Catalytic cracking regenerated catalyst system and gas collecting method

A regenerated catalyst and catalytic cracking technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problems of reducing the amount of flue gas from regenerated catalysts and cannot achieve removal, and achieve the goal of overcoming water Heat deactivation problem, simple structure, effect of improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

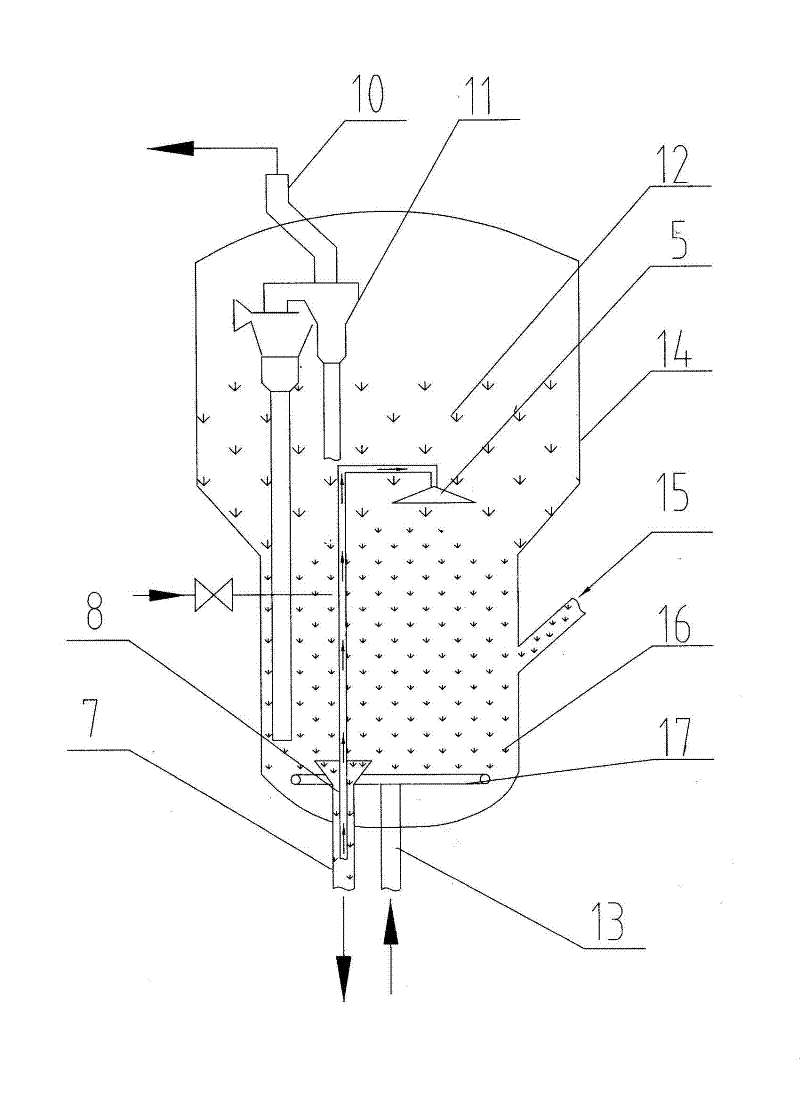

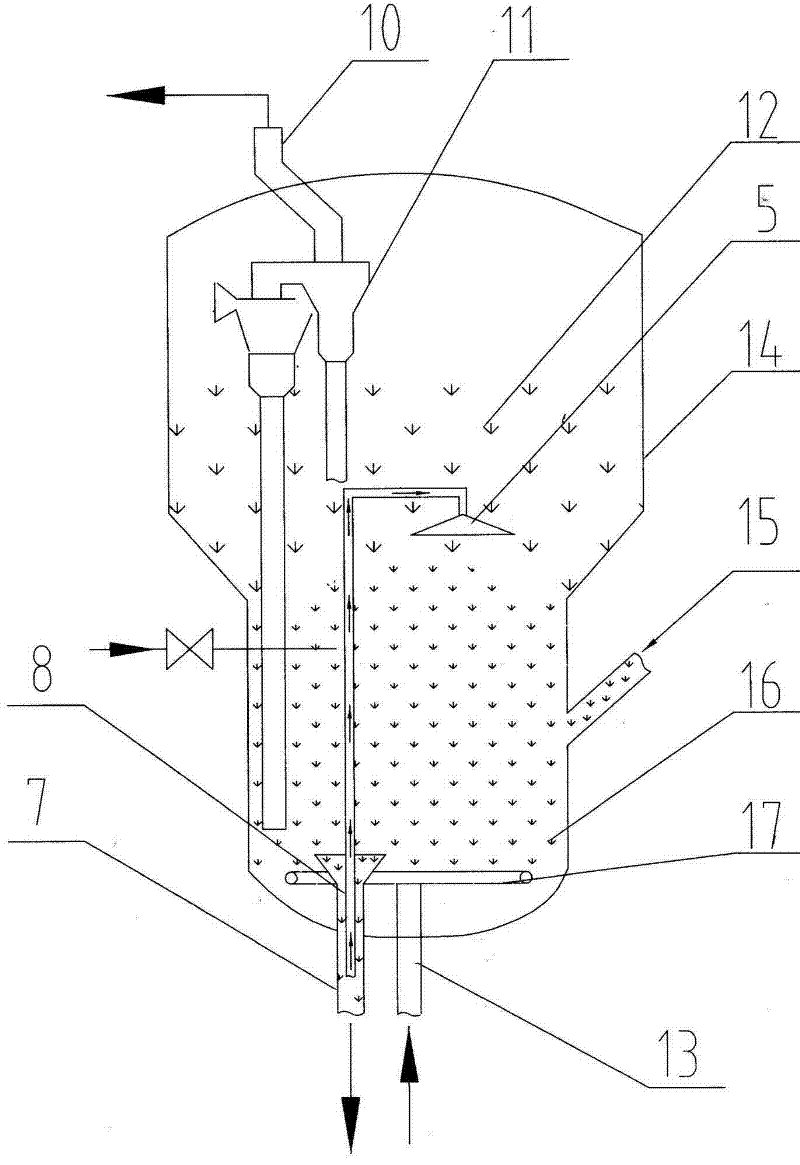

[0027] Depend on figure 1 , 2 It can be seen that the catalytic cracking regenerated catalyst system of the present invention comprises a regenerator 14 composed of a burnt air inlet 13, a regeneration standpipe 7, a standby catalyst inlet 15, a main air distributor 17, a smoke exhaust pipe 10 and a cyclone separator 11, and the The raw catalyst is fed into the regenerator 14 and forms a dense phase zone 16 and a dilute phase zone 12, wherein:

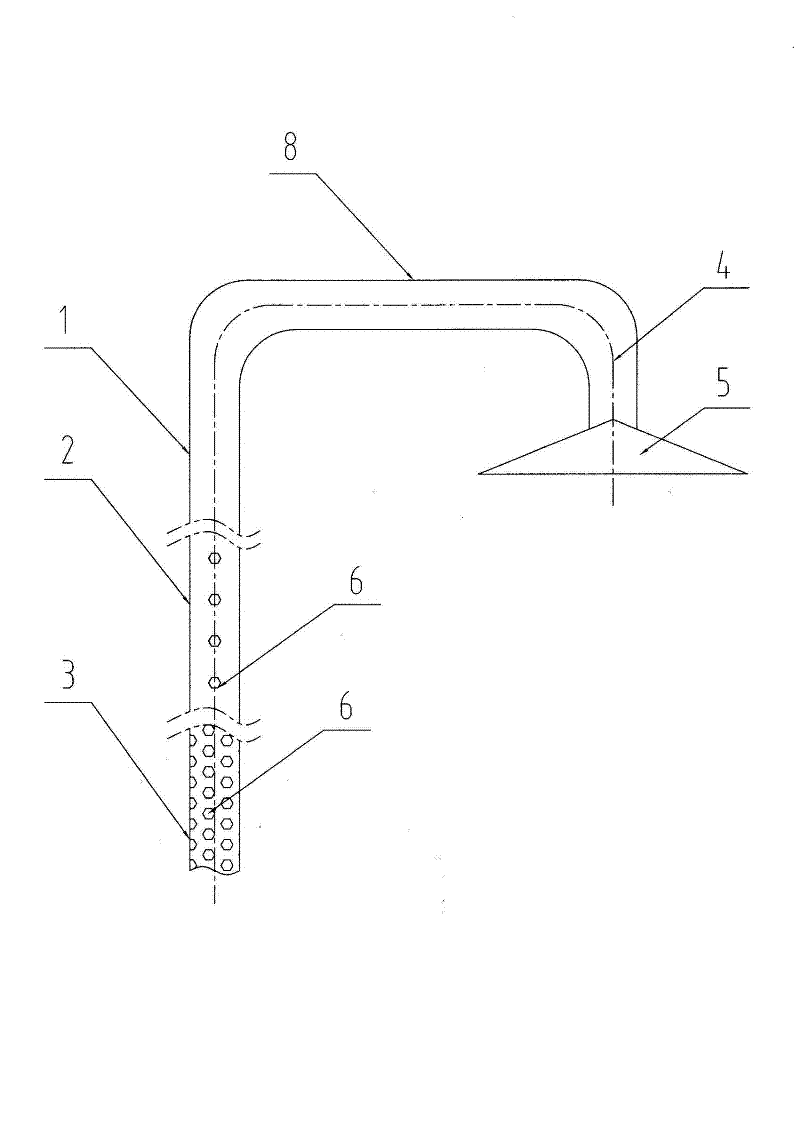

[0028] A gas collection device is fixed inside the regenerator 14 through a cantilever. The gas collection device is an air guide tube 8 with an inverted L-shaped structure, and the air guide tube 8 runs through the regeneration riser 7, the dense phase zone 16 and the dilute phase zone of the regenerator 14 as a whole. within 12;

[0029] The air guide pipe 8 includes a regeneration standpipe section 3, a dense phase section 2, a dilute phase section 1, an inverted L section 4 and a flue gas dispersion section 5, wherein the regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com