Patents

Literature

80results about How to "Reduce tower diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

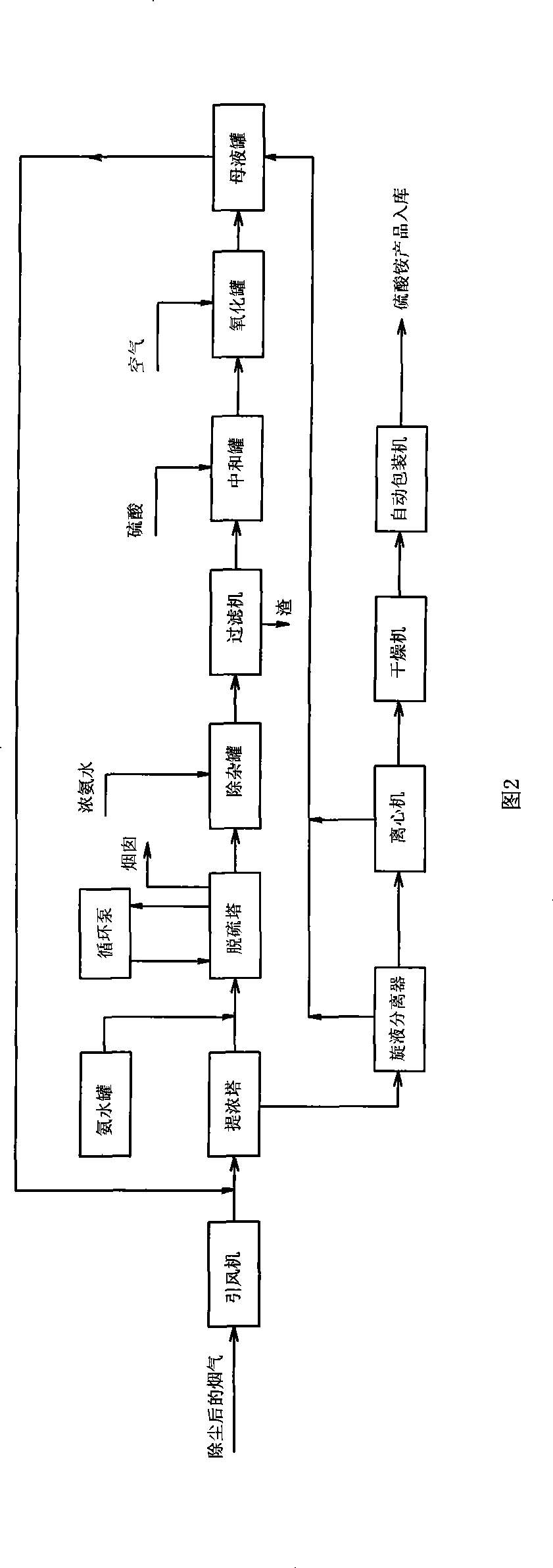

Multi-effect rectifying process of methanol

InactiveCN101570466AIncrease operating pressureIncrease productionOrganic compound preparationChemical industryChemistryReboiler

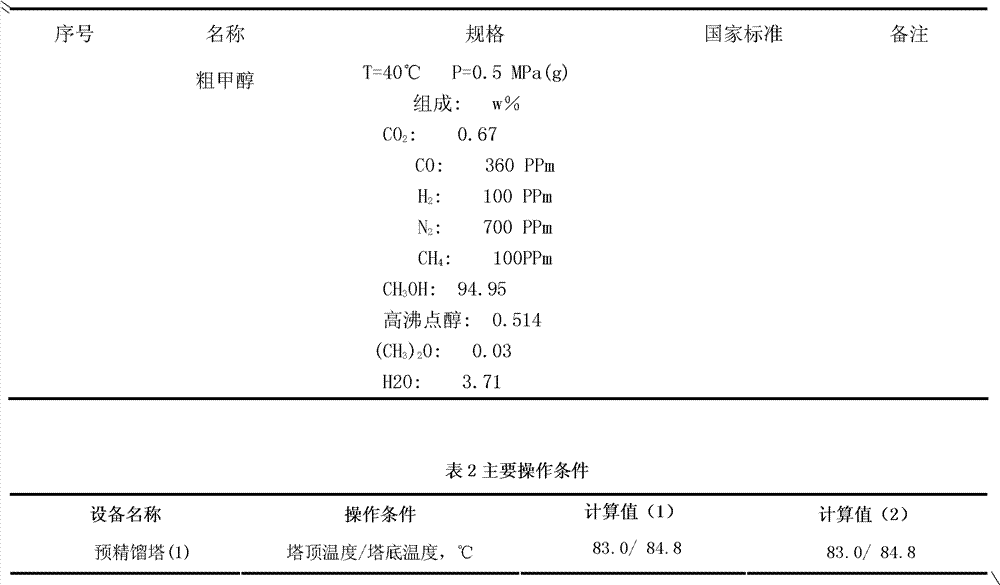

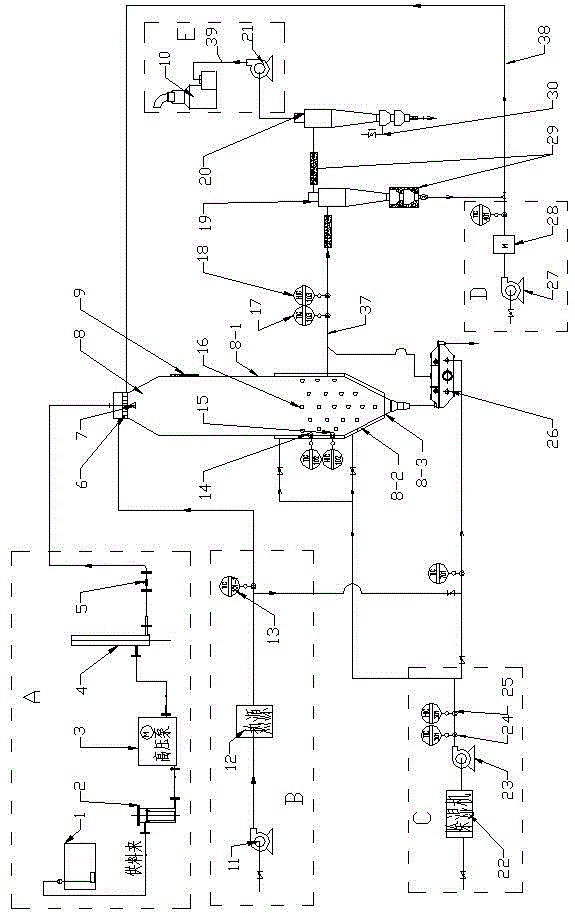

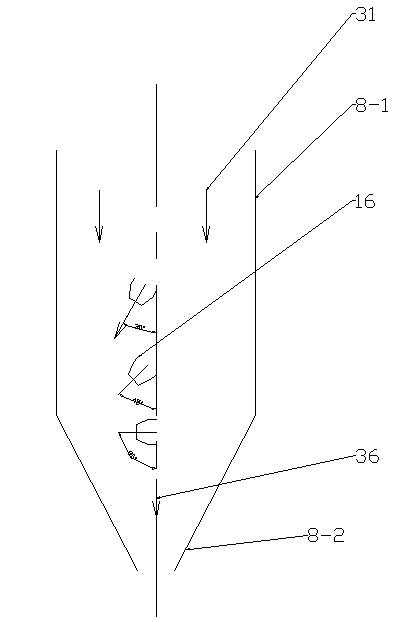

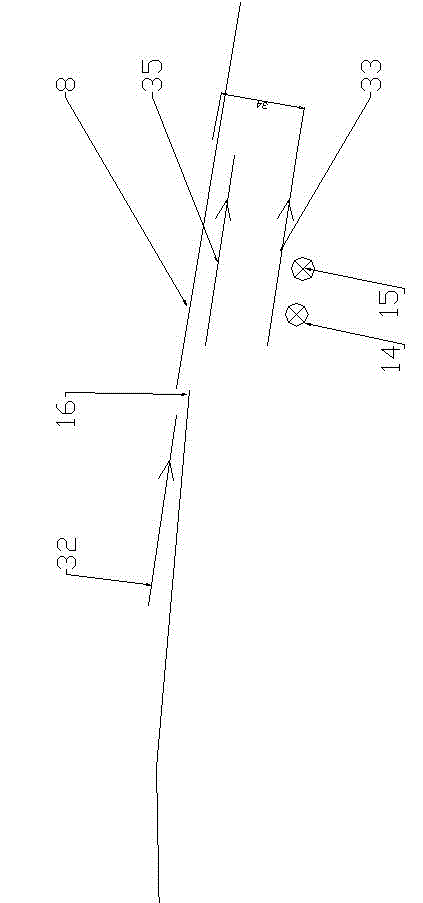

The invention relates to a multi-effect rectifying process of methanol, which belongs to the technical field of separation and purification of chemical products. In the process, a crude methanol raw material of coal-to-methanol is rectified by a pre-rectifying tower, a pressurizing tower I, a pressurizing tower II, an atmospheric tower and a recovery tower in turn at appropriate temperature and pressure so as to obtain a high-purity refined methanol product according with quality requirements. In the flow, methanol steam on the top of the pressurizing tower I is used for providing heat for a reboiler at the bottom of the pressurizing tower II, the methanol steam on the top of the pressurizing tower II is used for providing heat for a reboiler at the bottom of the atmospheric tower, and the pressurizing tower I, the pressurizing tower II and the atmospheric tower form multi-effect rectification; and simultaneously, the methanol steam on the top of the recovery tower is used for providing heat for a reboiler at the bottom of the pre-rectifying tower, and the recovery tower and the pre-rectifying tower form double-effect rectification. The invention provides an energy-saving methanol multi-effect rectifying process method which has the advantages of greatly reduced energy consumption, more stable production process, more easily controlled product quality, higher methanol recovery rate and basically equivalent investment compared with a three-tower rectifying process.

Owner:XI'AN PETROLEUM UNIVERSITY

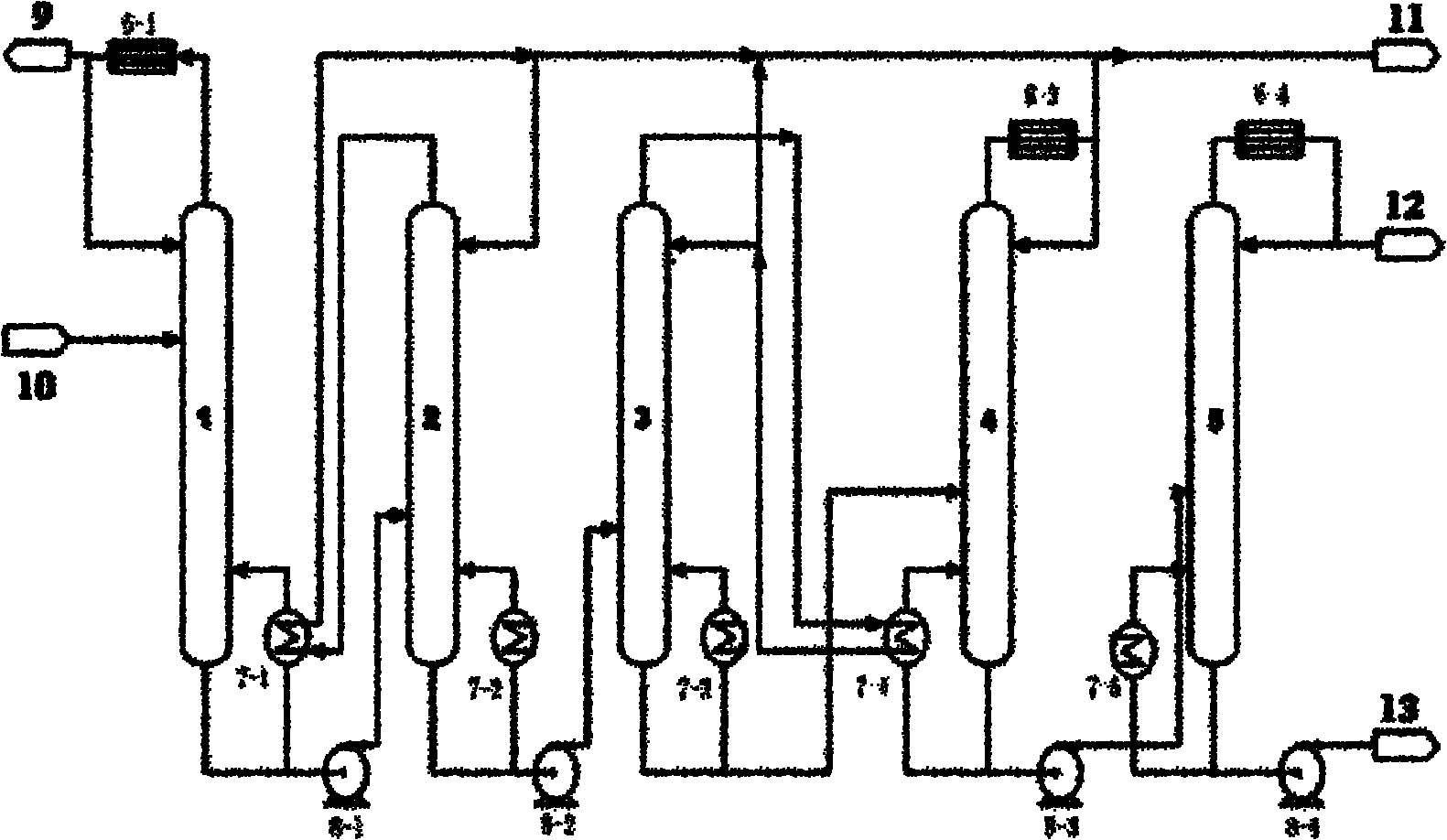

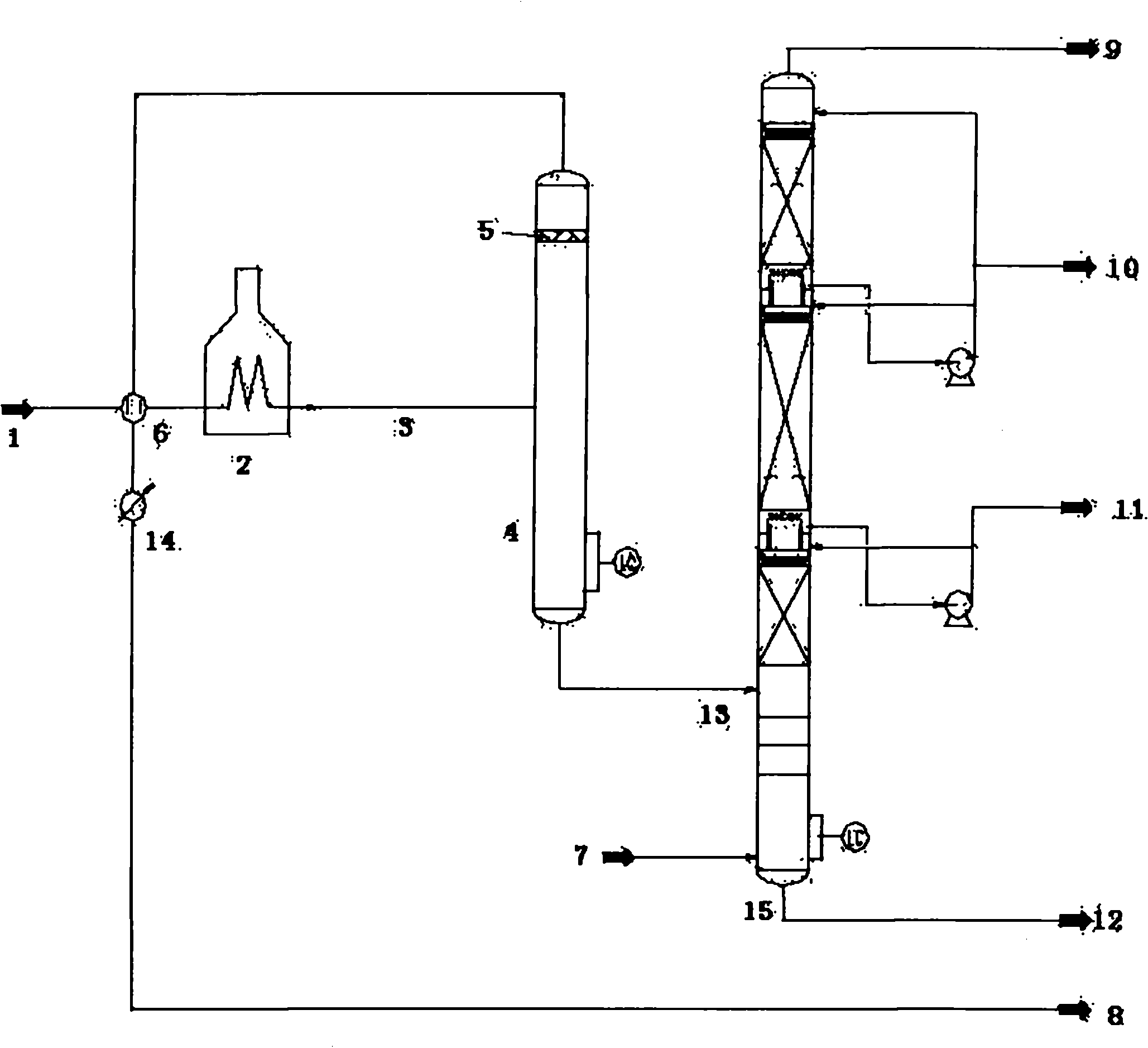

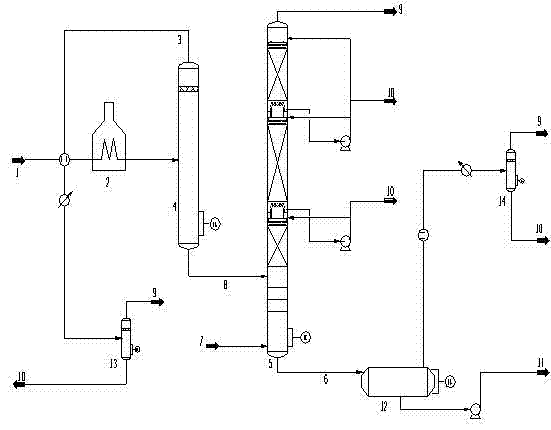

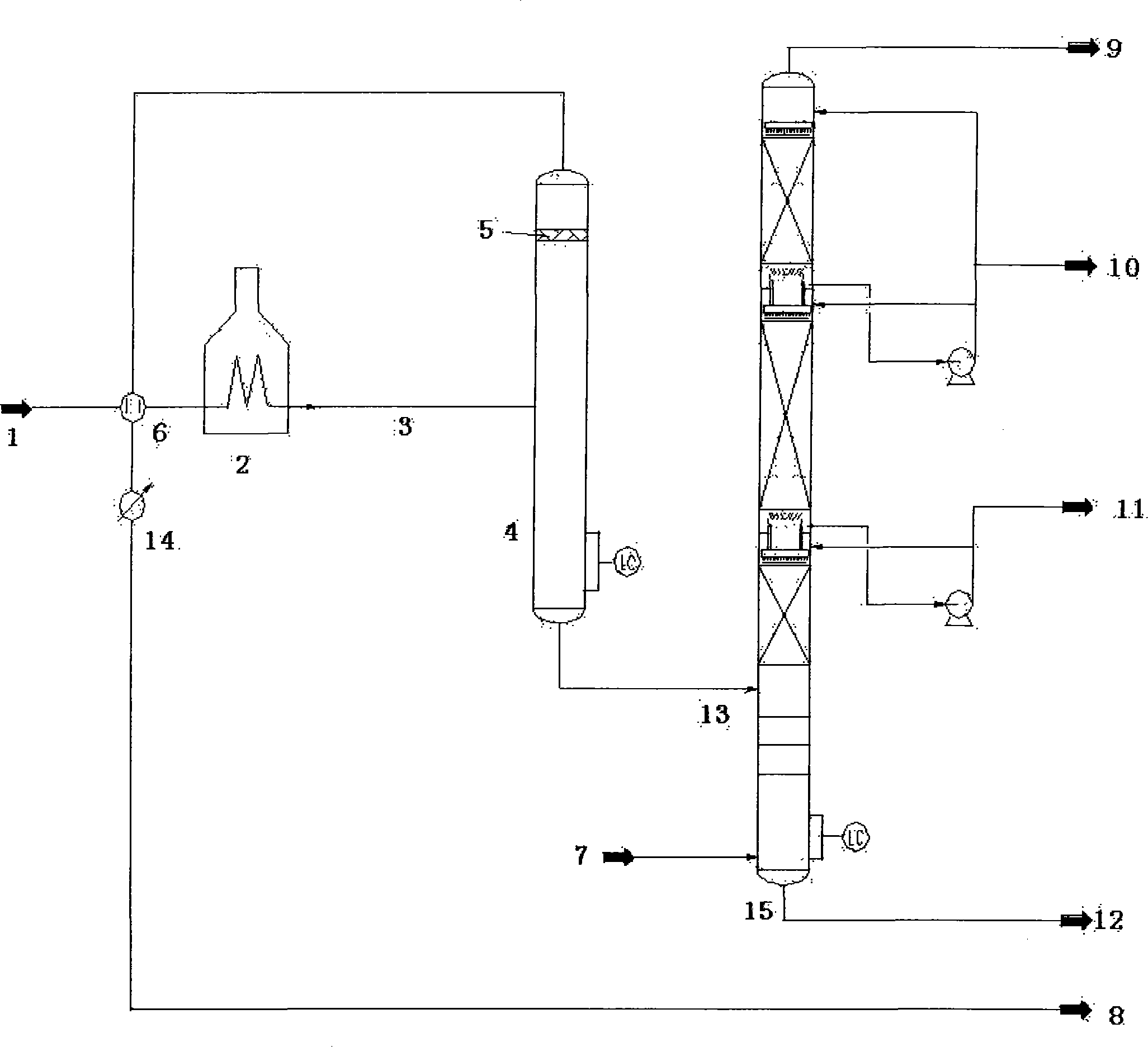

Method for recycling hydrogen chloride in tail gas of polysilicon production

ActiveCN101791487AHigh purityLarge storage capacityChlorine/hydrogen-chloride purificationSiliconDistillationChloride

The invention discloses a method for recycling hydrogen chloride in tail gas of polysilicon production. In the method, tail gas is cooled and condensed, so that most of chlorosilane is liquefied; compressed gas enters a hydrogen chloride absorption tower and absorbed by chlorosilane solution, and hydrogen gas is exhausted from the hydrogen chloride absorption tower and collected; liquid hydrogen-chloride-rich chlorosilane discharged from the bottom of the hydrogen chloride absorption tower is introduced into a hydrogen chloride distillation tower, and chlorosilane solution is discharged form the bottom of the hydrogen chloride distillation tower; and hydrogen chloride containing trace hydrogen gas is exhausted from the top of the hydrogen chloride distillation tower and enters a full condenser on the top of the distillation tower, condensate of the full condenser on the top of the distillation tower enters a return tank of the distillation tower, the trace hydrogen is exhausted from the top of the return tank of the distillation tower and collected, a part of the condensate of the return tank of the distillation tower is introduced into the hydrogen chloride distillation tower and used as return liquid, and the other part of the condensate enters a liquid hydrogen chloride reservoir for storage. The method improves the purity of recycled hydrogen chloride and the storage amount of hydrogen chloride and saves the investment of equipment.

Owner:CHINA TIANCHEN ENG

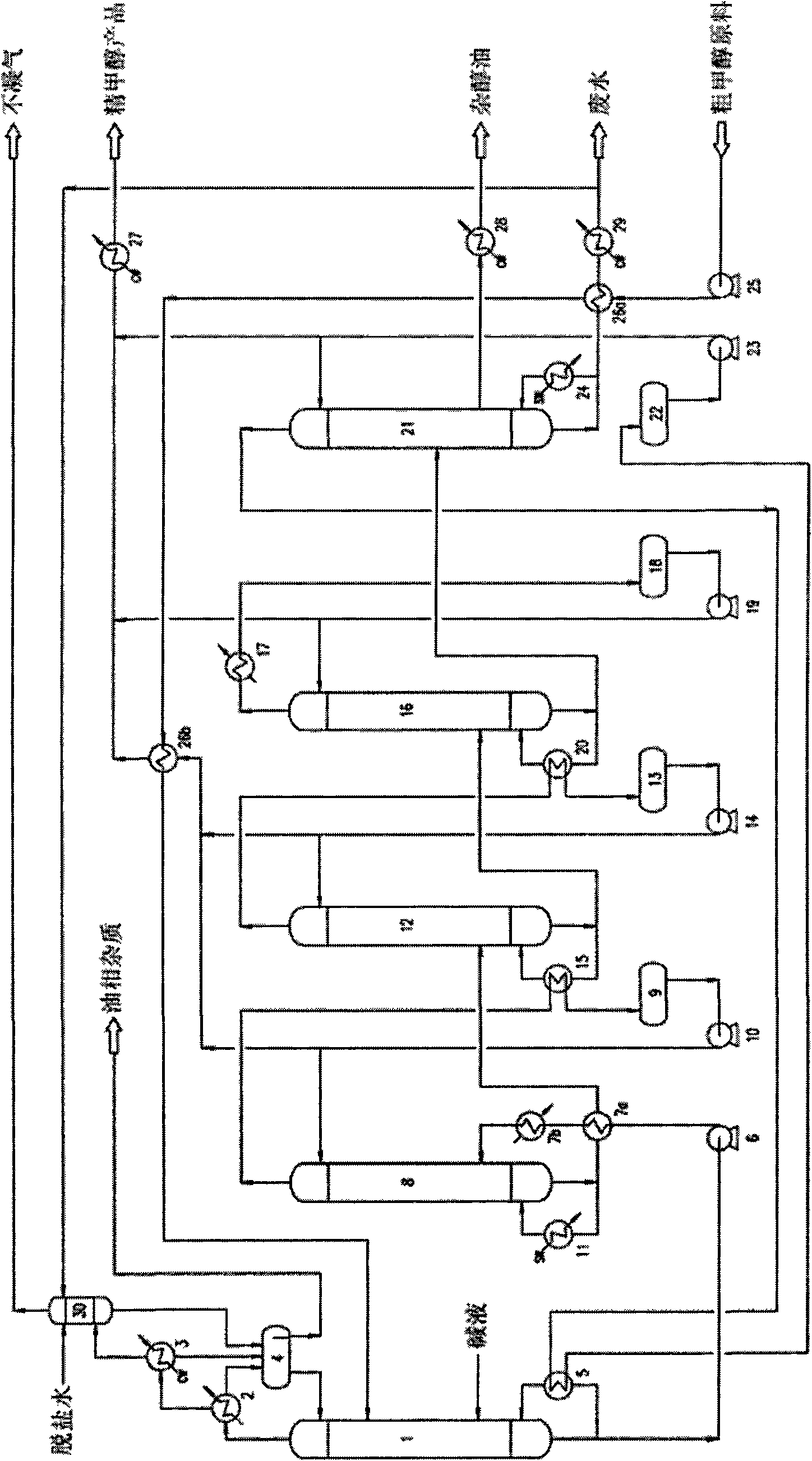

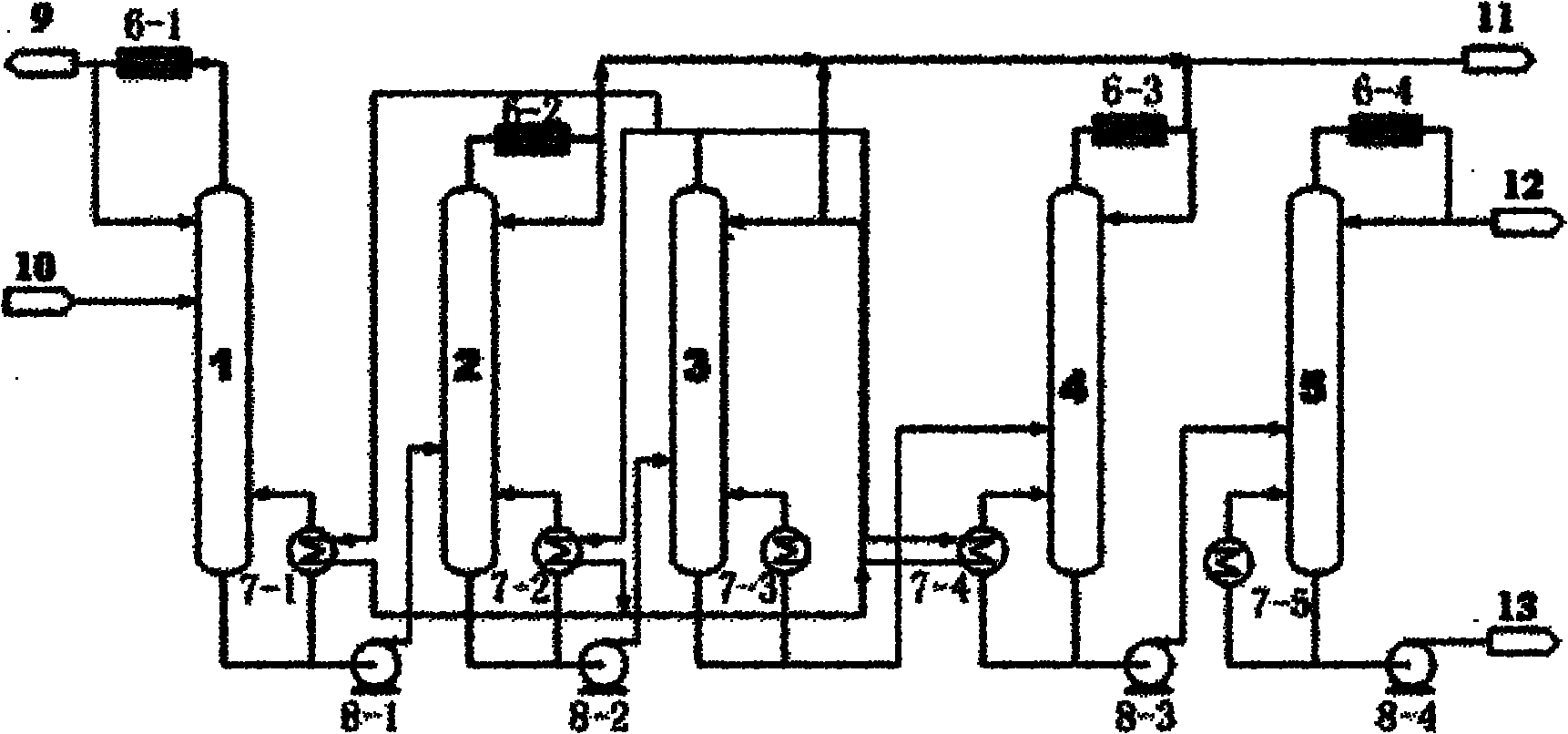

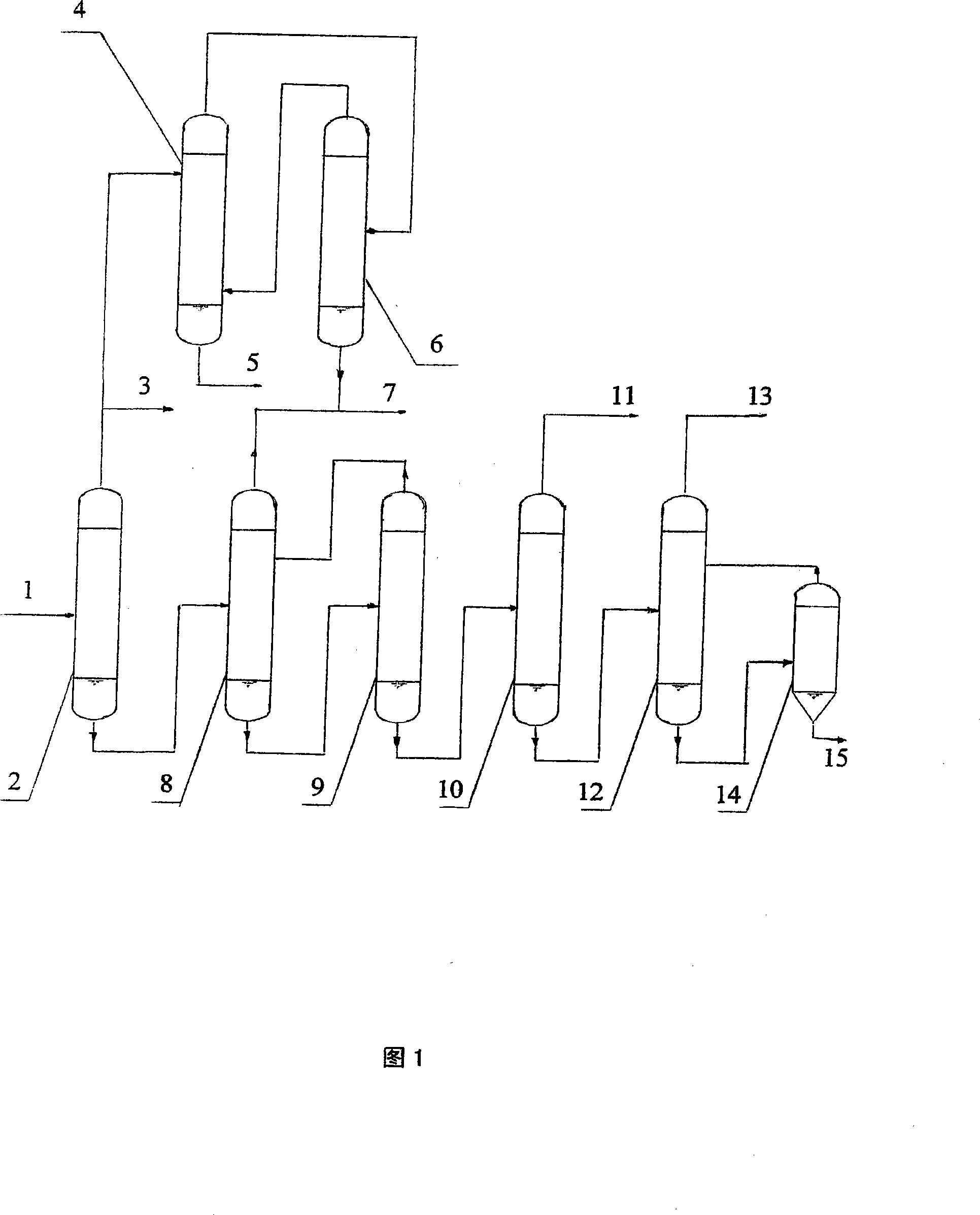

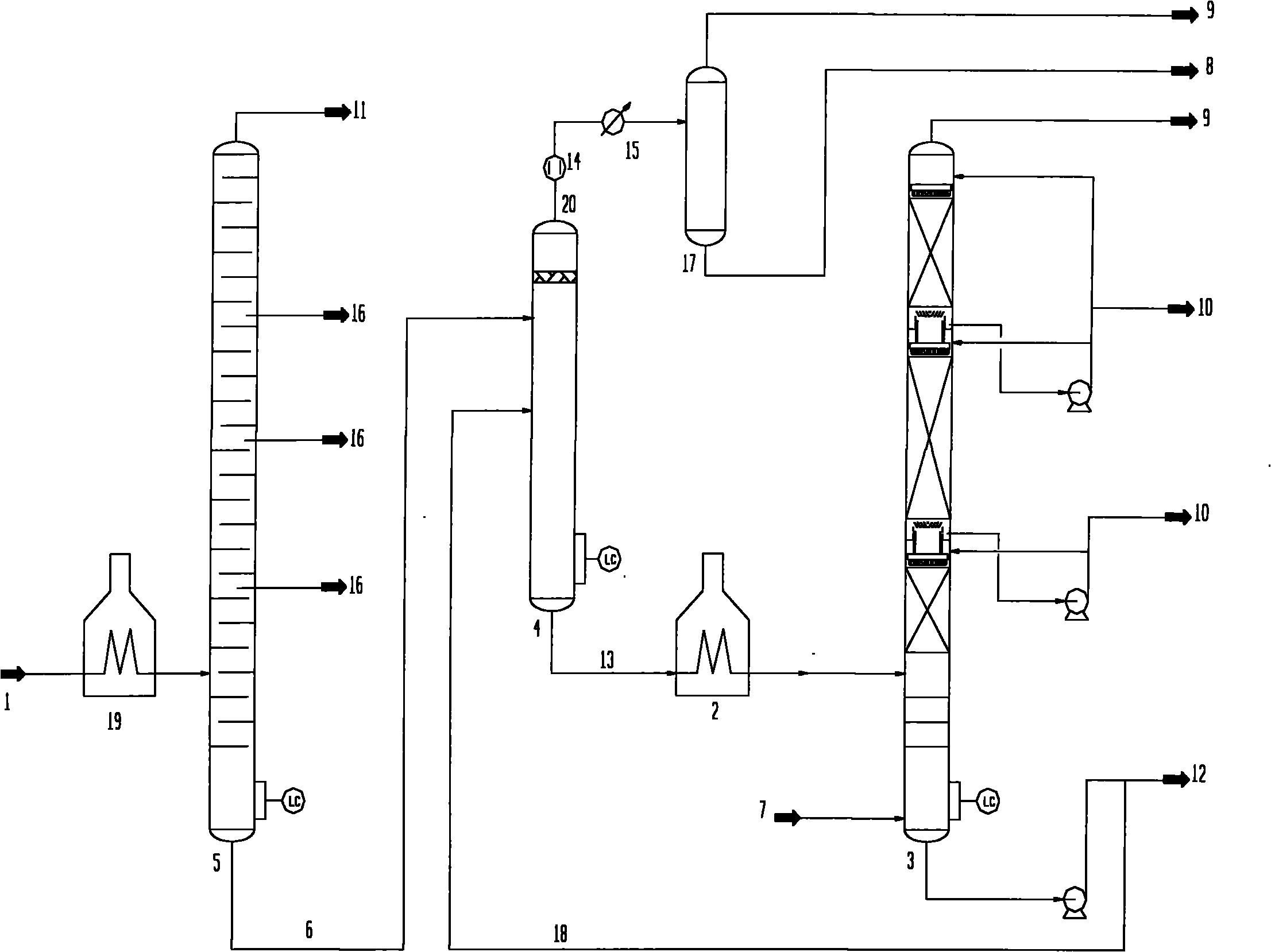

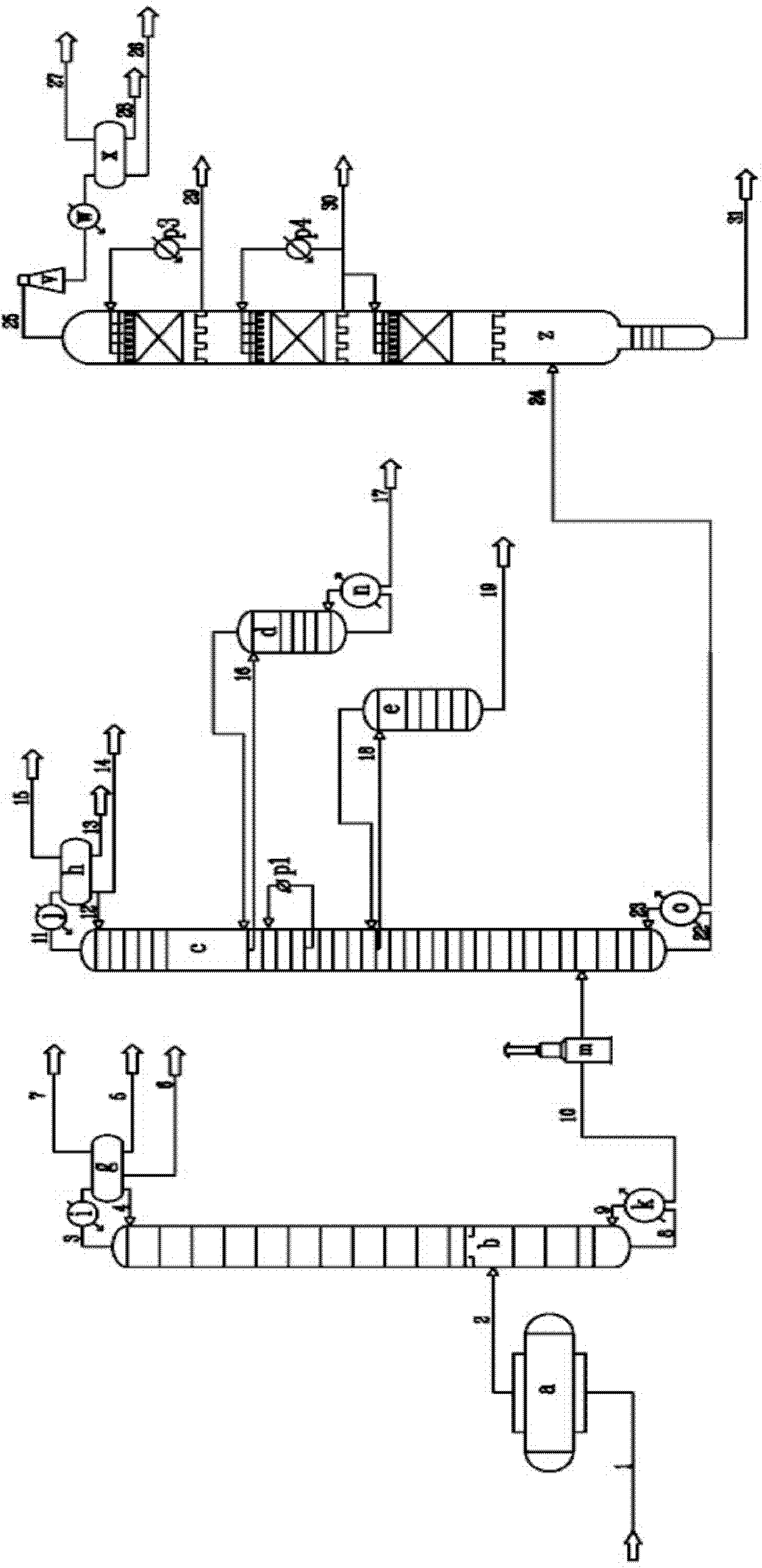

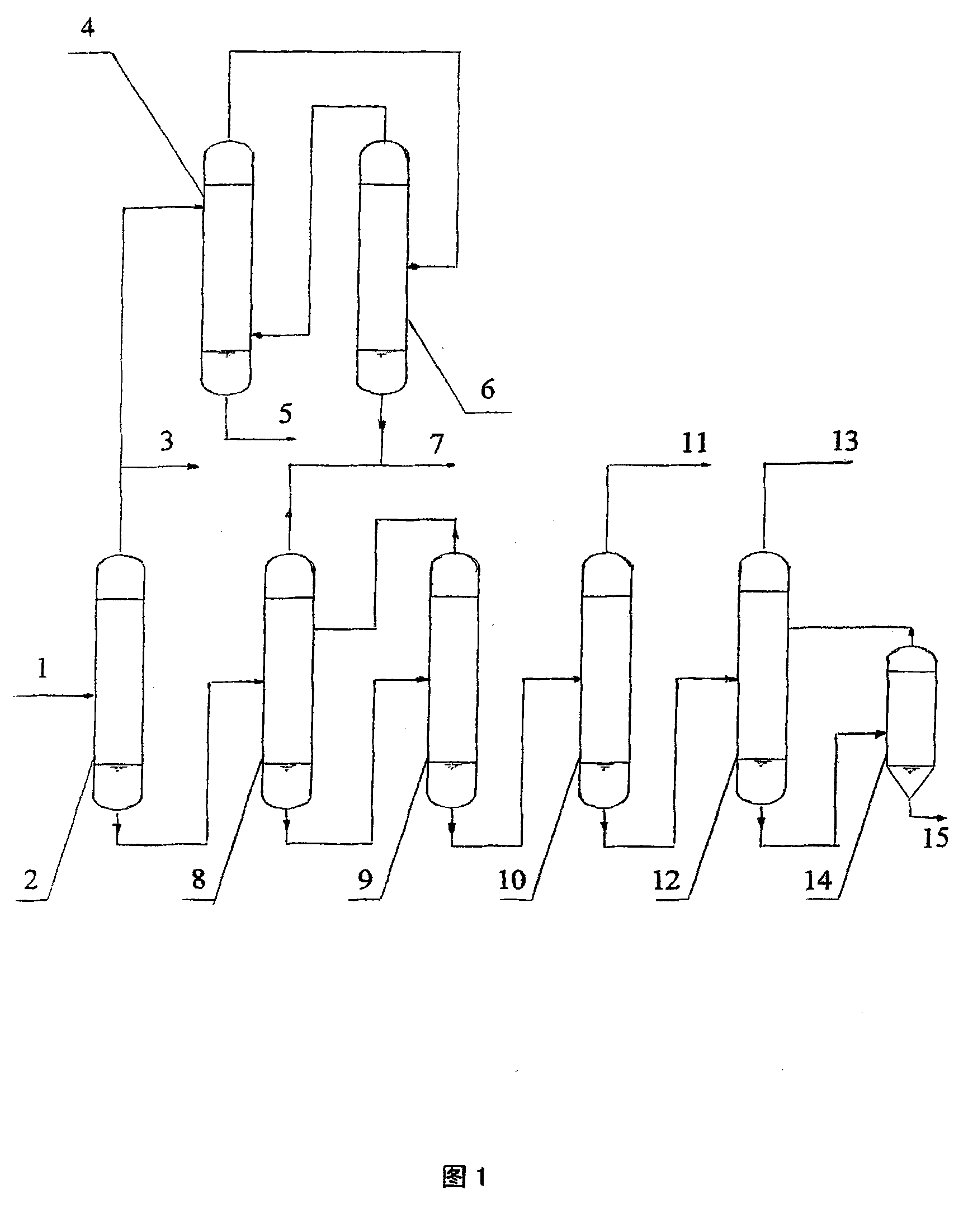

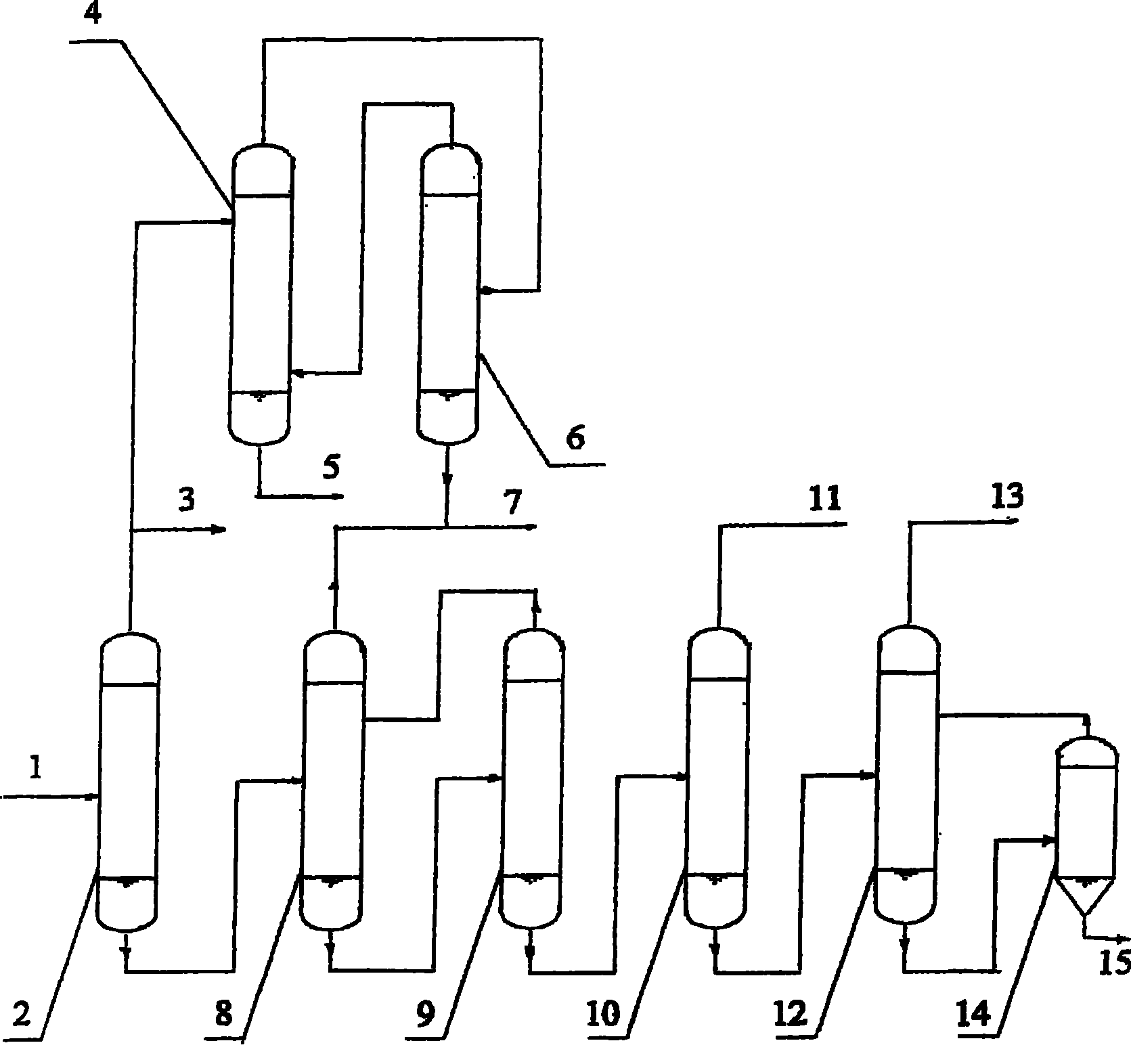

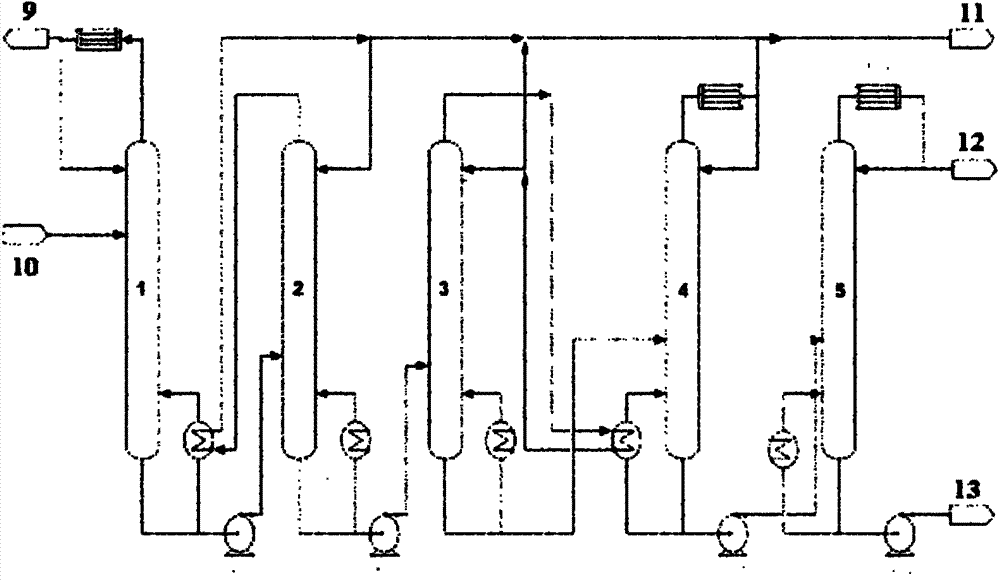

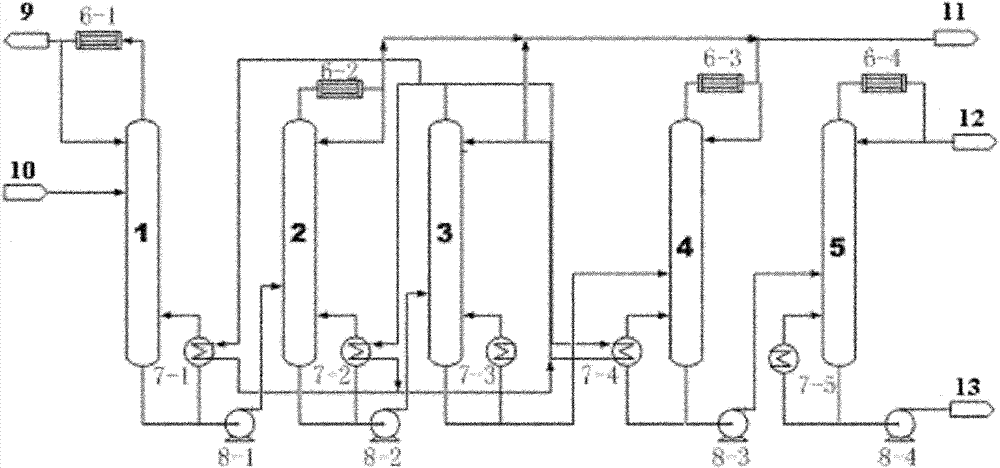

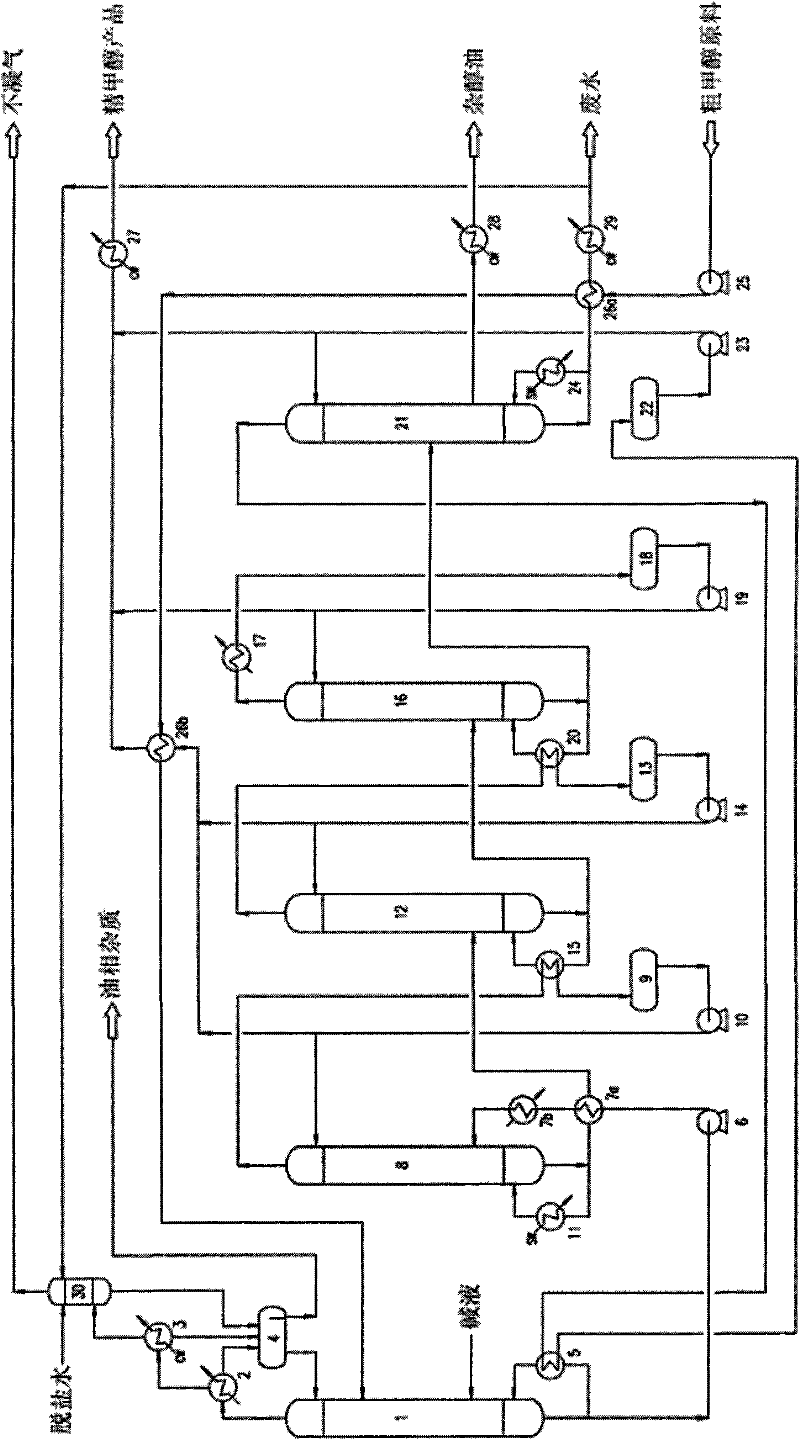

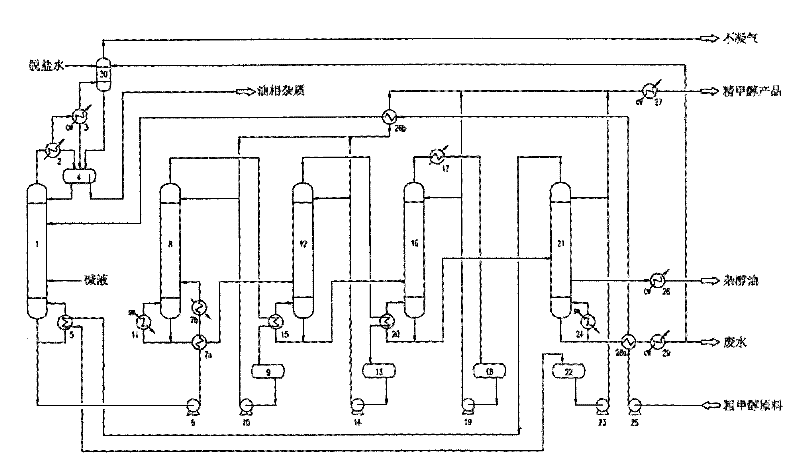

Large-scale methanol multi-effect energy-saving rectifying device and process

ActiveCN102039058AMake full use ofReduce exergy lossOrganic compound preparationChemical industryWastewaterProcess engineering

The invention relates to large-scale methanol multi-effect energy-saving rectifying device and process. Main equipment used in the process sequentially comprises a pre-rectifying tower, a second rectifying tower, a pressurizing tower, an atmospheric tower and a recovering tower, wherein the tops of the second rectifying tower, the pressurizing tower and the atmospheric tower are respectively usedfor discharging refined methanol, the top of the recovering tower is used for discharging fusel oil, and the bottom is used for discharging purified wastewater. Because one rectifying tower is additionally arranged, and the process parameter of each tower is adjusted, two methanol multi-effect energy-saving rectifying processes by five towers are obtained, the effective energy loss is reduced, thereby energy consumption is reduced. In addition, the diameter of each tower is reduced, the amplification effect of relevant equipment, caused by the oversize diameter of each tower, is greatly reduced. The process has the advantages of reasonable design, the energy is fully and reasonably utilized in the process, the energy consumption of the whole device used in the process is reduced by 20%-30% higher than that of the device used in the traditional double-effect process, and the purity of a product reaches the American AA-level standard.

Owner:TIANJIN UNIV

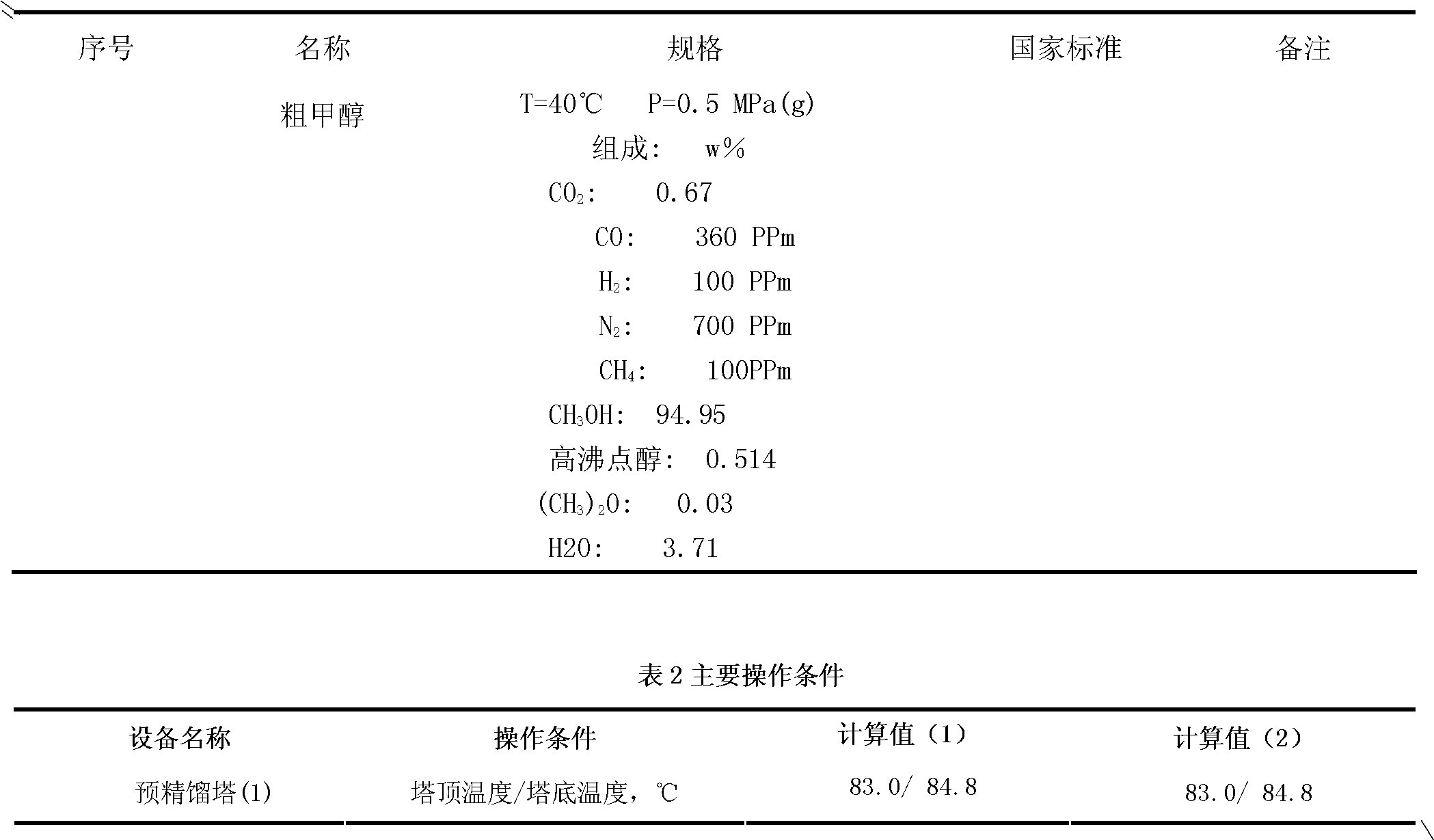

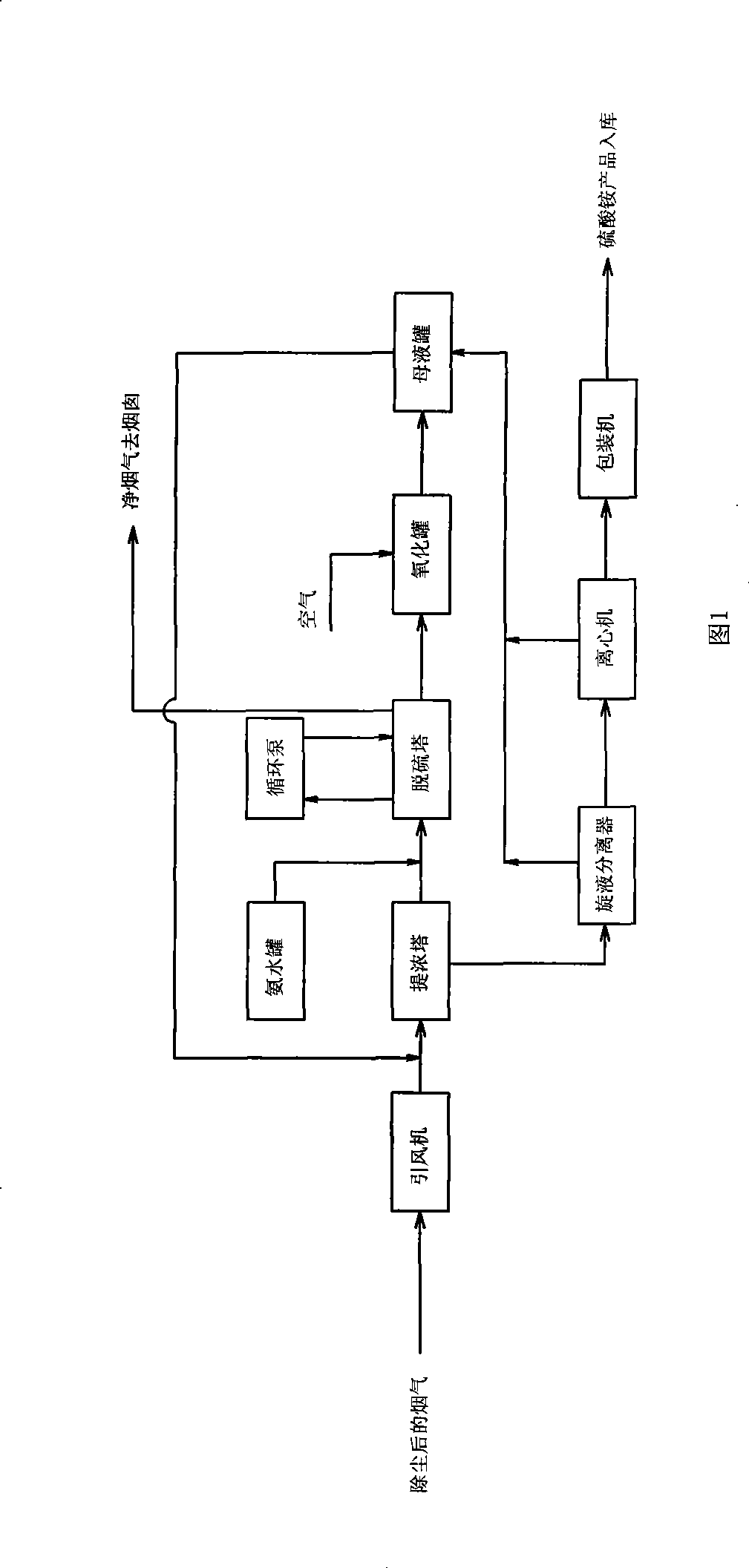

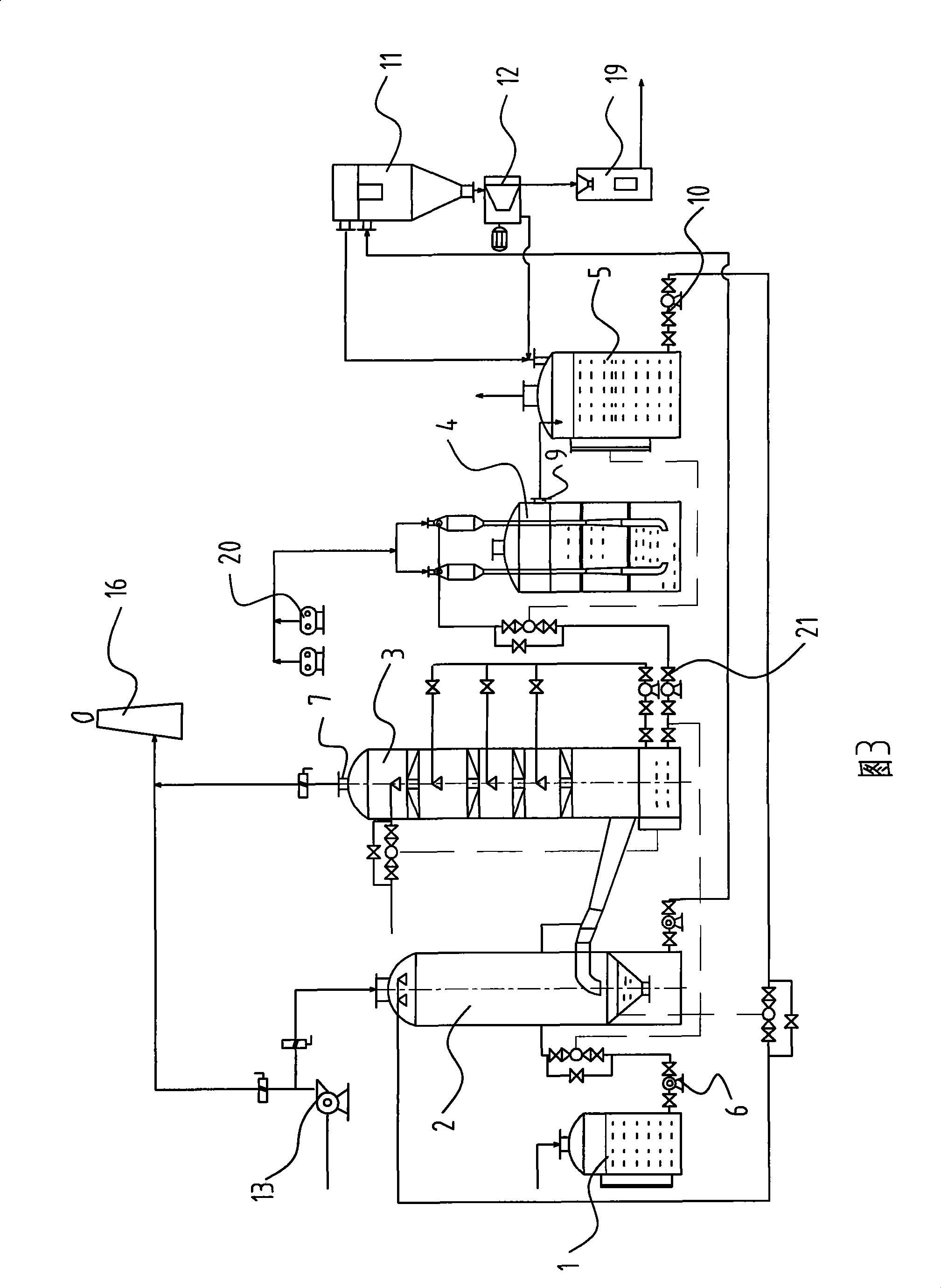

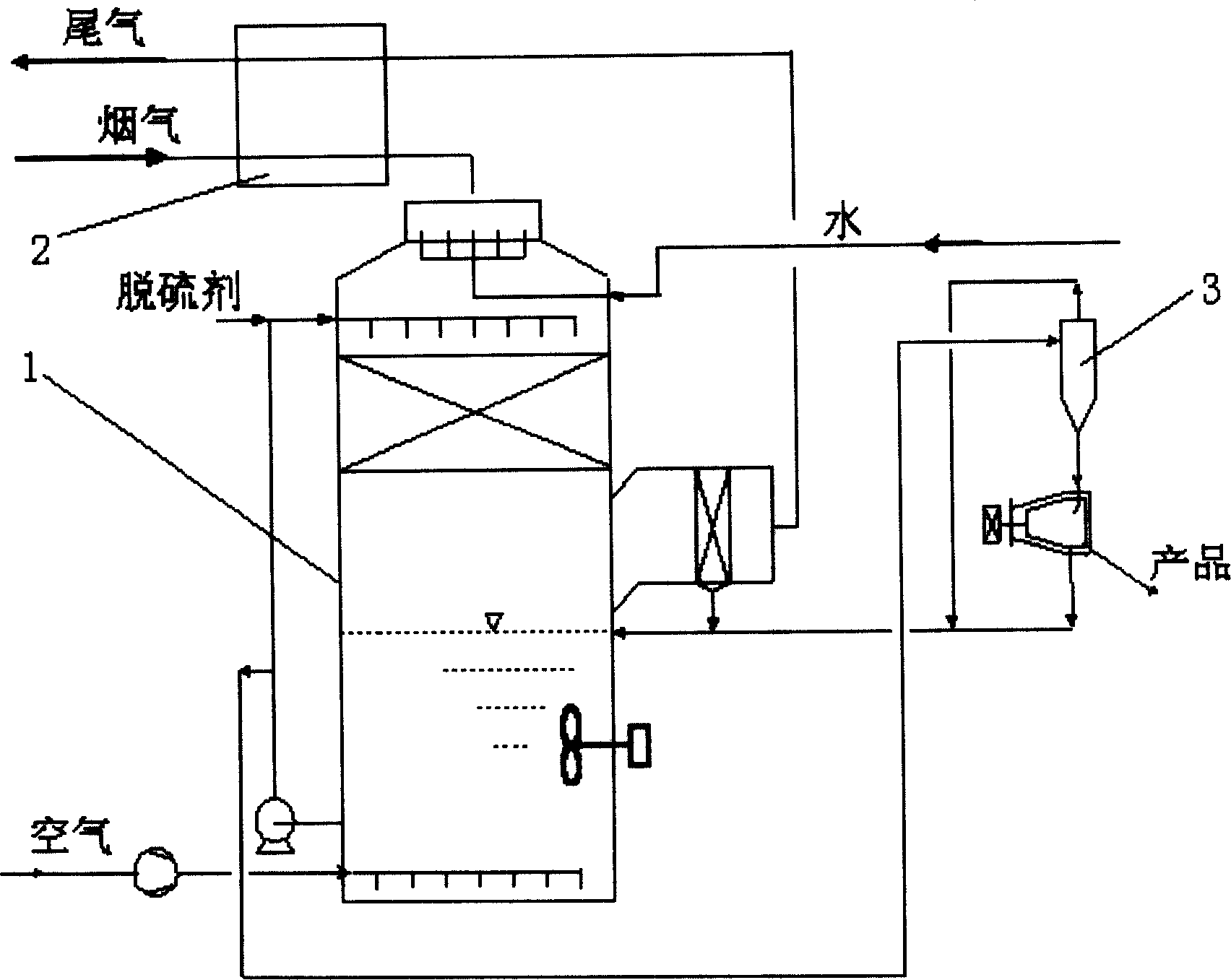

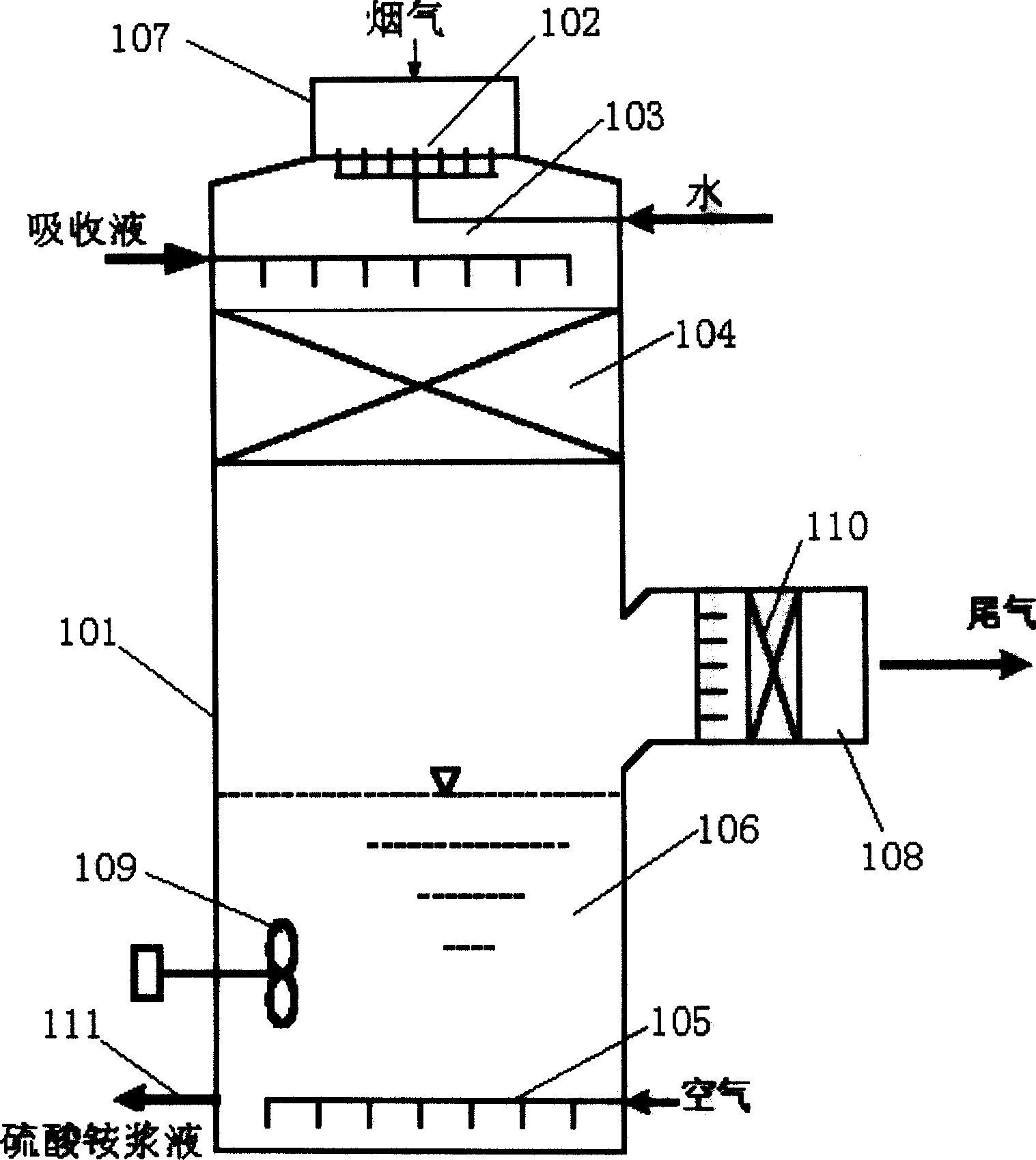

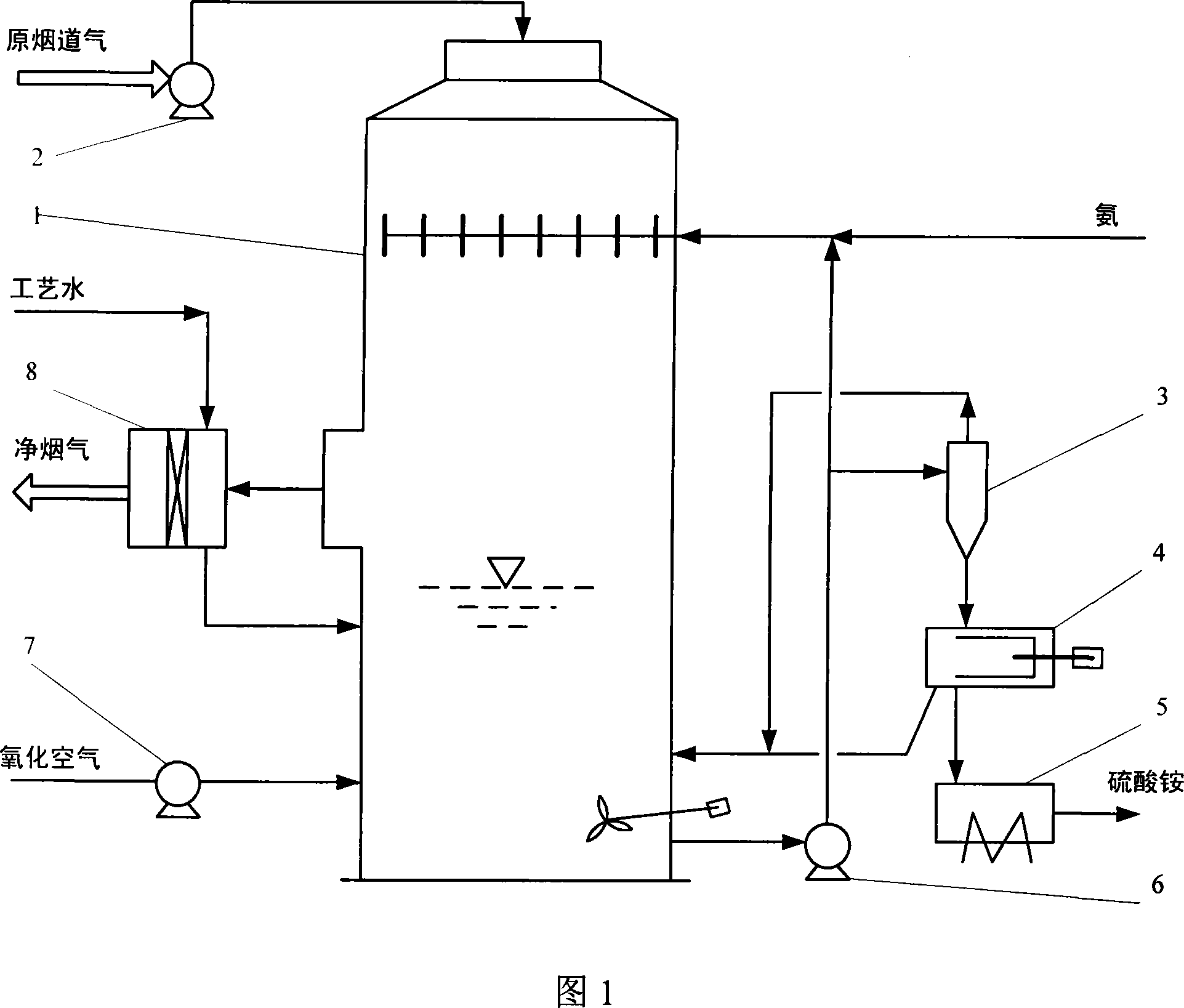

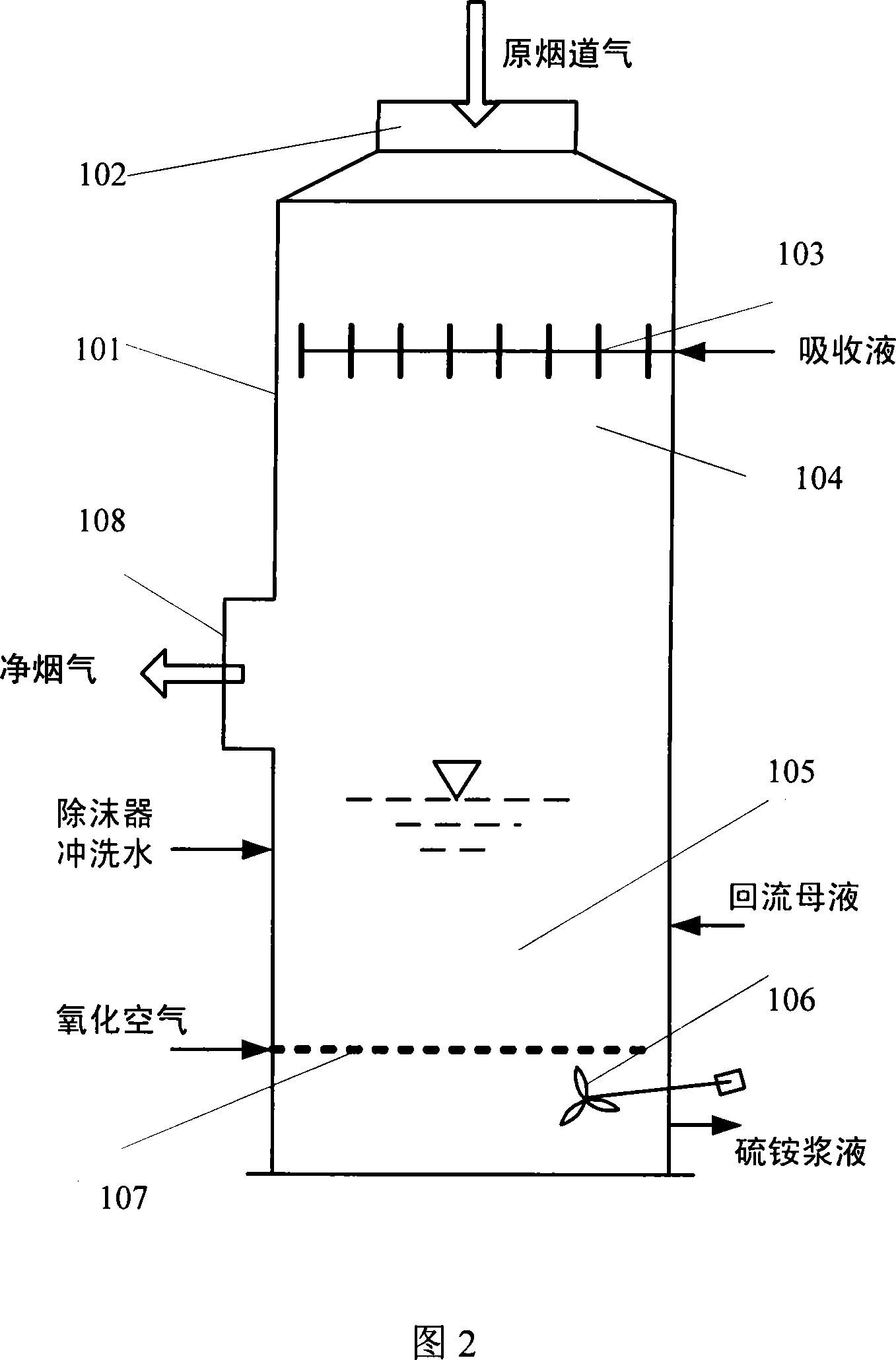

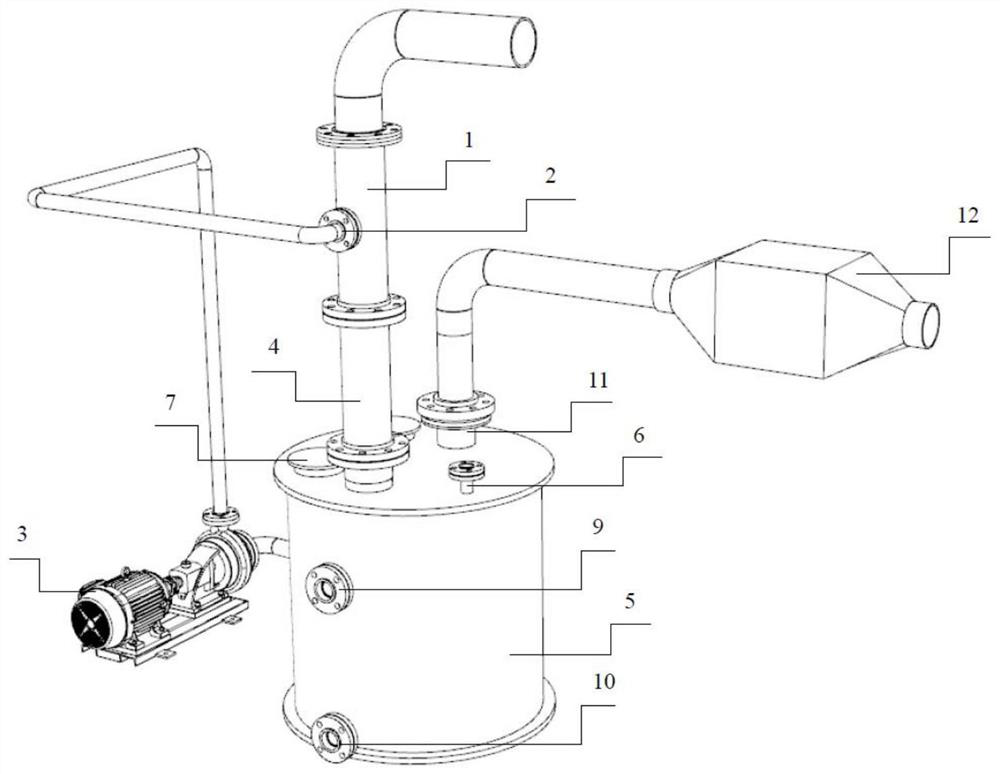

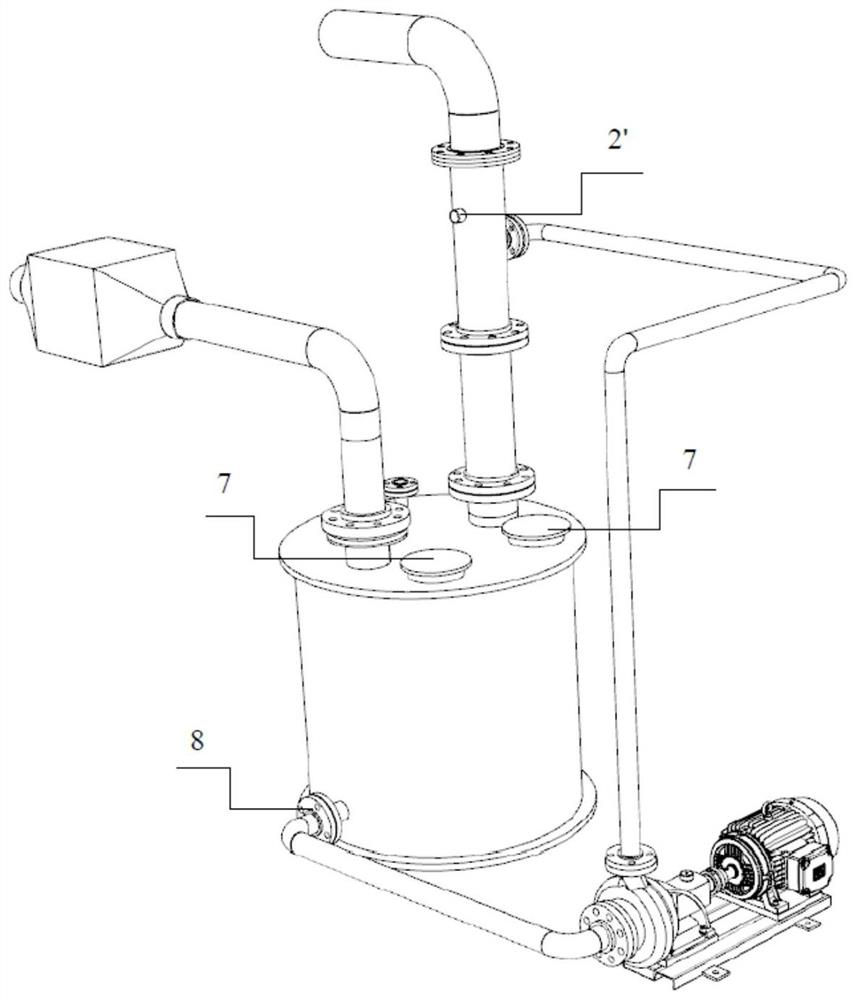

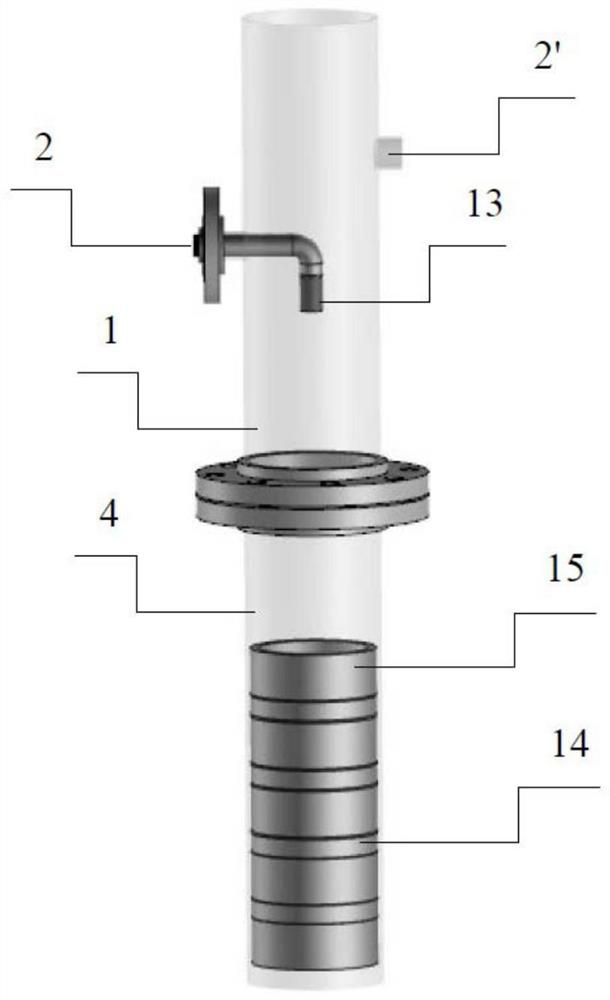

High-efficient wet-type ammonia recovering method desulfuration method with oxidation and concentration processes outside tower and device thereof

InactiveCN101433798AReduce the chance of being corrodedHigh gas velocityDispersed particle separationCycloneRecovery method

The invention discloses a high efficiency wet-type desulfurization method through ammonia recovery method for oxidation and concentration outside a tower, and a device thereof. The method comprises the following steps: (1) feeding flue gas into the top part of a concentrating tower after dust removal, cooling down and humidifying the flue gas, then feeding the flue gas into a first level venturi section of a desulfurization absorption system to contact atomized ammonia water so as to have the first level absorption reaction, performing the second level and the third level desulfurizations, and discharging the flue gas after the purification; (2) oxidizing the ammonium sulfite solution generated in a desulfurizing tower and then overflowing the ammonium sulfite solution into a mother liquor tank from the top part of an oxidation tank; and (3) pumping the ammonium sulfate solution in the mother liquor tank to the top part of the concentrating tower through a mother liquor pump to perform heat exchange with the high temperature flue gas after atomization so as to form a supersaturated solution containing 3 to 5 percent of crystal, wherein the supersaturated solution flows out of the bottom of the concentrating tower and is pumped into a hydraulic cyclone through a slurry pump to perform the first level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; the crystal-liquid mixed solution flowing out of the bottom of the concentrating tower automatically flows into a centrifugal machine to perform the second level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; and solid ammonia sulfate is fed into an automatic packaging machine to be packaged and put into storage. The method has simple processes, greatly reduces investment, and can reclaim agricultural level ammonia sulfate and industrial level ammonia sulfate.

Owner:HENAN XUHUI ENVIRONMENT PROTECTION ENG

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025AImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

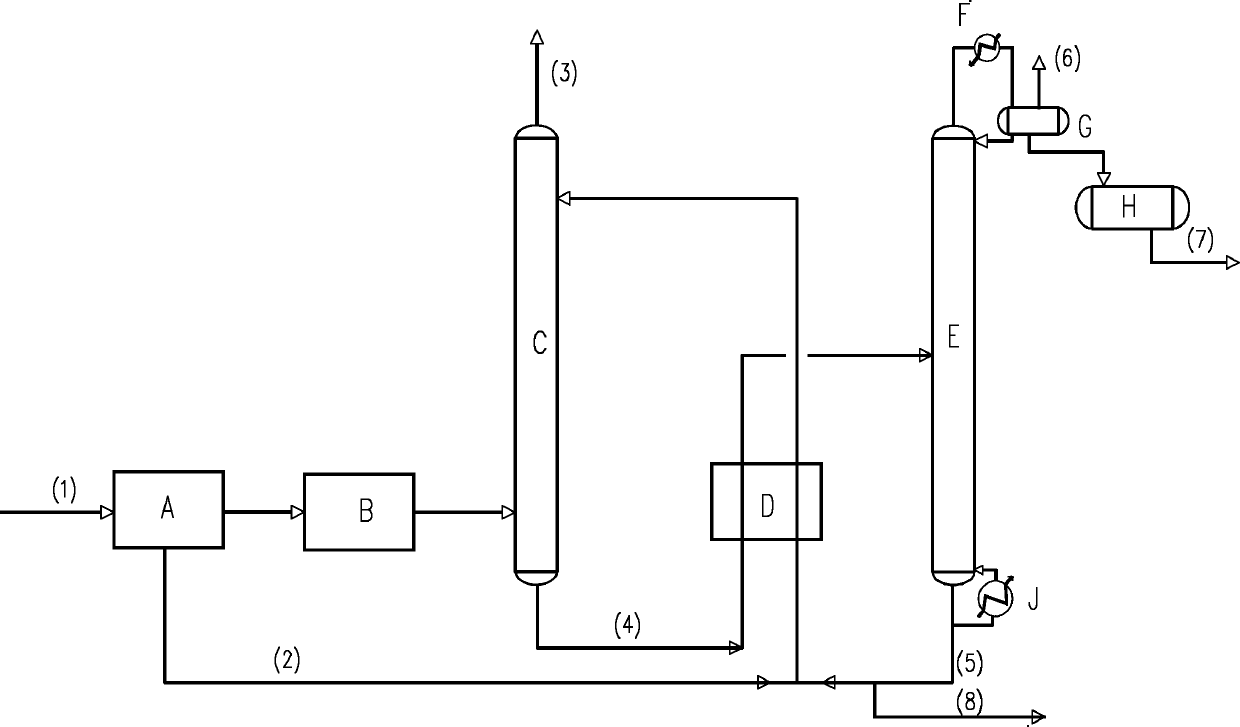

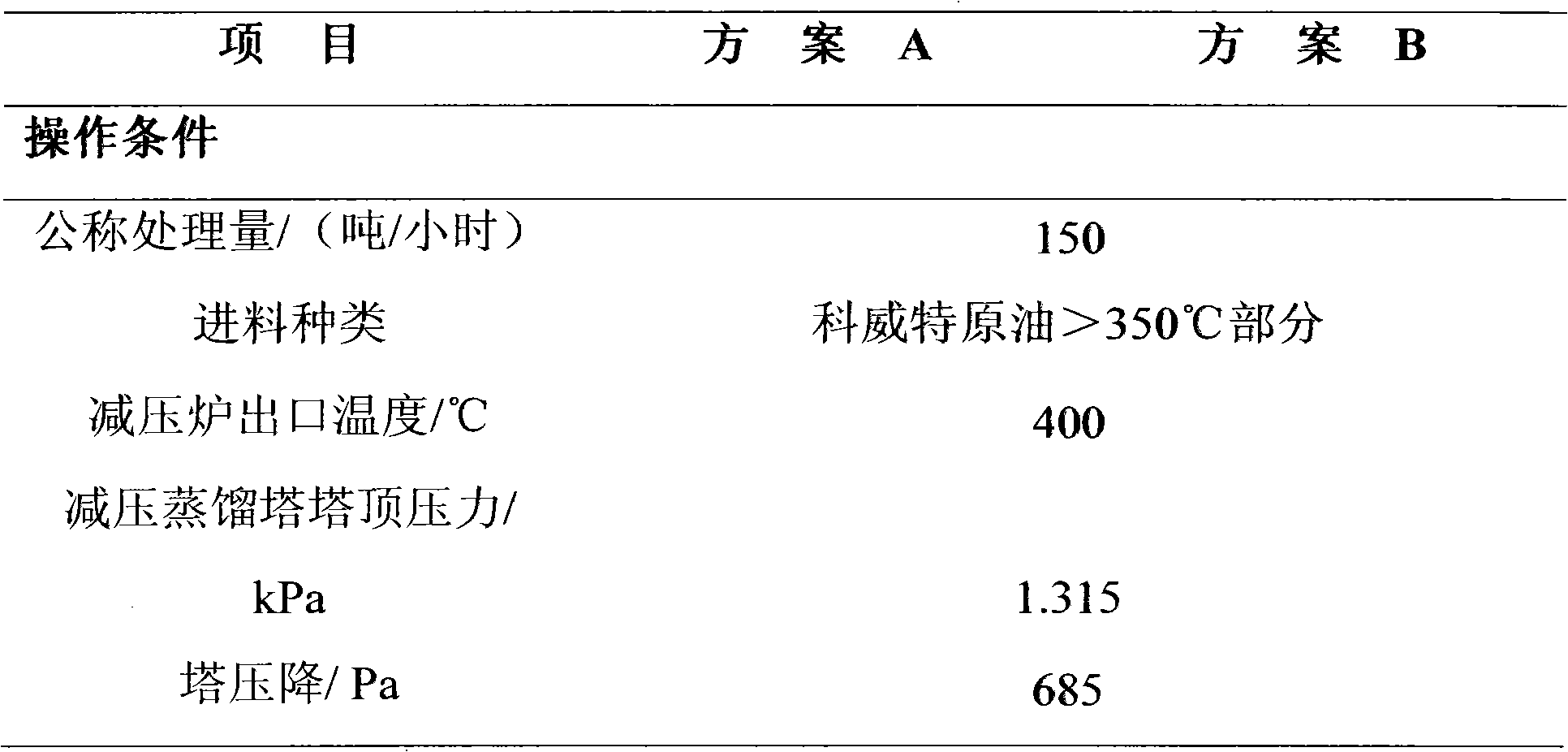

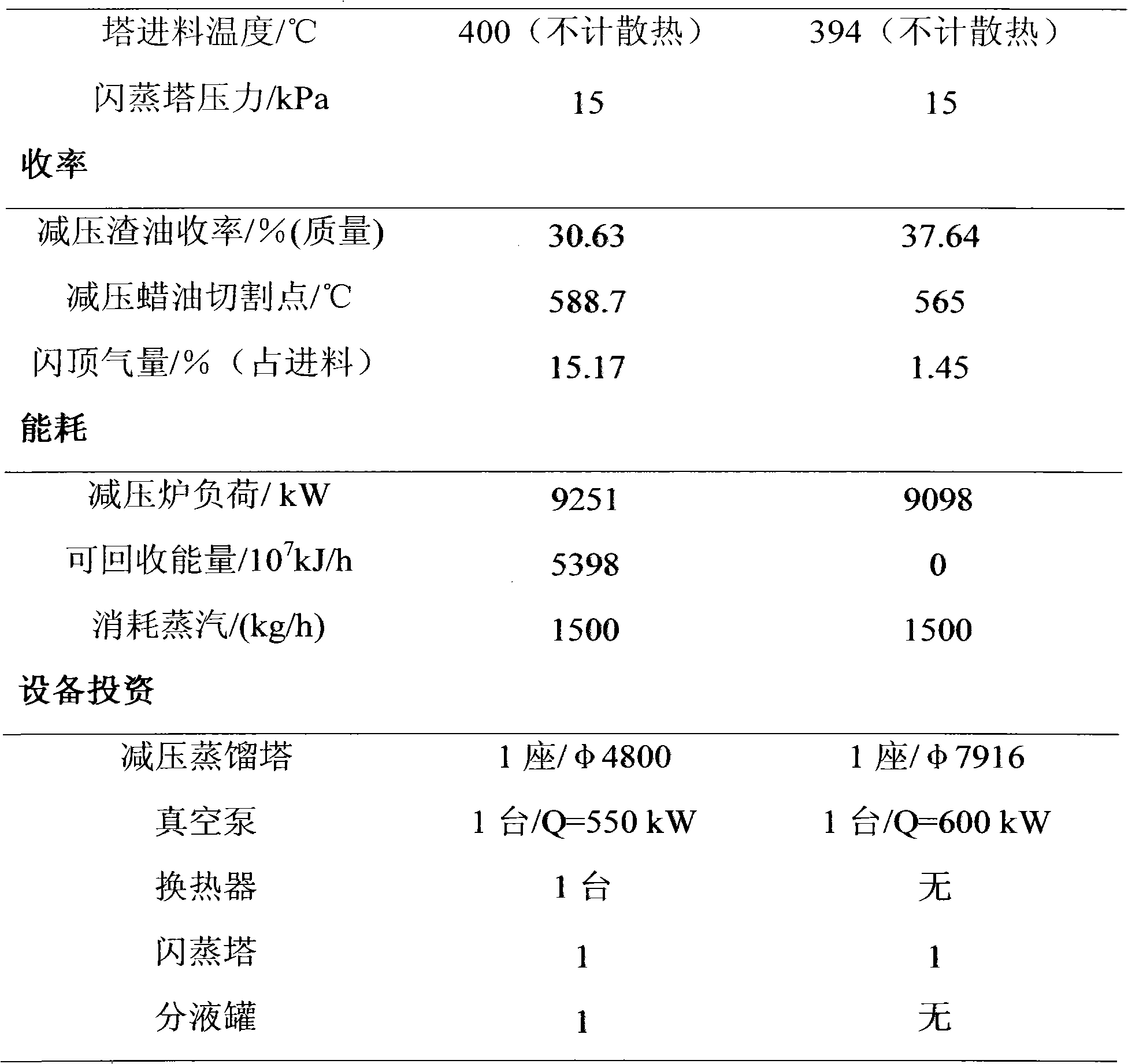

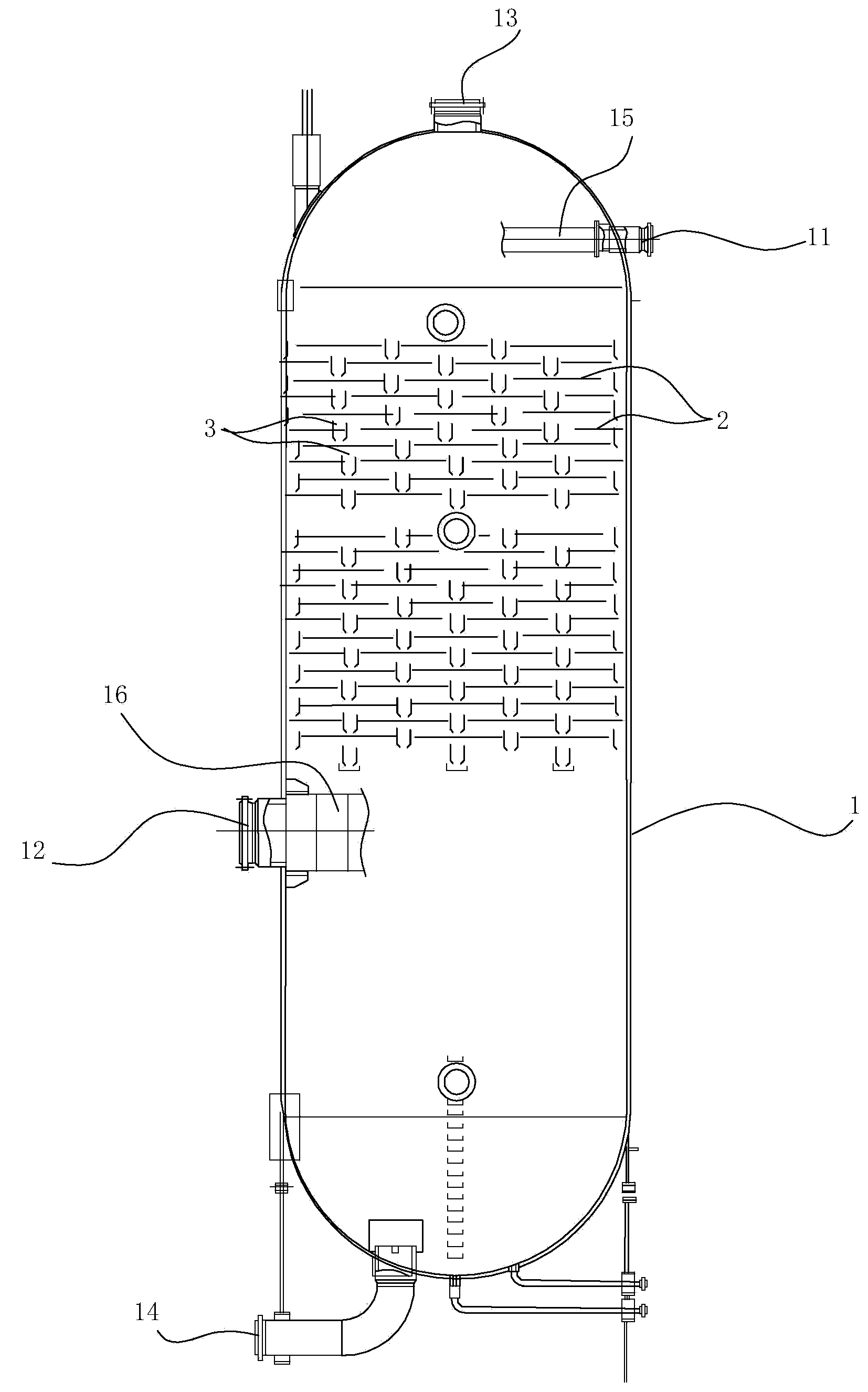

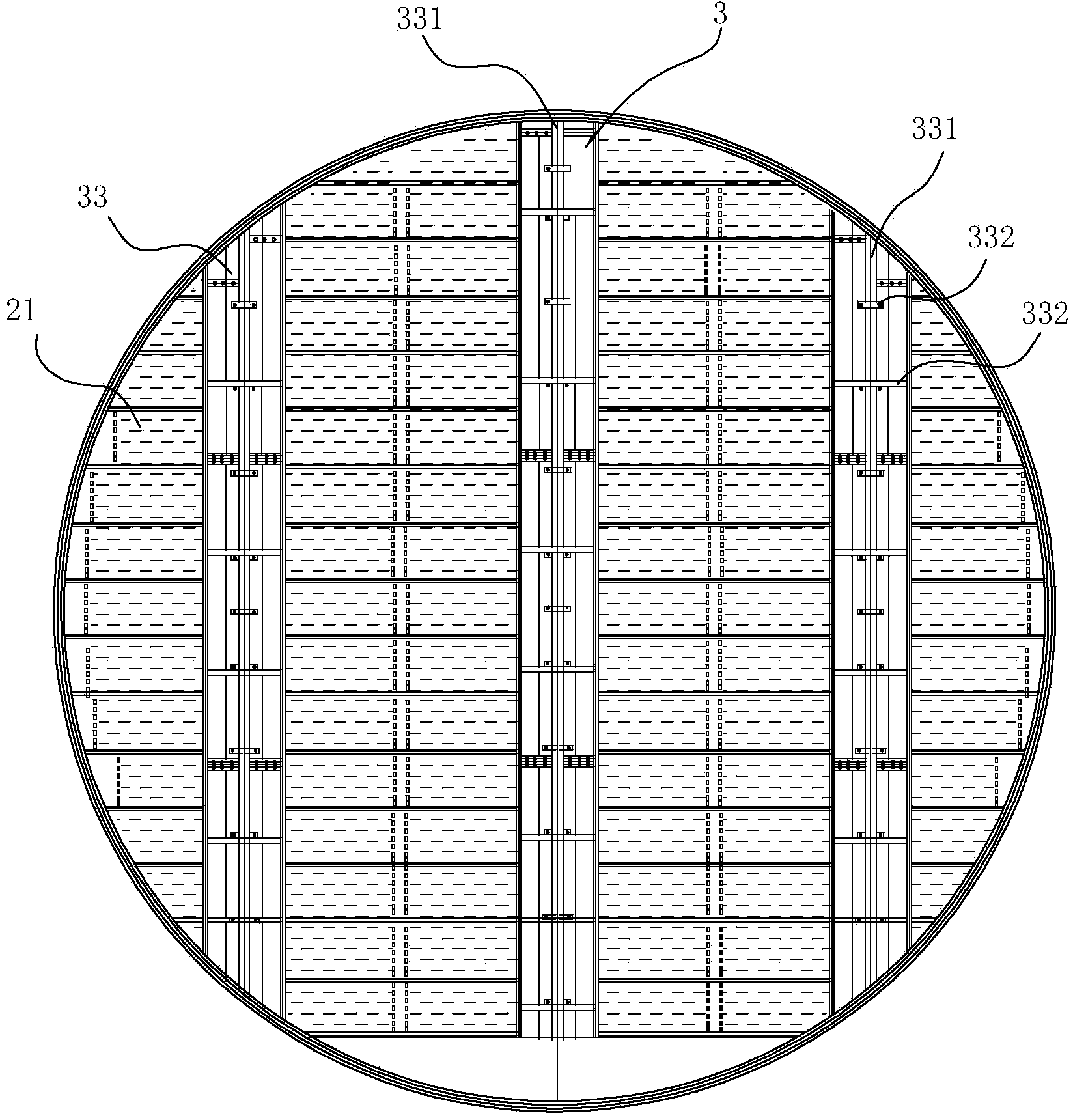

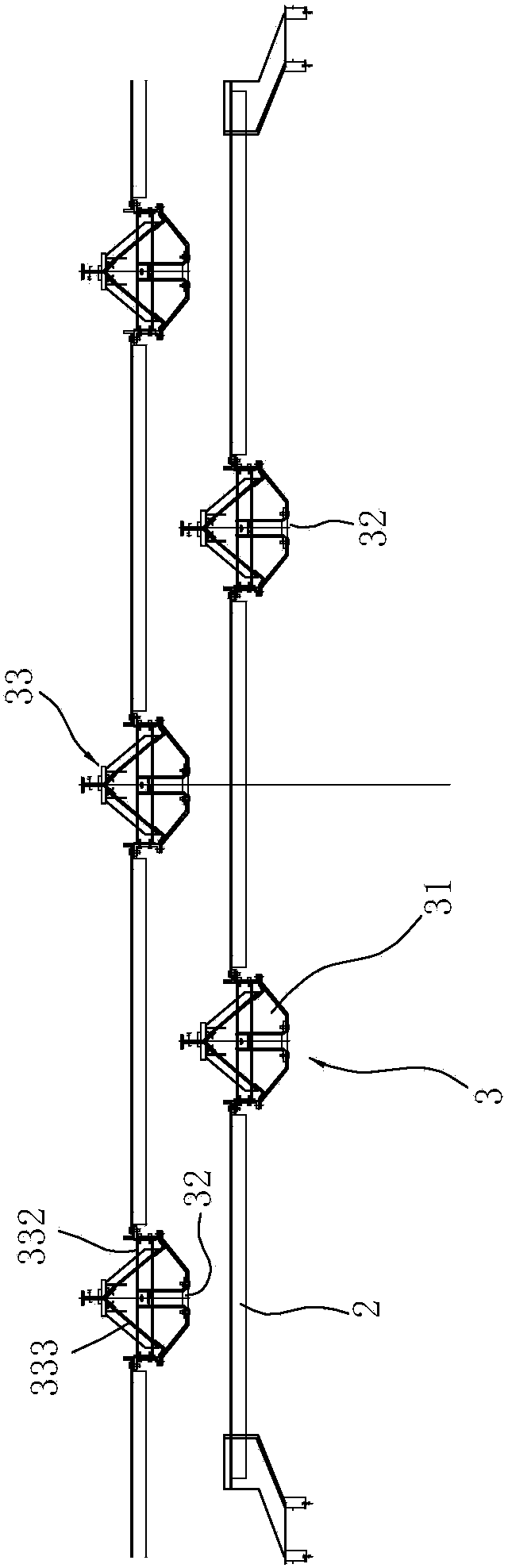

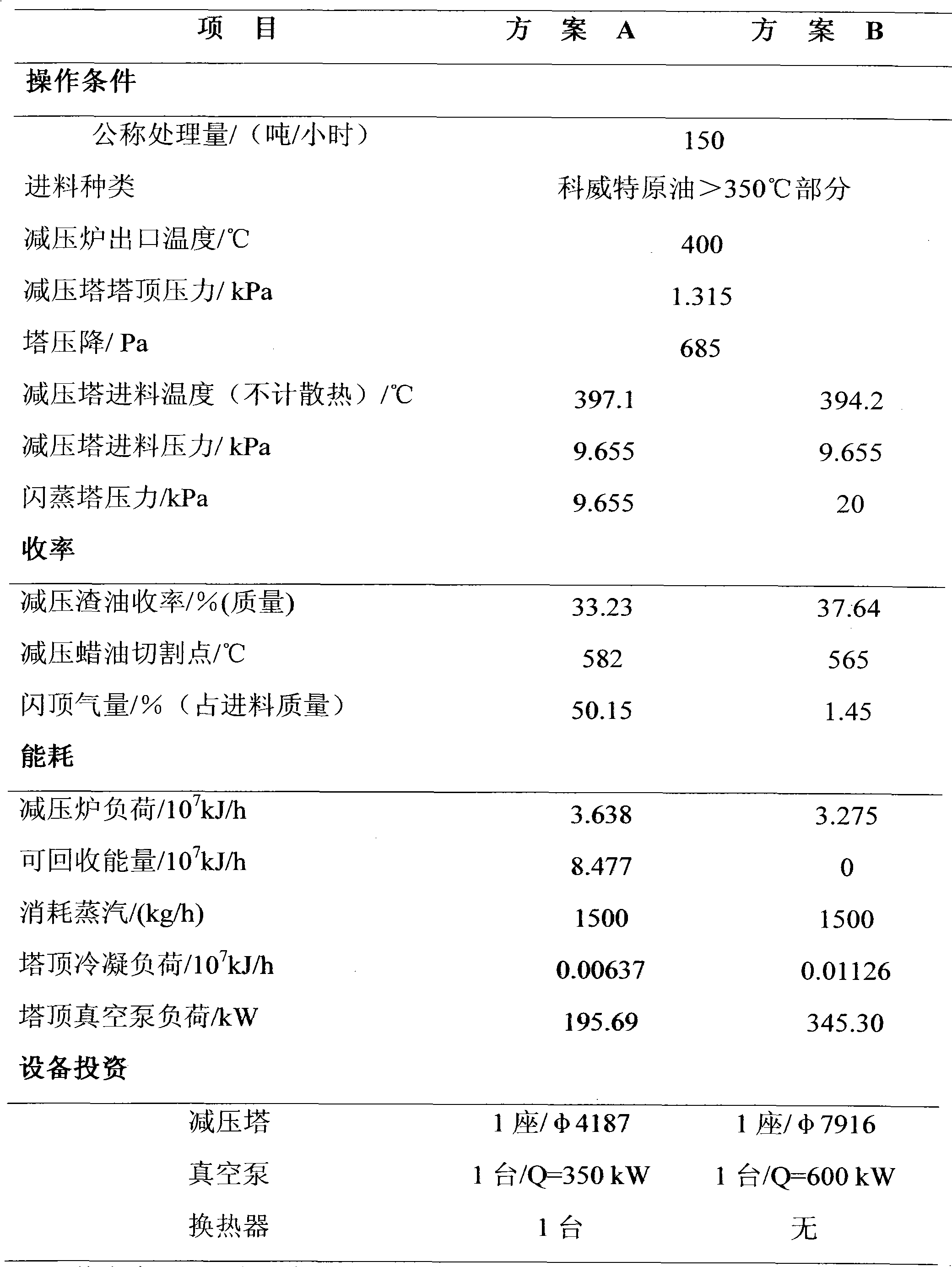

Distillate yield improving vacuum distillation method and device

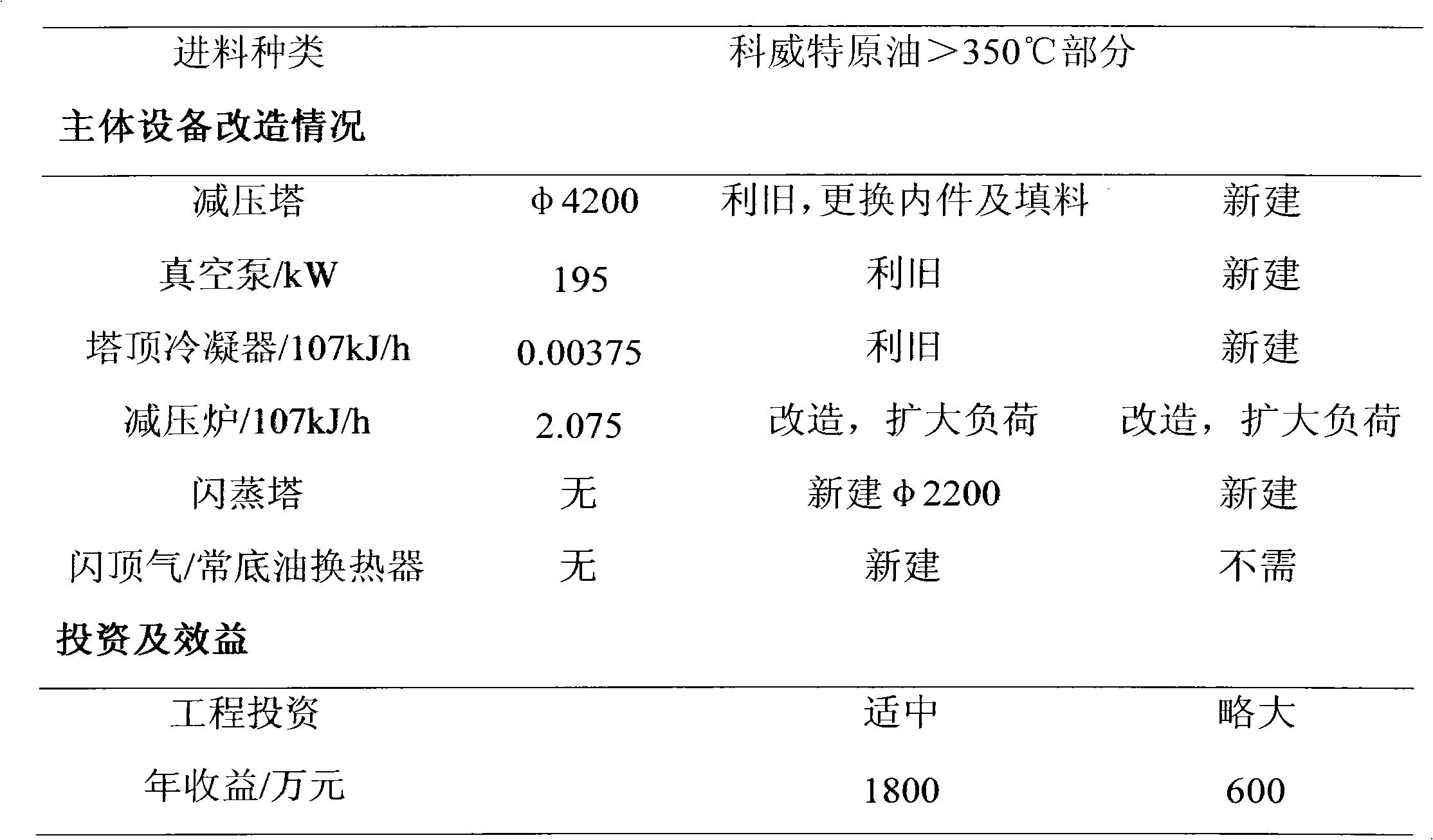

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

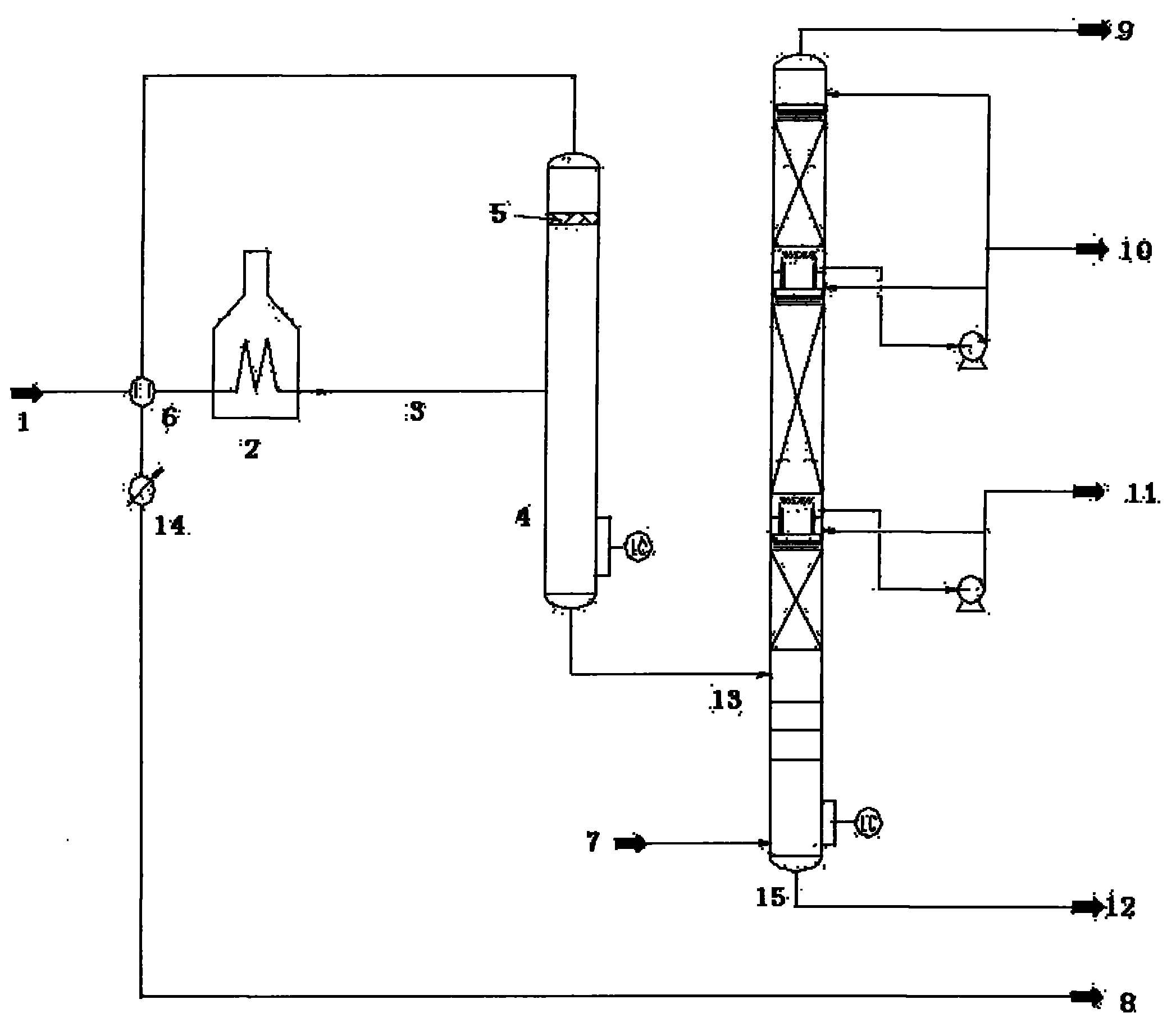

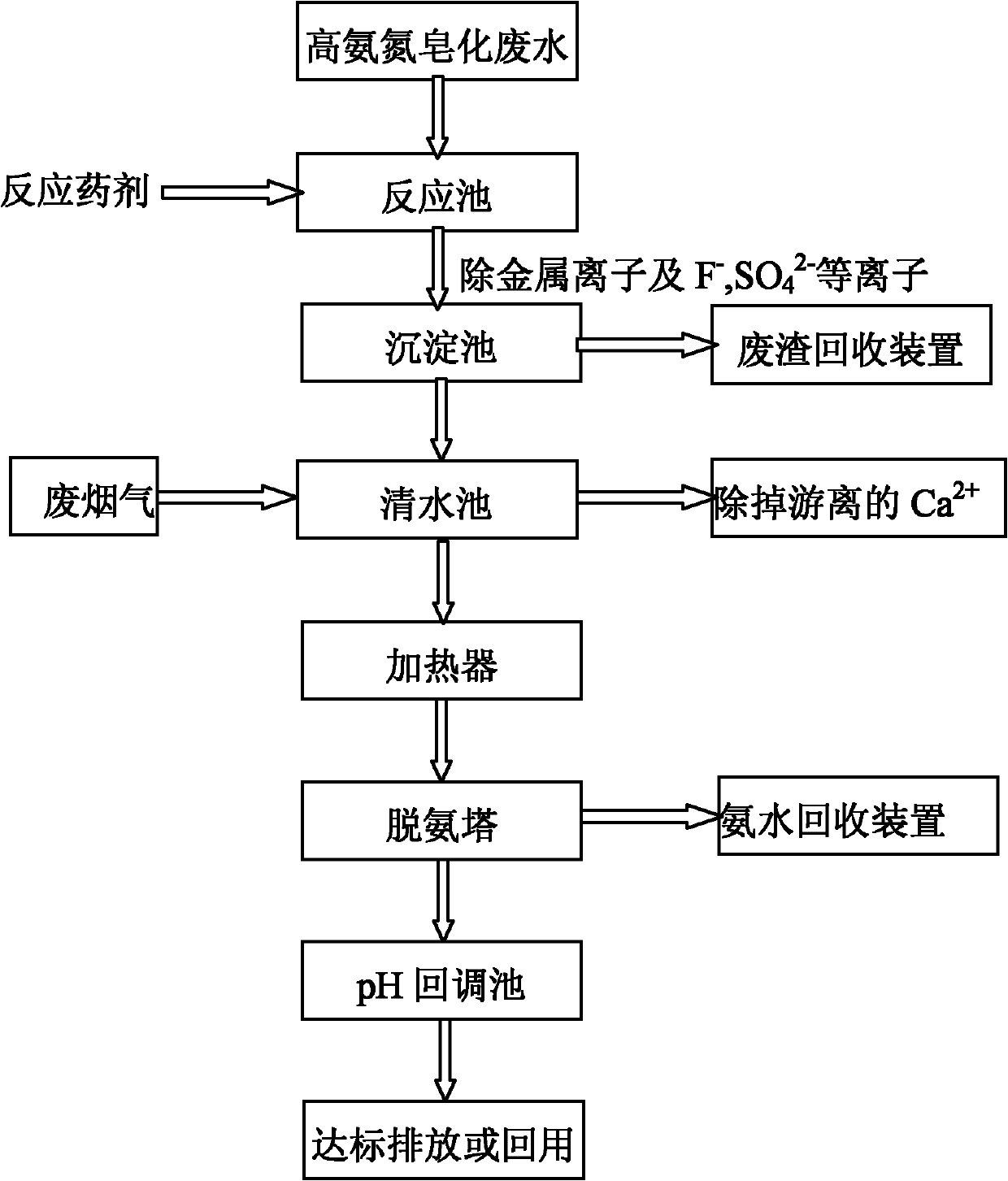

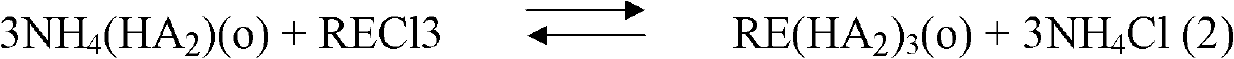

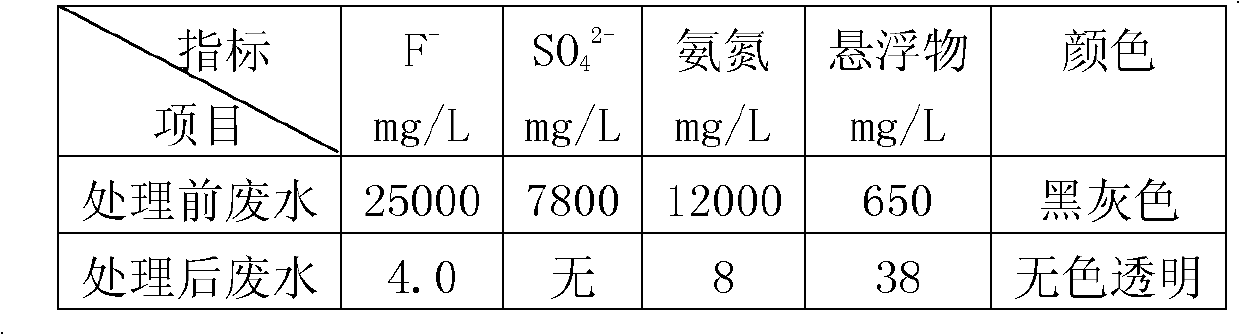

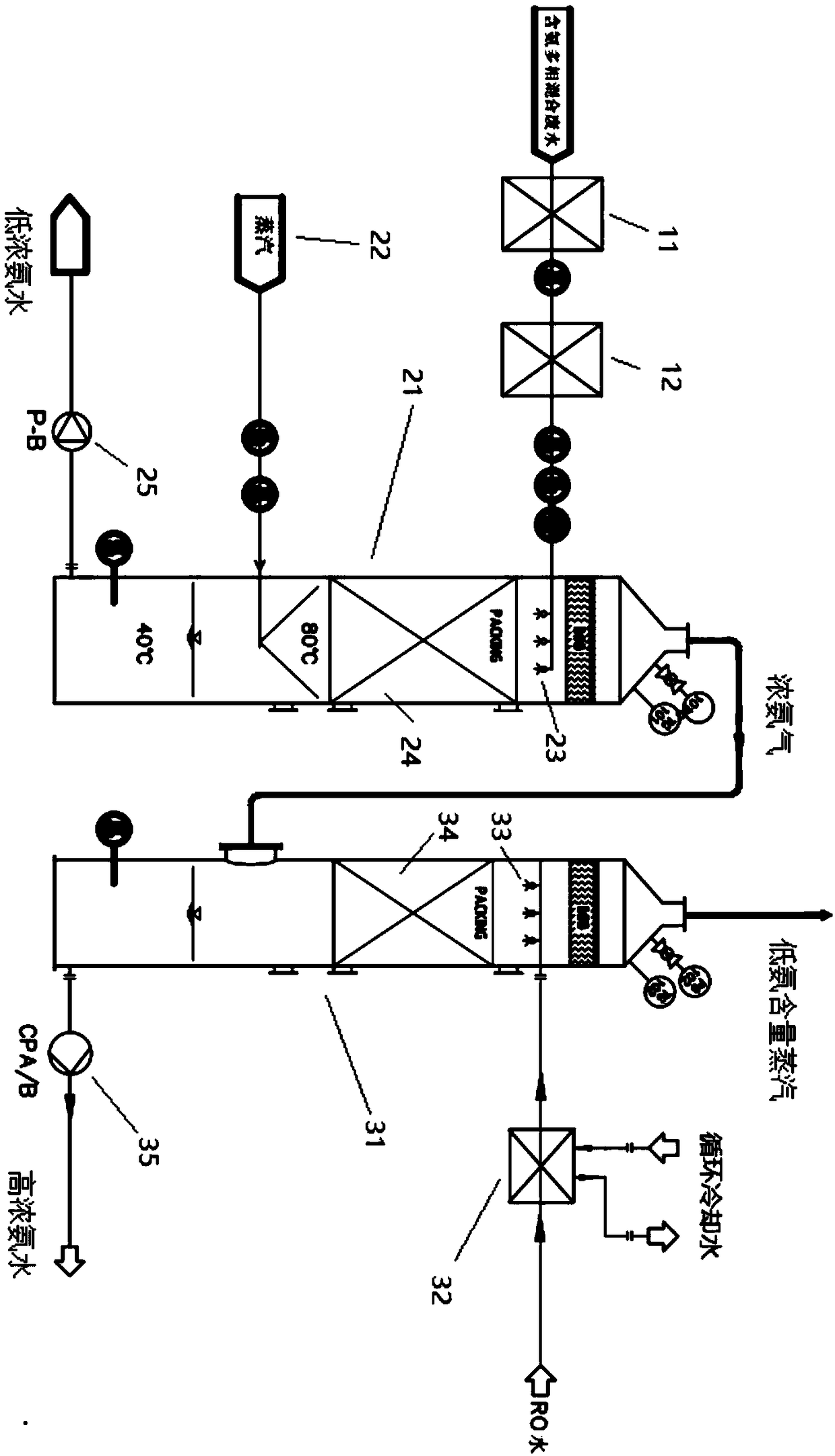

Deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater

ActiveCN102167467ASolve processing problemsEliminate scaling problemsProductsReagentsRare earthTower

The invention discloses a deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater. The technology is characterized by comprising the steps of: adding a reaction medicament into rare earth wet process-smelted extract liquor saponifying wastewater for reacting; precipitating after the reacting; separating out solid waste residue; feeding CO2-containing waste gas into clean water; leading the Ca2+ content in the wastewater to be less than 0.01mol / L; filtering; adjusting the PH value of the wastewater to be 10.5-11.0, and heating to be 55-65DEG C; feeding the adjusted wastewater into a deaminizing tower for performing negative pressure ammonia stilling type deamination; and adjusting the PH value of the wastewater to be 6-9 after the deaminizing. By matching the unslaked lime, the waste gas with the negative pressure stilled ammonia, the method can be used for removing not only various metal plasmas in the rare earth wet process-smelted extract liquor saponifying wastewater, such as F1<-> and SO4<2-> and the like, but also ignored calcium ions, so that the scaling problem of follow-up equipment is avoided, and the waste gas generated by a boiler is further treated.

Owner:JIANGSU HUASHAN ENVIRONMENTAL PROTECTION TECH

Method and device for producing thiamine from surface dioxide in recovered waste gas

InactiveCN1648048ASimple structureEasy to handleDispersed particle separationAmmonium sulfatesSulfur dioxideThiamine

The present invention discloses method and apparatus for recovering SO2 from waste gas to produce ammonium sulfate. The present invention has combined process of oxidizing ammonium sulfite into ammonium sulfate and crystallizing ammonium sulfate to simplify structure of desulfurizing tower, lower its height and facilitate use of GRP material. Inside the desulfurizing tower, high temperature fume as material enters from the top, the desulfurized product is exhausted from the bottom, and both the fume and the absorbing liquid flow from top to bottom, resulting in high mass transfer efficiency, simple structure, great fume processing capacity and high eliminating efficiency of harmful SO2, SO3, NOx, HCl, HF and dust. The present invention has high industrial application.

Owner:EAST CHINA UNIV OF SCI & TECH

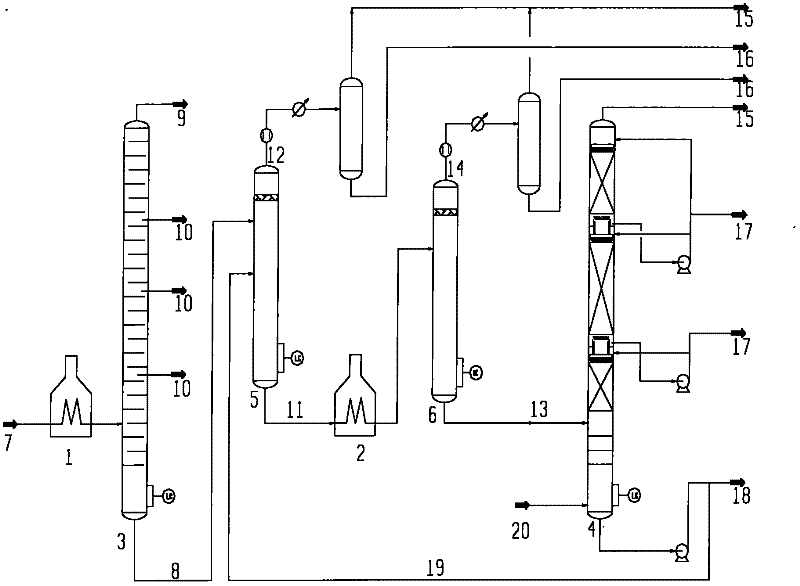

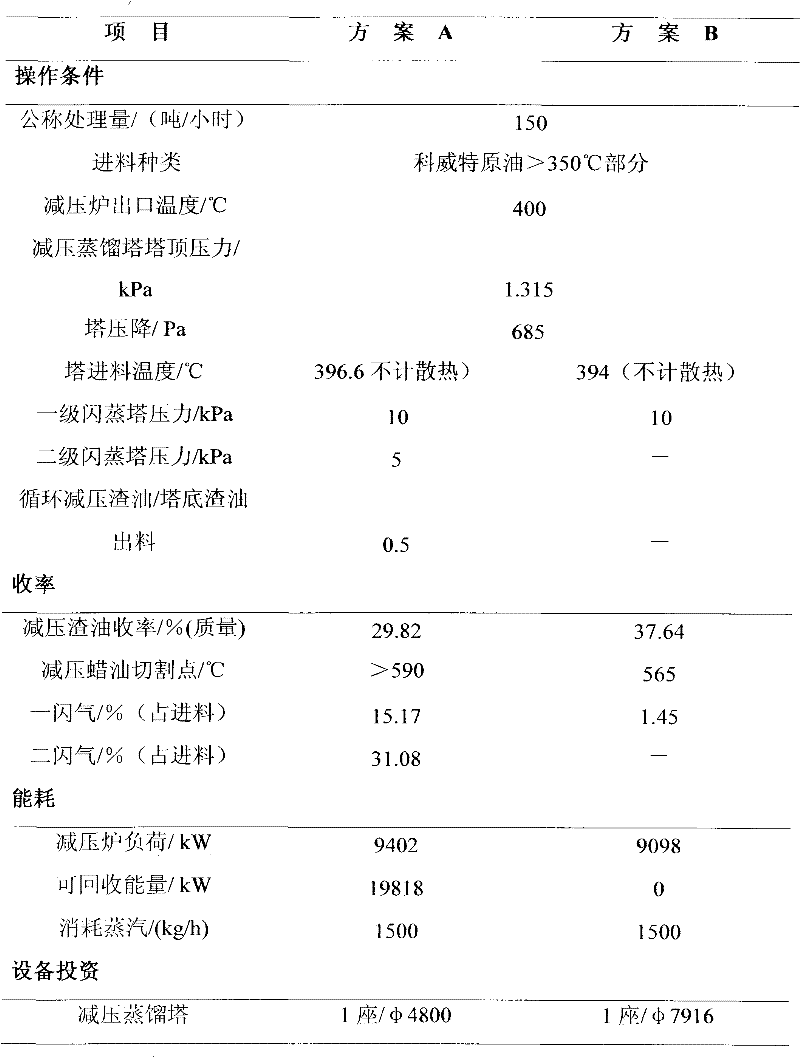

Crude oil processing method

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

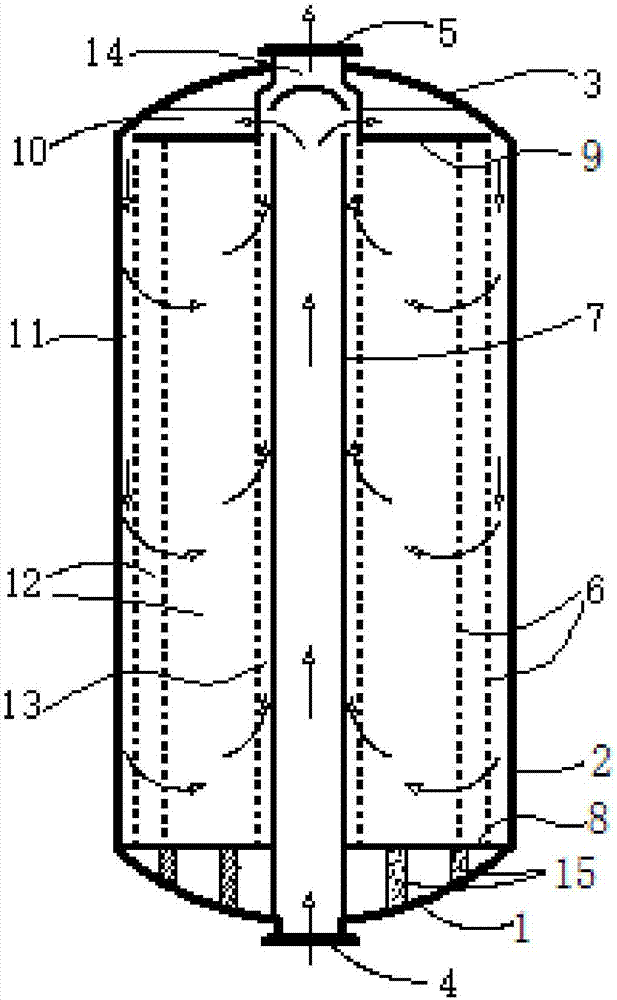

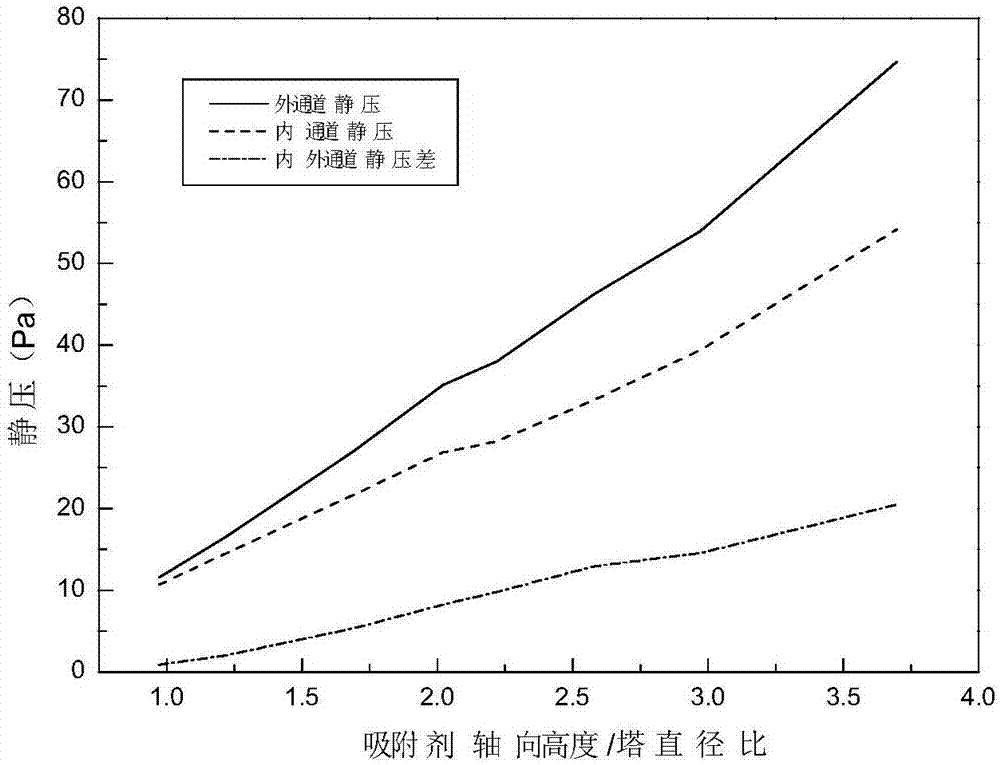

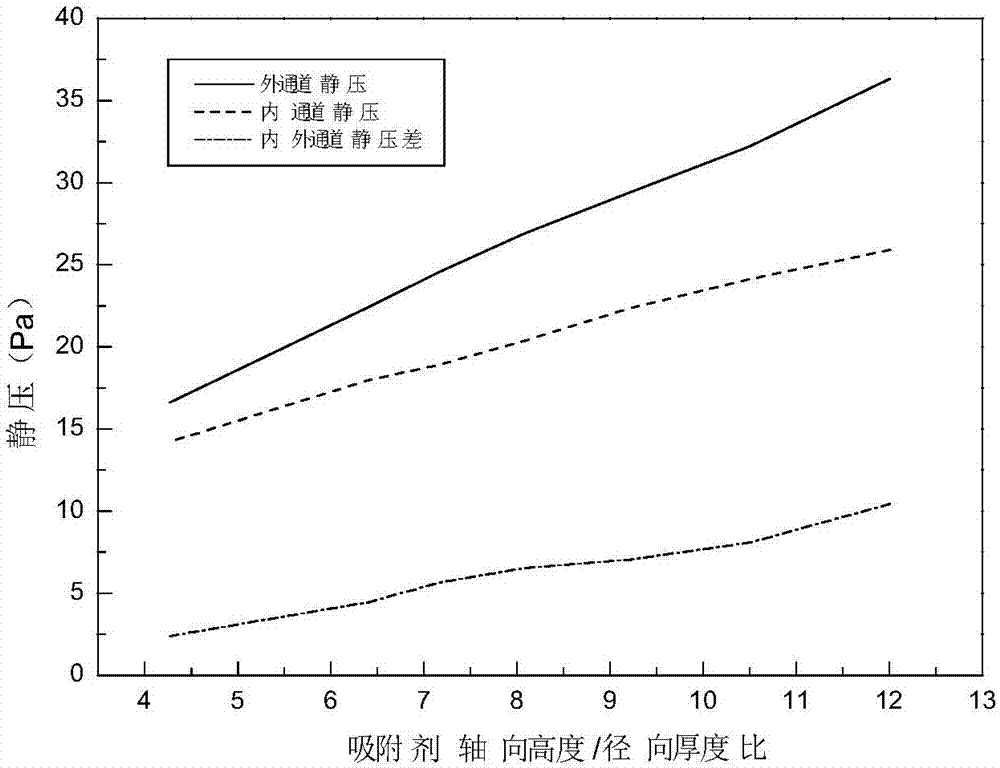

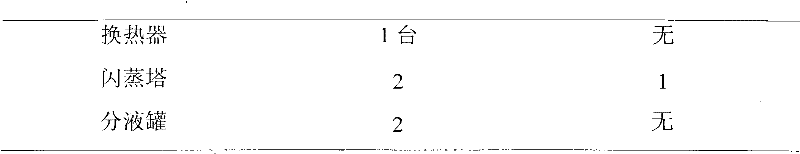

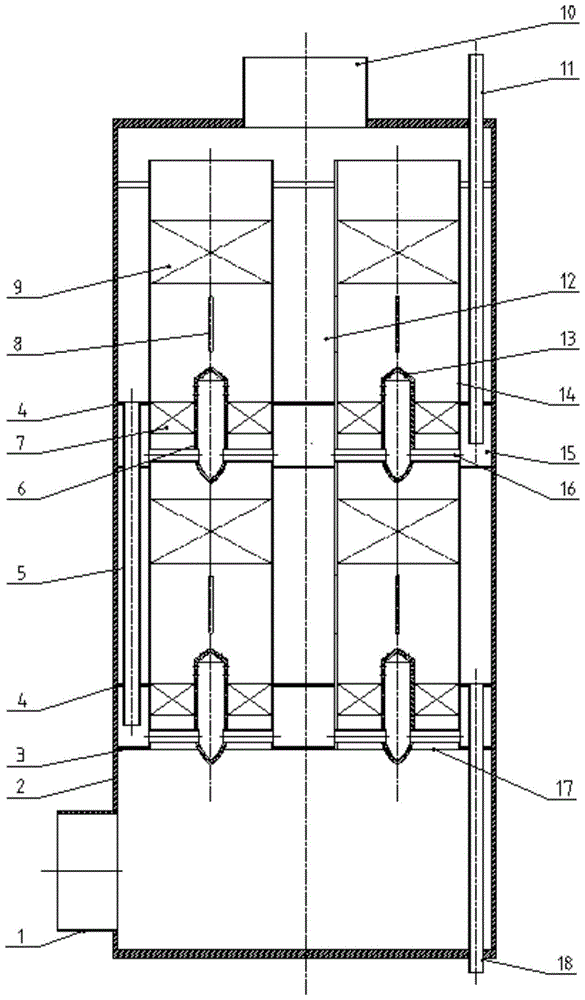

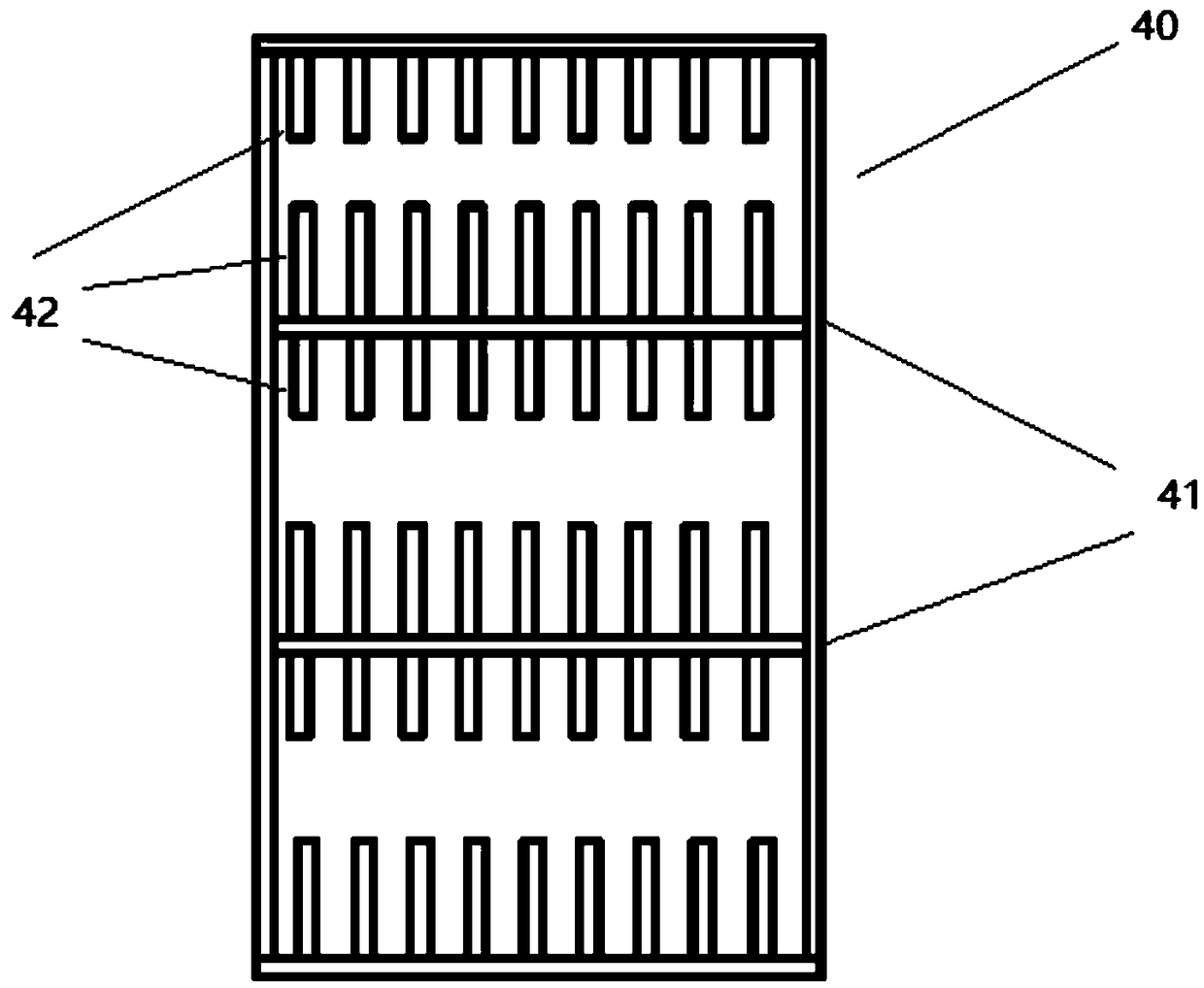

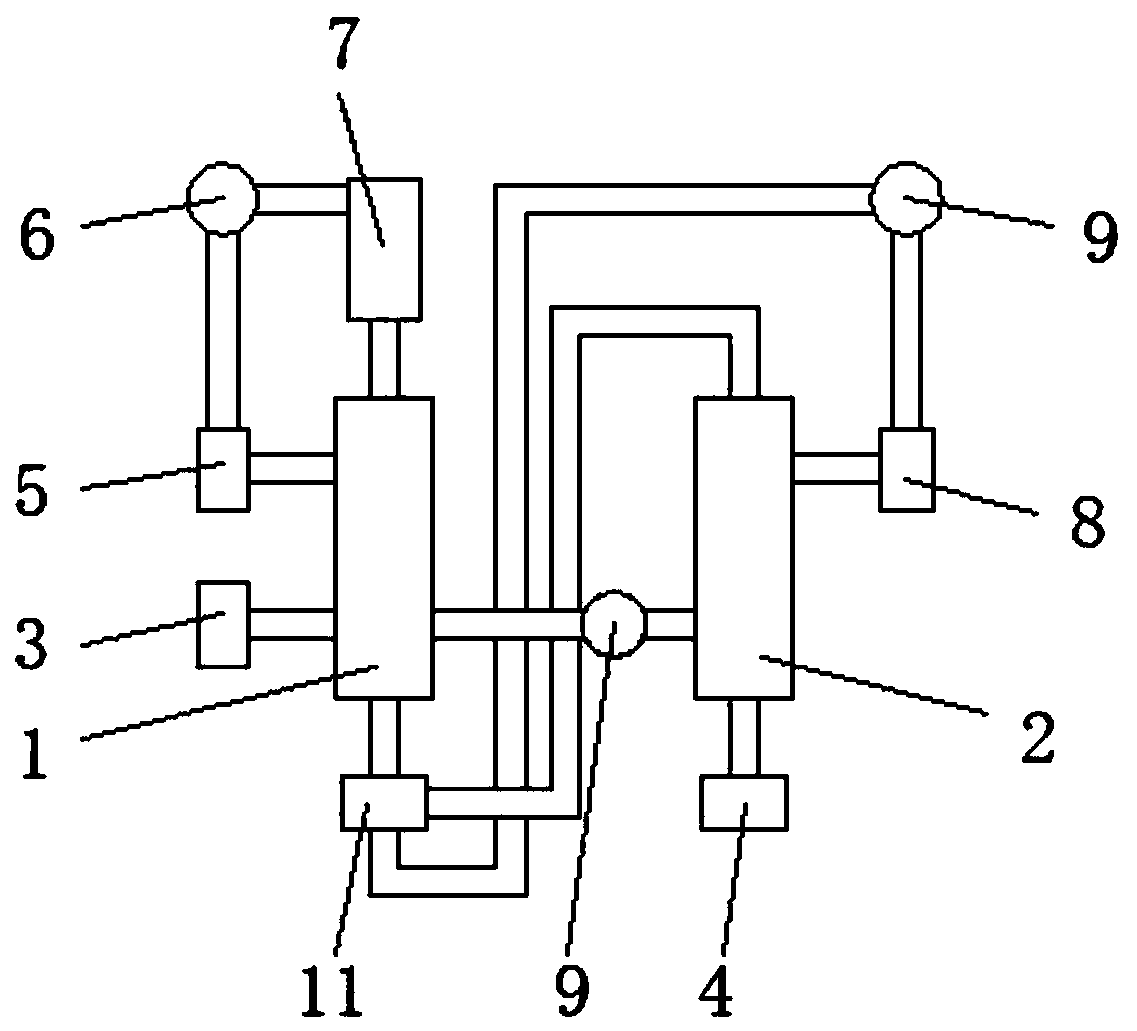

Novel radial flow adsorption tower for pressure swing adsorption

ActiveCN107126814AEvenly distributedReduce driftGas treatmentDispersed particle separationEngineeringTower

The invention provides a novel radial flow adsorption tower for pressure swing adsorption, and belongs to the technical field of adsorption tower. The novel radial flow adsorption tower comprises an upper seal head, a lower seal head, a tower cylinder body, an isolation drum and a center pipe, wherein the tower cylinder body, the isolation drum and the center pipe are distributed in a concentric circle way; an annular outer passage is formed between the outer drum wall of the isolation drum and the tower cylinder body, and an annular inner passage is formed between the inner drum wall of the isolation drum and the outer wall of the center pipe; a flow distributing pipe and an air exhaust pipe are arranged at the top part of the interior of the adsorption tower, the flow distributing pipe is used for communicating the center pipe and the annular outer passage, and the air exhaust pipe is connected and communicated with the annular inner passage; air flow hole passages are distributed on a drum body of the isolation drum, and an adsorbent is filled into the drum body. The novel radial flow adsorption tower has the advantages that the raw gas is guided into the annular outer passage by the center pipe passage via the flow distributing pipe, flown into the adsorbent layer in the radial way, and sent into the annular inner passage after adsorbing and separating; the gas flows outside the adsorption tower and in the inner passage to form the U-shaped flowing type, so that the change trends of static pressures in the inner passage and the outer passage are basically the same in the axial flowing direction of gas flow, and the uniform distribution of the gas flow is realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

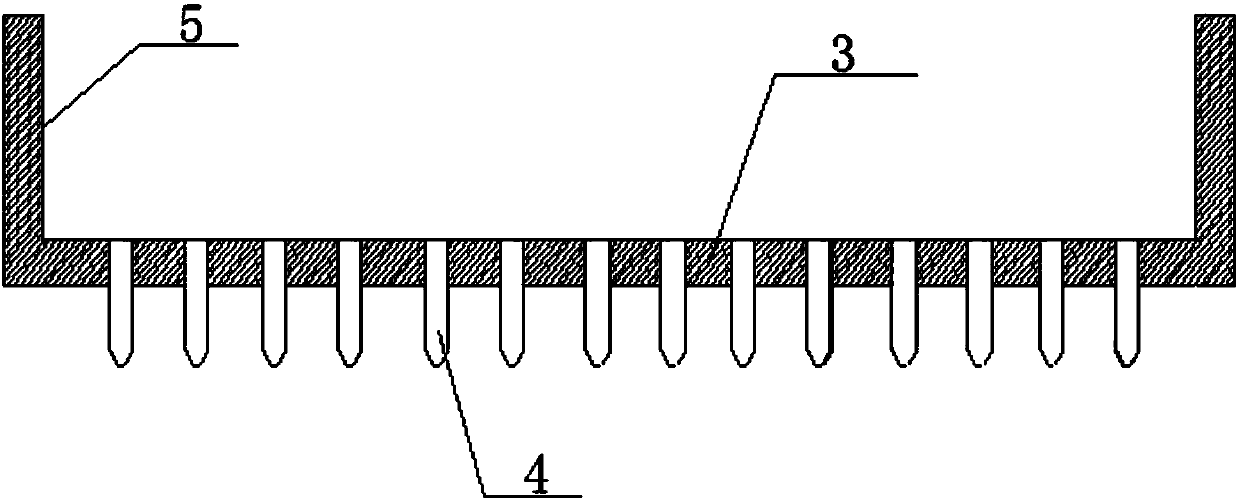

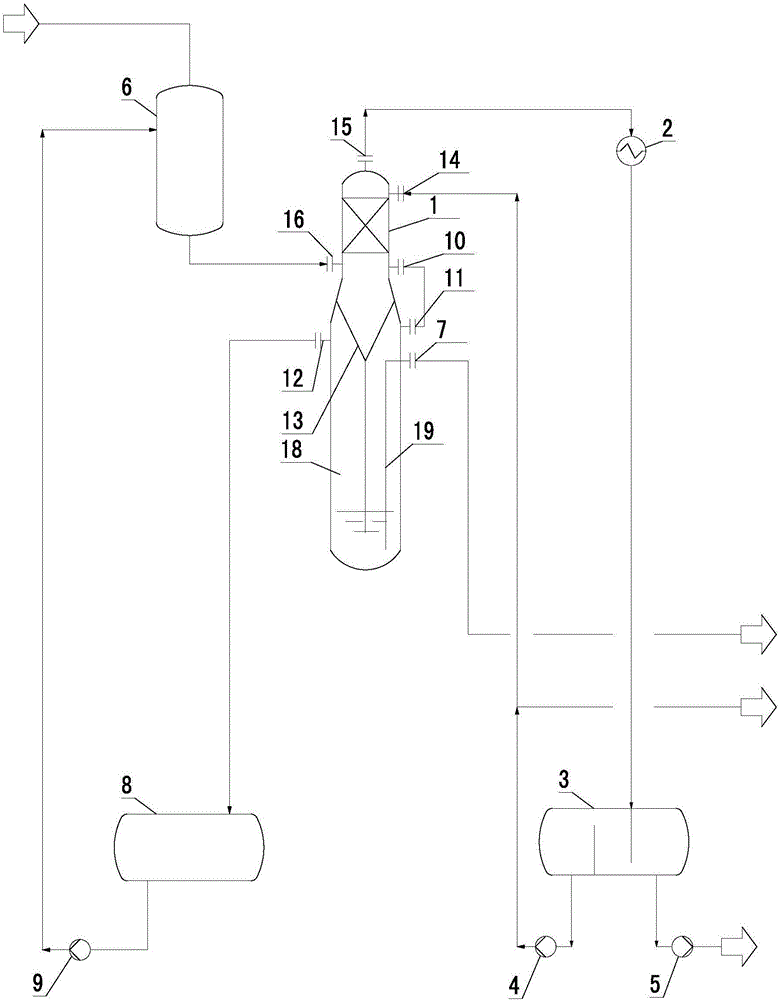

Extraction tower and process for removing methanol from residual C4 of etherification reaction

ActiveCN104225955ALower the altitudeReduce board spacingLiquid solutions solvent extractionExtraction purification/separationPtru catalystFluid phase

The invention relates to an extraction tower and a process for removing methanol from residual C4 of an etherification reaction. The extraction tower comprises a tower body which is internally provided with a plurality of supporting beams; each group of supporting beams corresponds to one layer of tower plate in parallel; a plurality of grooves are formed in each supporting beam at intervals; liquid flow holes communicated with the adjacent lower layer of tower plate are formed in the bottom surfaces of the grooves; each layer of tower plate is formed by splicing a plurality of secondary tower plate pieces; the supporting beams in each two adjacent groups are arranged in a staggered manner; a washing liquid inlet is formed in the upper part of the tower body and a C4 inlet is formed in the lower part of the tower body; a gas-phase outlet is formed in the tower top, and a liquid-phase outlet is formed in the tower bottom. Desalted water which is taken from the outside and has the temperature of 35-45 DEG C enters the tower body from the washing liquid inlet through a desalted water pump, residual C4 of the etherification reaction, which has the temperature of 35-45 DEG C, enters the tower body from the C4 inlet, and the flow ratio of the washing liquid to residual C4 of the etherification reaction is 1 to (20-25). Methanol in mixed C4 with the low methanol content can be removed and the content of methanol in processed mixed C4 is not more than 50ppm so that the consumption amount of a sulfuric acid catalyst in an isooctane device, the energy consumption of the device and the amount of waste acids can be reduced.

Owner:NINGBO HAIYUE NEW MATERIAL

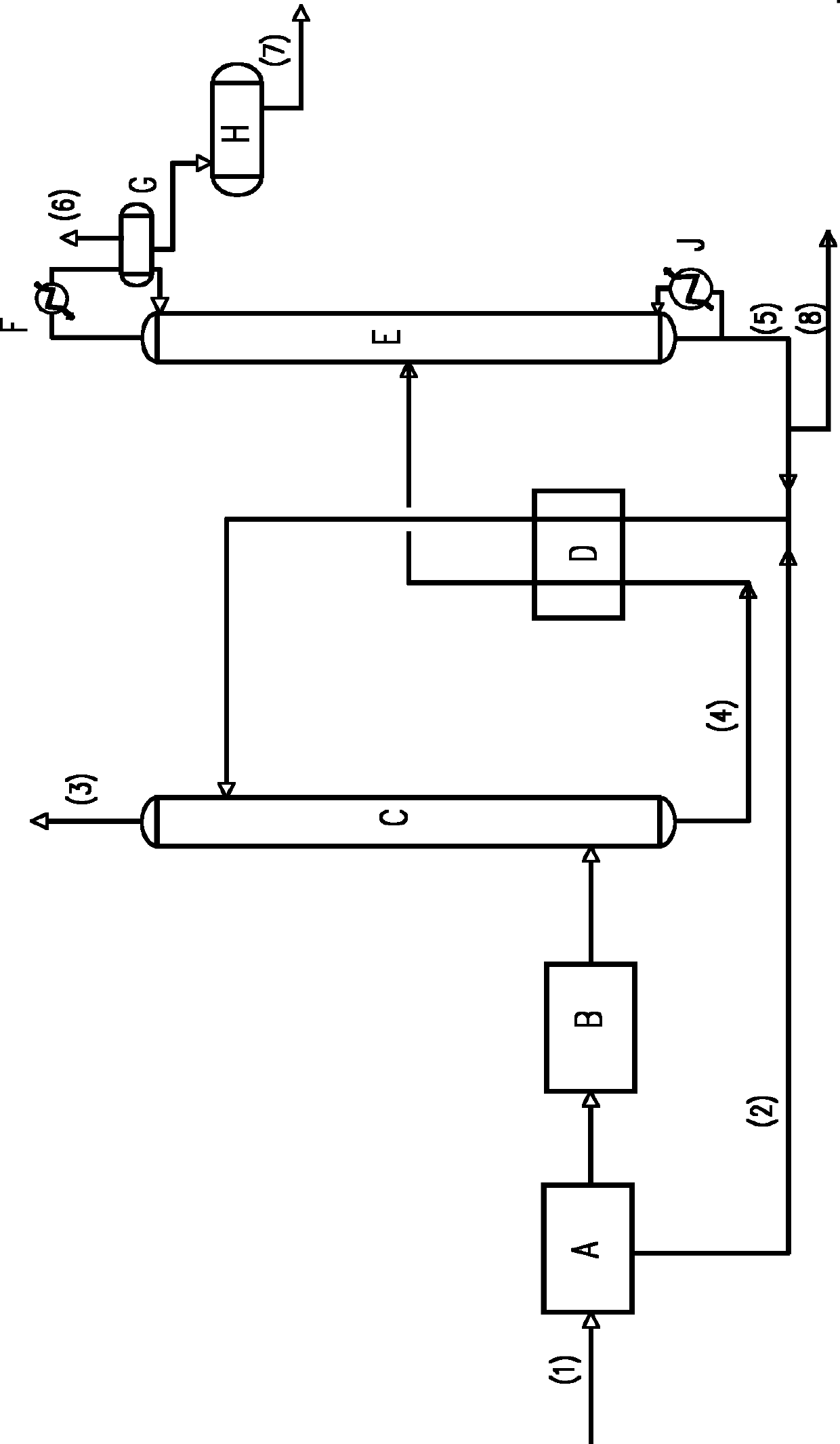

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method, system and product for reclaiming sulfoxides from flue gas

InactiveCN101054188AImprove corrosion resistanceShort construction periodDispersed particle separationAmmonium sulfatesGlass fiberSulfate

The present invention relates to a method and a system for recovering oxysulfide from flue gases, and the recovered products thereof. In the present invention, the process of oxidizing ammonium sulfite to ammonia sulfate and the crystallization process of ammonia sulfate are carried out at the bottom of the oxysulfide absorbing tower, thereby the structure of the oxysulfide absorbing tower is simplified and the height of the oxysulfide absorbing tower is reduced; the flue gases inlet is arranged at the top of the oxysulfide absorbing tower, and the flue gases outlet is arranged at the middle part of the oxysulfide absorbing tower, so that the flue gases with highest temperature is positioned at the top of the oxysulfide absorbing tower, while the flue gases temperature at other parts of the tower is less than 70 DEG C, thereby the oxysulfide absorbing tower is adapted to be integratedly manufactured by fiber glass reinforced plastics material, and excellent corrosion resistance and shorter construction cycle can be realized. The bottom of the oxysulfide absorbing tower is named as crystallization and oxidation reactor; the flue gases and absorbing liquid flow downwards from the top of the tower in a concurrent flow manner inside of the oxysulfide absorbing tower, and the oxysulfide absorbing tower has a simple structure, a large handling capacity, a high sulfur removing efficiency, and has a major industrialization prospect.

Owner:娄爱华

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

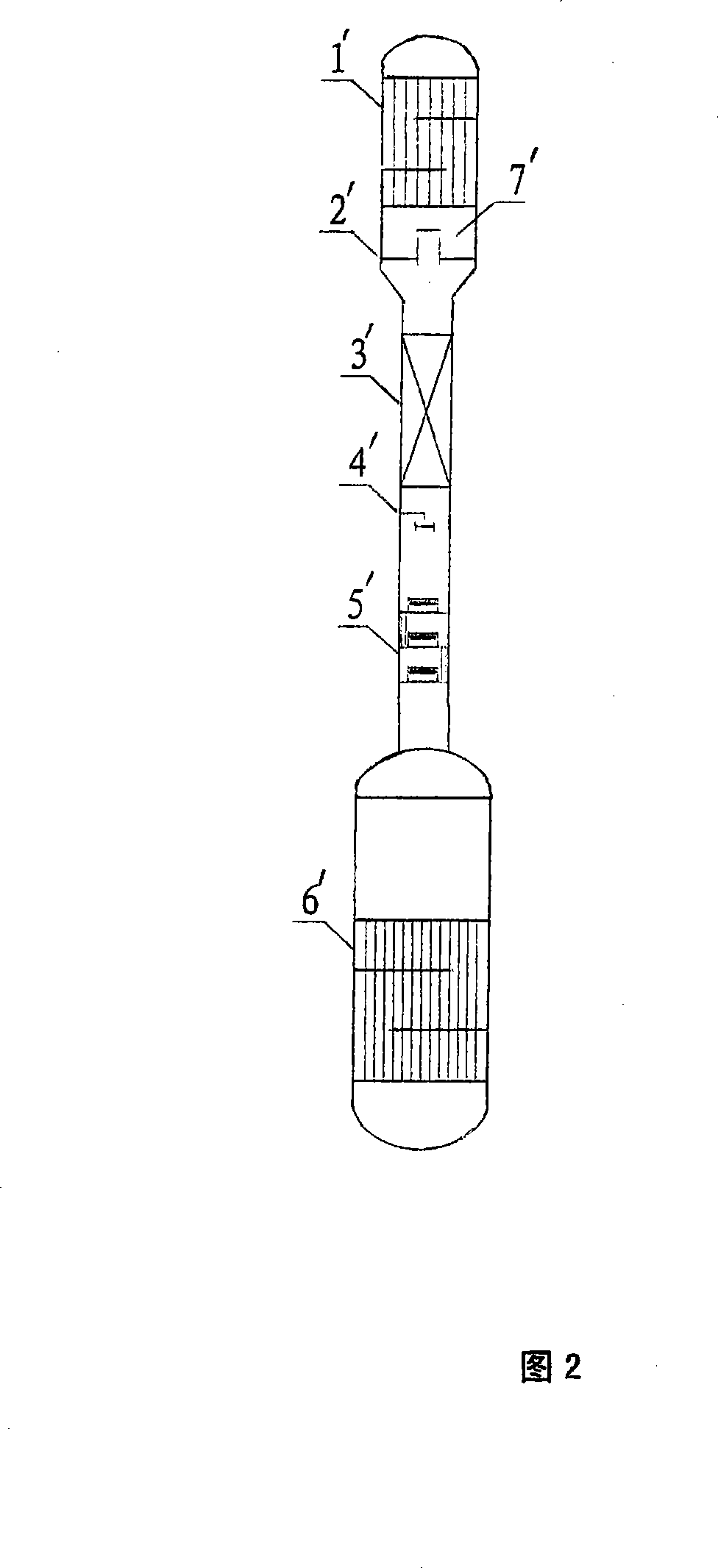

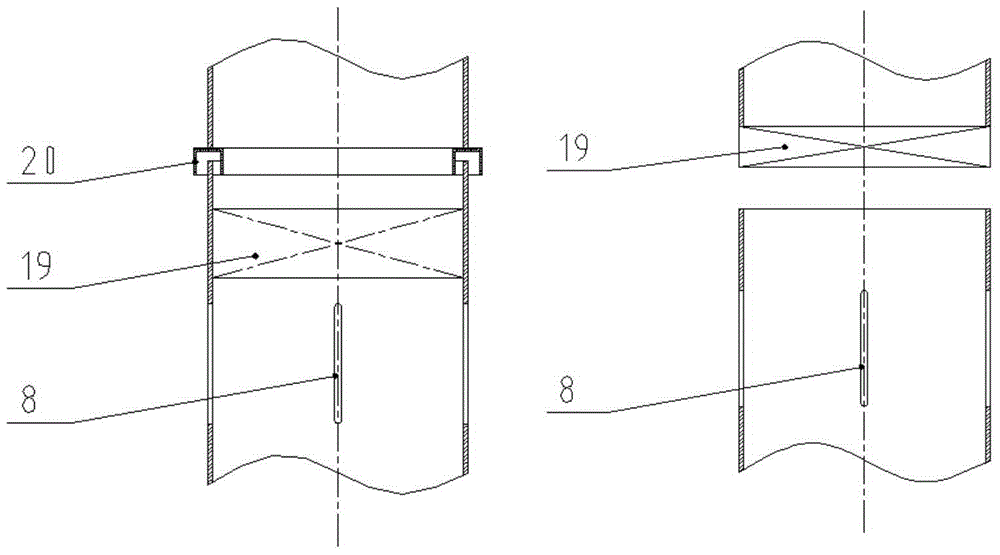

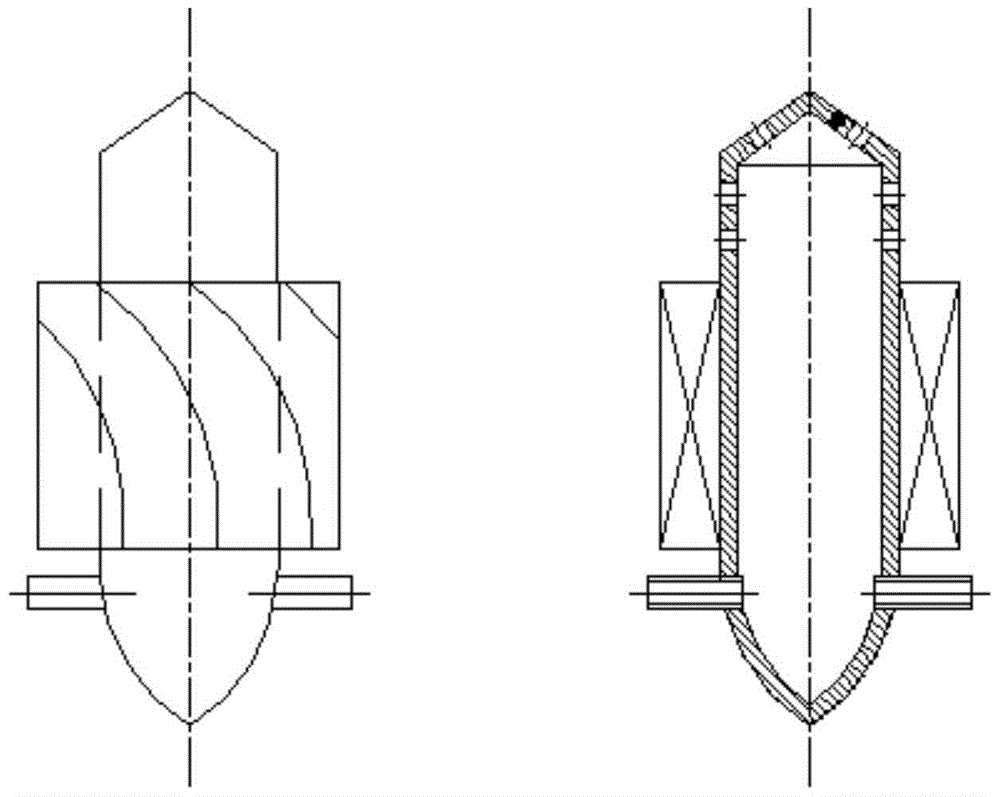

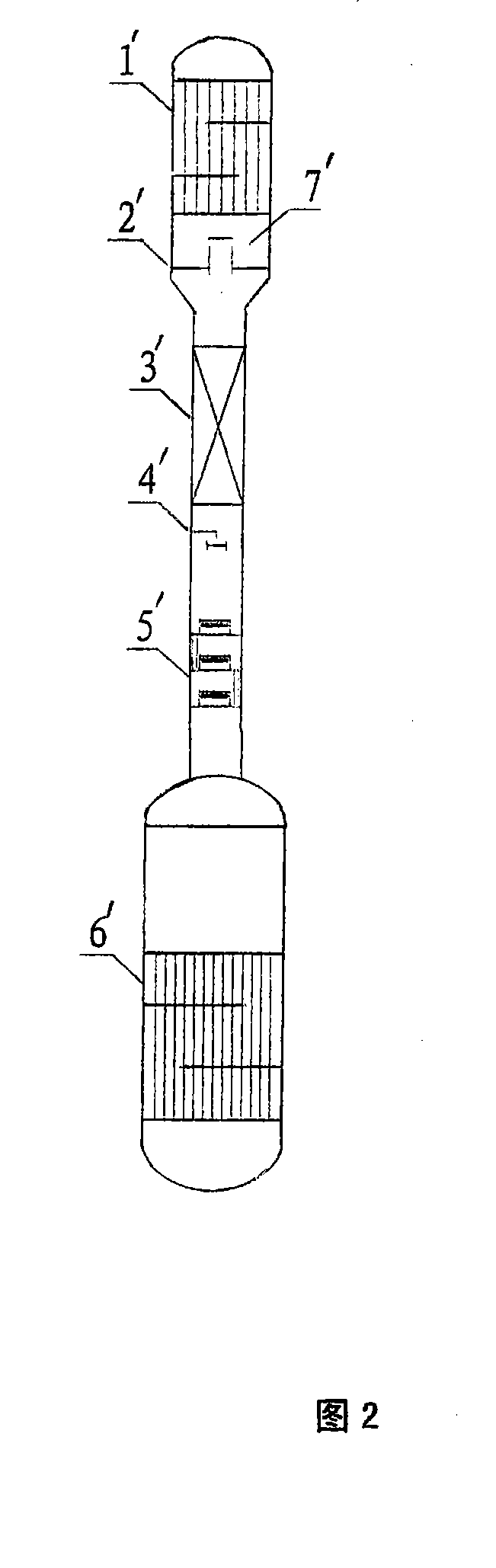

Airlift Cyclone Suction and Downcomer Isolation Tray

ActiveCN104959106BAvoid contactPrevent floodingDispersed particle separationChemical/physical/physico-chemical processesCycloneGas phase

The invention relates to an air-lift cyclone liquid absorption and liquid falling isolation-type tower plate. A sandwiched plate as well as a liquid flow falling guide pipe and a gas-phase rising pipe independent to each other, are additionally arranged below the tower plate. The rising airflow after transferring the mass by a centrifugal cyclone flow field is completely isolated from liquid phase flow after gas-phase mass transferring, so that the problem that the rising air flow causes flooding for the pushing of the falling liquid in an ordinary plate-type tower can be thoroughly avoided, the air speed of the tower plate can be greatly increased, the air-phase cyclone strength can be improved, the capability for breaking liquid drops can be improved, the mass transfer efficiency can be improved, and the tower path can be reduced. Since the rising airflow is isolated from the falling liquid phase, the air phase and the liquid phase after the high-speed cyclone contact mass transferring can be separated by virtue of a short height distance of the tower plate under the centrifugal action of the high-speed eddy flow, so that the distance between two adjacent layers of tower plates can be greatly reduced, and the height of the tower can be greatly reduced. The novel tower plate has the characteristics of small tower diameter, low tower height and high efficiency and has a prominent advantage in the field of high-air-flow effective mass transfer.

Owner:DALIAN UNIV OF TECH

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

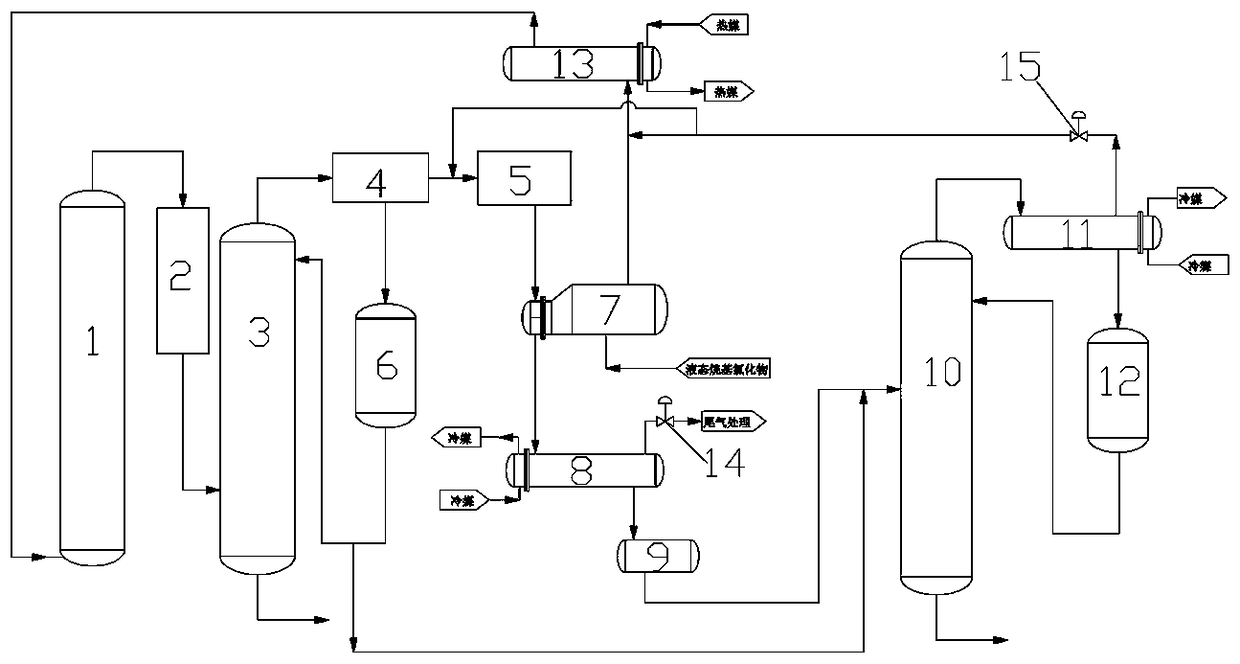

Methane chloride recycling and feeding process and device

ActiveCN108530260AEliminate damageEliminate quality issuesHalogenated hydrocarbon separation/purificationGas phaseBoiling point

The invention provides a methane chloride recycling and feeding process and device. The process comprises the following specific steps: removing the vast majority of dust from a methane-chloride-containing gas mixture from the top of a reactor via a dust removal system, and then washing the gas mixture via a dust removal tower to remove high-boiling-point substances and fine powder; after condensing a material on the top of the dust removal tower via a cooling system, taking part of the material as a cleaning solution, and feeding the other part of the material to a refining tower; feeding noncondensable gas in the cooling system to a compressing system; carrying out heat exchange on compressed gas and liquid methane chloride via a vaporizer, vaporizing the liquid methane chloride, coolingand condensing the compressed gas, and then feeding the compressed gas into a condenser for further condensing, carrying out tail gas removal treatment on noncondensable gas in the condenser, and feeding condensate to a buffering tank; enabling the methane chloride of the buffering tank and the methane chloride of a storage tank to enter the refining tower together; and enabling a gas phase on the top of the refining tower to enter a partial condenser for partial condensing, and feeding the condensate into a refluxing tank and totally refluxing the condensate into the refining tower. The methane chloride can be recycled effectively, the main content is higher than 99.5%, moreover, the process is simple, the investment of equipment is low, and energy conservation and consumption reductionare implemented.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

System and method for processing condensate oil

ActiveCN102807891AReduce tower diameterReasonable operating conditionsTreatment with plural serial refining stagesOil processingProcess engineering

The invention discloses a system and a method for processing condensate oil. The system comprises that: a vacuum distillation tower is arranged on the rear of a normal pressure distillation tower, the bottom of the normal pressure distillation tower or the bottom of the vacuum distillation tower is provided with a tower bottom reboiling furnace. The method comprises: transferring a part of light fractions to the vacuum distillation tower from the normal pressure distillation tower to carry out precipitation, and transferring a part of heat load in a feeding heating furnace to the tower bottom reboiling furnace. With the method of the present invention, a processing problem of low heavy component content in the condensate oil processing process in the prior art is solved. In addition, a process is simple, equipment investment is low, energy consumption is low, and operation is stable.

Owner:CHINA PETROCHEMICAL CORP +1

Recycling method of ammonia from ammonia-bearing multi-phase mixed wastewater

InactiveCN108689542AHigh removal rateEmission reductionWater treatment parameter controlWater contaminantsRecovery methodAbsorption column

The invention relates to a recycling method of ammonia from ammonia-bearing multi-phase mixed wastewater, which includes steps of: pretreatment of the ammonia-bearing multi-phase mixed wastewater, steam stripping for ammonia removal from the wastewater, and wet-type washing for recycling ammonia. The step of steam stripping for ammonia removal aims to strip concentrated ammonia gas from ammonia, in the ammonia-bearing multi-phase mixed wastewater, with steam in a steam stripping column, wherein the concentrated ammonia gas exits from the steam stripping column and enters a water tank at the bottom of the column, so that ammonia gas can be absorbed by cold water to form concentrated ammonia water at high efficiency, ammonia recycled as a resource; then the purified gas then is discharged from an outlet of the absorption column, and the wastewater, after ammonia removal, flows down into the water tank at the bottom of the column, while water with other components is discharged via a sewage pump and enters the next processing step. Through the steam stripping, ammonia in the ammonia-bearing wastewater can be removed, thus reducing emission of dangerous wastes. The method is high-effective and energy-saving, is high in economic value and practicability, is simple in equipment construction and low in cost, has great adaptability and can high-effectively and safely recover the ammonia, thus achieving reutilization of resources.

Owner:SUZHOU AITESI ENIRONMENTAL PROTECTION EQUIP

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025BImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

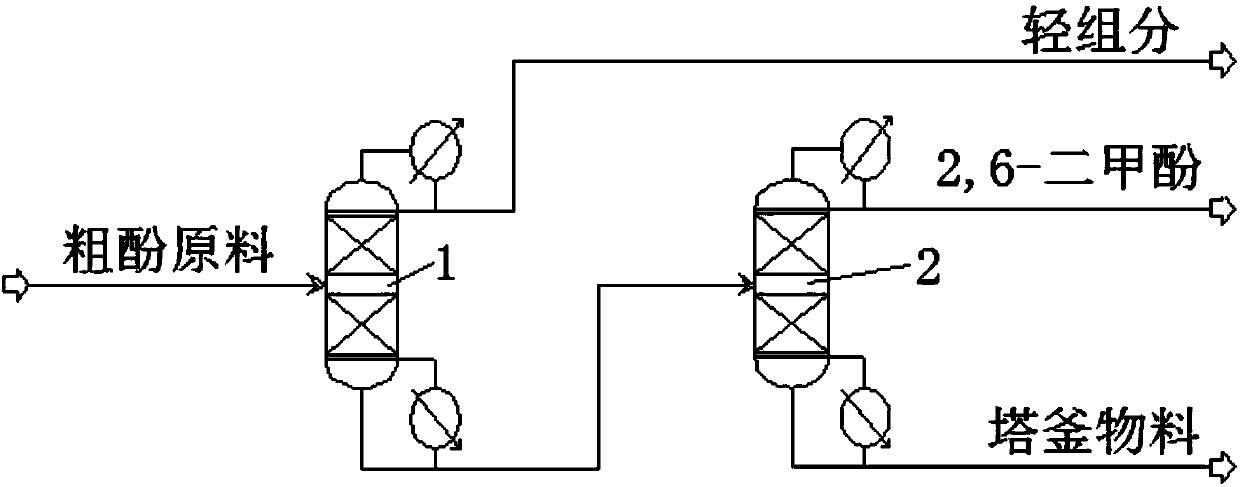

Method for extracting 2,6-dimethylphenol from crude phenol and device applied to method

ActiveCN107556165AReduce gas loadReduce tower diameterOrganic chemistryOrganic compound preparationChemistryHigh concentration

The invention discloses a method for extracting 2,6-dimethylphenol from crude phenol and a device applied to the method. A two-stage distillation technology is adopted for the method, primary distillation treatment is performed on crude phenol firstly to remove light components lighter than 2,6-dimethylphenol, the light components are prevented from affecting the effect of follow-up secondary distillation treatment, and product yield and quality of 2,6-dimethylphenol are improved; then secondary distillation treatment under specific operation conditions is performed, especially, the operationpressure of the secondary distillation treatment is controlled to be not higher than 5 KPa, so that on one hand, the relative volatility of 2,6-dimethylphenol and other components in a primary distillation product is improved and high-concentration 2,6-dimethylphenol can be obtained by extraction, on the other hand, 2,6-dimethylphenol cannot have an isomerism change in the distillation processes,and the 2,6-dimethylphenol separation effect is guaranteed. Tests prove that the yield of 2,6-dimethylphenol is as high as 99.98%, and the purity is as high as 99.9%.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

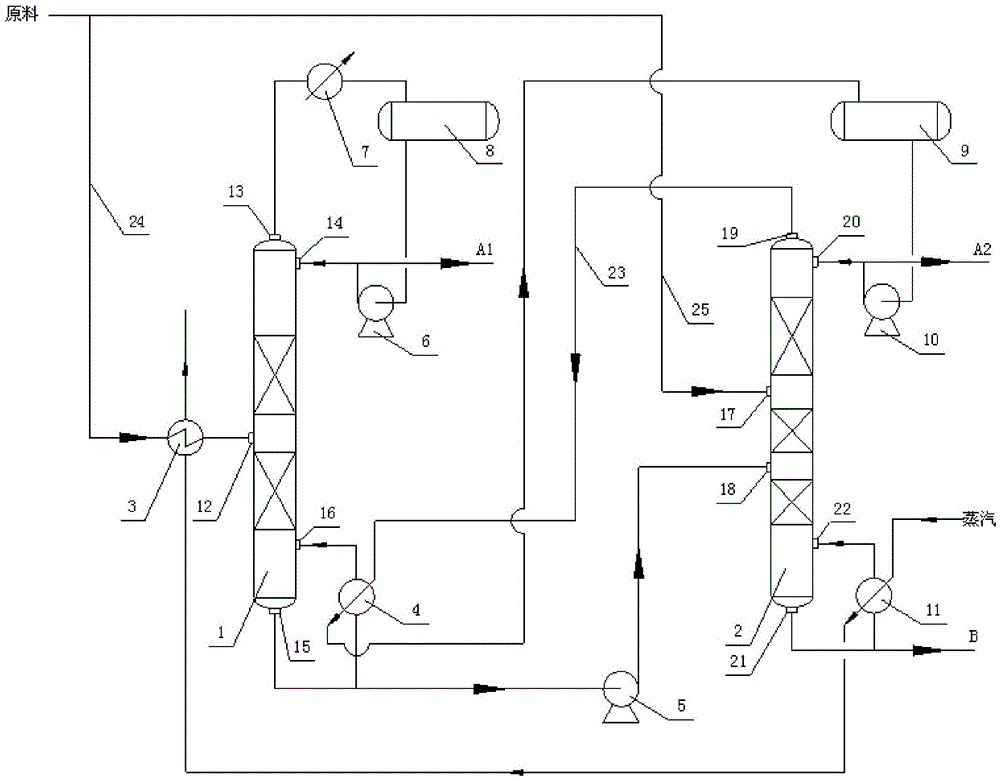

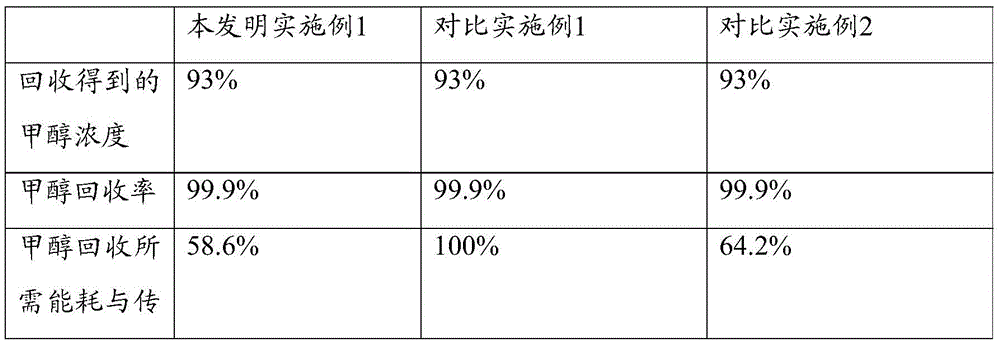

Methanol recovery method

ActiveCN105646147AImprove heat utilizationReduce tower diameterOrganic compound preparationHydroxy compound preparationVapor liquidRecovery method

The invention provides a methanol recovery method. The methanol recovery method includes the steps of providing a methanol recovery device comprising an atmospheric tower and a pressurized tower connected with the atmospheric tower; dividing crude methanol raw materials into a group-A raw material and a group-B raw material according to a mass ratio of 1.5-10:1, and adding the group-A raw material into the atmospheric tower for atmospheric pressure rectification so as to obtain atmospheric tower steam and atmospheric tower bottoms; adding the atmospheric tower bottoms and the group-B raw material into the pressurized tower for pressurized rectification so as to obtain pressurized tower methanol steam which is used for providing heat for atmospheric pressure rectification. The methanol recovery method has the advantages that a specific quantity of crude methanol raw materials are added into the atmospheric tower and the pressurized tower respectively, and condensation heat of the methanol steam produced by the pressurized tower is just required by a reboiler of the atmospheric tower, so that pressurized tower top methanol steam heat utilization ratio is increased; additionally, vapor-liquid load of the atmospheric tower and the pressurized tower is in the superior state, so that the tower diameters of the atmospheric tower and the pressurized tower are decreased, and equipment investment is reduced.

Owner:SHENZHEN CANDORTECH INC CO

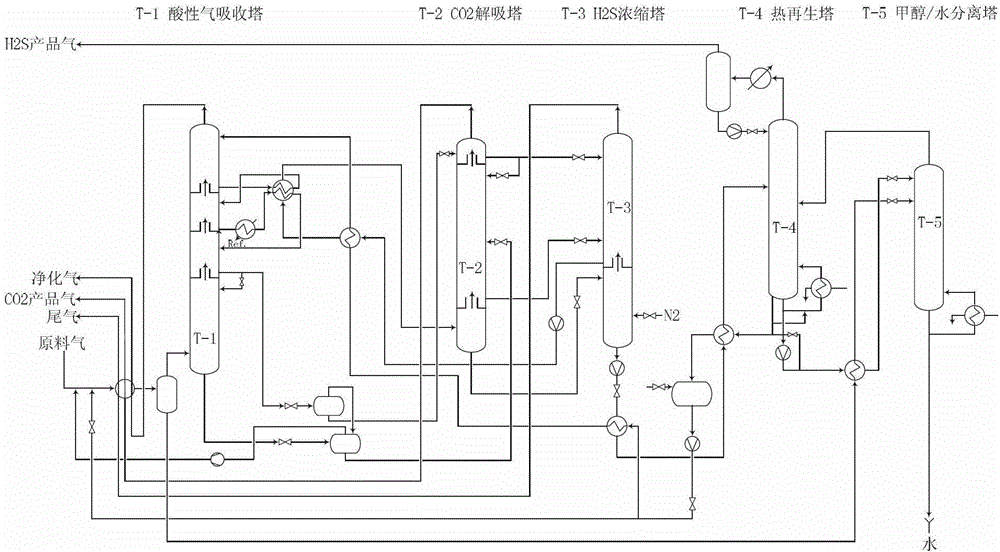

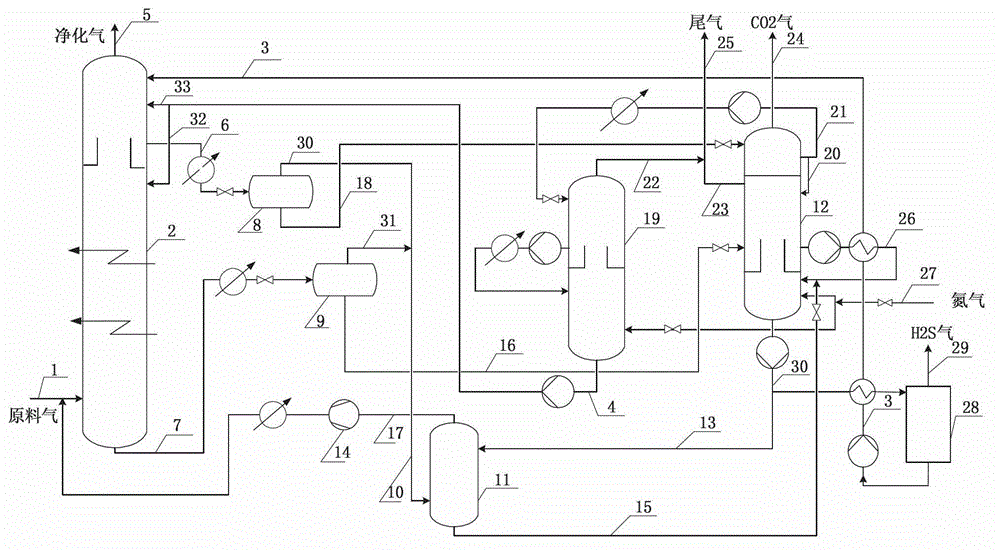

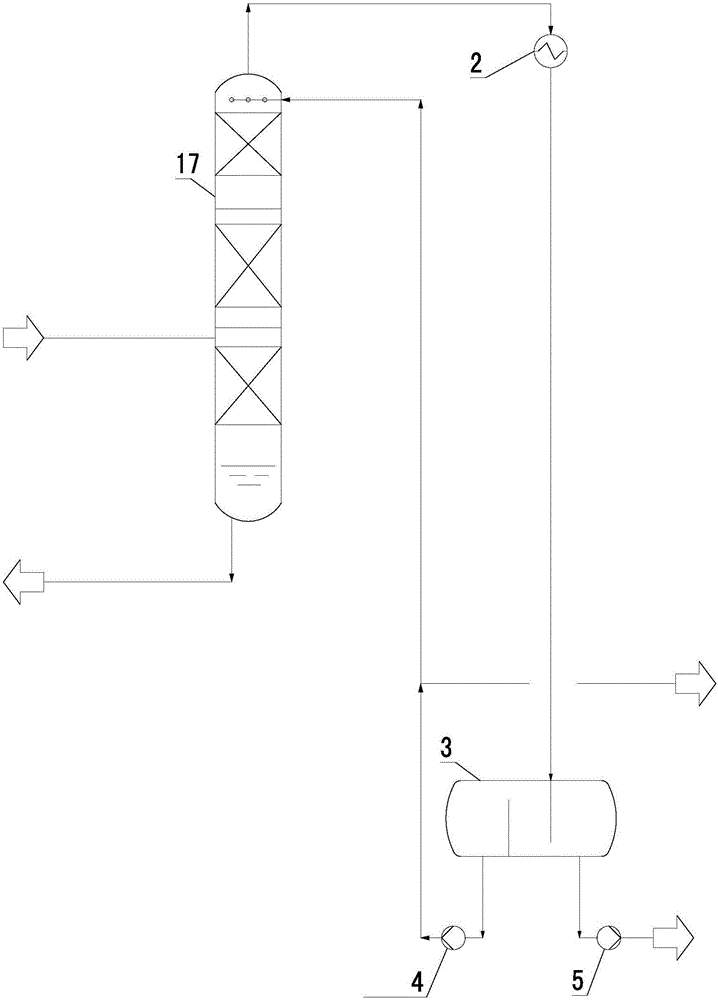

Energy-saving one-step rectisol method

ActiveCN102806000BReduce loadEfficient use ofDispersed particle separationAir quality improvementProduct gasSulfide

An energy-saving one-step rectisol method belongs to the technical field of gas purification. The method is characterized in that two or three desulfuration segments of an absorption tower employ a sulfur-free semi-lean solution for absorption; intersegment coolers are adopted; the desulfuration segments can remove sulfide and approximately 50-60% of CO2 from virgin gas simultaneously; only one decarbonization segment of the absorption tower is adopted; a lean solution is used at the top of the tower, and the sulfur-free semi-lean solution is added; flash steam is absorbed by a sulfur-containing semi-lean solution in the medium-pressure flash evaporation process; after most of CO2 in the flash steam is absorbed, the solution is delivered to a lower tower of an H2S concentrating tower for gas stripping; a sulfur-free methanol solution gas stripping tower is additionally adopted and divided into one or two segments; solutions at the segments are heated appropriately before entering the tower; and the sulfur-free semi-lean solution is delivered to the absorption tower after the gas stripping. The energy-saving one-step rectisol method has the effects and benefits that the number of plates of the absorption tower is reduced by about 20%, the tower diameter is shortened, the circulation volume of a methanol lean solution is reduced, the regeneration load of a rich solution is also reduced, the energy consumption of a device is saved by about 30%, and the device investment is saved.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

Large-scale methanol multi-effect energy-saving rectifying device and process

ActiveCN102039058BMake full use ofReduce exergy lossOrganic compound preparationChemical industryWastewaterProcess engineering

The invention relates to large-scale methanol multi-effect energy-saving rectifying device and process. Main equipment used in the process sequentially comprises a pre-rectifying tower, a second rectifying tower, a pressurizing tower, an atmospheric tower and a recovering tower, wherein the tops of the second rectifying tower, the pressurizing tower and the atmospheric tower are respectively used for discharging refined methanol, the top of the recovering tower is used for discharging fusel oil, and the bottom is used for discharging purified wastewater. Because one rectifying tower is additionally arranged, and the process parameter of each tower is adjusted, two methanol multi-effect energy-saving rectifying processes by five towers are obtained, the effective energy loss is reduced, thereby energy consumption is reduced. In addition, the diameter of each tower is reduced, the amplification effect of relevant equipment, caused by the oversize diameter of each tower, is greatly reduced. The process has the advantages of reasonable design, the energy is fully and reasonably utilized in the process, the energy consumption of the whole device used in the process is reduced by 20%-30% higher than that of the device used in the traditional double-effect process, and the purity of a product reaches the American AA-level standard.

Owner:TIANJIN UNIV

A spray drying system for easy-to-stick materials

ActiveCN103920299BAvoid stickingSolve the sticky situationEvaporation by sprayingAir volumeEngineering

The invention relates to a spray drying system for wall-attaching materials, and relates to the technical field of material drying. According to the invention, a layer of air wall wind with adjustable temperature, humidity and air volume is directly formed at the power-attaching part in a tower, the temperature and the humidity of the air wall wind are lower than the thermal boning temperature and the moisture absorption humidity of powder and particle materials, the air wall wind and the wind in the tower are finally mixed to form mixed wind, the temperature and humidity of the mixed wind are lower than the thermal boning temperature and the moisture absorption humidity of the powder and particle materials, and the temperature of the particle materials under the action of air wall wind before contacting the tower wall is lower than the thermal boning temperature. With the adoption of the system provided by the invention, three wall-attaching conditions of materials can be solved or reduced, and the effects of improving the production efficiency, improving the per unit yield, reducing energy consumption, prolonging the continuous production time, improving the production safety and the improving the quality of a product are achieved through high air inlet temperature.

Owner:陈林书

Efficient chemical deodorization device and method

PendingCN113996168ALarge amount of processingSmall pressure dropDispersed particle separationAtomized substancesThermodynamicsLiquid storage tank

The invention discloses an efficient chemical deodorization device and method. The device comprises: an absorption liquid storage tank, wherein a reaction pipe is connected to a gas inlet of the absorption liquid storage tank, and a demister connected to a gas outlet of the absorption liquid storage tank; a liquid spraying pipe, wherein the lower end of the liquid spraying pipe is connected with the reaction pipe, and an external fan connected with the upper end of the liquid spraying pipe; and a circulation mechanism, wherein the extraction end of the circulation mechanism is connected with the liquid outlet of the absorption liquid storage tank, and the discharge end of the circulating mechanism is connected with the liquid spraying pipe. According to the efficient chemical deodorization device, a gas-liquid co-flow chemical technology is adopted; and the device is large in treatment capacity, small in pressure drop, free of a flooding phenomenon, and capable of remarkably reducing a tower diameter and a tower height and decreasing the investment cost of the device.

Owner:BEIJING DRAINAGE EQUIP

Distillate yield improving vacuum distillation method and device

ActiveCN102311772BAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light oil and wide fraction separation technology and equipment applicable to tar distillation

ActiveCN106590715AReduced condensing cooling loadReduce the reflux ratioTar working-up by distillationSeparation technologyProcess engineering

The invention provides a light oil and wide fraction separation technology and equipment applicable to tar distillation. The equipment comprises a quench tower, an ammonia water tank, a distillation tower, an oil and water separation tank and a condenser cooler, wherein the quench tower is connected with a feeding port of the distillation tower; an ammonia water outlet of the distillation tower is connected with the ammonia water tank which is connected with the quench tower through an ammonia water pump; a light fraction escape port in the top of the distillation tower is connected with the condenser cooler; the condenser cooler is connected with the oil and water separation tank which is connected with a reflux port of the distillation tower through a light oil reflux pump. Compared with the prior art, the technology and the equipment have beneficial effects as follows: 1), condensing cooling load of the top of a rectifying tower is greatly reduced, and a reflux ratio of the top of the rectifying tower is reduced; 2), heavy components capable of being separated out through cooling are firstly guided into an oil and water separation region at the lower part of the tower through quenching, so that unnecessary circulation of materials in the equipment is reduced; 3), the diameter of the rectifying tower is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Multi-effect rectifying process of methanol

InactiveCN101570466BIncrease operating pressureIncrease productionOrganic compound preparationChemical industryReboilerChemical products

Owner:XI'AN PETROLEUM UNIVERSITY

Recovery technology of methyl alcohol production waste heat

InactiveCN109796309AImprove heat utilizationReduce heat consumptionOrganic compound preparationChemical industryThermal energyVapor liquid

The invention discloses a recovery technology of methyl alcohol production waste heat. An atmospheric tower and a pressurizing tower are included, the left side of the atmospheric tower is communicated with the right side of the pressurizing tower, the bottom of the left side of the atmospheric tower is communicated with a preheating device through a pipeline, and the bottom of the pressurizing tower is communicated with a heating device through a pipeline. The recovery technology comprises the steps that 1, a methyl alcohol raw material is divided into two parts of raw materials with the massratio being 1.5:1-10:1, the first part of the methyl raw material with the mass ratio of 1.5:1 is added to the atmospheric tower, and atmospheric distillation is conducted. The recovery technology has the advantages that the heat of methyl alcohol vapour of the atmospheric tower is thoroughly utilized, the thermal energy utilization rate of the methyl alcohol at the top of the pressurizing toweris higher, the overall thermal energy consumption is lower in the methyl alcohol recovery process, a certain amount of methyl alcohol raw material is added to the atmospheric tower and the pressurizing tower respectively to allow vapor-liquid loads of the atmospheric tower and the pressurizing tower to be in the optimal state, the diameter of the two towers is reduced, and equipment investment isreduced to help people to use the towers.

Owner:ANHUI HAOYUAN CHEM IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com