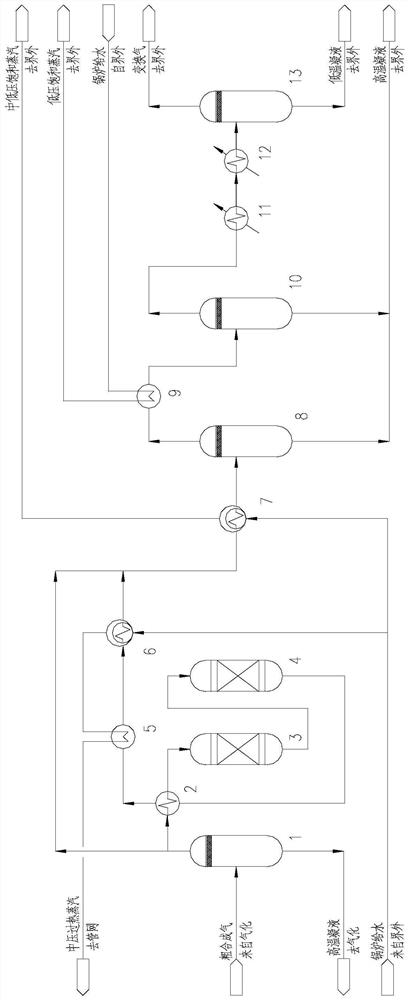

Carbon monoxide conversion system and method for coal water slurry gasification-to-methanol device

A carbon monoxide and conversion system technology, applied in chemical instruments and methods, inorganic chemistry, hydrogen/synthesis gas production, etc., can solve problems such as unreasonable heat utilization, high equipment investment, large gas load, etc., and achieve good energy integration effect, Reasonable use of waste heat and the effect of reducing gas load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 439105kg / h crude synthesis gas (mainly composed of CO, H 2 , CO 2 、H 2 S, H 2 O, etc., 6.25MPa), enter the first gas-liquid separator (1), the equipment operating temperature is controlled at 240 ° C, after gas-liquid separation, the top gas phase is divided into two gases, one of which accounts for 60% of the total gas volume After being heated to 260°C by the crude gas preheater (2), it enters the detoxification tank to remove impurities, and then enters the shift furnace for carbon monoxide shift reaction. This reaction is a strong exothermic process, and the temperature of the shift gas at the outlet of the shift furnace rises to After 390°C, after the crude gas preheater (2) is cooled to 350°C, it enters the medium-pressure steam superheater, superheats the saturated steam to 300°C and sends it to the external steam pipe network, and the transformed gas enters the medium-pressure steam generator Saturated steam (2.5Mpa, 31500kh / h) is produced as a by-product. Th...

Embodiment 2

[0029] 439105kg / h crude synthesis gas (mainly composed of CO, H 2 , CO 2 、H 2 S, H 2O, etc., 6.25MPa), enter the first gas-liquid separator (1), the equipment operating temperature is controlled at 245 ° C, after the gas-liquid separation, the top gas phase is divided into two gases, one of which accounts for 50% of the total gas volume , is heated to 280°C by the crude gas preheater (2), enters the detoxification tank to remove impurities, and then enters the shift furnace for carbon monoxide shift reaction. This reaction is a strong exothermic process, and the temperature of the shift gas at the outlet of the shift furnace rises to After 410°C, after the crude gas preheater (2) is cooled to 359°C, it enters the medium-pressure steam superheater, superheats the saturated steam to 300°C and sends it to the external steam pipe network, and the transformed gas enters the medium-pressure steam generator By-product saturated steam (2.5Mpa, 28500kh / h), the shifted gas is further...

Embodiment 3

[0031] 439105kg / h crude synthesis gas (mainly composed of CO, H 2 , CO 2 、H 2 S, H 2 O, etc., 6.25MPa), enter the first gas-liquid separator (1), the equipment operating temperature is controlled at 250 ° C, after the gas-liquid separation, the top gas phase is divided into two gases, one of which accounts for 40% of the total gas volume , is heated to 300°C by the crude gas preheater (2), enters the detoxification tank to remove impurities, and then enters the shift furnace for carbon monoxide shift reaction. This reaction is a strong exothermic process, and the temperature of the shift gas at the outlet of the shift furnace rises to After 430°C, after being cooled to 370°C by the crude gas preheater (2), it enters the medium-pressure steam superheater, superheats the saturated steam to 320°C and sends it to the external steam pipe network, and the transformed gas enters the medium-pressure steam generator Saturated steam (4.0Mpa, 18500kh / h) is produced as a by-product. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com