Deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater

A technology for advanced treatment and saponification of wastewater, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the environmental pollution of wastewater containing high concentrations of ammonia nitrogen, and avoid scaling problems , tower height reduction, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

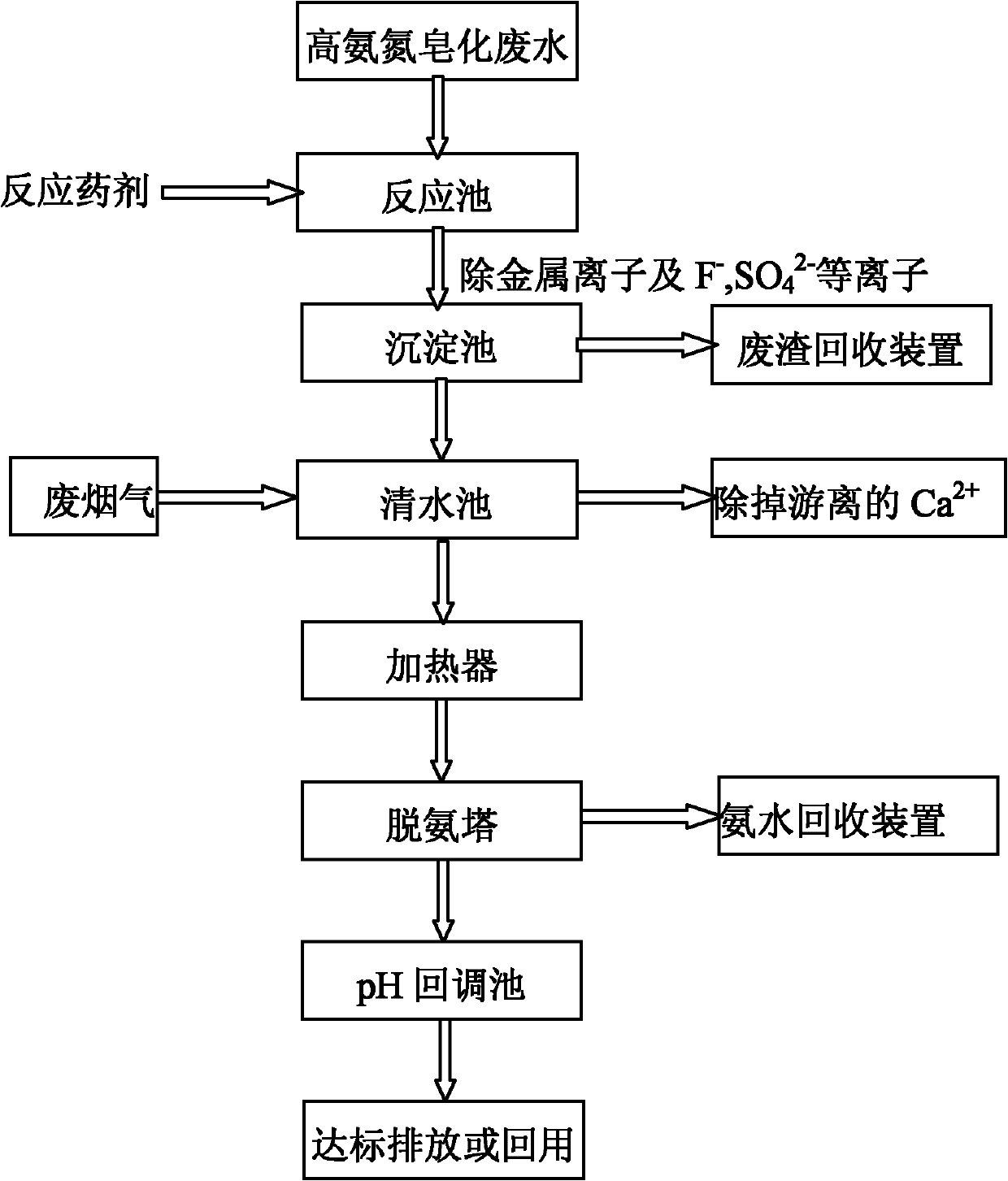

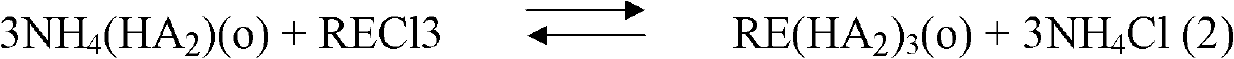

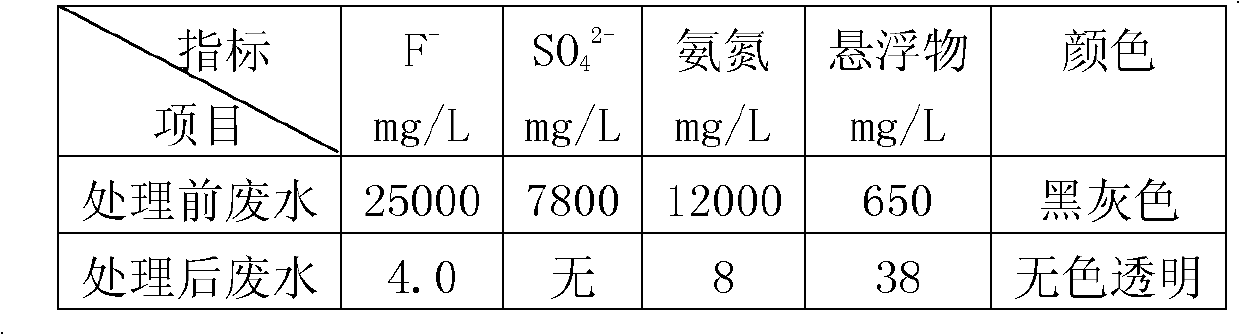

[0032] 1) For the high-concentration ammonia-nitrogen wastewater produced in the rare earth extraction process, 30-50m 3 The flow rate of / h flows into the reaction pool, and according to the amount of 10-20kg CaO and CaS mixed reaction agent (including CaSO. metal ions and F - , SO 4 2- Plasma;

[0033]2) After fully reacting in the reaction tank for 2 hours, pump it into the sedimentation tank. After 2 hours of sedimentation, the waste water flows into the clear water tank, and the waste residue containing various metal ions is pumped into the waste residue recovery device for recycling through the sludge pump;

[0034] 3) The exhaust from the heating boiler contains CO 2 The waste flue gas is passed into the clear water pool, to Ca 2+ The content is below 0.01mol / L, filter and use the CO in the waste flue gas 2 Free Ca in precipitation wastewater 2+ Ions; use the strong alkaline environment of clean water to absorb sulfides, nitrogen oxides, etc. in waste flue gas, a...

Embodiment 2

[0041] 1) For the high-concentration ammonia-nitrogen wastewater produced in the rare earth extraction process, 30-40m 3 The flow rate of / h flows into the reaction pool, and according to the dosage of 10-20kg CaO and CaS mixed reaction agent (including CaS0.4-0.5 kg / ton) per ton of waste water, it is added to the reaction pool to remove waste water. Various metal ions and F - , SO 4 2- Plasma;

[0042] 2) After fully reacting in the reaction tank for 2 hours, pump it into the sedimentation tank. After 2 hours of sedimentation, the waste water flows into the clear water tank, and the waste residue containing various metal ions is pumped into the waste residue recovery device for recycling through the sludge pump;

[0043] 3) The exhaust from the heating boiler contains CO 2 The waste flue gas is passed into the clear water pool, to Ca 2+ The content is below 0.01mol / L, filter and use the CO in the waste flue gas 2 Free Ca in precipitation wastewater 2+ Ions; use the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com