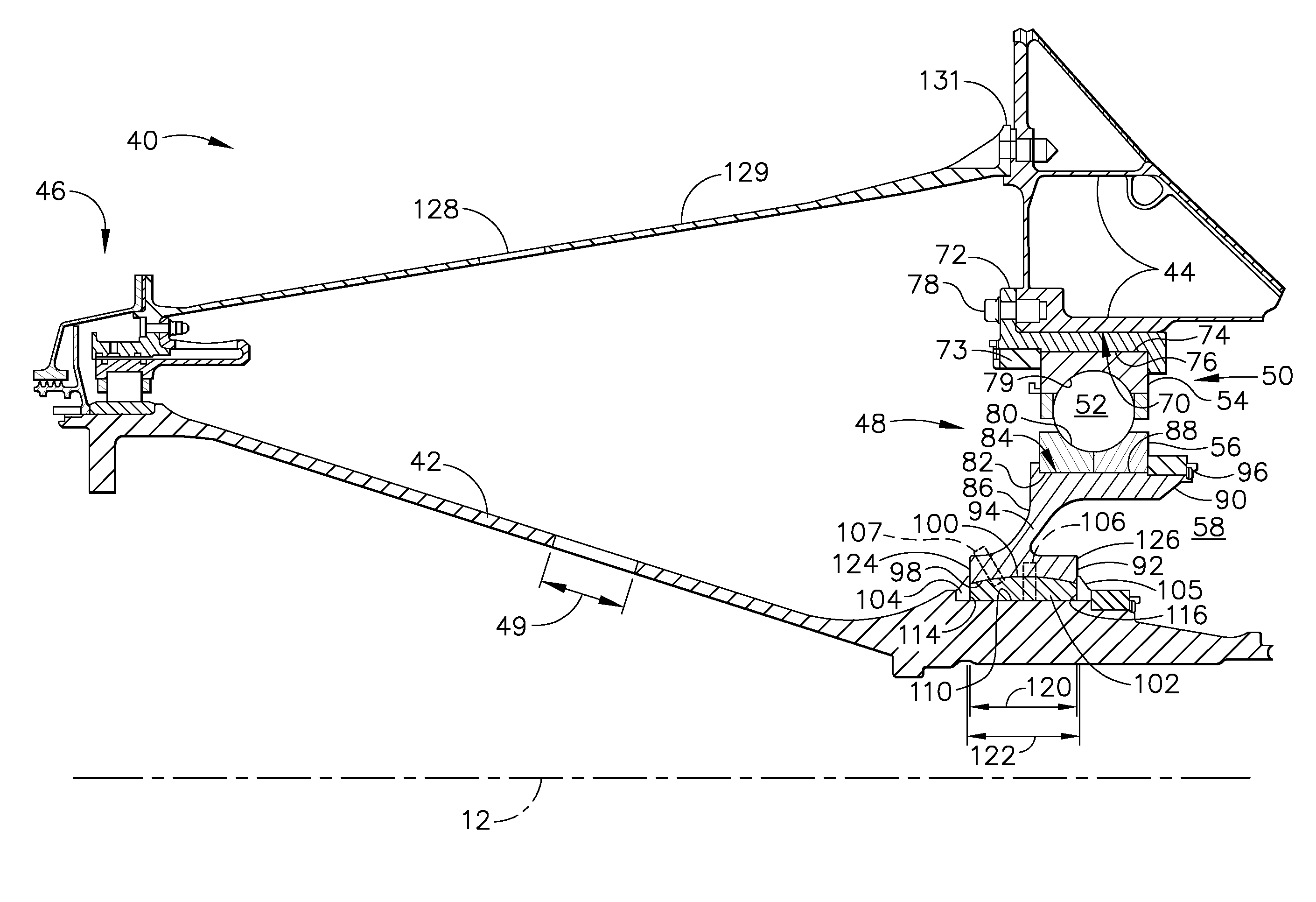

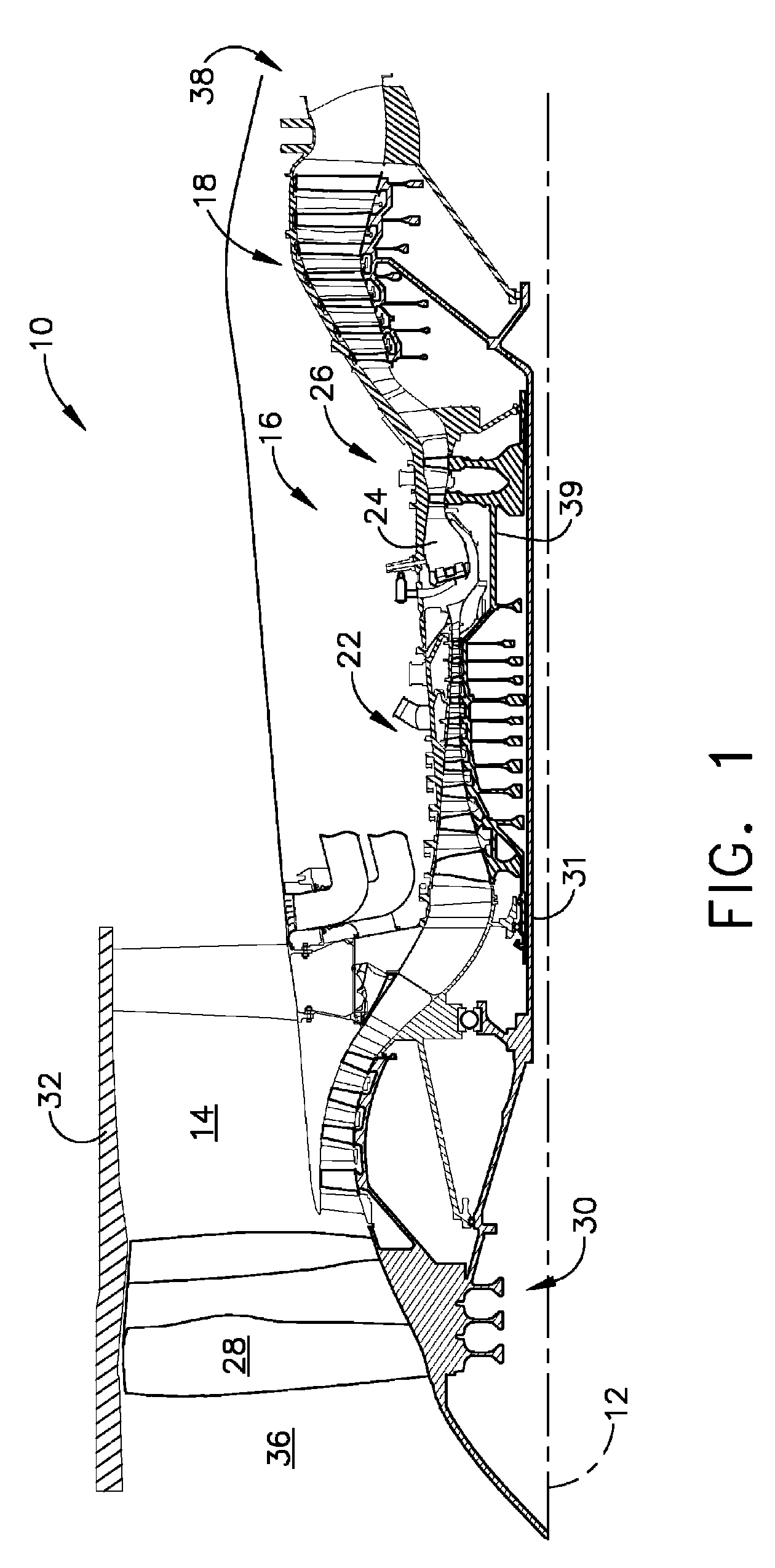

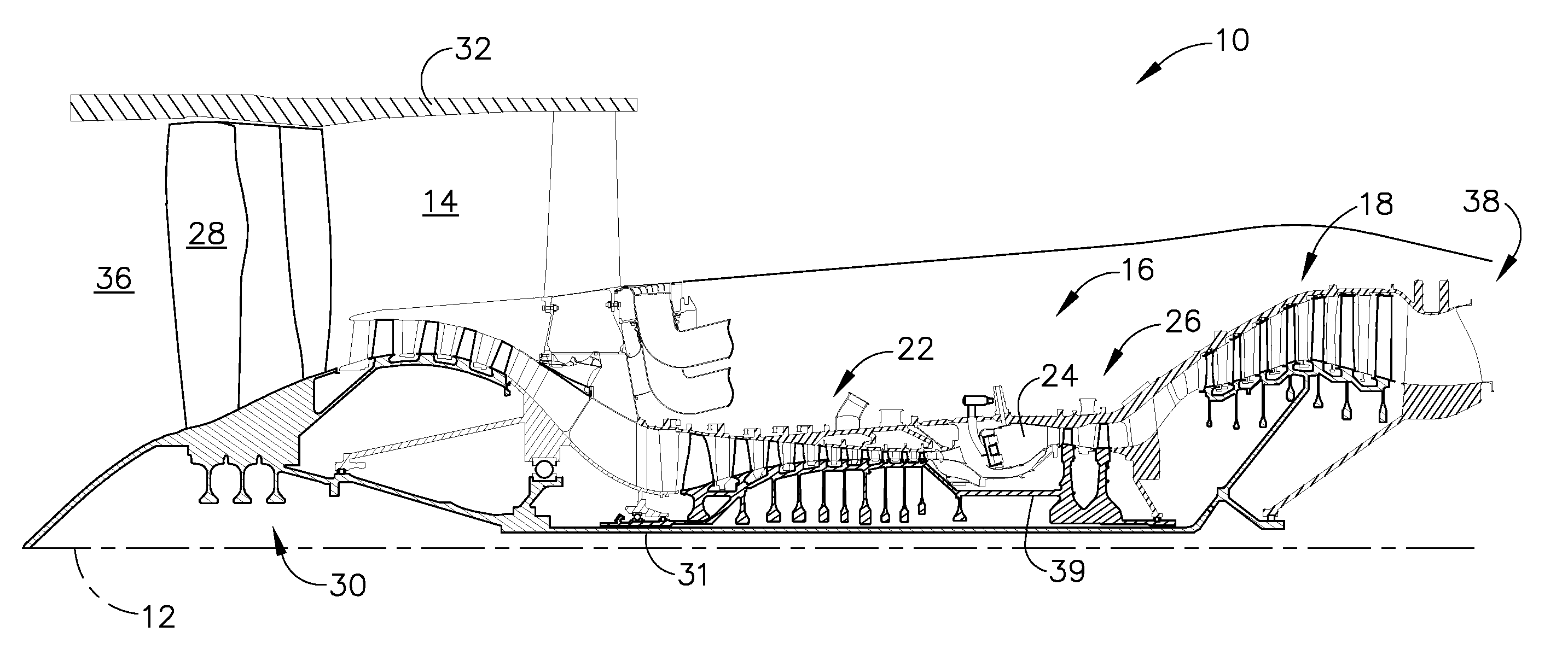

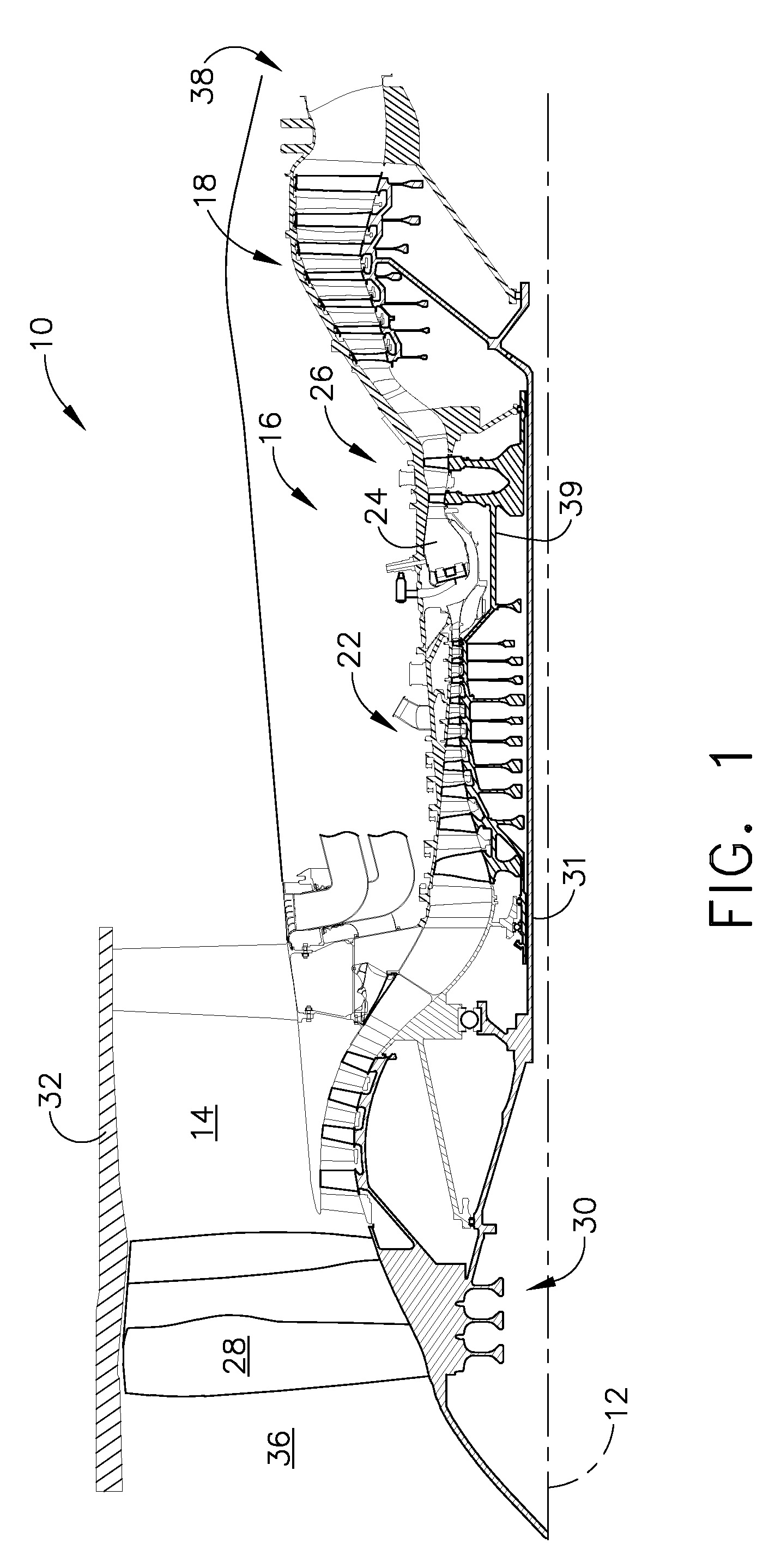

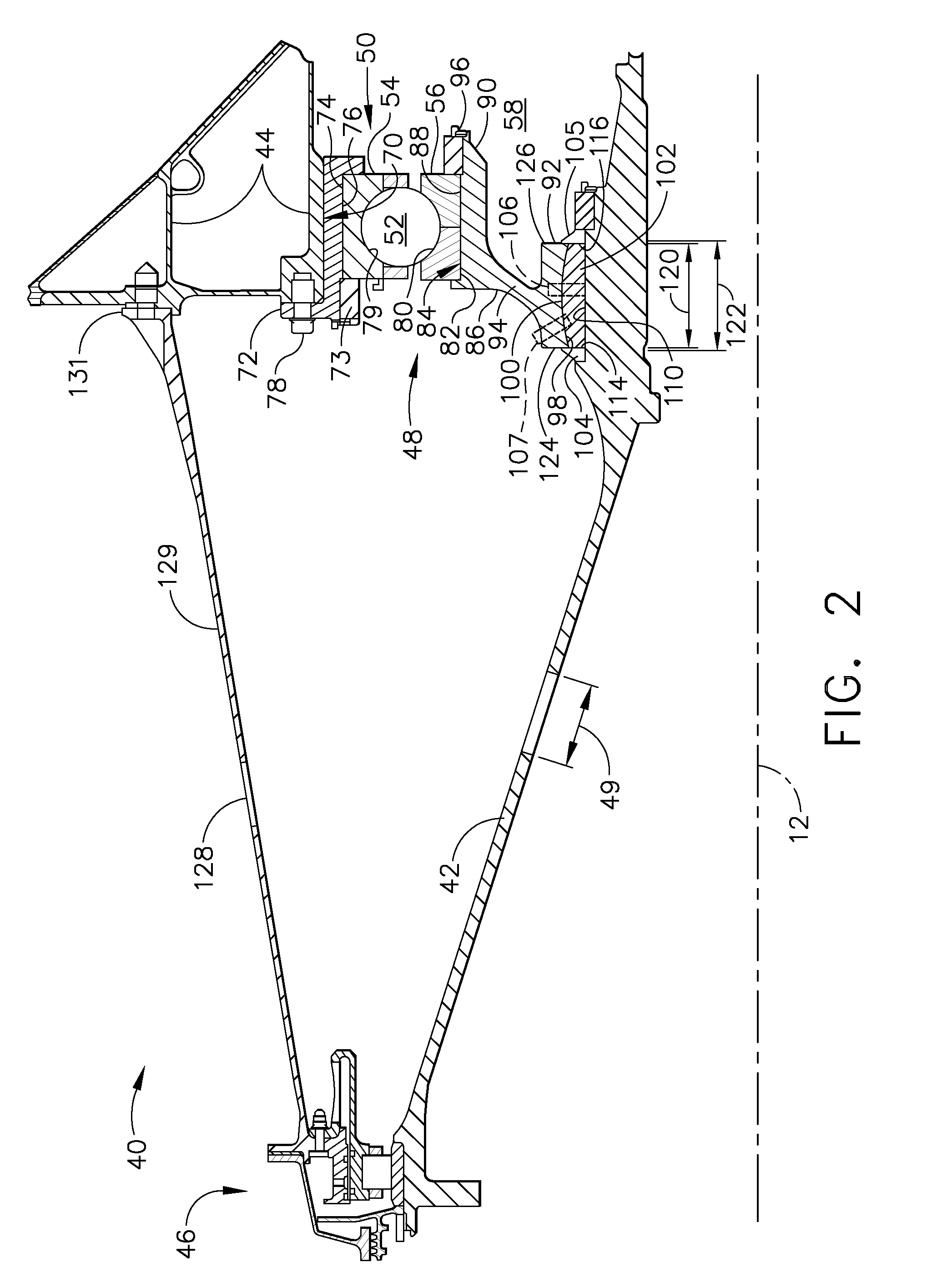

Method and apparatus for supporting rotor assemblies during unbalances

A method and apparatus for reducing dynamic loading of a gas turbine engine is provided. The gas turbine engine includes a rotor shaft assembly including a rotor shaft, a bearing assembly, a mounting race, and a support frame, the mounting race including a spherical surface. The method includes supporting the rotor shaft on the gas turbine engine support frame with the bearing assembly, the rotor shaft including a yield portion configured to permit bending of the rotor shaft during an imbalance operation.

Owner:GENERAL ELECTRIC CO

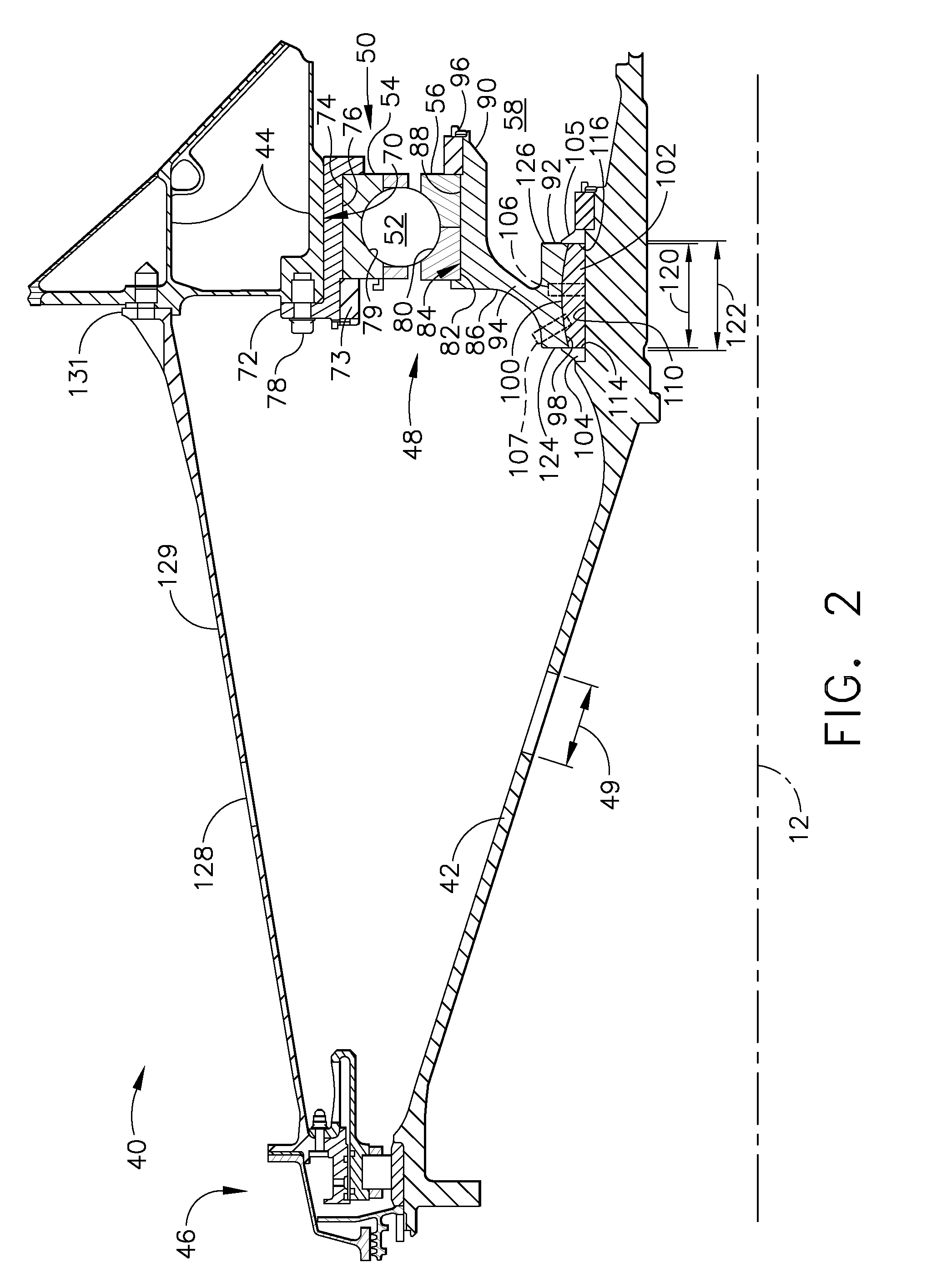

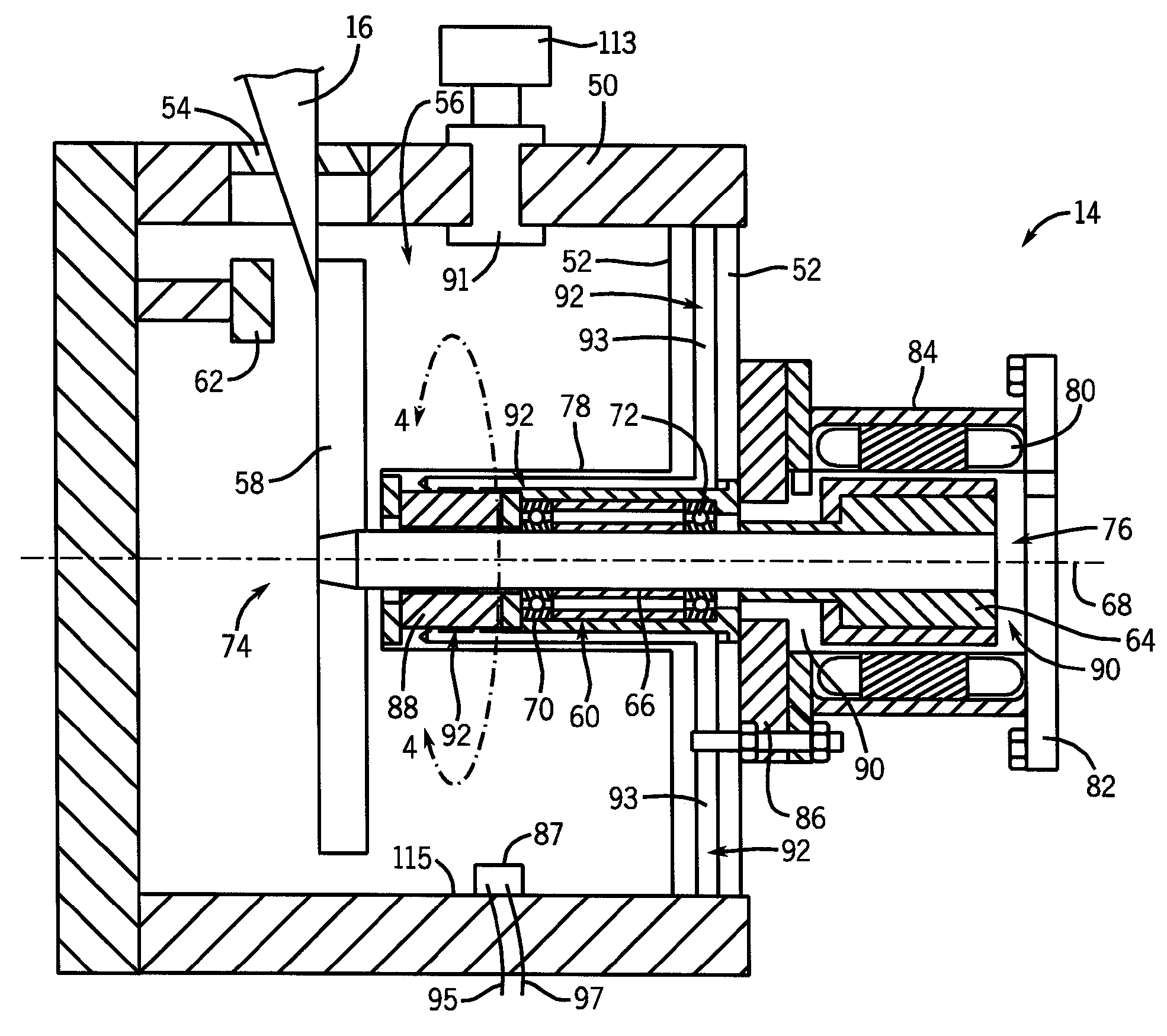

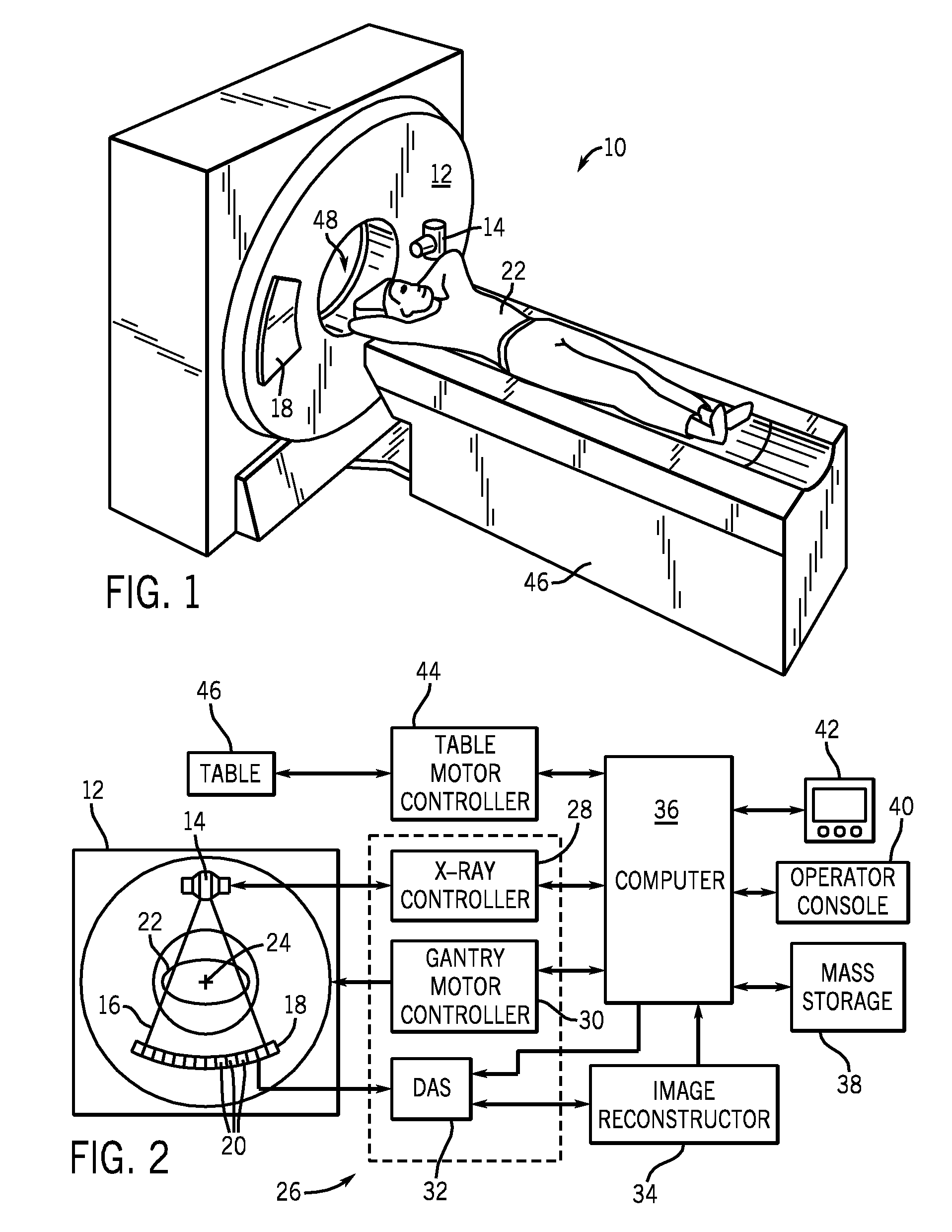

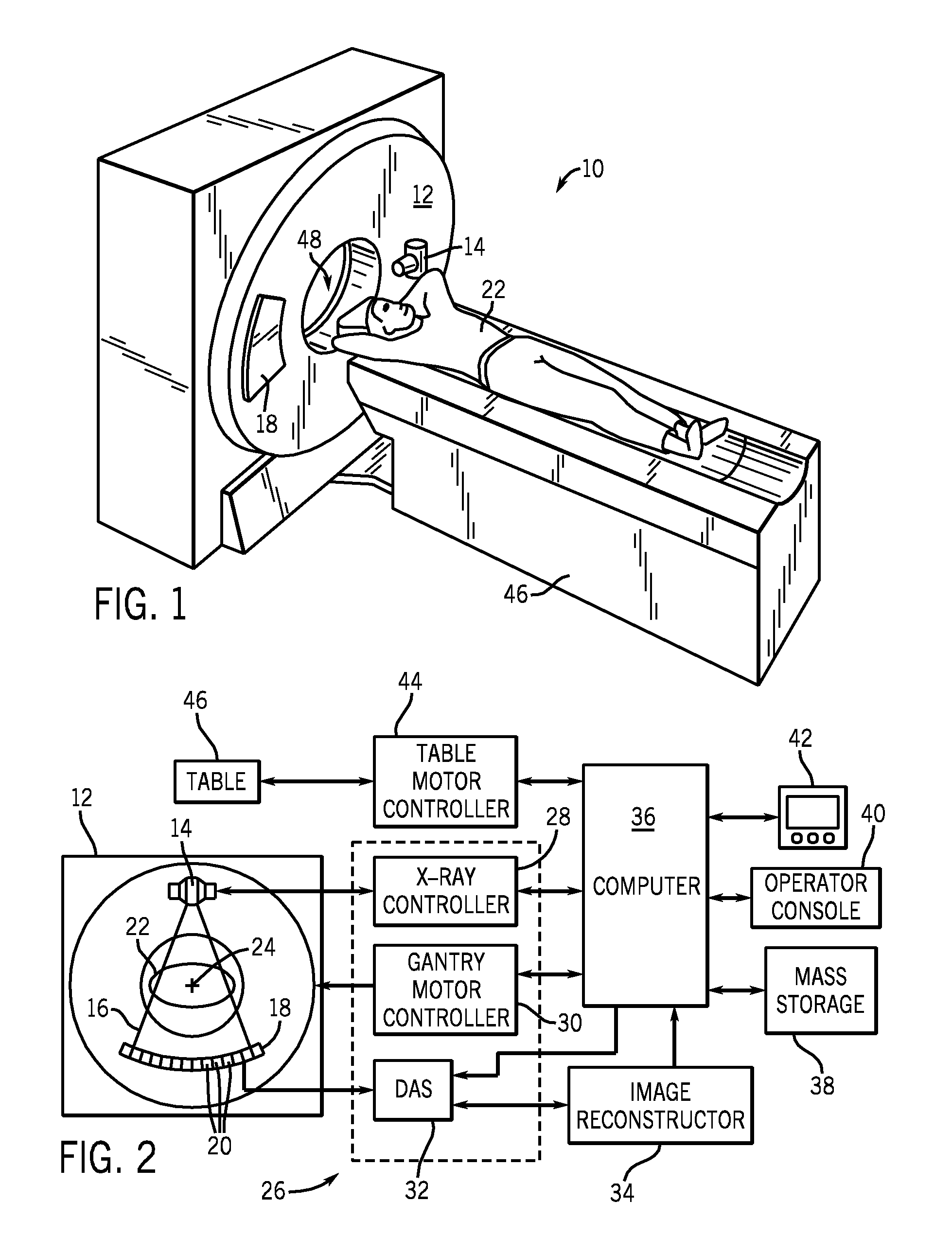

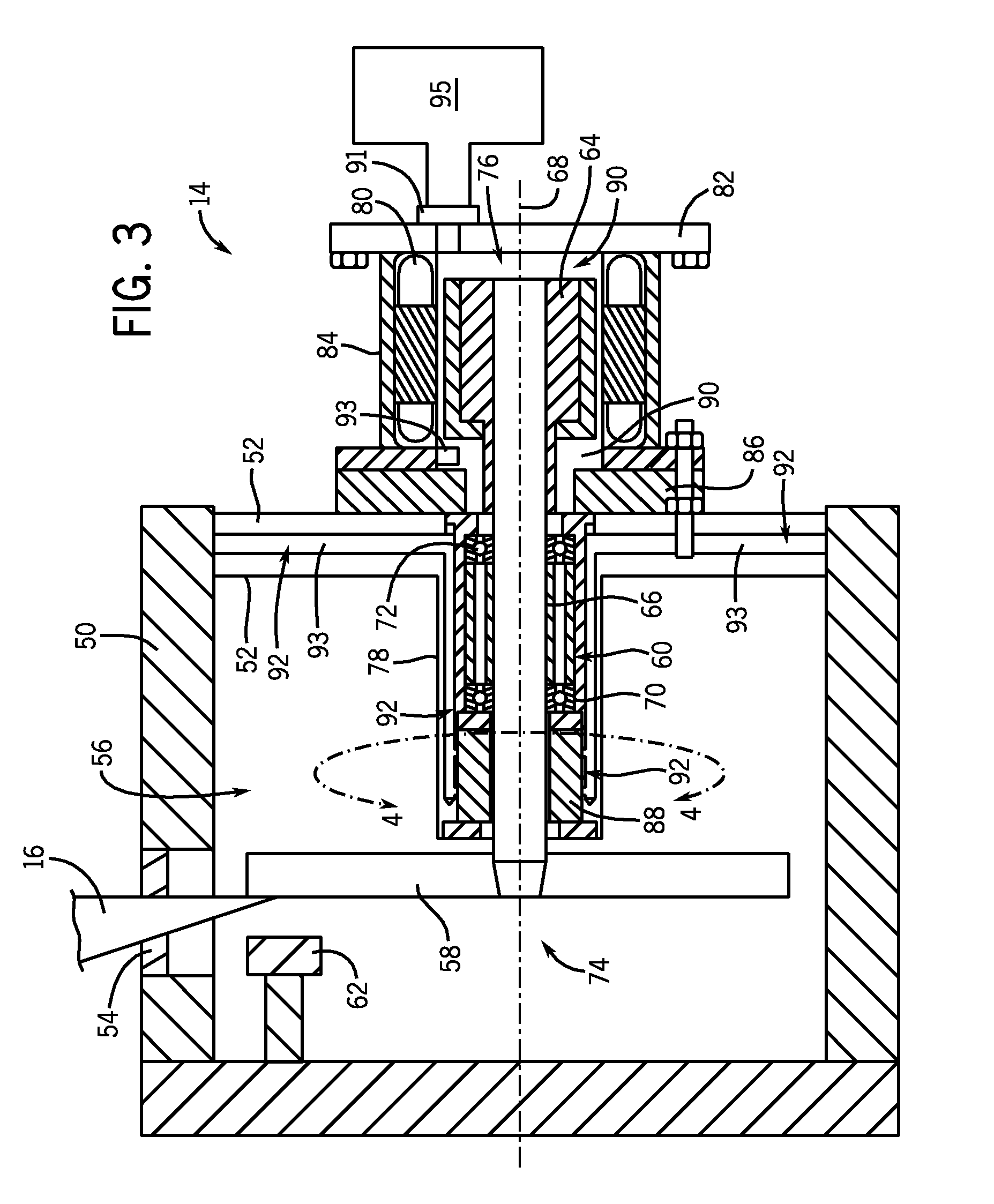

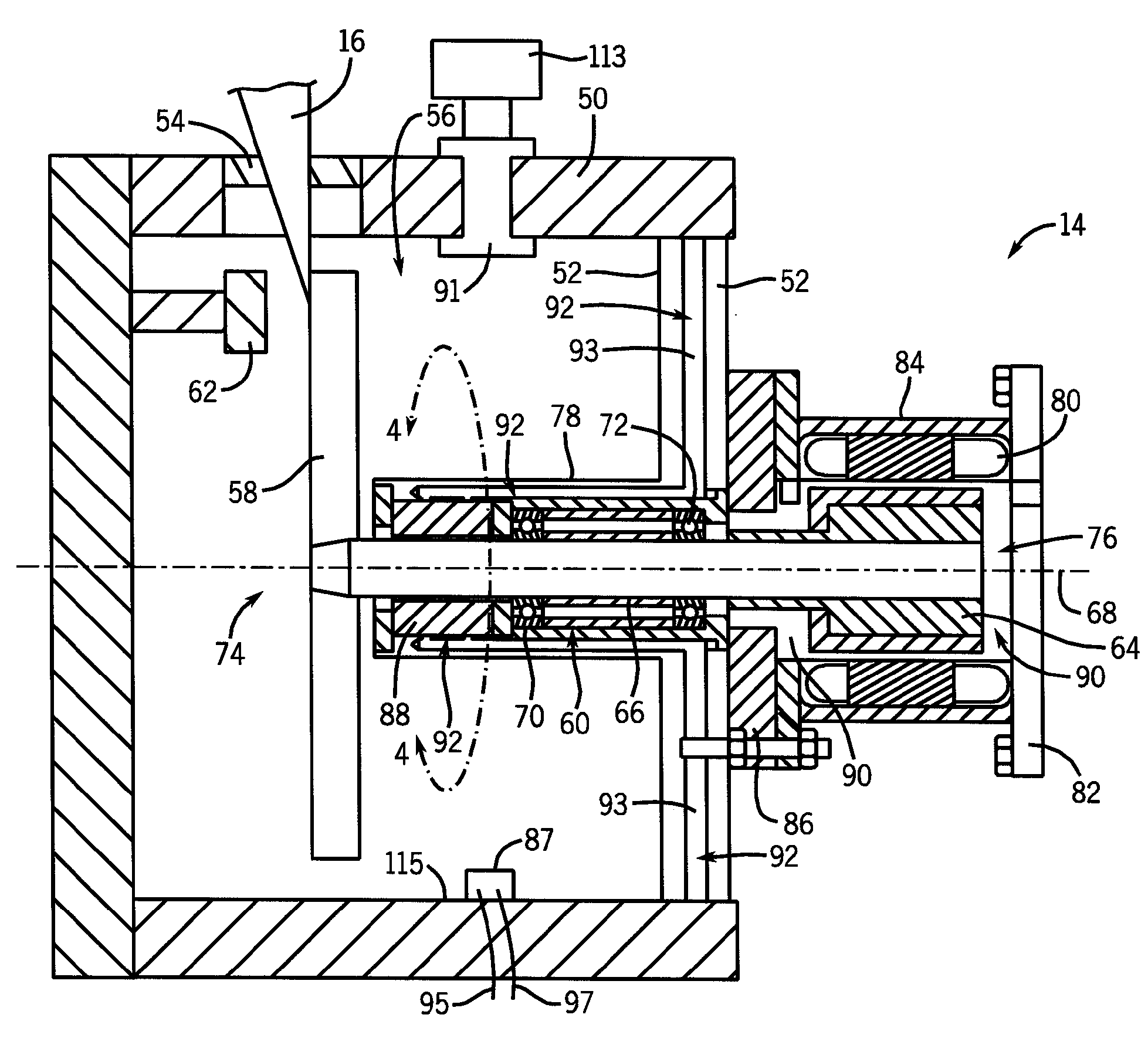

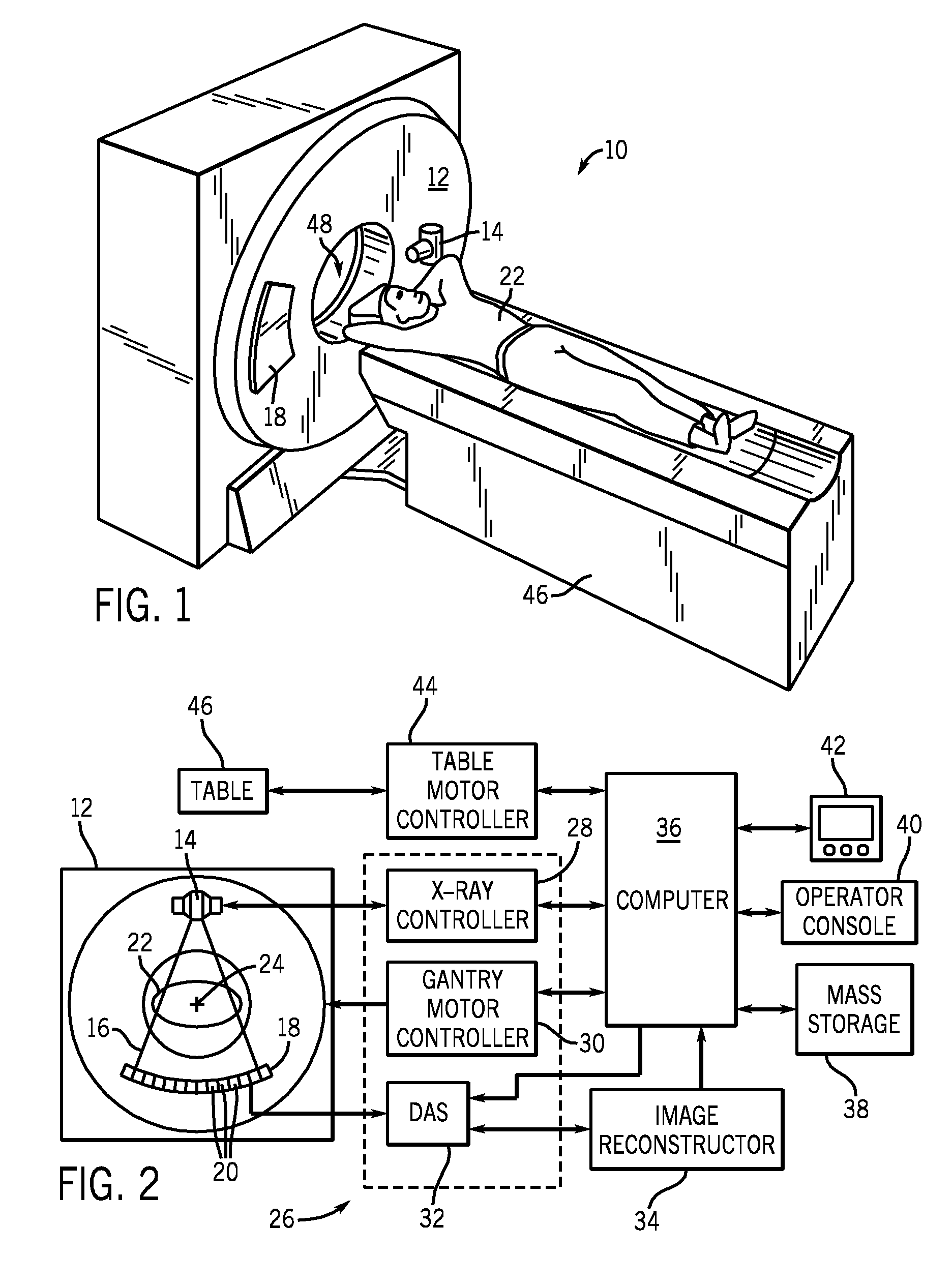

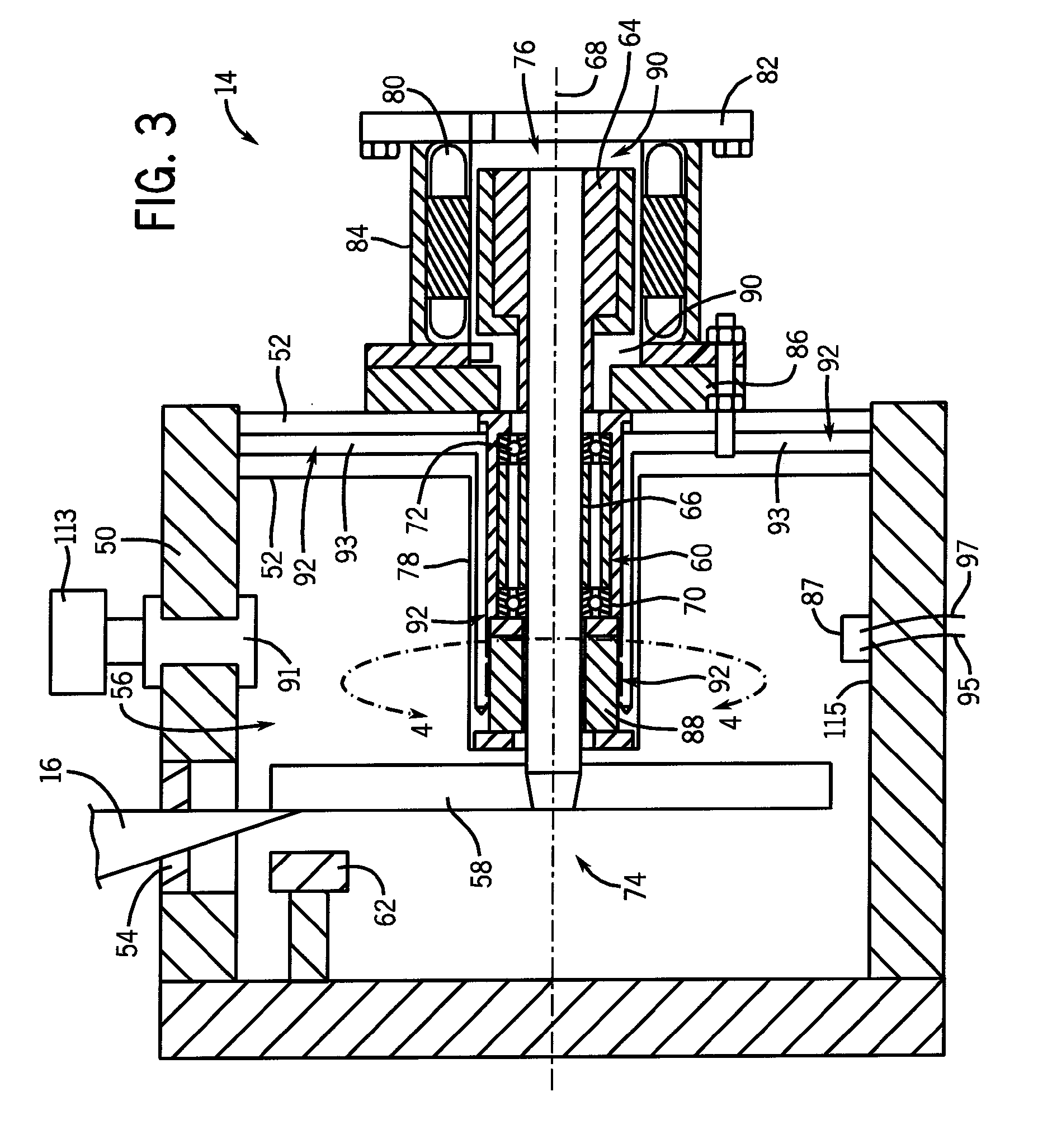

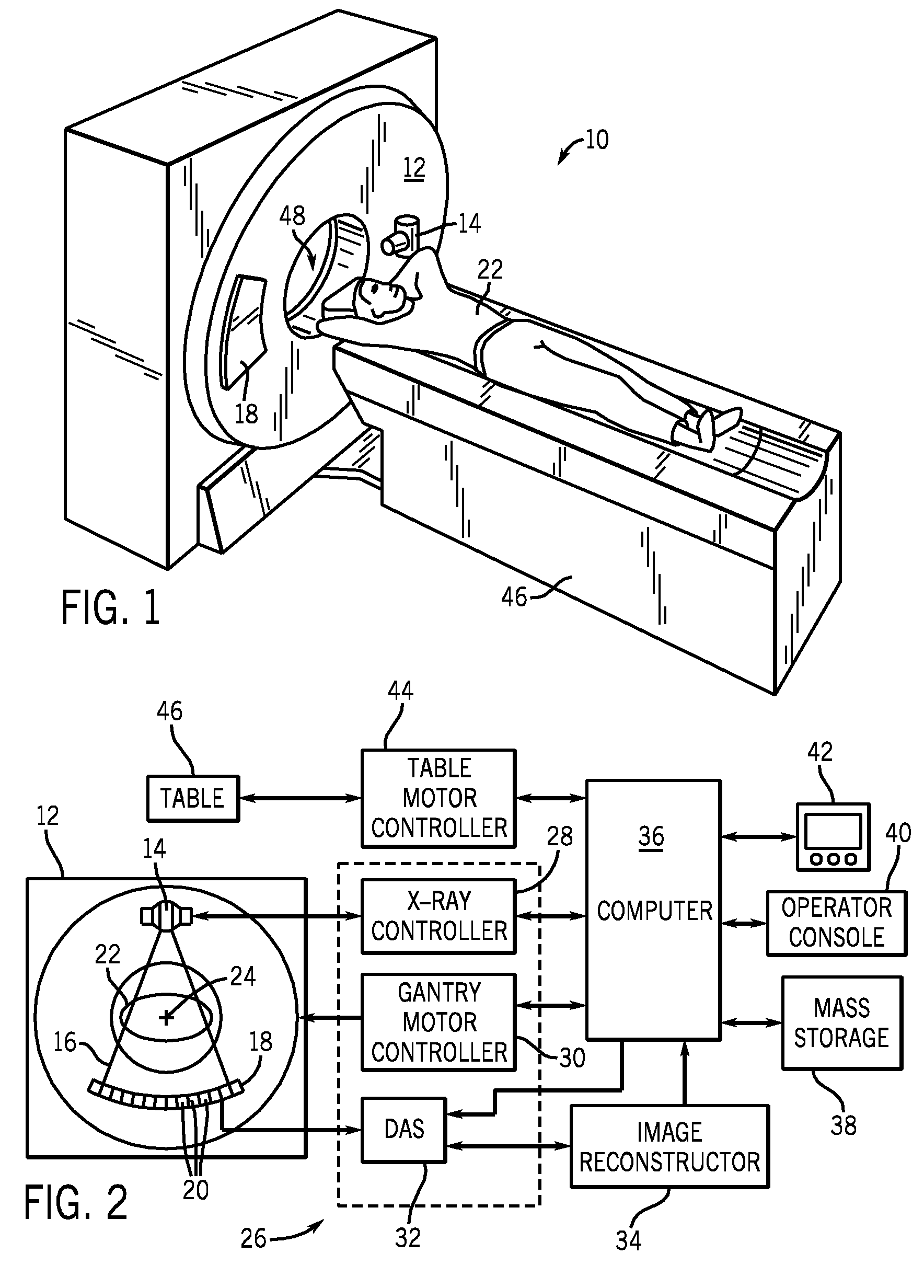

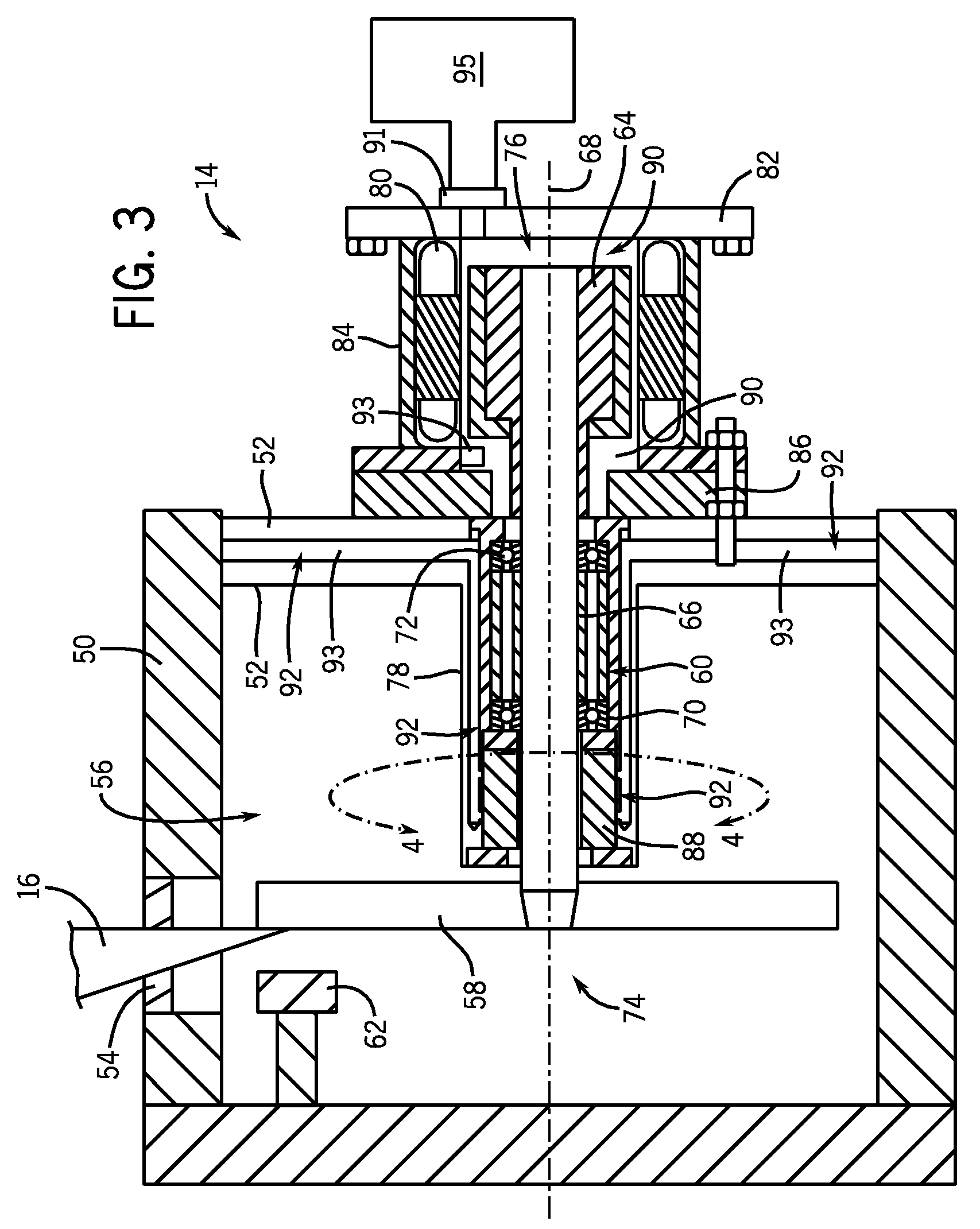

Pumping schemes for X-ray tubes with ferrofluid seals

A system for mitigating a gas load imposed upon a high vacuum chamber, thereby reducing the overall pressure, includes a device mounted onto a rotating gantry. The device has a first chamber enclosing a high vacuum and a first region in which anode bearings are positioned. A rotatable shaft has a first portion extending into the first chamber and a second portion extending into the first region. A ferrofluid seal is positioned about the rotatable shaft and positioned between the first portion and the second portion, the ferrofluid seal fluidically separating the first chamber from the first region. At least one pressure-reducing unit is fluidically connected to the first chamber.

Owner:GENERAL ELECTRIC CO

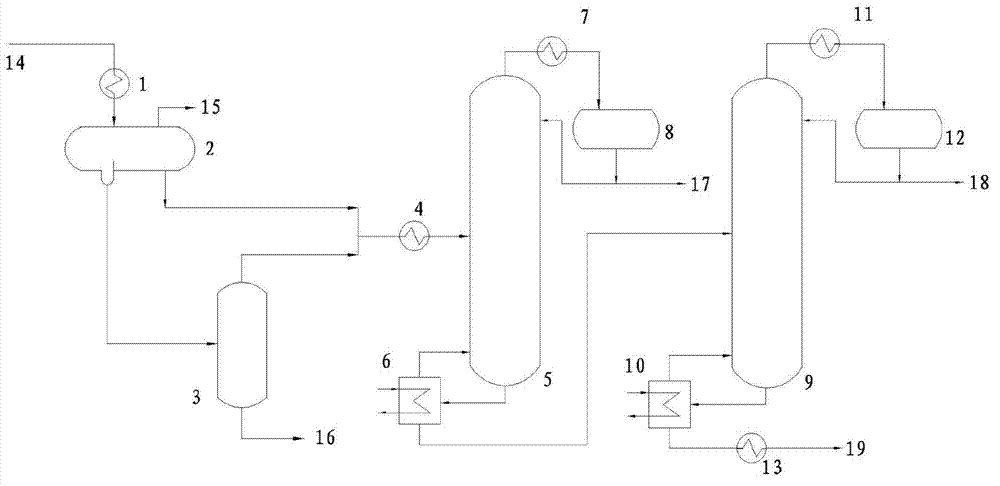

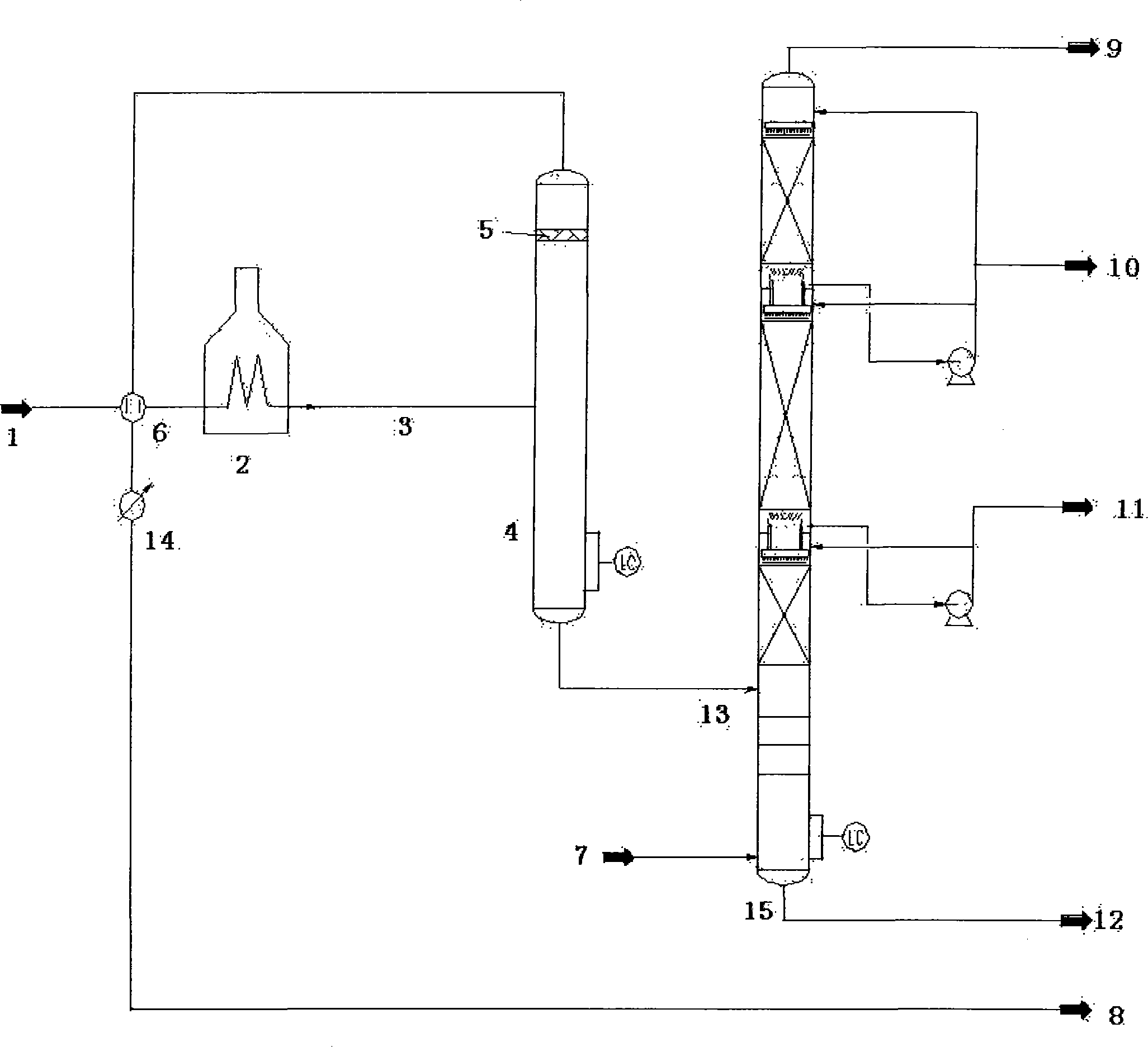

Method for separating benzene/toluene and methanol-alkylated reaction product

InactiveCN102731243AReduce gas loadThe amount of acetic acid decreasedDistillation purification/separationHydrocarbonsBenzeneToluene

The invention discloses a method for separating benzene / toluene and a methanol-alkylated reaction product. The method comprises the steps of: condensing the alkylated reaction product and separating a water phase and an oil phase from the condensed alkylated reaction product by an oil-water separation tank; making the water phase enter an efficient oil-water separator to be subjected to deep separation so as to separate the oil phase and the water phase; making the oil phase separated by the oil-water separator and the efficient oil-water separator enter an equal-diameter benzene / toluene tower to rectify to separate; returning the components on the top of the benzene / toluene tower to a reactor for continuously reacting or discharging out the components as process products from the benzene / toluene tower; making the components on the bottom of the tower continuously enter a dimethylbenzene rectification tower to rectify; and, finally separating the dimethylbenzene product. The process provided by the invention reduces the rectification need of benzene / toluene in the equipment. A separation process of alkylated reaction products that reduces the investment cost of the equipment is provided. The rectification efficiency and the recovery rate of the products are enhanced.

Owner:NINGXIA BAOTA PETROCHEM GROUP

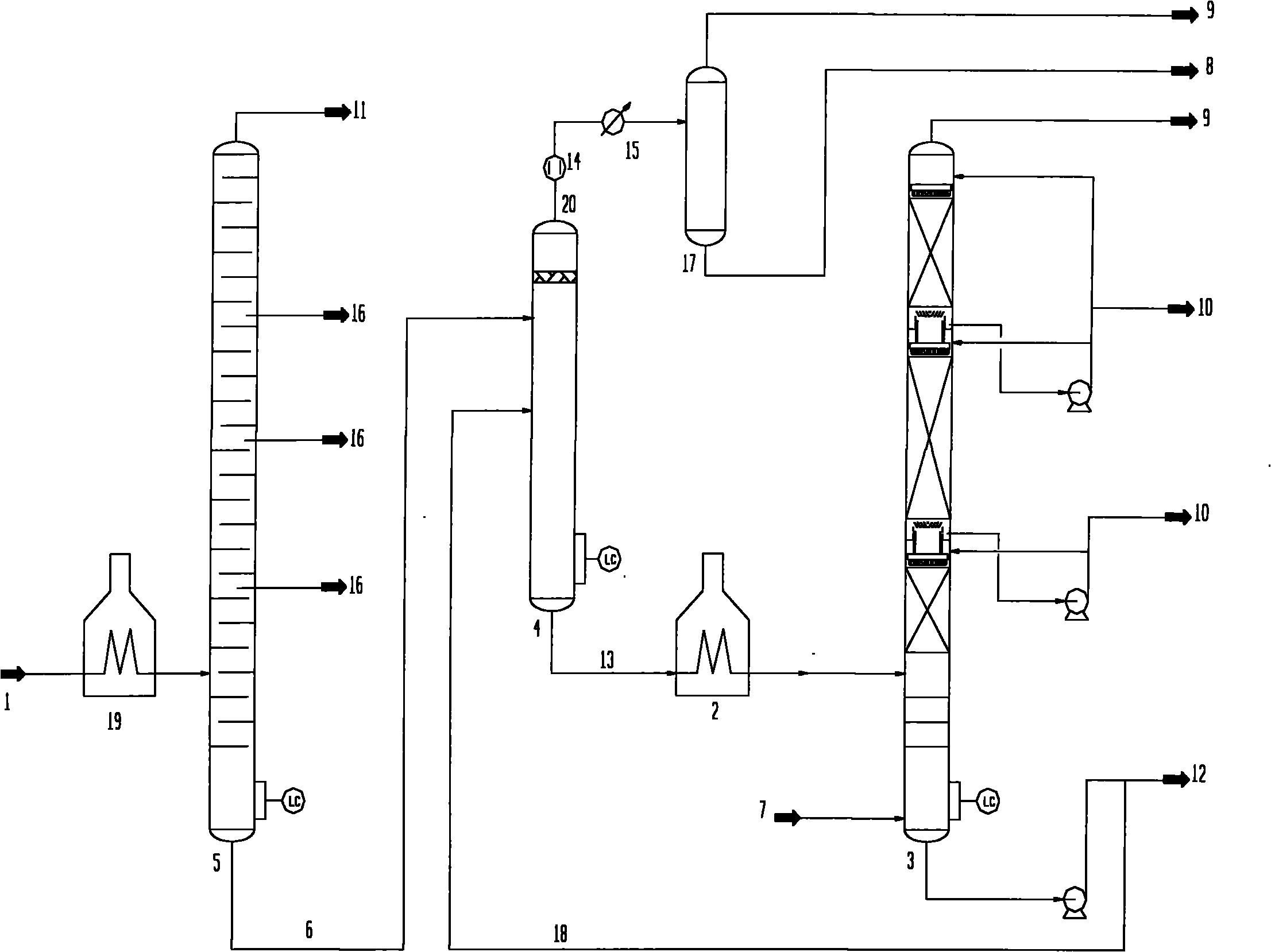

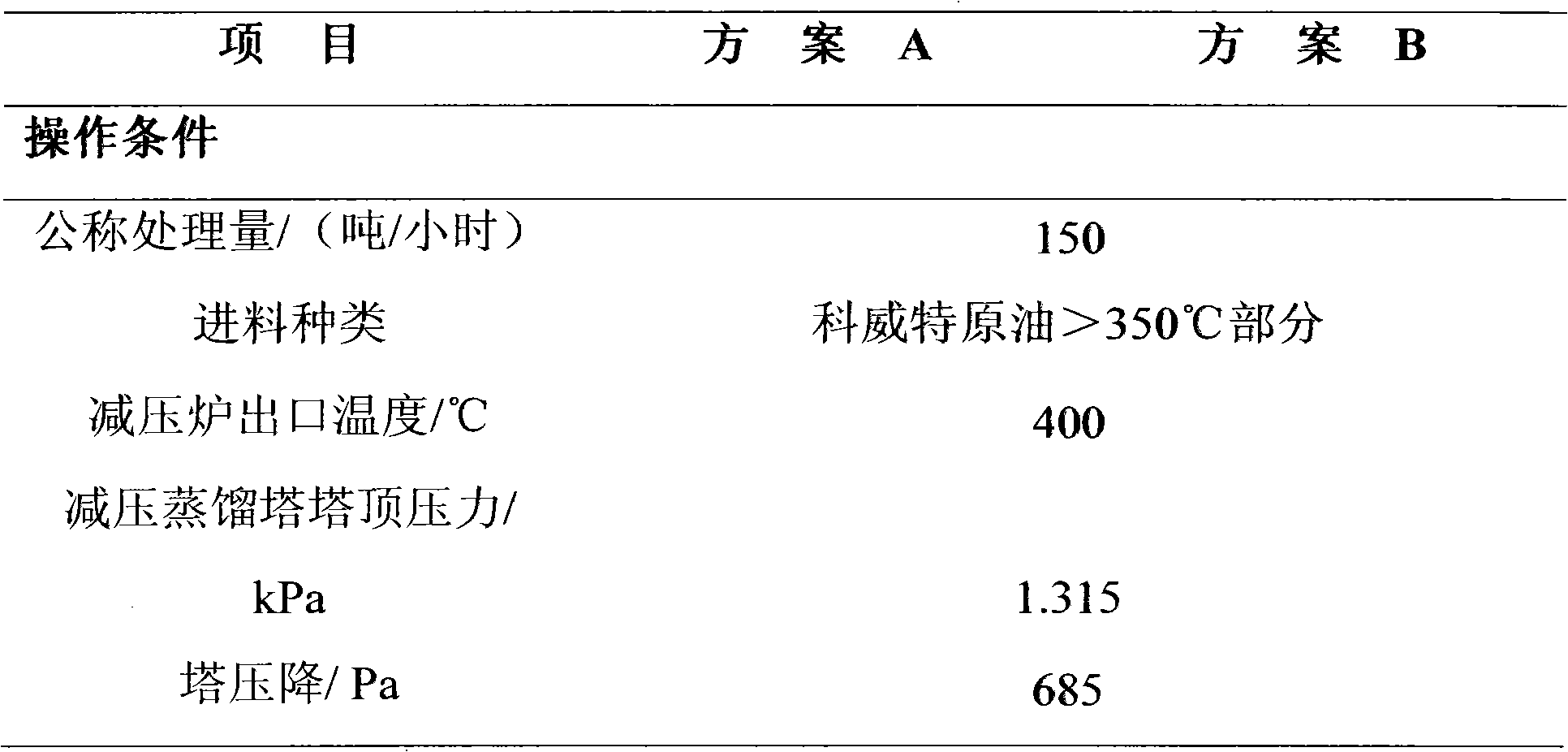

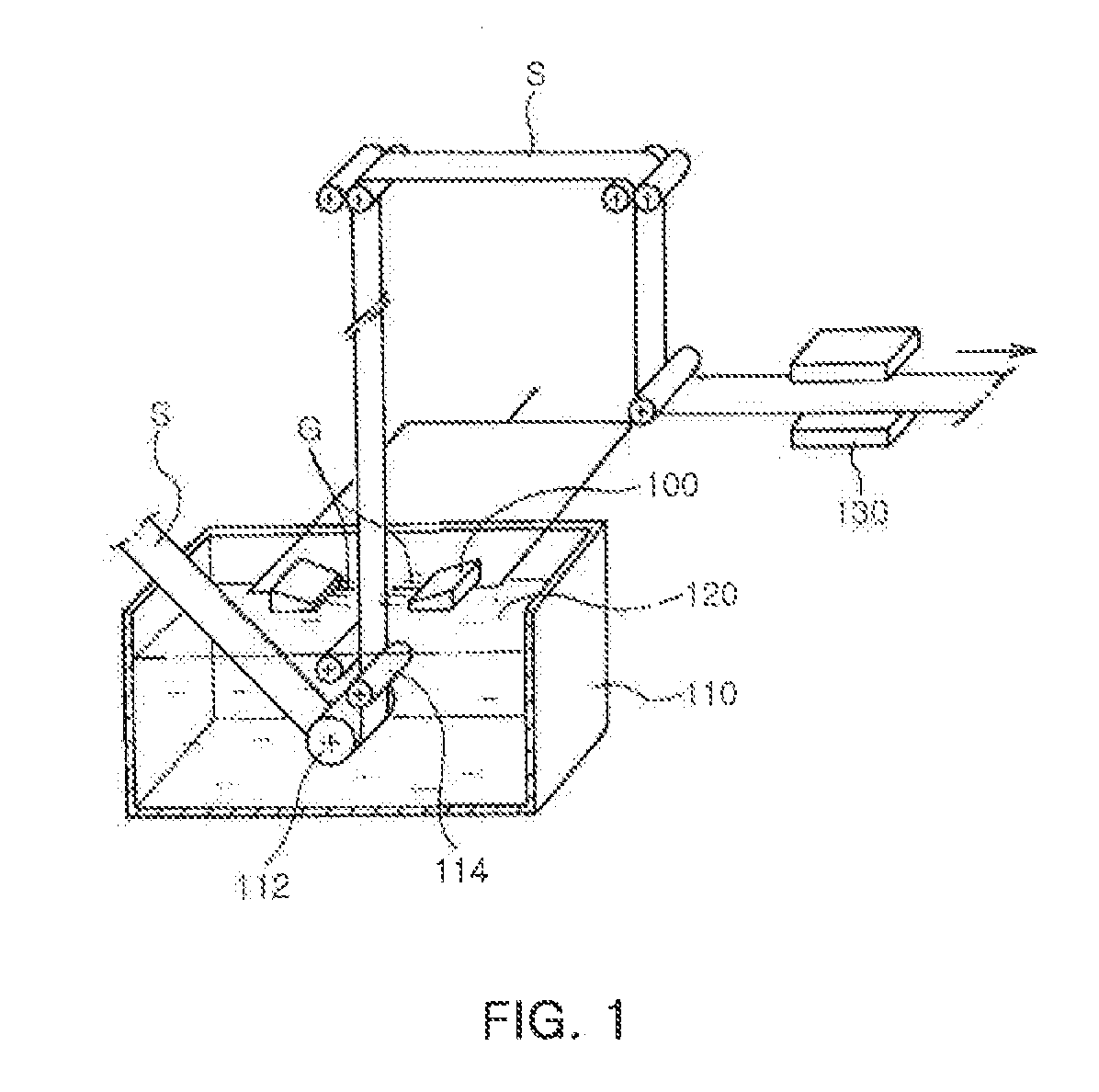

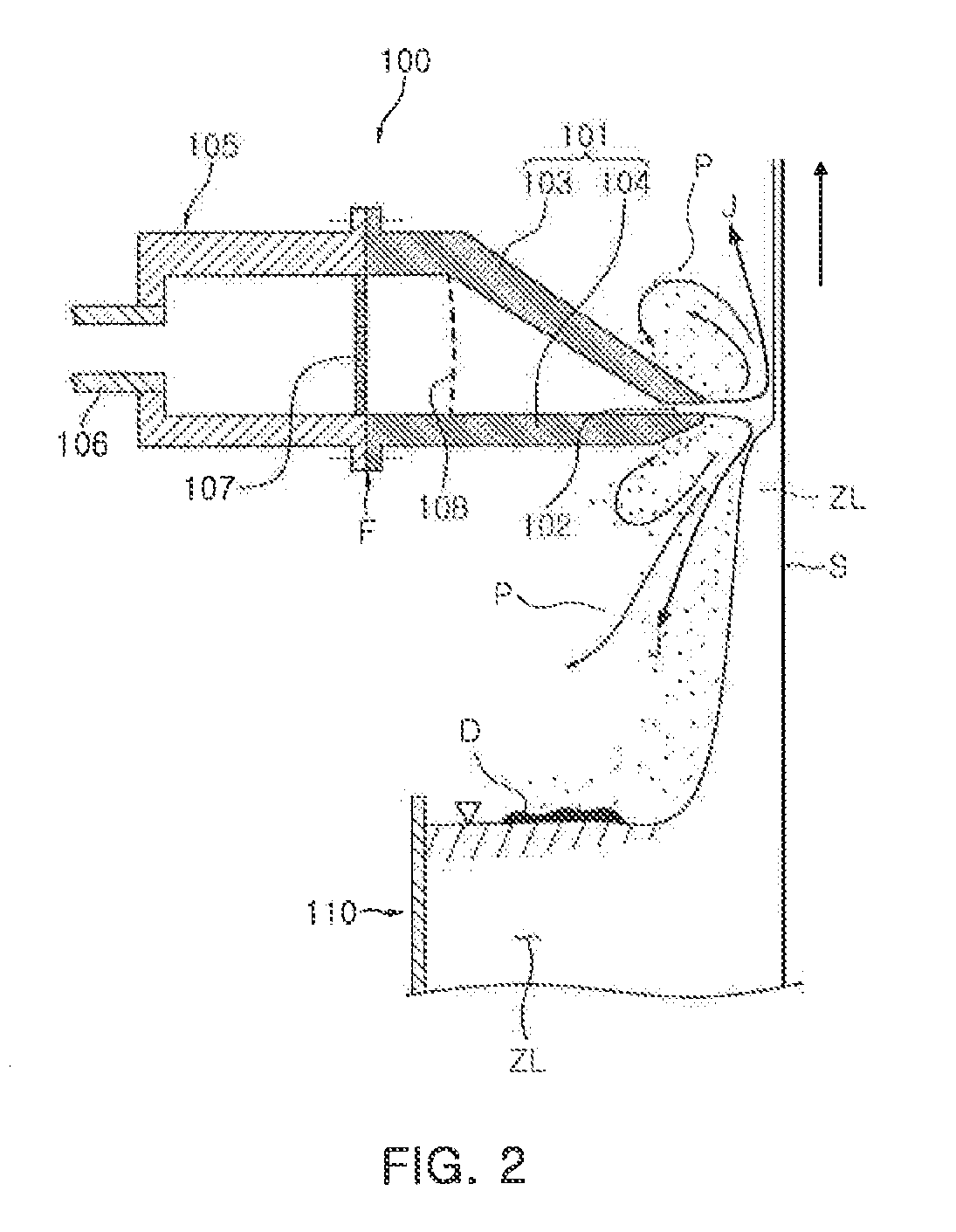

Distillate yield improving vacuum distillation method and device

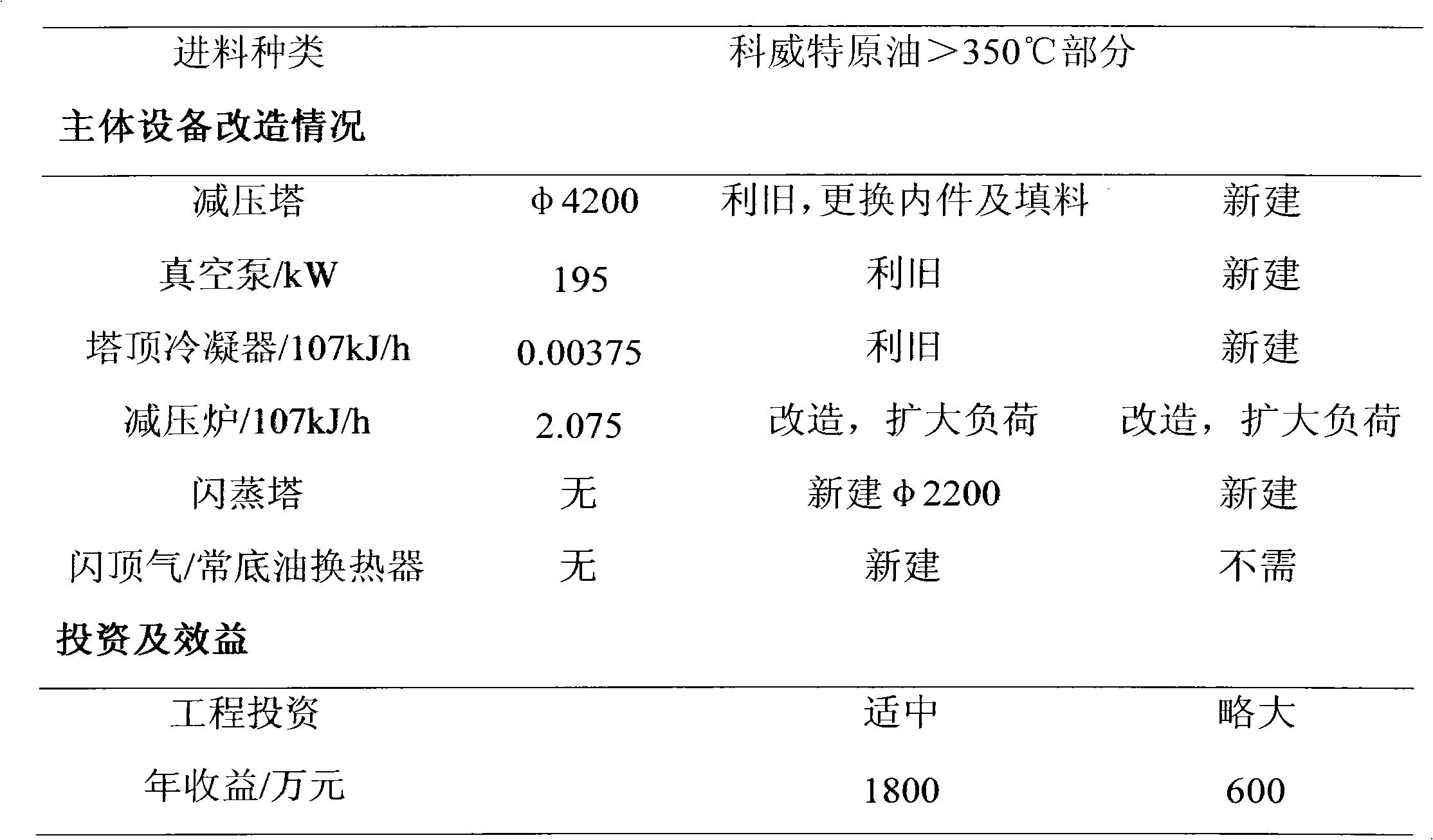

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Means for removing unwanted ions from an ion transport system and mass spectrometer

InactiveUS20060151690A1Reduce decreaseEasy accessStability-of-path spectrometersSamples introduction/extractionTransport systemIon beam

The present invention relates to inductively coupled plasma mass spectrometry (ICPMS) in which a collision cell is employed to selectively remove unwanted artefact ions from an ion beam by causing them to interact with a reagent gas. The present invention provides a first evacuated chamber (6) at high vacuum located between an expansion chamber (3) and a second evacuated chamber (20) containing the collision cell (24). The first evacuated chamber (6) includes a first ion optical device (17). The collision cell (24) contains a second ion optical device (25). The provision of the first evacuated chamber (6) reduces the gas load on the collision cell (24), by minimising the residual pressure within the collision cell (24) that is attributable to the gas load from the plasma source (1). This serves to minimise the formation, or re-formation, of unwanted artefact ions in the collision cell (24).

Owner:THERMO FISHER SCI BREMEN

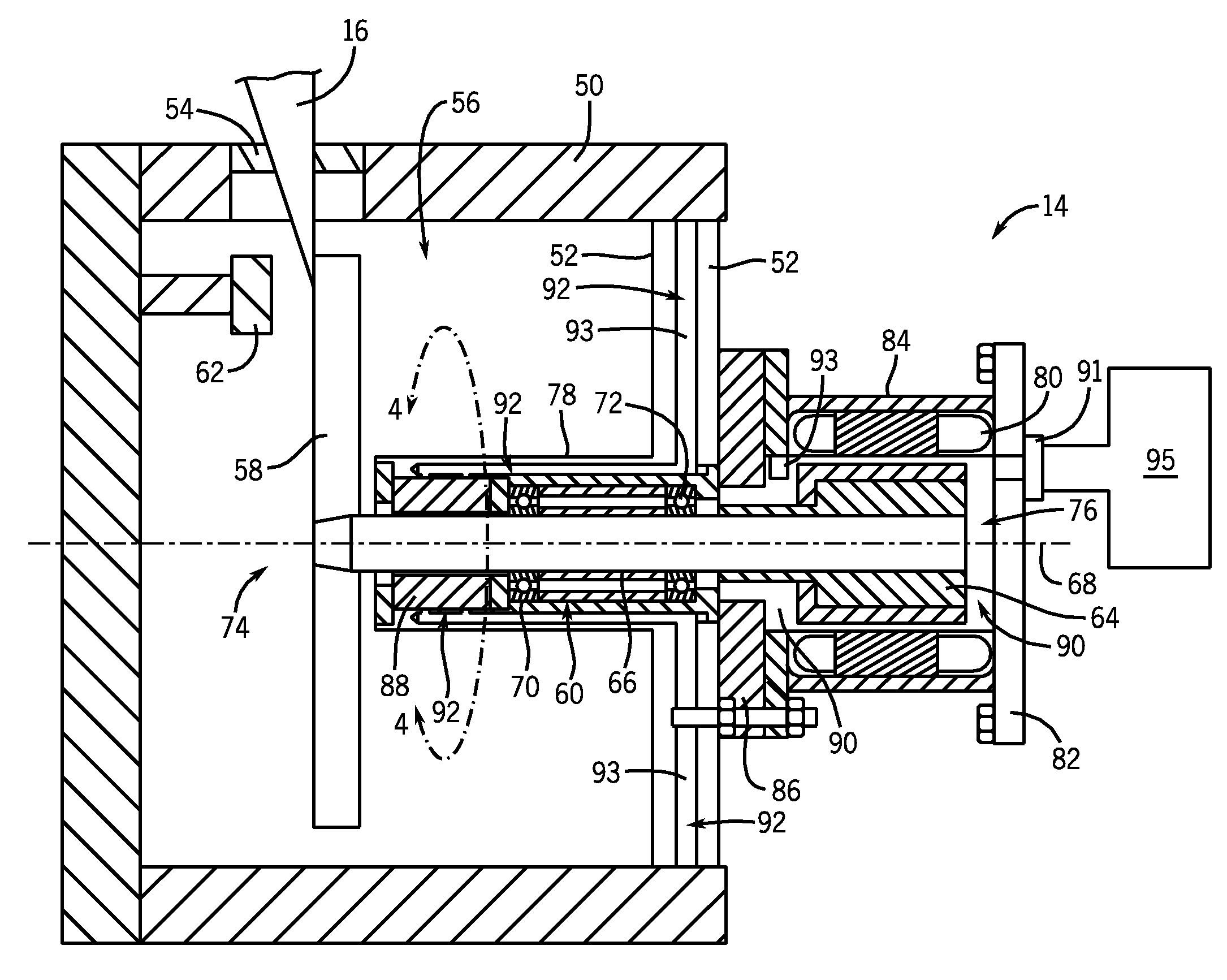

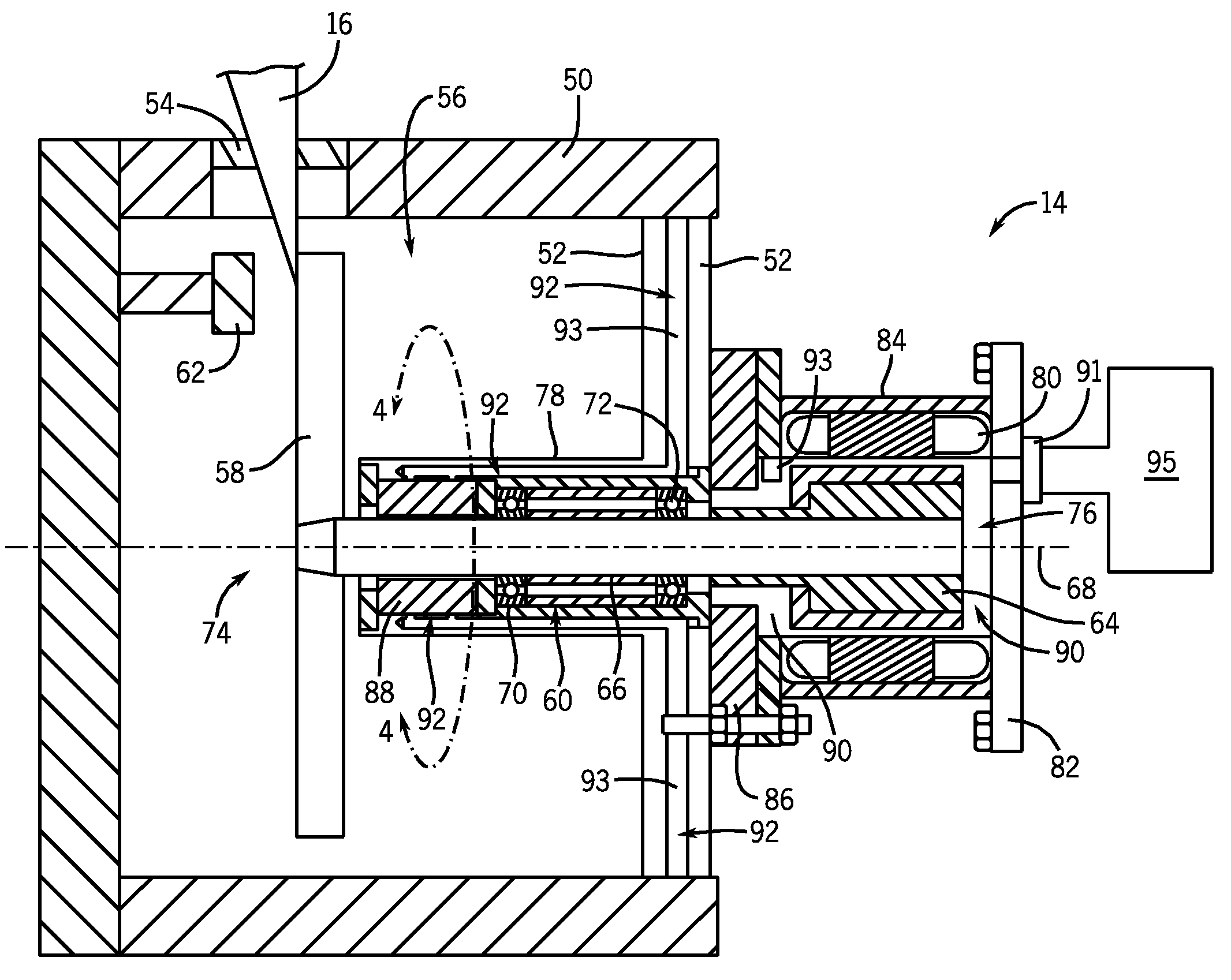

Antechamber control reducing leak through ferrofluid seals

A system for controlling a gas load imposed upon a high vacuum chamber includes a first chamber enclosing a high vacuum and positioned within an ambient environment, a second chamber enclosing a gas and positioned within the ambient environment adjacent to the first chamber, and a rotatable shaft having a first portion extending into the first chamber and a second portion extending into the second chamber. A ferrofluid seal is positioned about the rotatable shaft and positioned between the first portion and the second portion and the ferrofluid seal fluidically separates the first chamber from the second chamber. A control unit is attached to the second chamber and configured to control the gas enclosed in the second chamber such that a gas load in the first chamber is reduced.

Owner:GENERAL ELECTRIC CO

Thermal analyzer provided with cooling mechanism

ActiveUS20050053115A1Reduce gas loadReduce loadMaterial heat developmentCalorimeterElectricityEngineering

The present invention provides a thermal analyzer having a cooling device which can realize cooling of a specimen to a temperature equal to or below −100° C. by suppressing the consumption of gas also in performing rapid cooling. The cooling device includes a cooling gas inlet port and a cooling gas discharge port for a gas cooling device and an electric cooling device fixing mechanism, wherein the cooling device and the thermal analyzer are brought into thermal contact with each other. Due to such a constitution, it is possible to simultaneously connect the gas cooling device and the electric cooling device.

Owner:HITACHI HIGH TECH SCI CORP +1

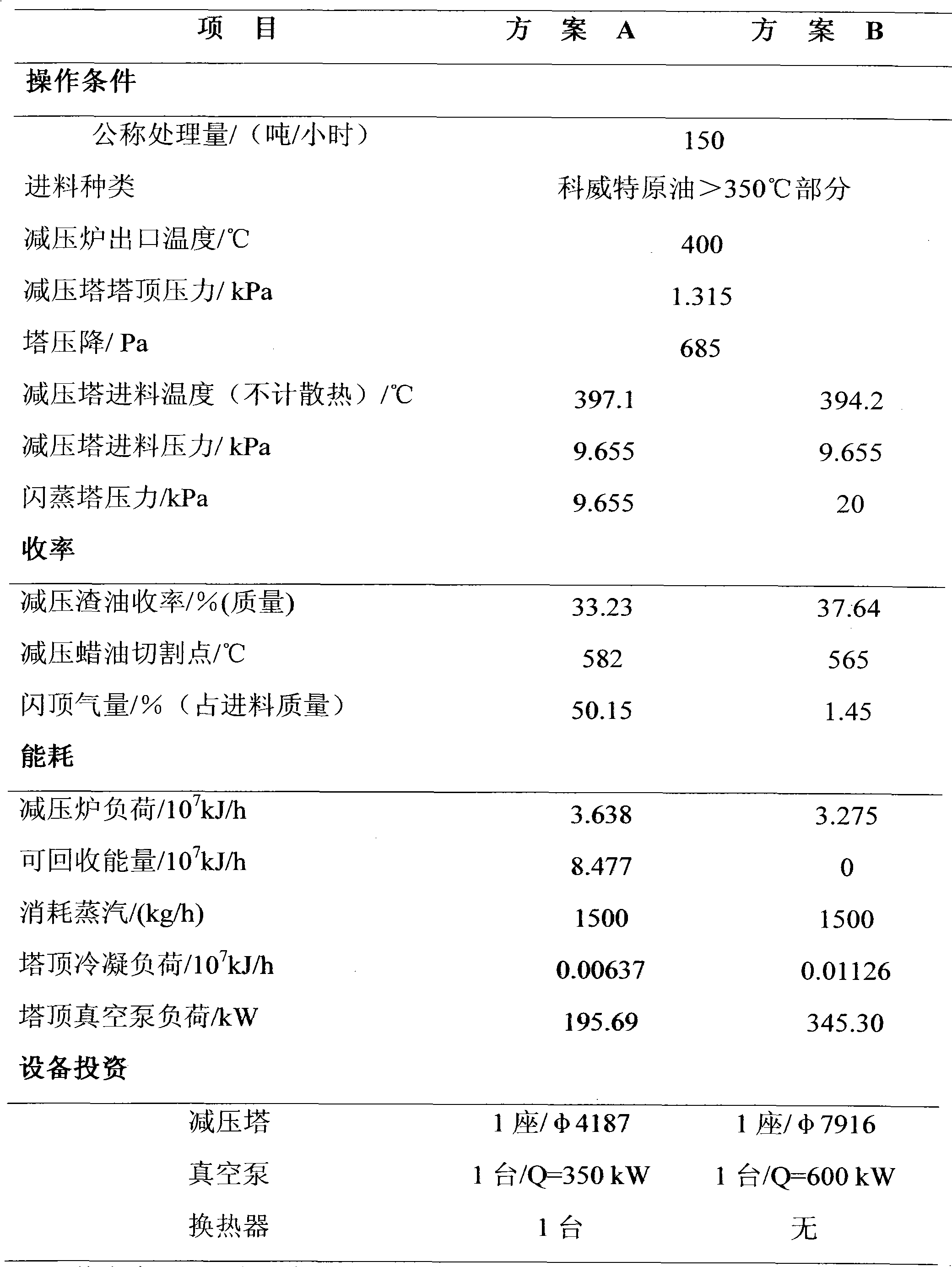

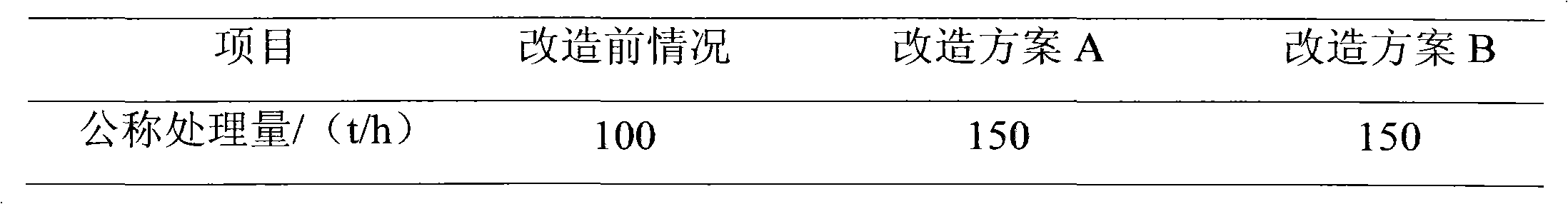

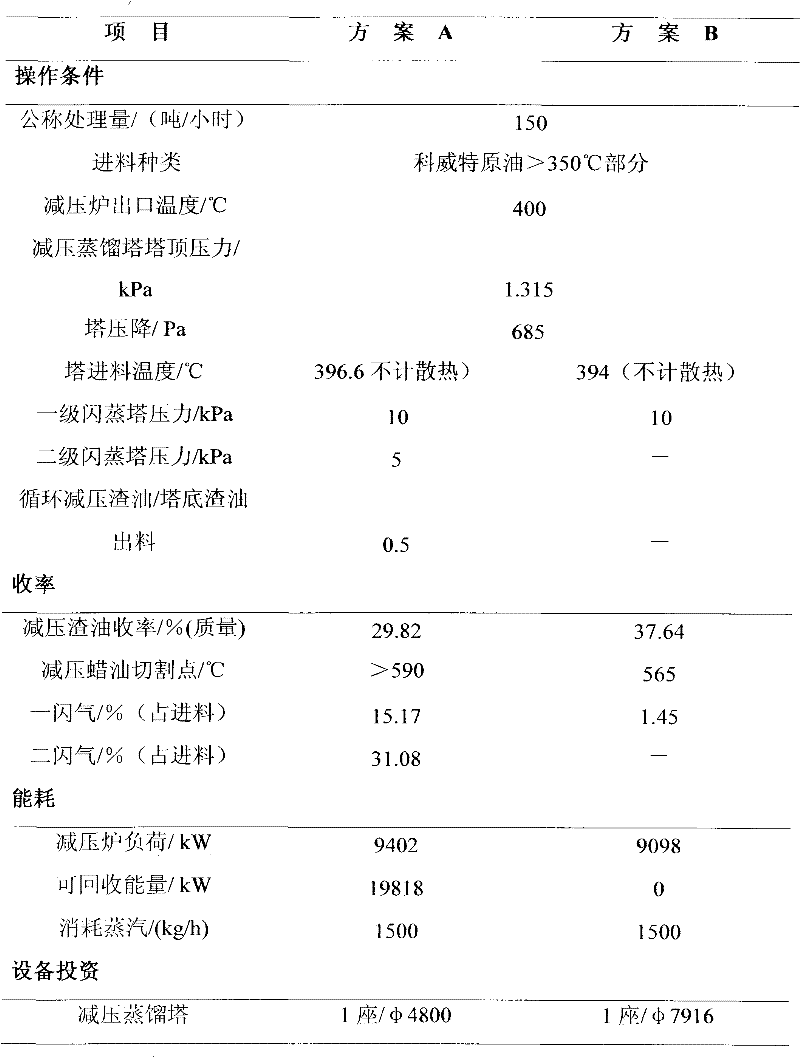

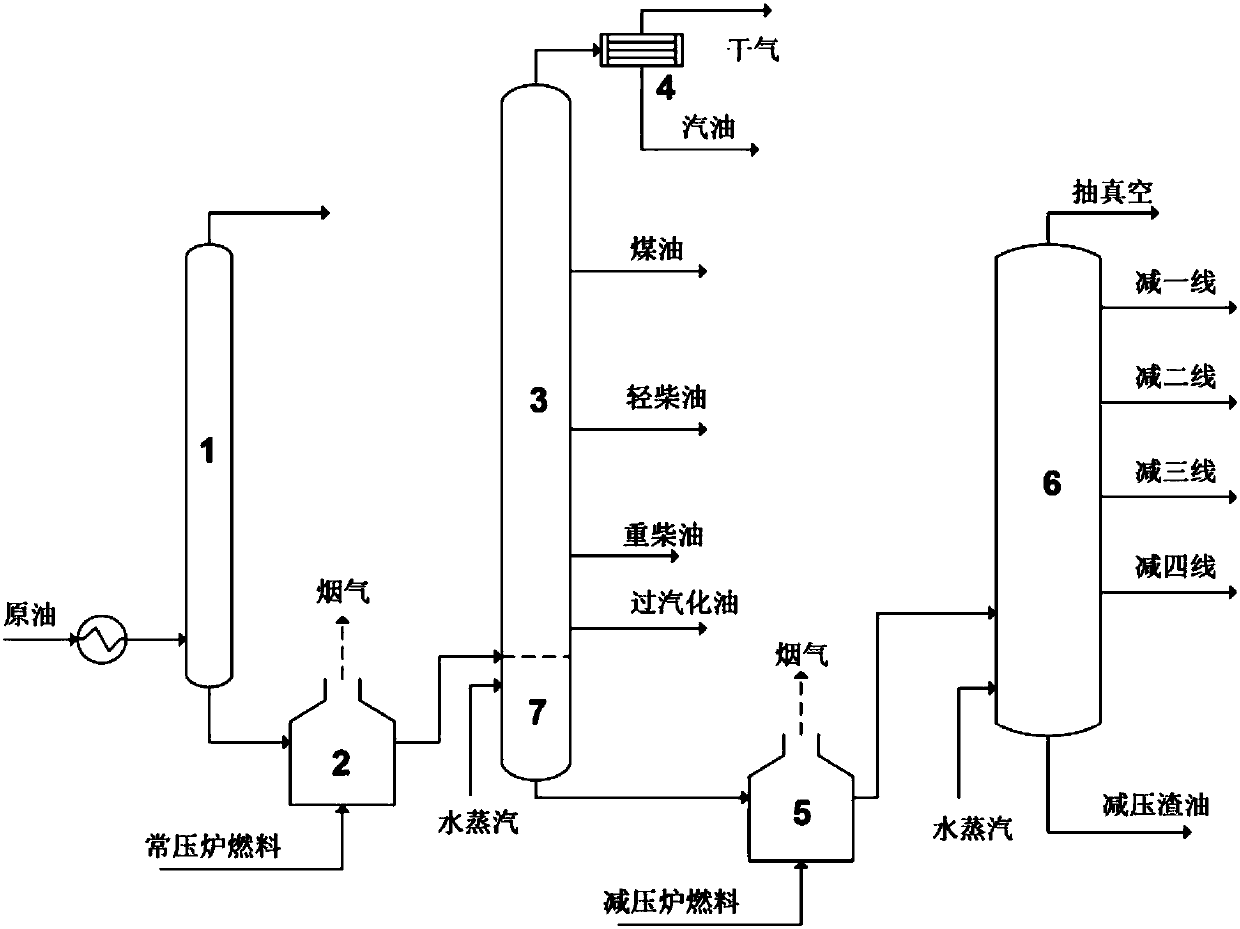

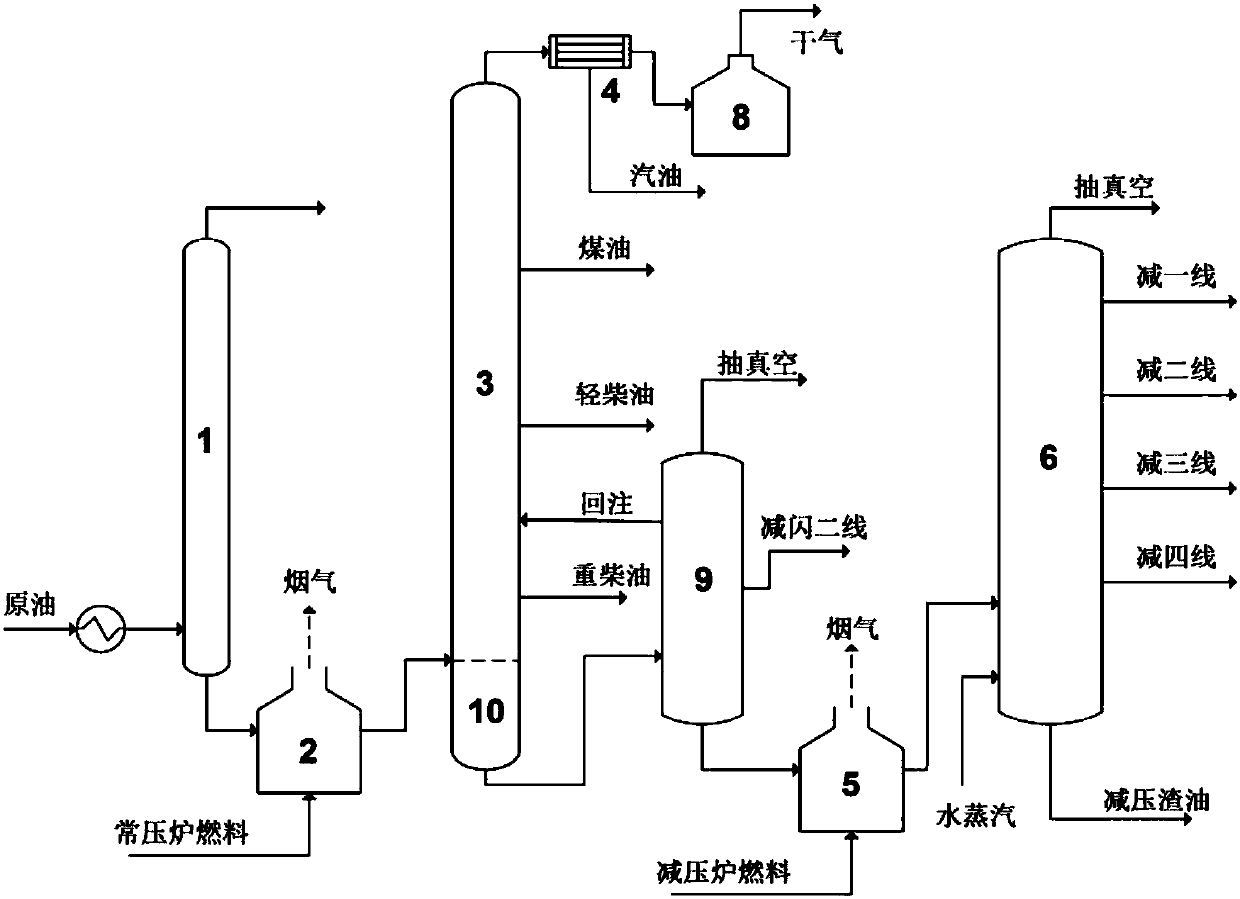

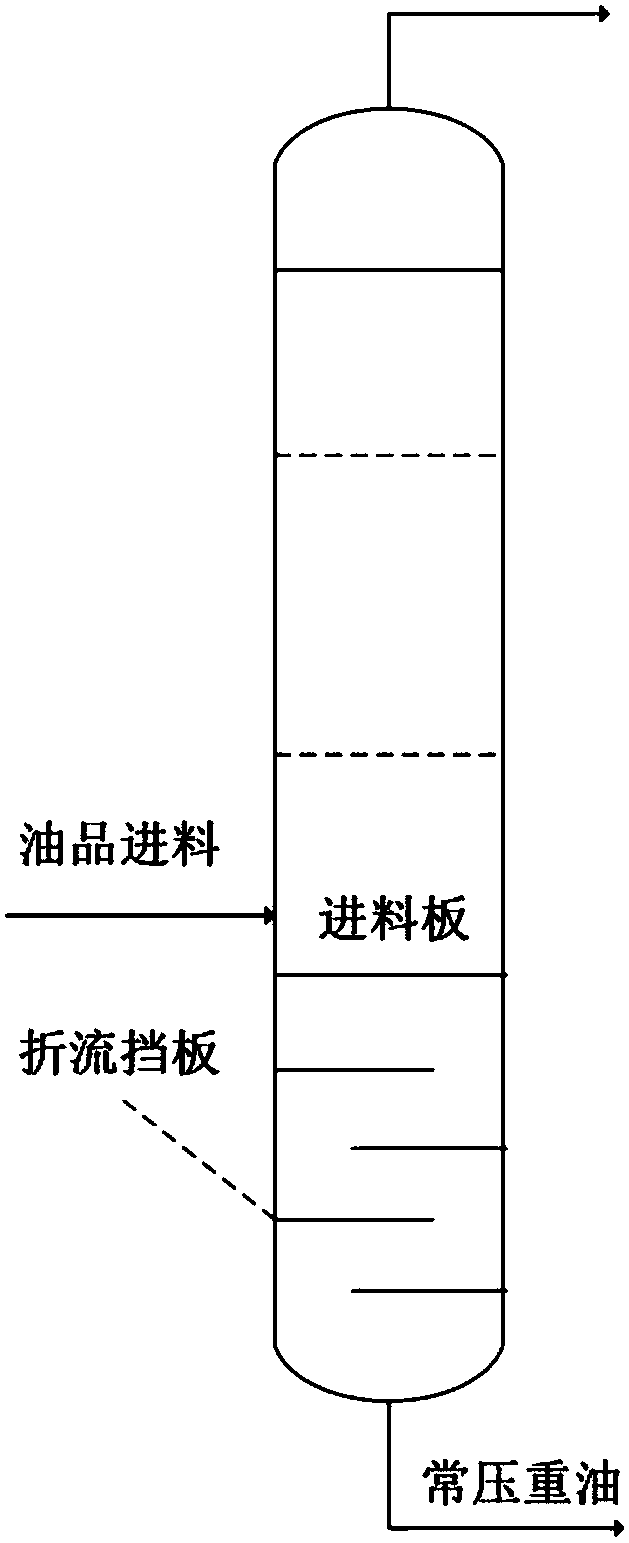

Crude oil processing method

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pumping schemes for x-ray tubes with ferrofluid seals

A system for mitigating a gas load imposed upon a high vacuum chamber, thereby reducing the overall pressure, includes a device mounted onto a rotating gantry. The device has a first chamber enclosing a high vacuum and a first region in which anode bearings are positioned. A rotatable shaft has a first portion extending into the first chamber and a second portion extending into the first region. A ferrofluid seal is positioned about the rotatable shaft and positioned between the first portion and the second portion, the ferrofluid seal fluidically separating the first chamber from the first region. At least one pressure-reducing unit is fluidically connected to the first chamber.

Owner:GENERAL ELECTRIC CO

Electromagnetic wiping device, steel sheet wiping device including same, and method for manufacturing steel sheet

ActiveUS20140356548A1Reduce gas loadReduce loadHot-dipping/immersion processesLiquid surface applicatorsProduction rateSheet steel

Provided are an electromagnetic wiping device for controlling the amount of coating of a steel sheet, a steel sheet wiping device including the same, and a method for manufacturing the steel sheet. The present invention can prevent overcoating at least at the edge of the steel sheet by removing a coating layer of at least an edge part of the steel sheet passing through a plating bath by using electromagnetism and forming the gas wiping, and can reduce gas wiping capabilities while maintaining the line speed of the steel sheet so as to reduce the amount of scattered material or dross due to the scattered material, thereby ultimately improving the coating quality and the productivity of the steel sheet.

Owner:POHANG IRON & STEEL CO LTD

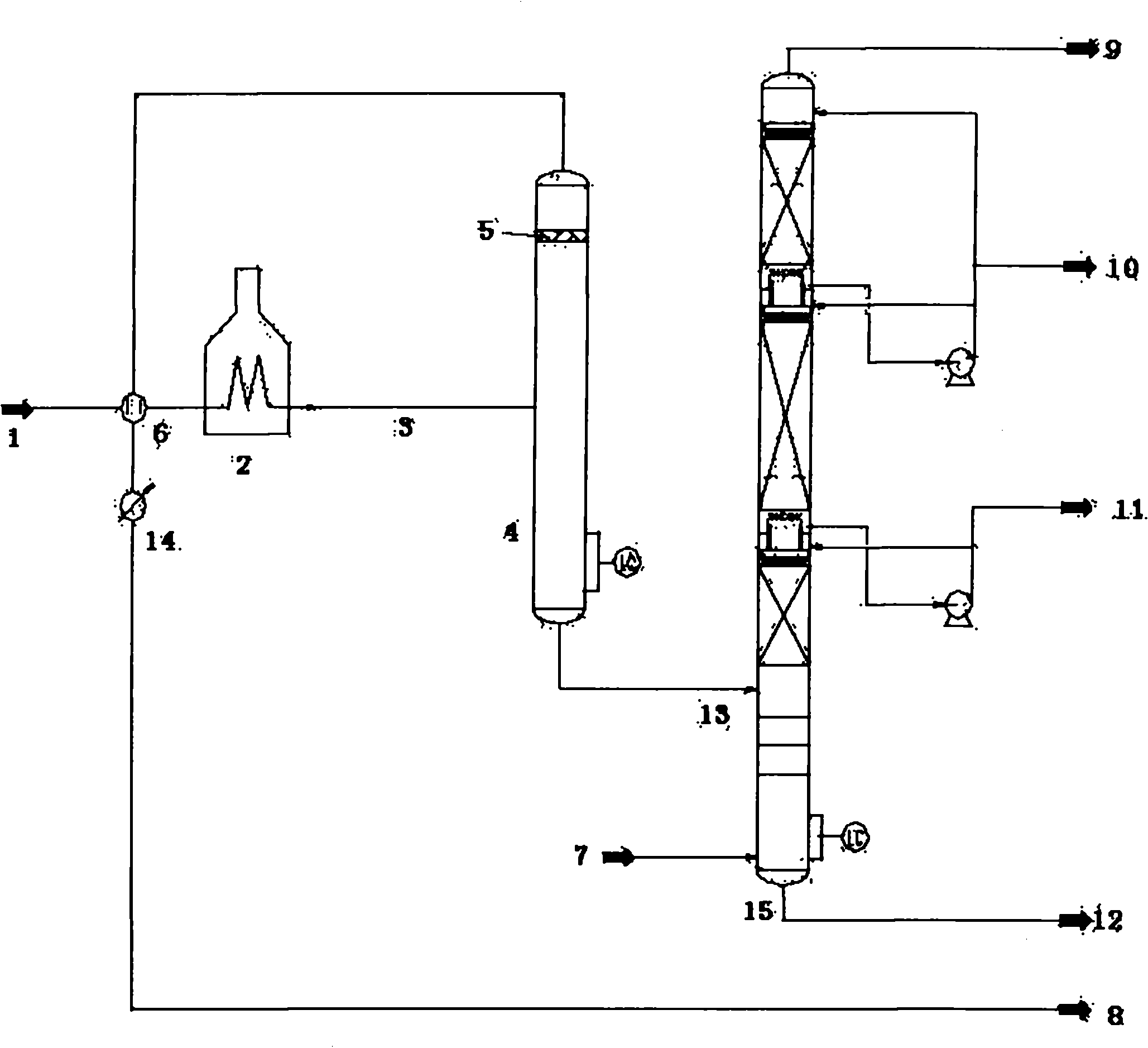

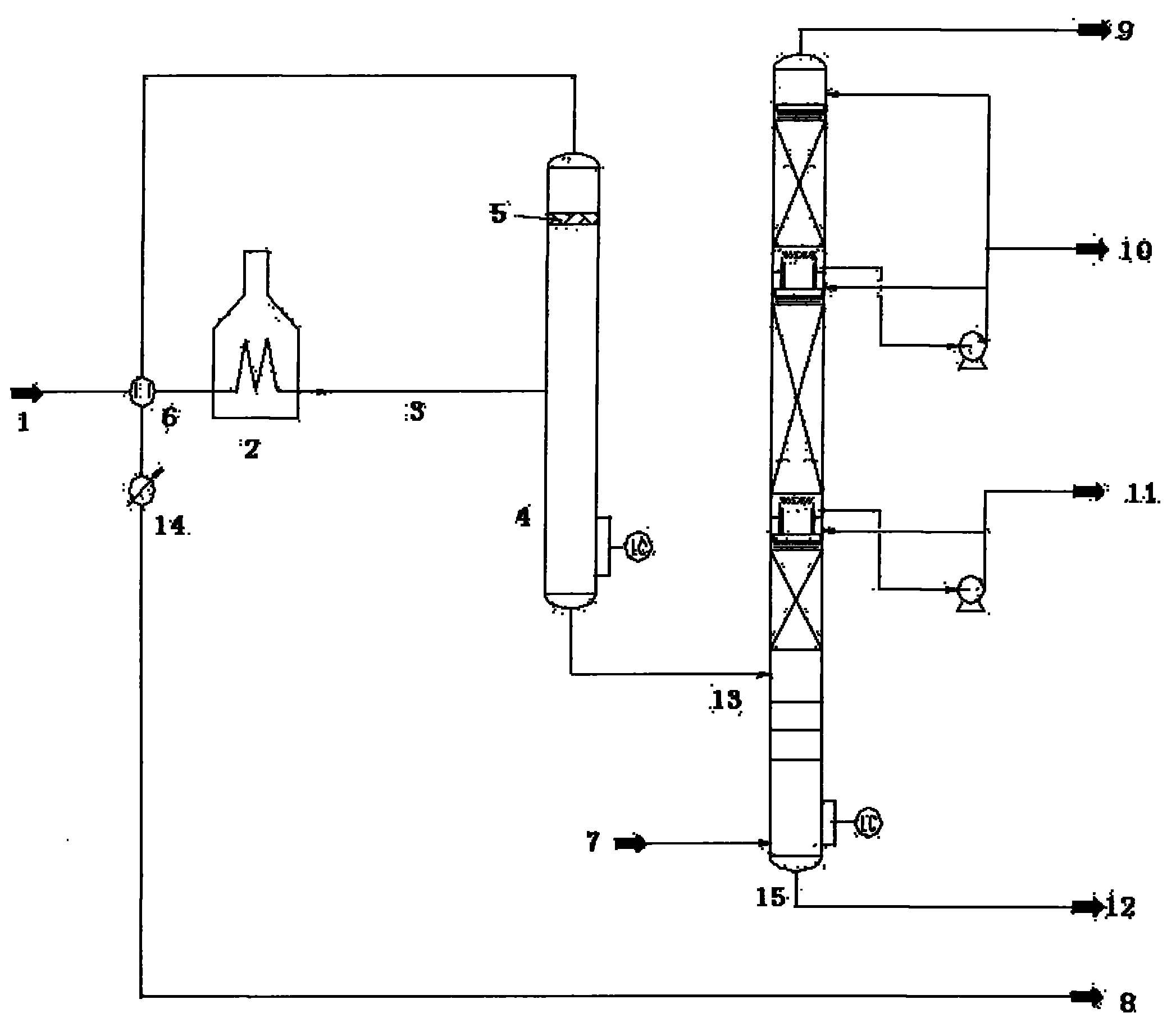

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

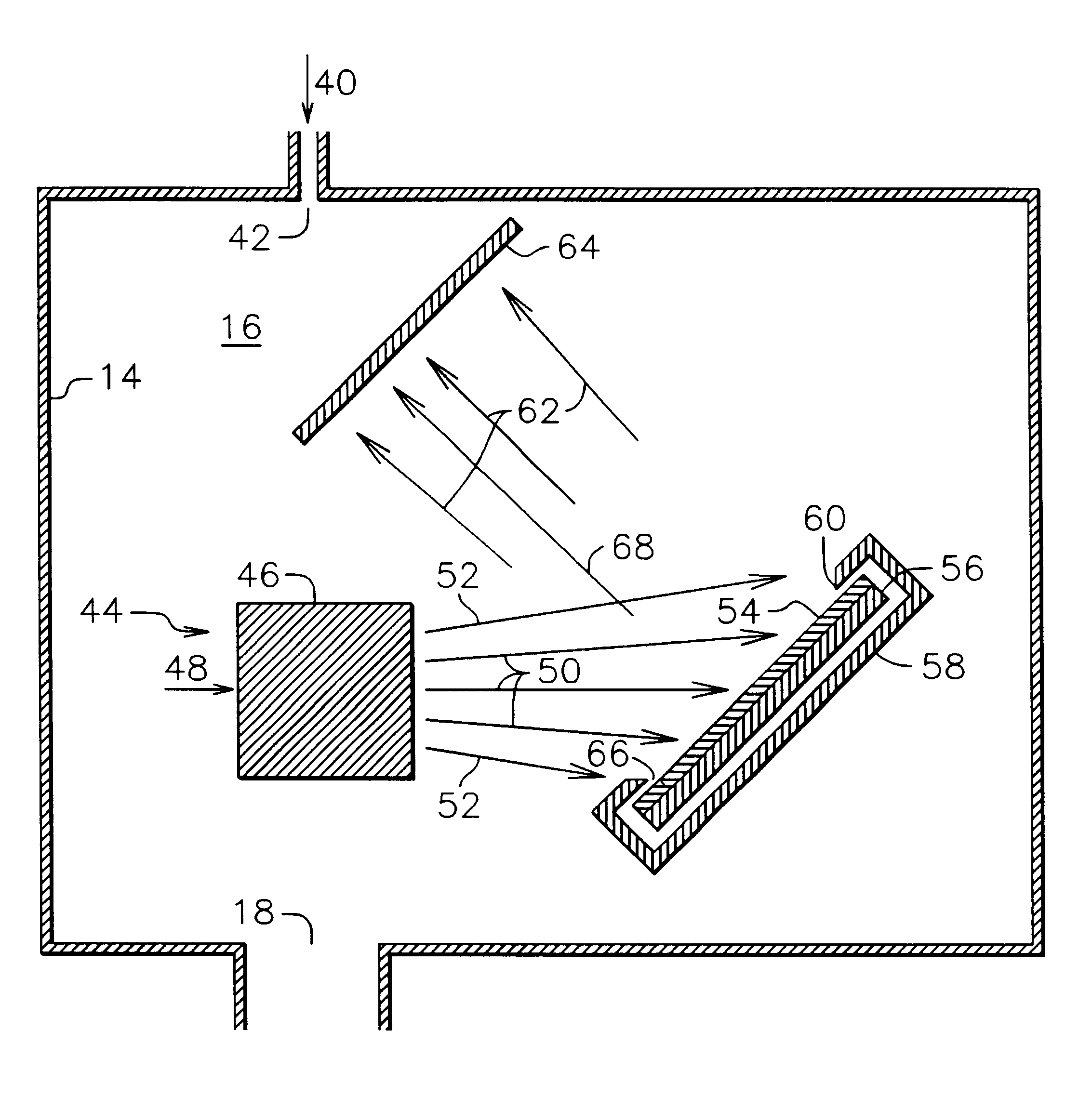

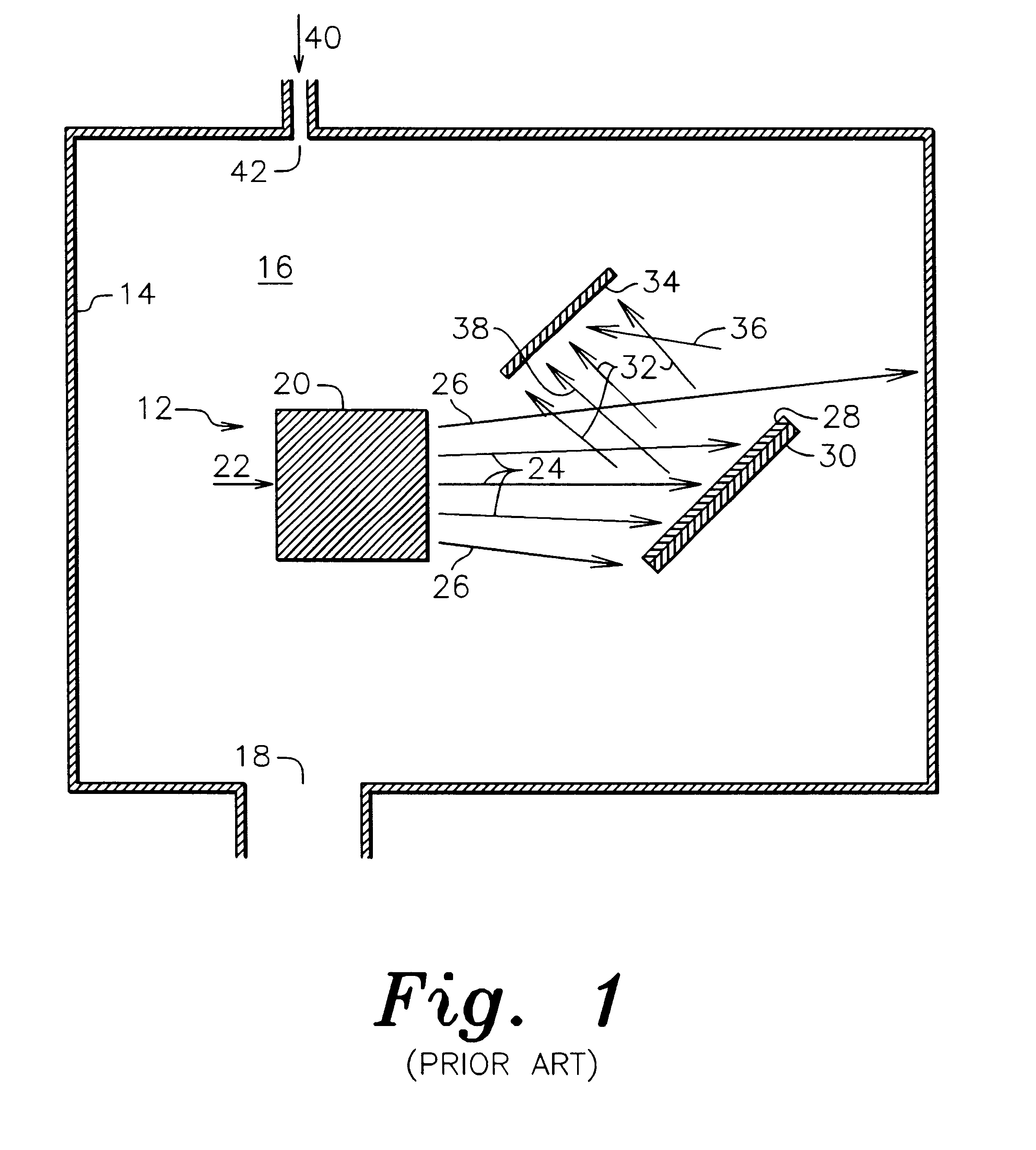

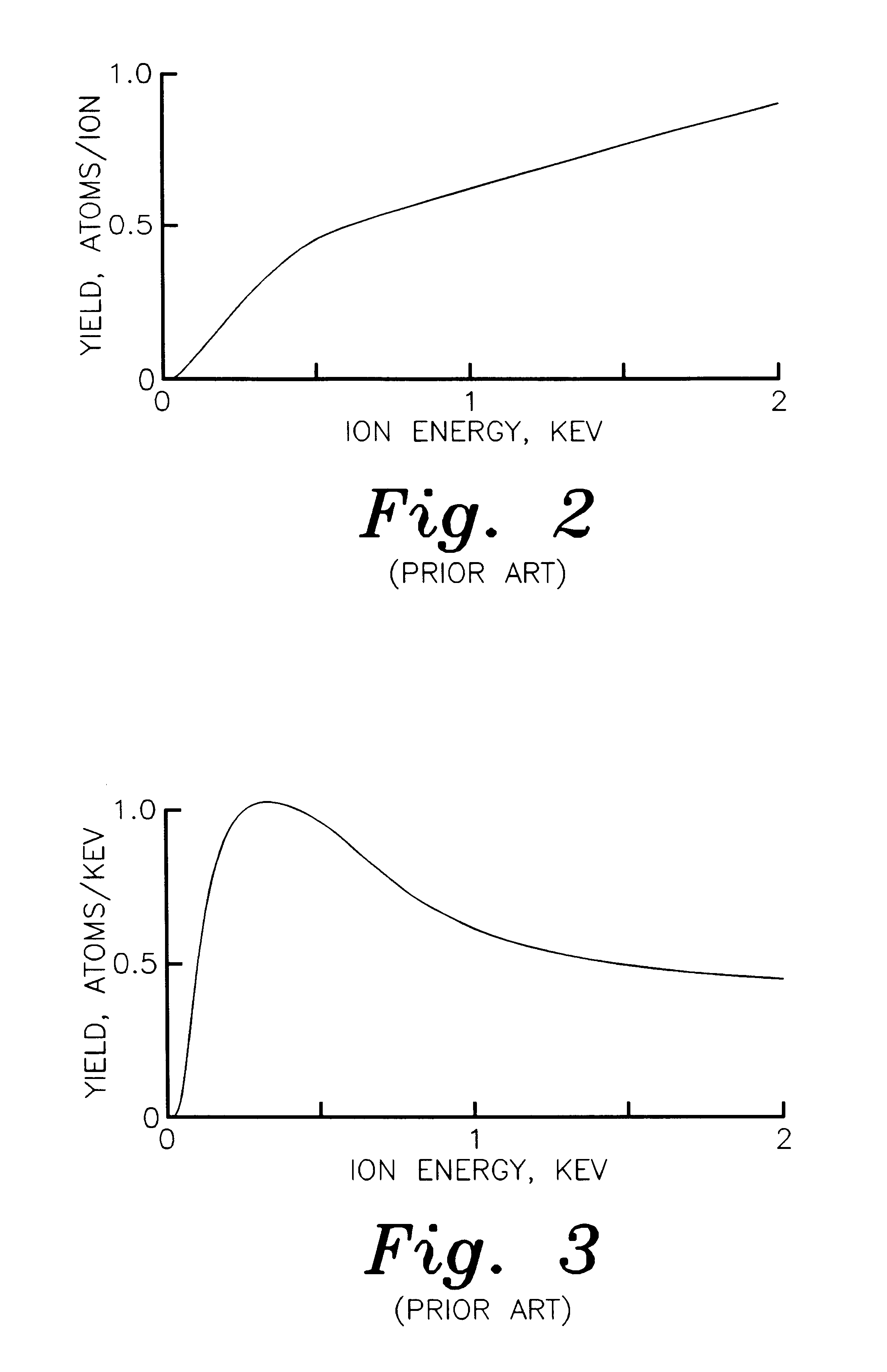

Apparatus for sputter deposition

InactiveUS6682634B1Minimize damageIncrease pressureCellsElectric discharge tubesIon beamHigh pressure

In accordance with one specific embodiment of the present invention, the apparatus for sputter deposition within an evacuated volume comprises a compact ion source to generate ions into which an ionizable gas is introduced and from which ions leave with directed energies near or below the sputtering threshold, a sputter target near that source and located within the beam of ions leaving that source, a sputter target with a grounded shield that defines the target portion exposed to sputtering, and a power supply to bias the target negative relative to ground so that ions are attracted to and sputter the target. Particles sputtered from the target are deposited on a deposition substrate separate from both the ion source and the sputter target. For an insulating target, the target is biased with a radiofrequency power supply and the bias has a mean negative value rather than a direct-current negative value relative to ground. The rate and energy with which the ions arrive at the target determine the rate with which that target is sputtered and the deposition rate on the substrate. In using a compact gridless ion source, the high pressure required for generating ions is confined to the ion source, reducing the pumping gas load. For ion energies at or near the sputtering threshold, the sputtering from extraneous hardware is reduced or eliminated. In addition, the target biases can be low enough to minimize the damage due to energetic neutrals that result from reflection of energetic target ions.

Owner:VEECO INSTR +1

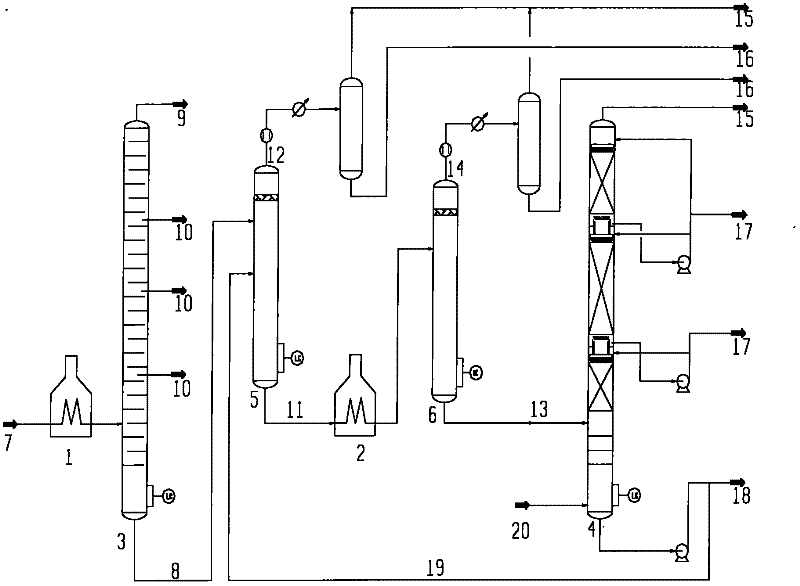

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

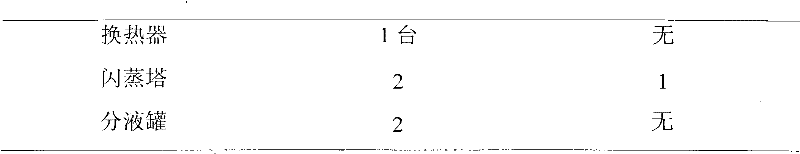

Water-free atmospheric vacuum distillation technology and device

ActiveCN107699273AEasy to separateSolve the problem of low temperature dew point corrosionHydrocarbon distillation control/regulationVacuum distillationReboilerFuel oil

The invention provides a water-free atmospheric vacuum distillation technology and device. The technology is characterized in that a normal-pressure tower and a vacuum tower adopt a four-time gasification and feeding manner; after crude oil is heated through a normal-pressure furnace, materials are fed from a tower kettle of the normal-pressure tower; water steam is not introduced into the tower kettle; each sideline product is heated by adopting a reboiler; alkali washing is carried out on tower top dry gas which is condensed and cooled at a tower top of the normal-pressure tower; a vacuum flashing tower is additionally arranged between the normal-pressure tower and a vacuum furnace; normal-pressure heavy oil from the tower kettle of the normal-pressure tower enters the vacuum flashing tower; the vacuum flashing tower is provided with a plurality of sidelines for drawing out products; the product drawn out from the first sideline is injected into the normal-pressure tower again; the heavy oil of the tower kettle enters the vacuum furnace and is further heated, and then enters the vacuum tower; pressure of the vacuum flashing tower is controlled between the pressure of the normal-pressure tower and the pressure of the vacuum tower. The invention further provides the water-free atmospheric vacuum distillation device. By adopting the device and the technology, provided by the invention, the low-temperature dew-point corrosion problem of the top of the normal-pressure tower can be solved, refinery wastewater is reduced and the diesel oil extraction rate of the normal-pressureheavy oil is improved; serious entrainment of the vacuum tower is alleviated and the decompression and deep drawing vacuum degree is reduced. The long-period, safe, stable and operation performance ofthe device is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method and apparatus for supporting rotor assemblies during unbalances

A method and apparatus for reducing dynamic loading of a gas turbine engine is provided. The gas turbine engine includes a rotor shaft assembly including a rotor shaft, a bearing assembly, a mounting race, and a support frame, the mounting race including a spherical surface. The method includes supporting the rotor shaft on the gas turbine engine support frame with the bearing assembly, the rotor shaft including a yield portion configured to permit bending of the rotor shaft during an imbalance operation.

Owner:GENERAL ELECTRIC CO

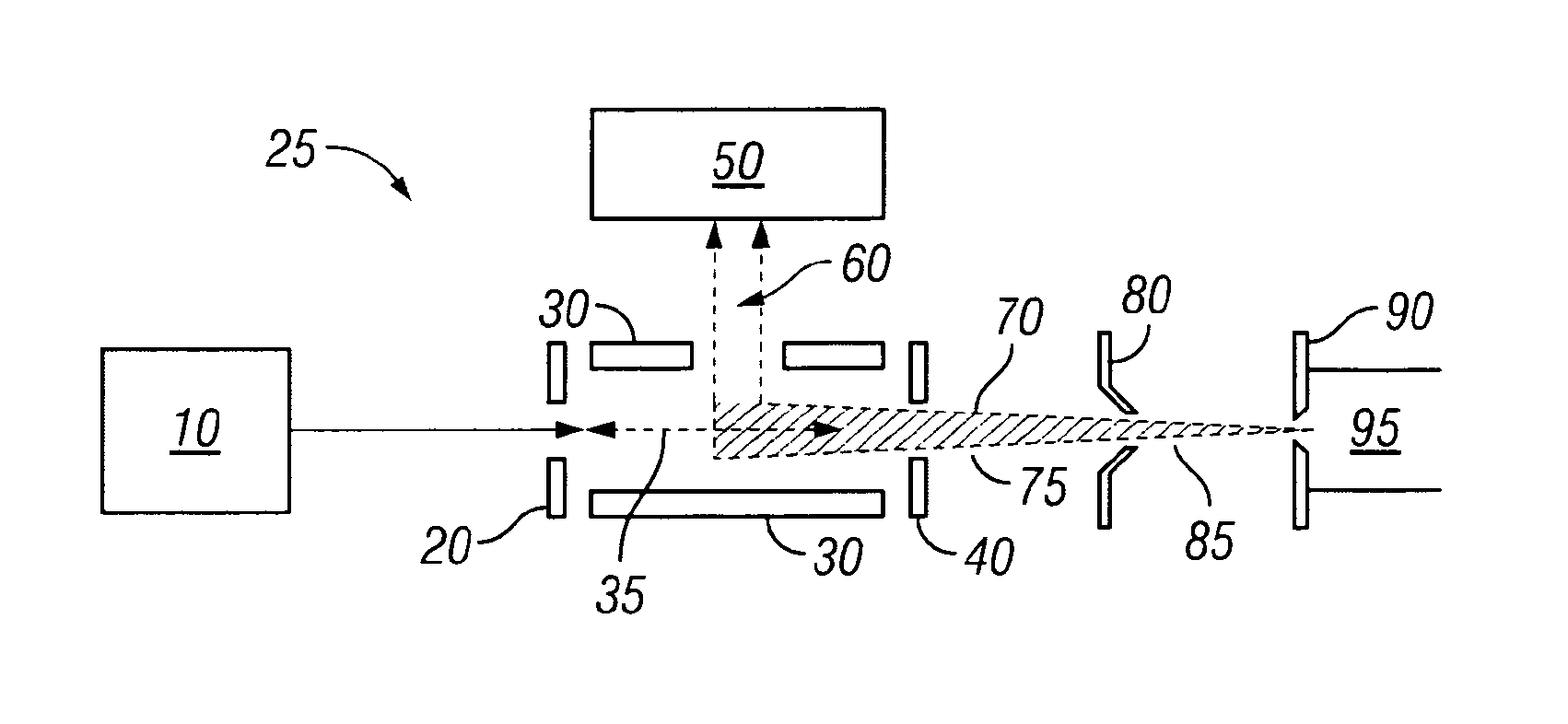

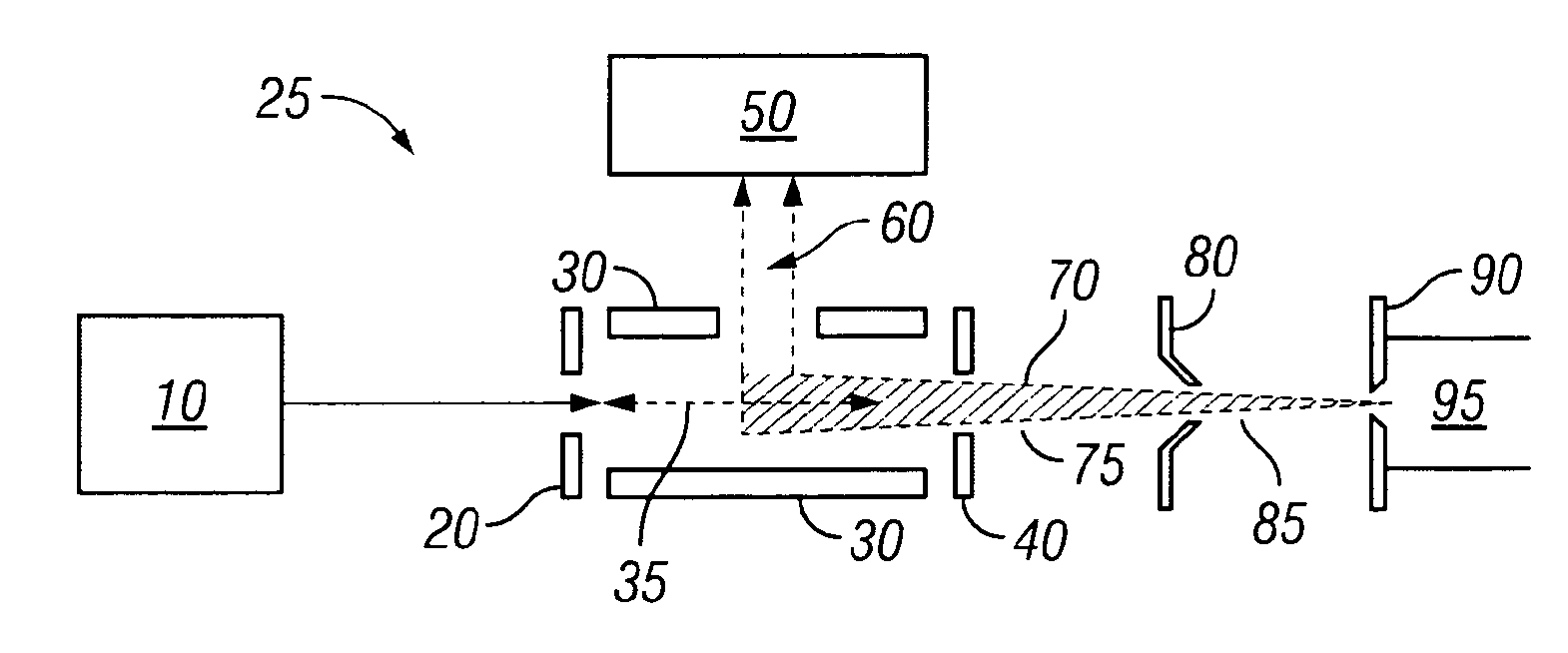

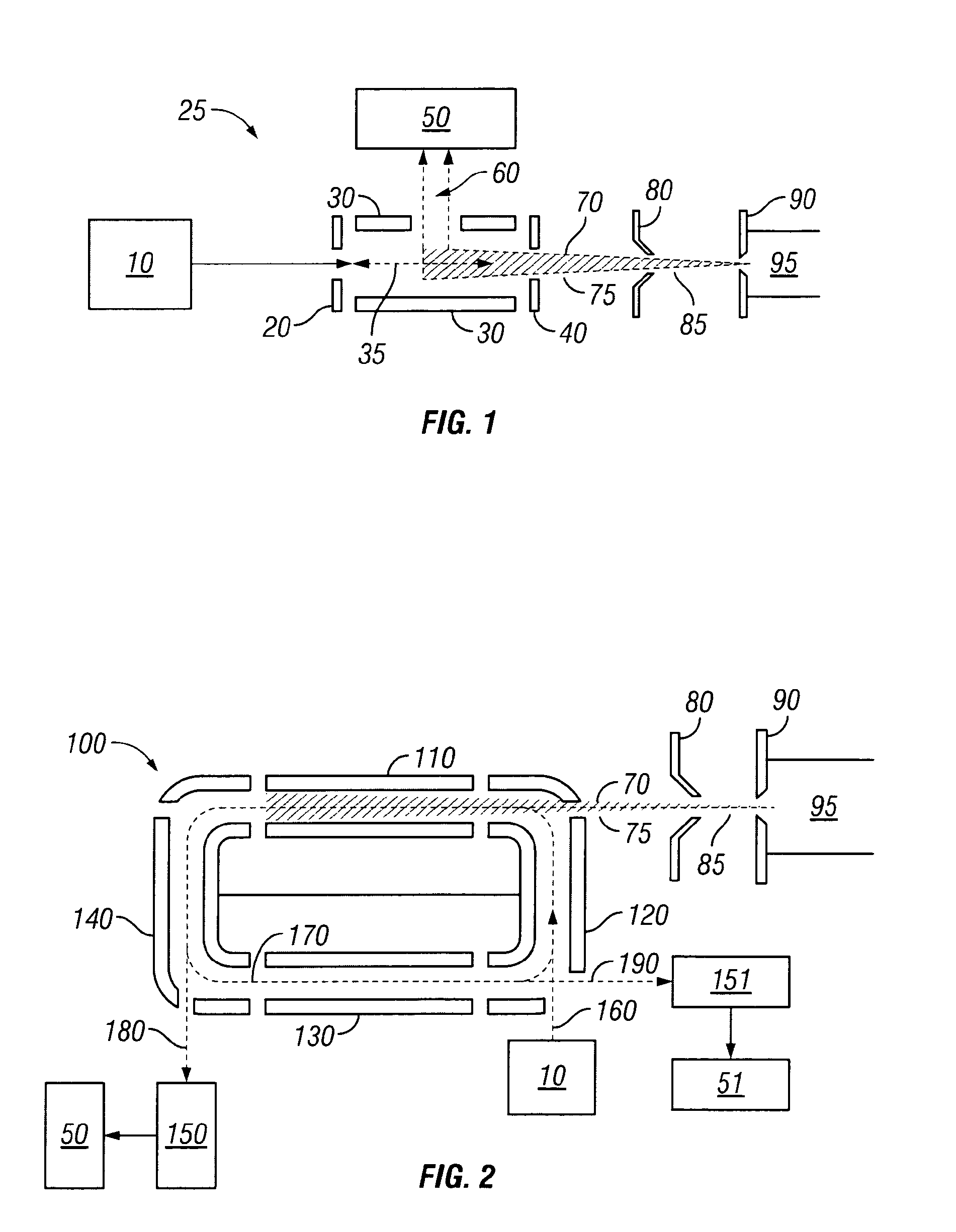

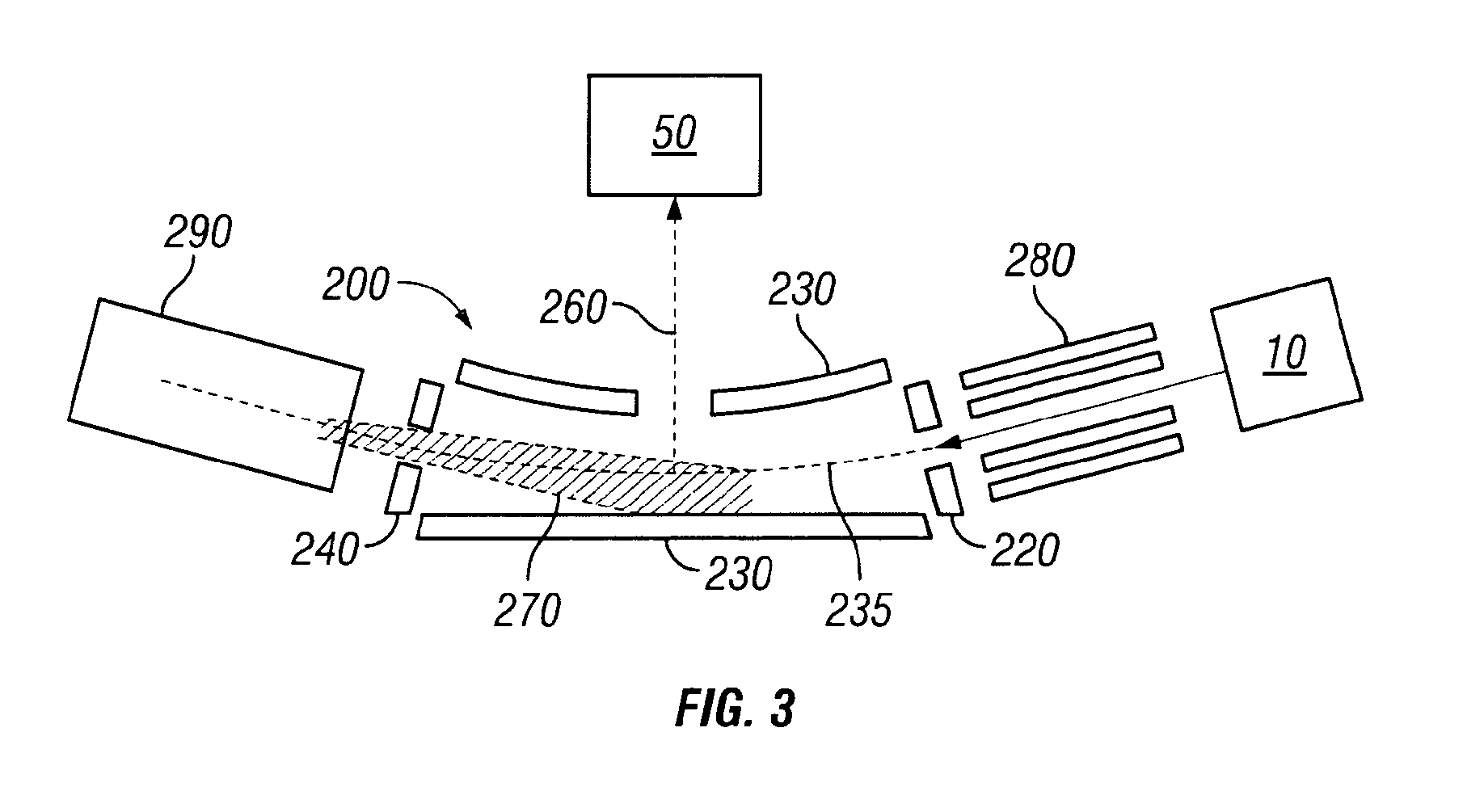

Ion Trap for Cooling Ions

ActiveUS20110163227A1Reduce gas loadSaving complexitySamples introduction/extractionMaterial analysis by electric/magnetic meansIon trap mass spectrometryTrapping region

A method of changing the kinetic energy of ions is provided, comprising: trapping ions in a trapping region of an ion trap; and directing a beam of gas through the trapping region, so as to change the kinetic energy of the trapped ions thereby. Also provided is a method of separating ions, the method comprising: causing ions to enter a trapping region of an ion trap along a first axis of the trapping region; directing a beam of gas along the first axis and applying an electric potential in the direction of the first axis so as to cause separation of the ions based on their ion mobility. An ion trap and a mass spectrometer for performing the methods are also provided.

Owner:THERMO FISHER SCI BREMEN

Ultra-thin membrane for chemical analyzer and related method for forming membrane

ActiveUS8956696B2Reduce gas loadEasy to detectMembranesSemi-permeable membranesPorous substrateThin membrane

A method for forming an ultra-thin membrane for use in a chemical analyzer such as a mass spectrometer includes the step of applying a sacrificial blocking layer onto a porous substrate, applying a semi-permeable membrane layer onto the sacrificial blocking layer, and removing the sacrificial blocking layer following cure of the membrane layer. In a preferred version, at least one of the blocking layer and the membrane layer are applied to the porous support by means of spin coating, though other deposition techniques can be employed.

Owner:INFICON GMBH

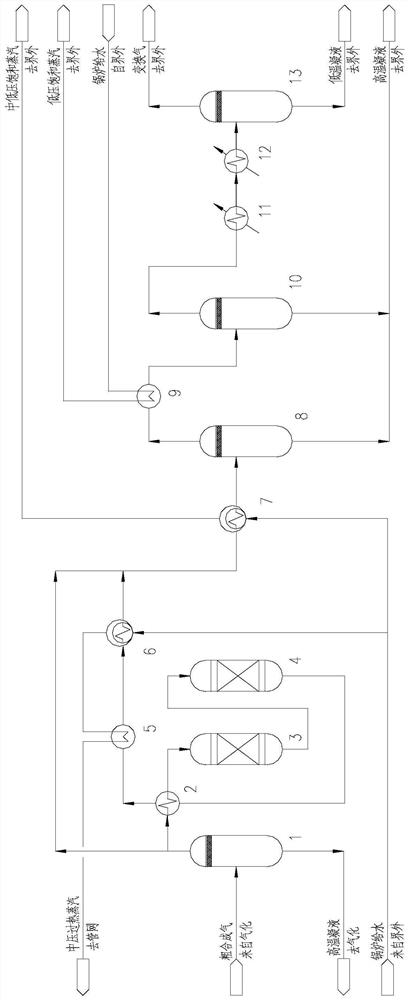

Carbon monoxide conversion system and method for coal water slurry gasification-to-methanol device

PendingCN111646430AReduce gas loadGood energy integration effectHydrogenEnergy inputChemical reactionEngineering

The invention belongs to the technical field of coal chemical industry device process design optimization and waste heat recycling. The invention provides a carbon monoxide conversion system and method for a coal water slurry gasification-to-methanol device. In combination with the characteristics of partial conversion of carbon monoxide and energy utilization of a coal-to-methanol device, the technological process is optimized and built, crude synthesis gas from an upstream gasification device is divided into two streams, and one stream is heated by a crude gas preheater and then enters a conversion furnace through a detoxification tank to be subjected to a chemical reaction; and the other stream of non-shifted gas which does not participate in the reaction is used as mixing gas to be mixed with the shifted gas subjected to the reaction. And a good energy utilization effect is obtained while the process production requirements are met, and the investment cost is saved.

Owner:SINOPEC NANJING ENG & CONSTR +1

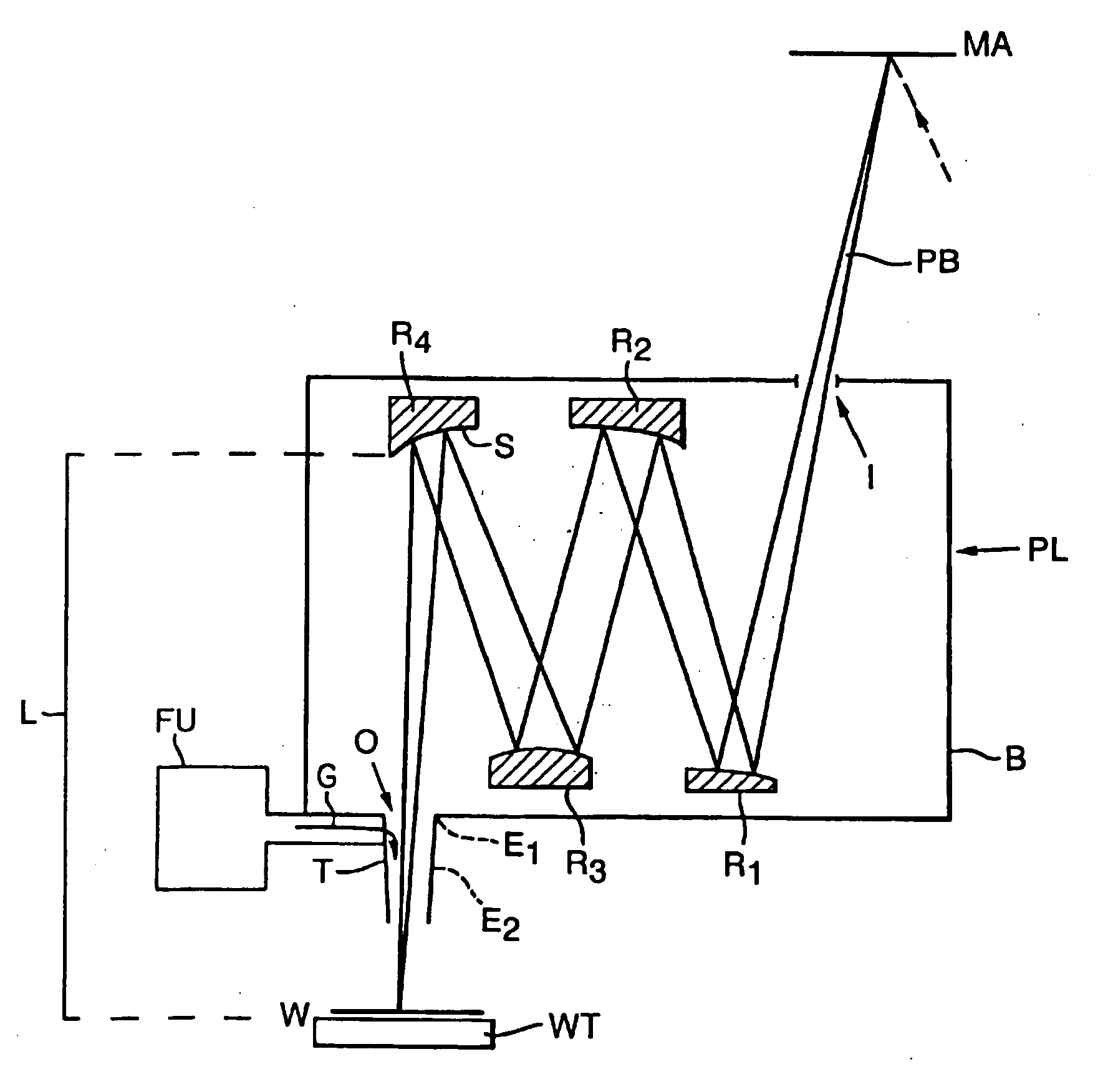

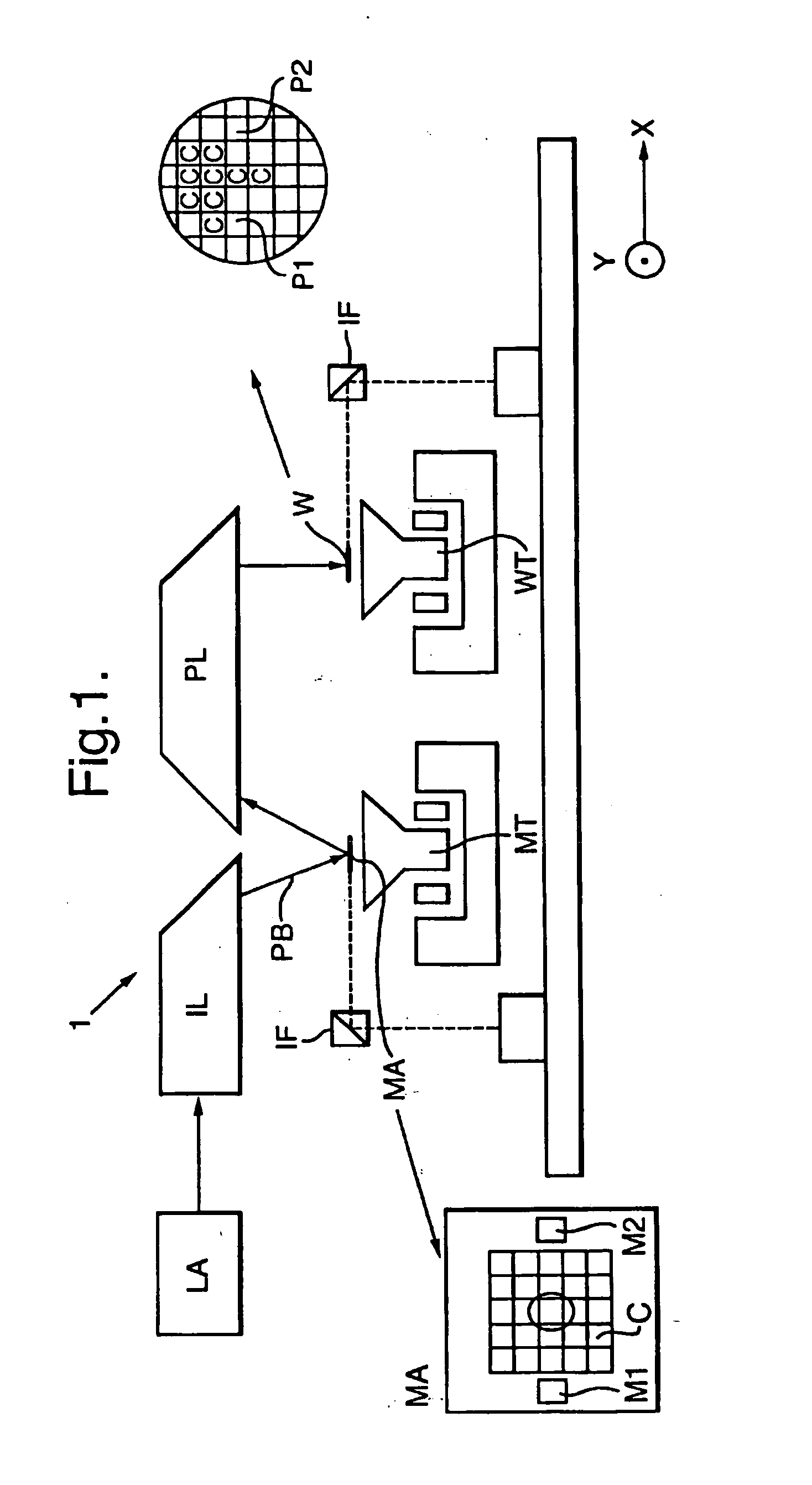

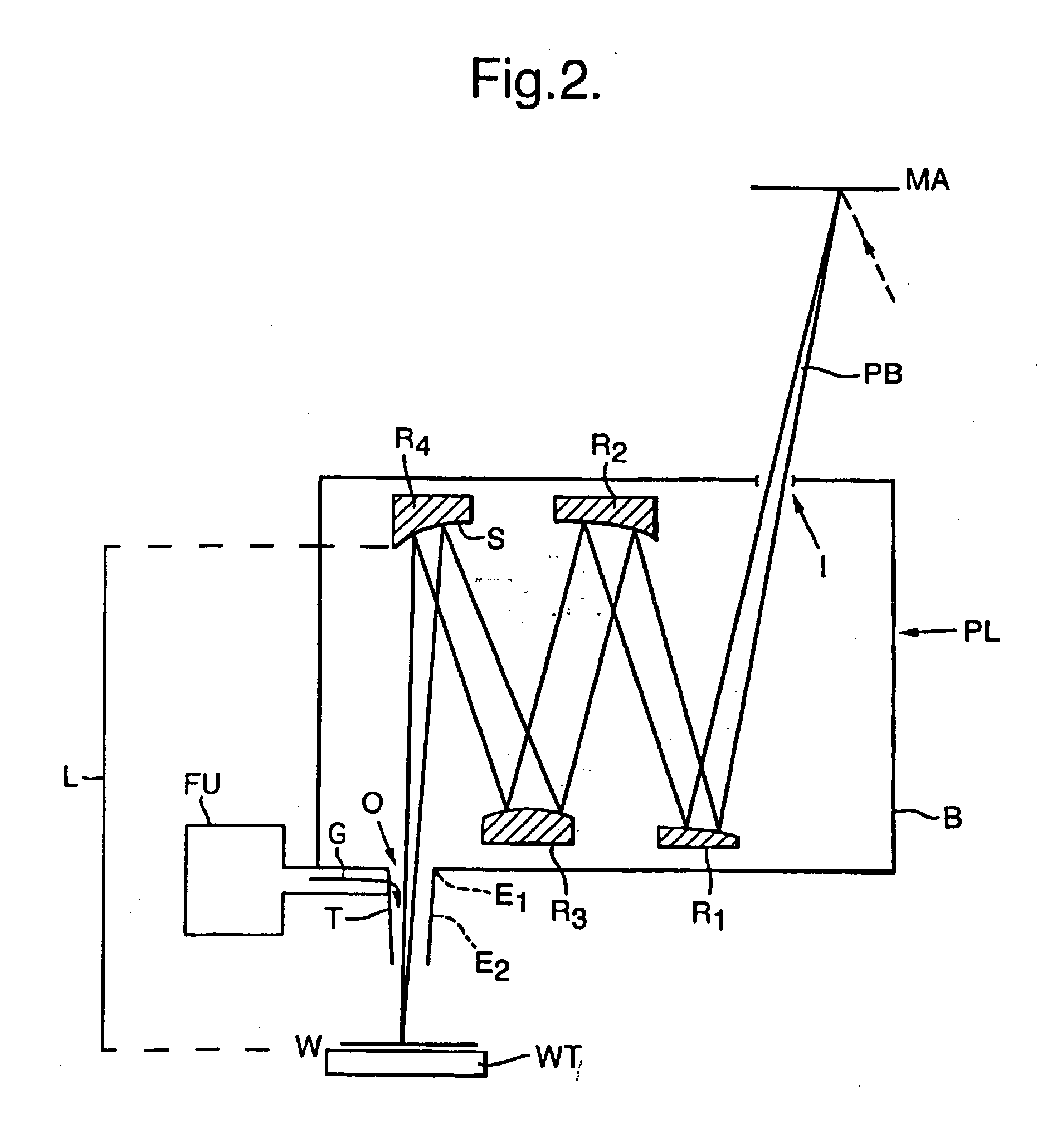

Lithographic projection apparatus, device manufacturing method and device manufactured thereby

InactiveUS20070085984A1Reduction in operation performanceLower performance requirementsPhotomechanical apparatusPhotographic printingHydrogenEngineering

A lithographic projection apparatus includes a radiation system configured to supply a beam of radiation; a mask table provided with a mask holder for holding a mask; a substrate table provided with a substrate holder for holding a substrate; a projection system configured to image an irradiated portion of the mask onto a target portion of the substrate, wherein the projection system is separated from the substrate table by an intervening space that is at least partially evacuated and is delimited at the location of the projection system by a solid surface from which the employed radiation is directed toward the substrate table; the intervening space contains a hollow tube located between the solid surface and the substrate table and situated around the path of the beam of radiation, the tube being configured such that beam of radiation focused by the projection system onto the substrate table does not intercept a wall of the hollow tube; a flushing system is configure to continually flush the inside of the hollow tube with a flow of gas, wherein the gas is hydrogen, the flow of the gas is opposed to the flow of contaminants from the substrate and / or the hollow tube is in fluid communication with the intervening space.

Owner:ASML NETHERLANDS BV

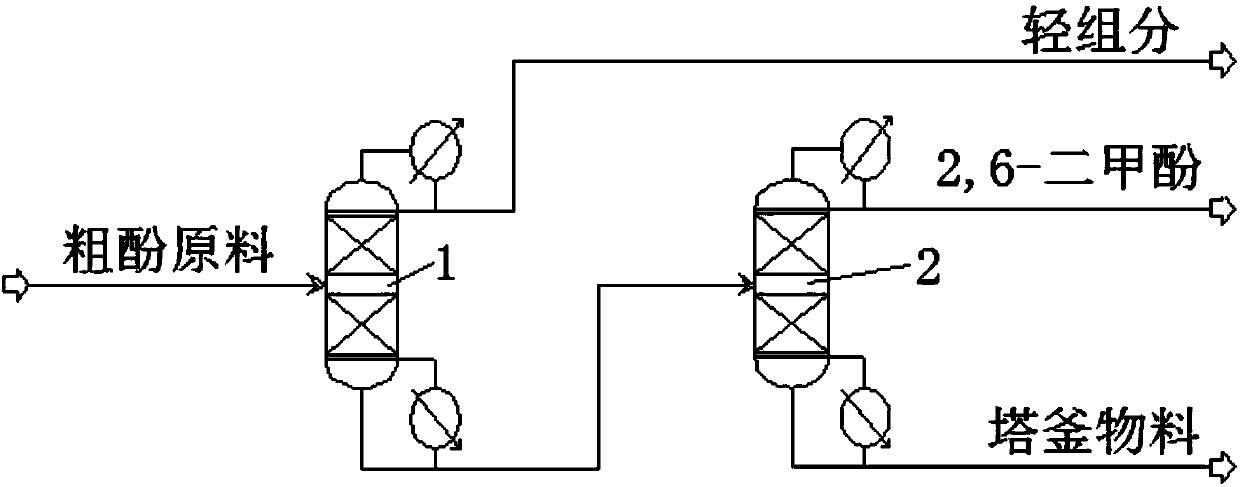

Method for extracting 2,6-dimethylphenol from crude phenol and device applied to method

ActiveCN107556165AReduce gas loadReduce tower diameterOrganic chemistryOrganic compound preparationChemistryHigh concentration

The invention discloses a method for extracting 2,6-dimethylphenol from crude phenol and a device applied to the method. A two-stage distillation technology is adopted for the method, primary distillation treatment is performed on crude phenol firstly to remove light components lighter than 2,6-dimethylphenol, the light components are prevented from affecting the effect of follow-up secondary distillation treatment, and product yield and quality of 2,6-dimethylphenol are improved; then secondary distillation treatment under specific operation conditions is performed, especially, the operationpressure of the secondary distillation treatment is controlled to be not higher than 5 KPa, so that on one hand, the relative volatility of 2,6-dimethylphenol and other components in a primary distillation product is improved and high-concentration 2,6-dimethylphenol can be obtained by extraction, on the other hand, 2,6-dimethylphenol cannot have an isomerism change in the distillation processes,and the 2,6-dimethylphenol separation effect is guaranteed. Tests prove that the yield of 2,6-dimethylphenol is as high as 99.98%, and the purity is as high as 99.9%.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

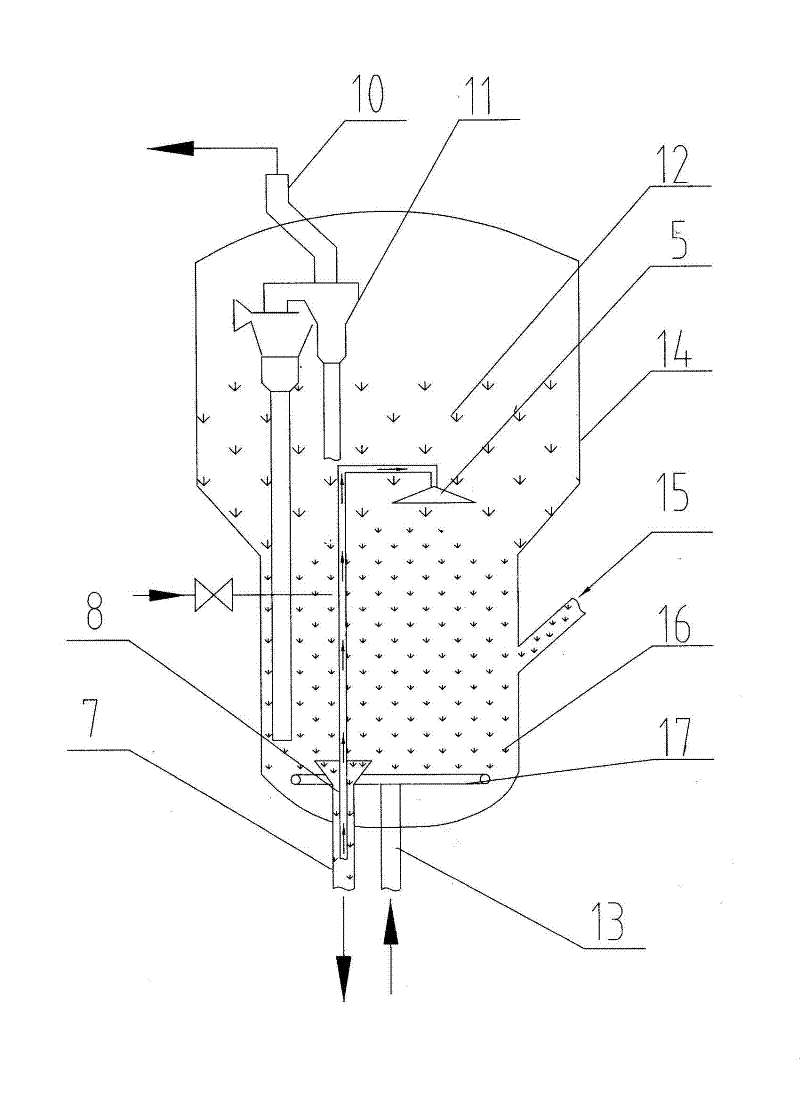

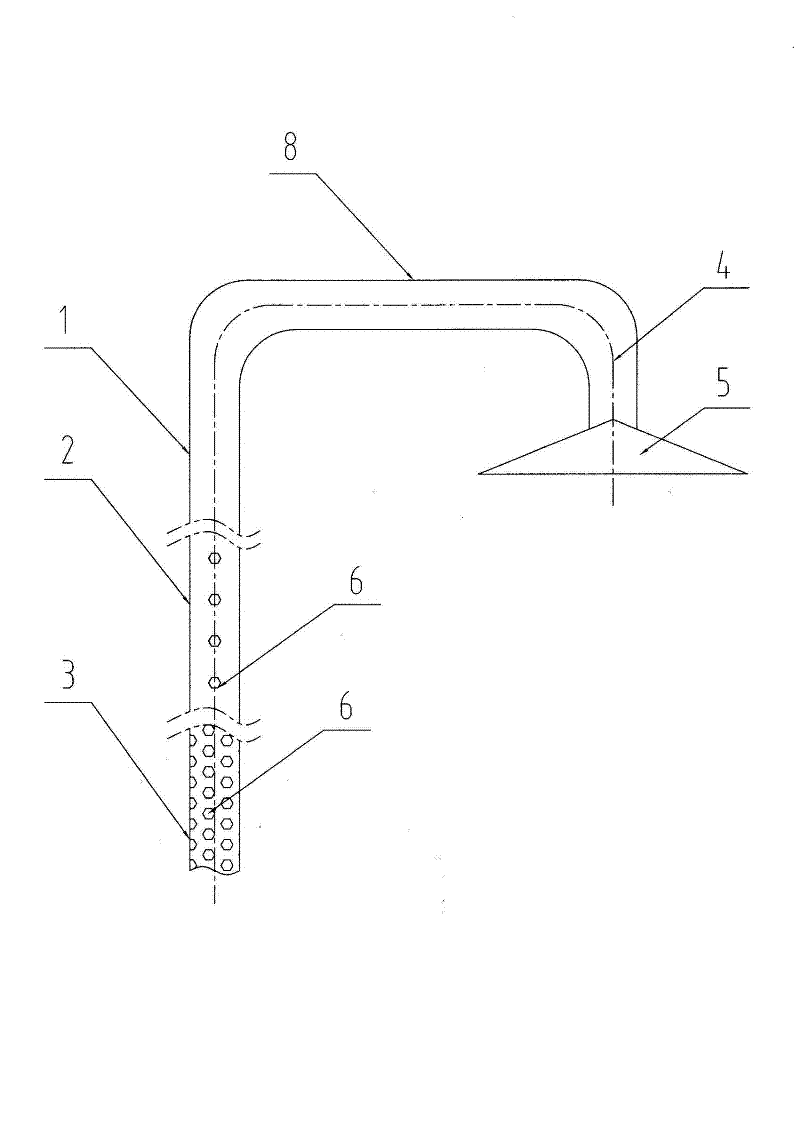

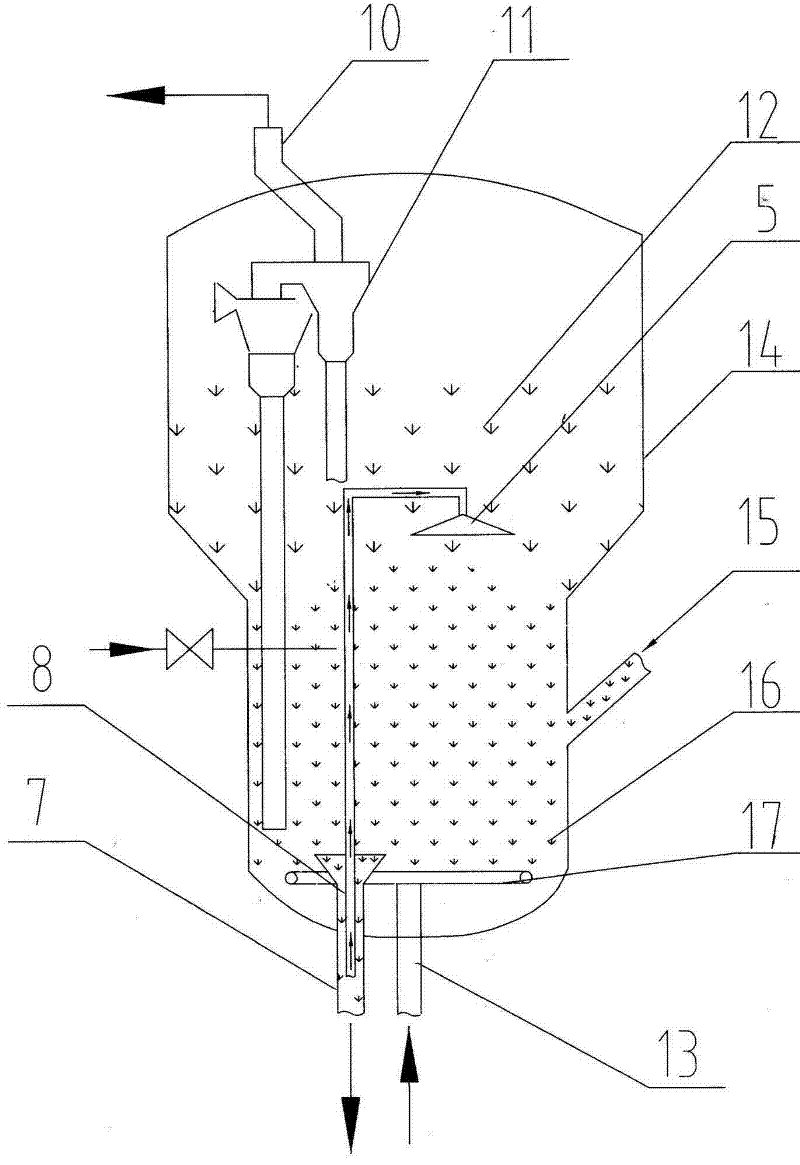

Catalytic cracking regenerated catalyst system and gas collecting method

ActiveCN102489342ASmall and portableOvercome the problem of hydrothermal deactivationCatalyst regeneration/reactivationProduct gasEngineering

The invention relates to a catalytic cracking regenerated catalyst system and a gas collecting method. The catalytic cracking regenerated catalyst system comprises a regenerator; a gas collecting device is arranged in the regenerator, is a gas-guide pipe with an inverted L-shaped structure and comprises a stretching regenerated vertical pipe section, a dense phase region section, a dilute phase region section, an inverted L-shaped section and a smoke dispersing section, wherein the stretching regenerated vertical pipe section is inserted into a regenerated vertical pipe; the smoke dispersing section is arranged in a dilute phase region and is bell mouth-shaped; and notches for collecting gases are uniformly arranged on the stretching regenerated vertical pipe section and the dense phase region section. According to the gas collecting method provided by the invention, smoke in a regenerated catalyst is pressed into the gas-guide pipe through the notches arranged on the gas collecting device inside the regenerated vertical pipe by mainly using a pressure difference between a dense phase region and the dilute phase region, then enters the dilute phase region through the smoke dispersing section and finally is absorbed and discharged through a cyclone separator. According to the gas collecting method, the amount of the smoke in the regenerated catalyst carried into a follow-up reaction system is effectively reduced, and the processing capacity is increased.

Owner:岳阳恒忠机械工程技术有限公司 +2

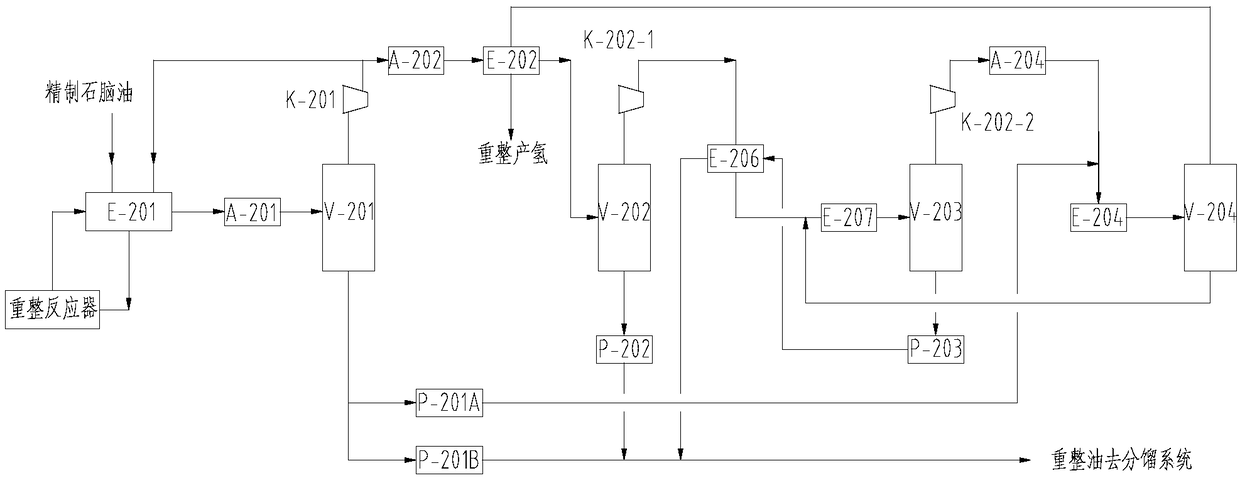

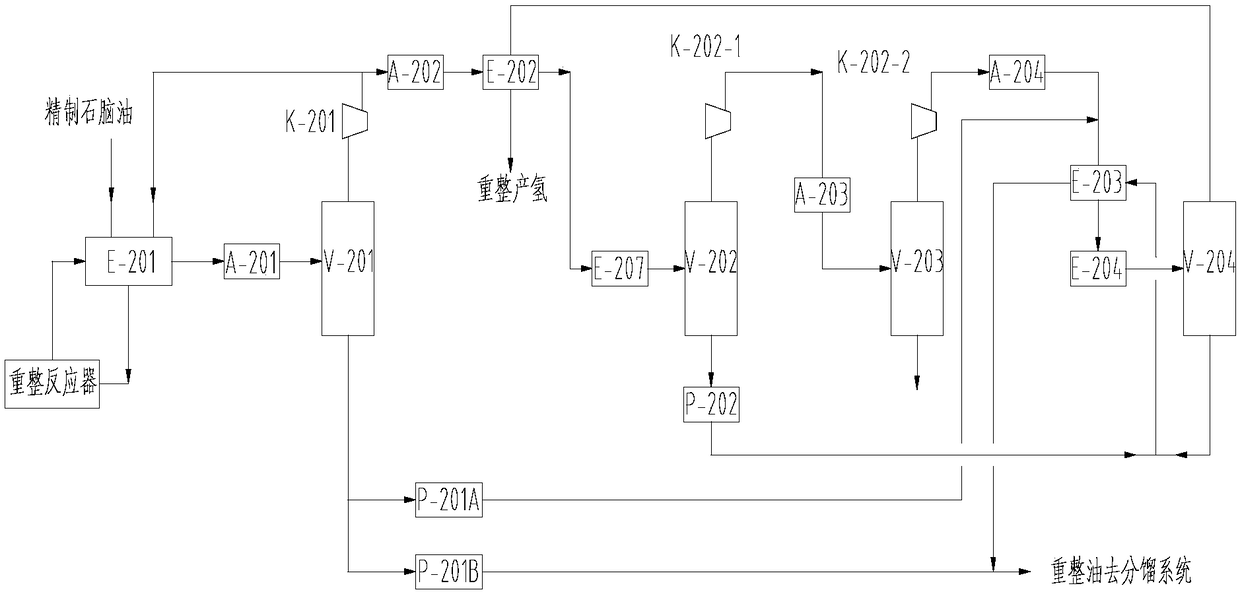

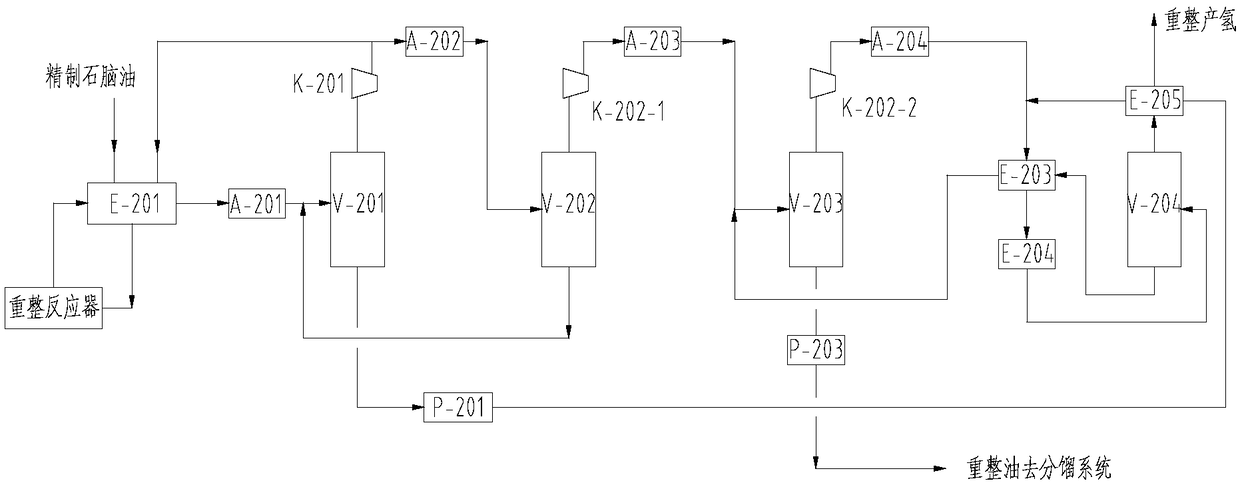

Catalytic reforming recontacting process with cold capacity equalization setting

The invention relates to a catalytic reforming recontacting process with cold capacity equilibrium setting, introduced based on the research on the characteristics of the reforming reaction recontacting process flow and the gas-liquid equilibrium characteristics of the product. Two pumps are installed at the bottom of the first gas-liquid separation tank, after being boosted, two-stranded liquid phase enter a recontacting system and a reforming oil fractionation system respectively, the ratio of the two liquid phases can be flexibly adjusted to optimize the recontacting effect and reduce energy consumption; second, third and fourth gas-liquid separation tanks use the way of heat exchange or setting a cooler to reduce the recontacting temperature, reduce the gas phase load of the compressorinlet and the energy consumption; the liquid phase of the second and third gas-liquid separation tanks directly enters the subsequent reforming oil separation system to reduce the accumulation and circulation of the liquefied gas and the above hydrocarbon components in the recontacting system to reduce the energy consumption of device.

Owner:SHANGHAI HOTO PETROCHEM ENG

Antechamber control reducing leak through ferrofluid seals

A system for controlling a gas load imposed upon a high vacuum chamber includes a first chamber enclosing a high vacuum and positioned within an ambient environment, a second chamber enclosing a gas and positioned within the ambient environment adjacent to the first chamber, and a rotatable shaft having a first portion extending into the first chamber and a second portion extending into the second chamber. A ferrofluid seal is positioned about the rotatable shaft and positioned between the first portion and the second portion and the ferrofluid seal fluidically separates the first chamber from the second chamber. A control unit is attached to the second chamber and configured to control the gas enclosed in the second chamber such that a gas load in the first chamber is reduced.

Owner:GENERAL ELECTRIC CO

Distillate yield improving vacuum distillation method and device

ActiveCN102311772BAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Novel Delayed Coking Method

ActiveCN104560110BImprove distribution efficiencyIncrease injection speedThermal non-catalytic crackingGas phasePetrochemical

The invention relates to a novel coking method, belonging to the field of petrochemical industry. The coking method disclosed by the invention comprises the step of adding an antifoamer into a coking tower during coking reaction when foam in the coking tower reaches a certain extent, wherein the antifoamer enters the coking tower in a gas phase carrier carrying manner and contains polyborosiloxane, ethyl cellulose, ultrahigh-viscosity linear polydimethyl siloxane, ferriferous polysilazane, higher fatty alcohol and a solvent. According to the coking method disclosed by the invention, the antifoaming efficiency of a delayed-coking tower can be increased, the antifoamer is high in service efficiency and low in consumption, and the phenomenon that an antifoamer filling pipeline is subjected to coking and blocking due to rising oil gas can be inhibited, so that the overall economical efficiency and stability of a delayed coking device can be improved to a certain extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com