Method for extracting 2,6-dimethylphenol from crude phenol and device applied to method

A technology of xylenol and crude phenol, which is applied in the field of coal chemical industry, can solve the problems of poor selectivity, and achieve the effects of high quality, reduced gas phase load, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

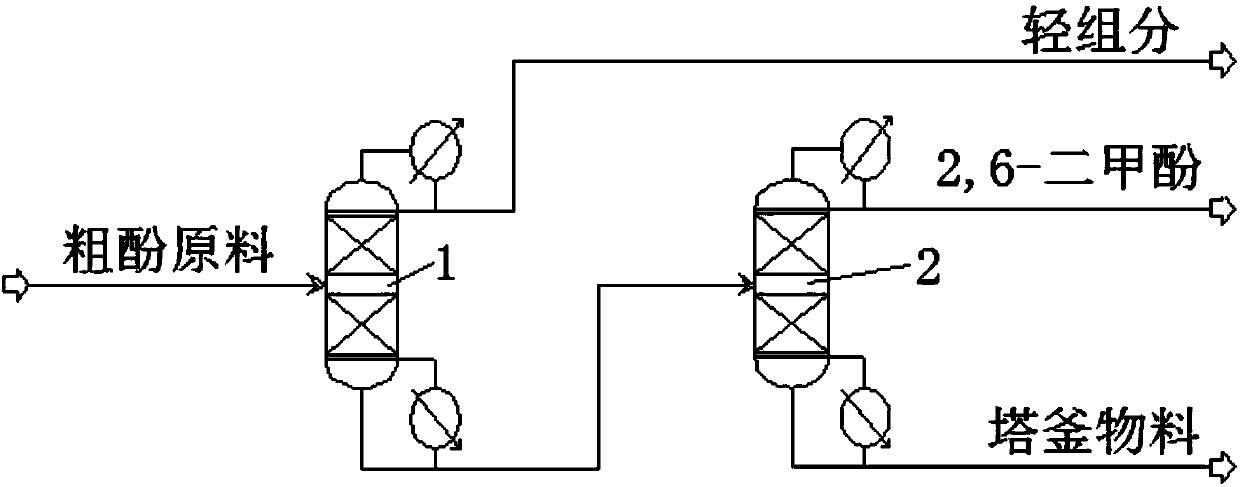

[0037] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0038] 1) Select the crude phenol raw material, which contains light components such as 0.18wt% phenol, 5.03wt% 2,6-xylenol, 66.51wt% m-p-cresol and 28.28wt% other dicresols in this crude phenolic raw material heavy components such as cresol, and preheat the crude phenol raw material to 155°C;

[0039] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled at 25KPa, and the operating temperature is The temperature is 130°C, the reflux ratio is 14, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the primary distillation tower, and the primary distillation product is collected from the bottom of the towe...

Embodiment 2

[0042] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0043]1) Select the crude phenol raw material, which contains light components such as 0.22wt% phenol, 2.07wt% 2,6-xylenol, 66.56wt% m-p-cresol and 31.15wt% other dicresols in this crude phenolic raw material heavy components such as cresol, and preheat the crude phenol raw material to 154°C;

[0044] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled to 0.5Pa. The temperature is 160°C, the reflux ratio is 5, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the first-stage rectification tower, and the first-stage rectification product is collected from the bottom of the tower, and the first-stage re...

Embodiment 3

[0047] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0048] 1) Select the crude phenol raw material, which contains light components such as 0.05wt% phenol, 15wt% 2,6-xylenol, 60wt% m-p-cresol and 24.5wt% other xylenols in this crude phenolic raw material Equal weight components, and preheat the crude phenol raw material to 153°C;

[0049] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled at 50KPa, and the operating temperature is The temperature is 100°C, the reflux ratio is 20, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the primary distillation tower, and the primary distillation product is collected from the bottom of the tower, and the prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com