Method for recycling hydrogen chloride in tail gas of polysilicon production

A hydrogen chloride and polysilicon technology, which is applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve the problems of high hydrogen concentration and difficult storage of gaseous hydrogen chloride, and achieve the advantages of improving purity, reducing tower diameter and saving investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

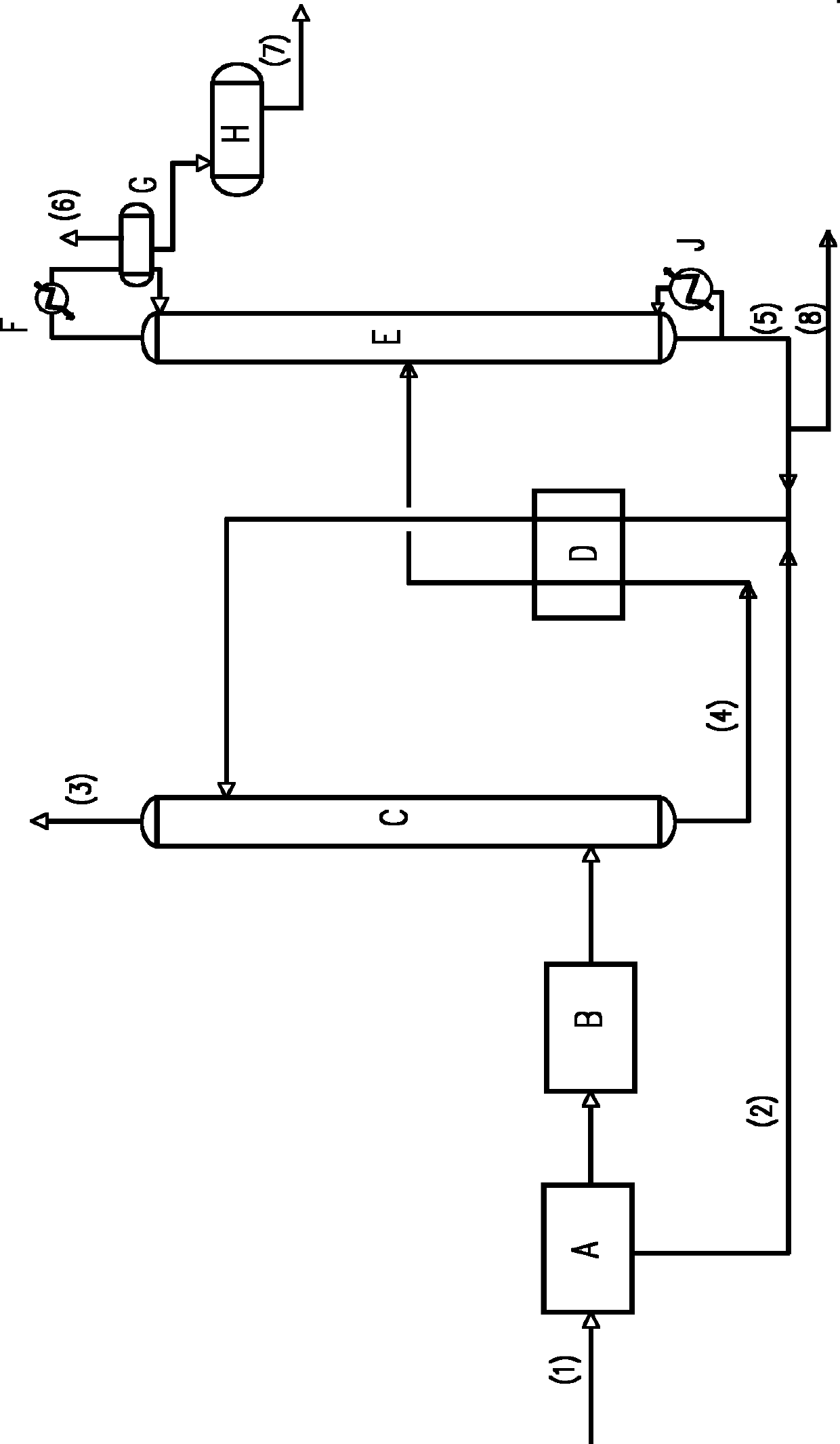

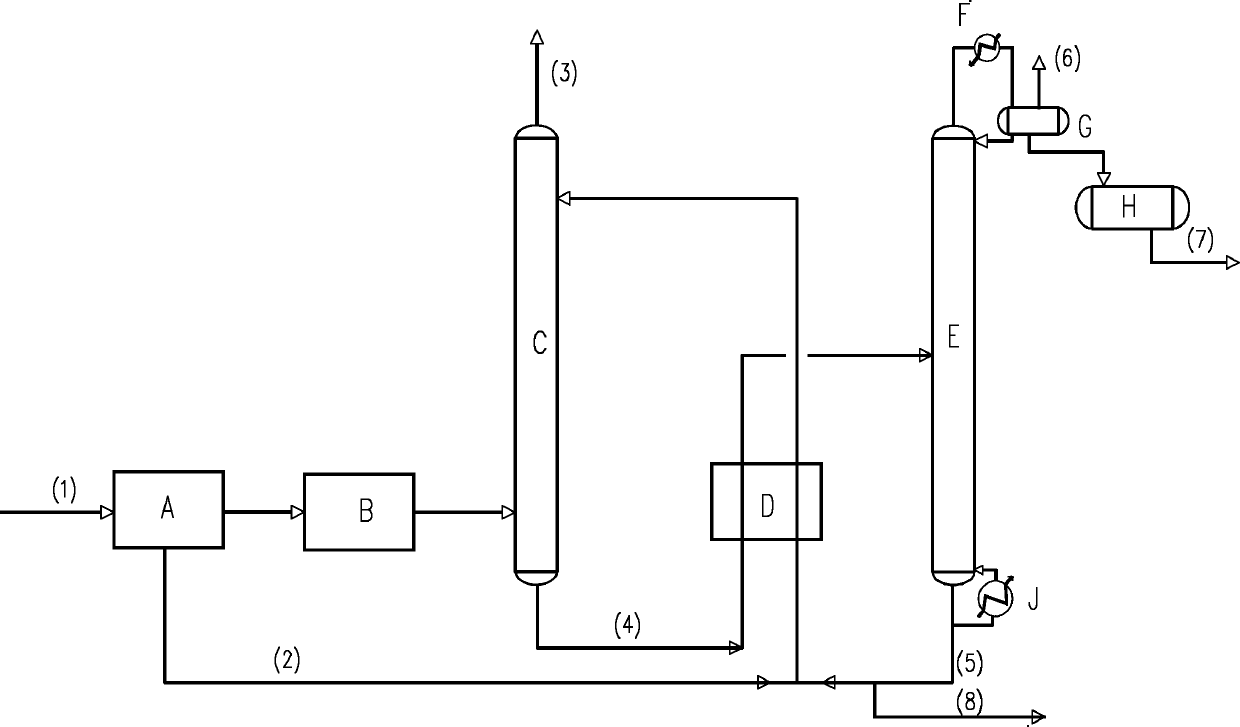

[0027] A method for reclaiming hydrogen chloride in the tail gas produced by polysilicon, comprising the steps of:

[0028] After cooling and condensing the tail gas produced in the reduction furnace and / or hydrogenation furnace in polysilicon production, most of the dichlorodihydrogen silicon, trichloro silicon and silicon tetrachloride are liquefied, and the gas enters the hydrogen chloride absorption tower after compression. Use chlorosilane solution to absorb hydrogen chloride and gaseous chlorosilane in the gas, and most of the hydrogen is discharged and collected from the top of the hydrogen chloride absorption tower; the hydrogen chloride-rich chlorosilane liquid discharged from the bottom of the hydrogen chloride absorption tower (its molar composition is as follows: H2 0.59%, HCL5.18%, DCS 4.57%, TCS 0.0064%, TET 49.65%) into the hydrogen chloride rectification tower for rectification, before entering the hydrogen chloride rectification tower, use the chlorosilane solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com