Methane chloride recycling and feeding process and device

A methane chloride and feeding technology, which is applied in chemical instruments and methods, organic chemistry, disproportionation separation/purification of halogenated hydrocarbons, etc., can solve the problems of high equipment investment and complicated process, so as to save operating costs and reduce operating temperature , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

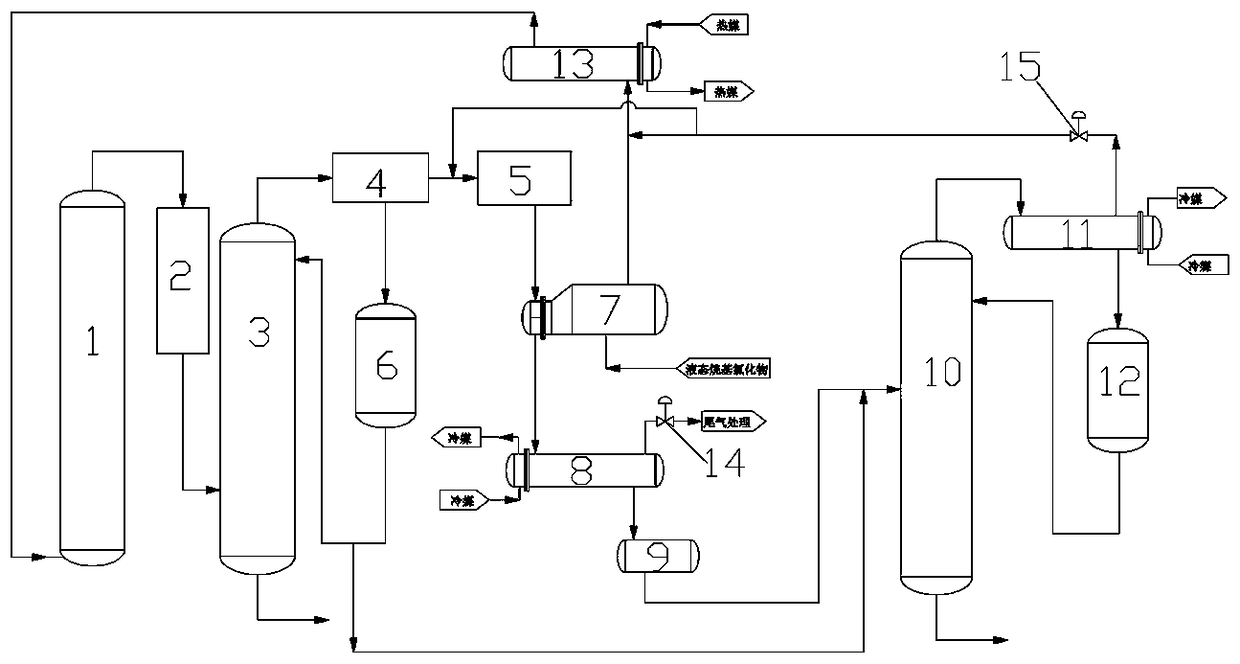

[0023] A device for recovering and feeding methane chloride. Reactor 1 is connected to dust removal system 2, dust removal system 2 is connected to dust removal tower 3, dust removal tower 3 is connected to cooling system 4, and cooling system 4 is connected to vaporizer 7 via compression system 5 , The vaporizer 7 is connected to the condenser 8, the condenser 8 is connected to the refining tower 10 via the buffer tank 9, the refining tower 10 and the top are connected to the reflux tank 12 via the partial condenser 11, and the reflux tank 12 is connected to the refining tower 10 via a pipeline.

[0024] The condenser 11 is connected to the heater 13 through a pipeline one way, and the heater 13 is connected to the reactor 1; one way is merged with the cooling system 4 and then connected to the compression system 5.

[0025] The cooling system 4 is connected to a storage tank 6, the storage tank 6 is connected to the dust removal tower 3 all the way, and the other way is connected ...

Embodiment 2

[0028] The gas mixture containing methane chloride from the top of the reactor 1 is removed by the dust removal system 2 to remove most of the dust, and then washed by the dust removal tower 3 to remove high boiling point substances and fine powder. The material at the top of the dust removal tower 3 is condensed to 5°C by the cooling system 4, and the condensate enters the storage tank 6, part of the material in the storage tank 6 is used as a washing liquid, and about 24t / h of the material goes to the refining tower 10. The non-condensable gas in the cooling system 4 is about 17t / h, and the pressure is 0.25MPa (G). The decompression system 5 compresses to 1.0MPa (G) and 100°C. Liquid methane chloride of 11t / h enters the vaporizer 7 and vaporizes through heat exchange with the methane chloride from the compression system 5, and the temperature is about 30°C. The methane chloride from the compression system 5 then enters the condenser 8 to be further condensed to -10°C, the non...

Embodiment 3

[0030] The gas mixture containing methane chloride from the top of the reactor 1 is removed by the dust removal system 2 to remove most of the dust, and then washed by the dust removal tower 3 to remove high boiling point substances and fine powder. The material at the top of the dust removal tower 3 is condensed to 4° C. through the cooling system 4, and the condensate enters the storage tank 6, part of the material in the storage tank 6 is used as a washing liquid, and about 25.6t / h of material goes to the refining tower 10. The non-condensable gas in the cooling system 4 is about 11.2t / h and the pressure is 0.2MPaG. The compression system 5 compresses to 1.1MPa(G) and 130°C. Liquid methane chloride 11.3t / h enters the vaporizer 7 and vaporizes through heat exchange with the methane chloride from the compression system 5 at a temperature of about 30°C. The methane chloride from the compression system 5 then enters the condenser 8 to be further condensed to -10°C, the non-conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com