Novel radial flow adsorption tower for pressure swing adsorption

A pressure swing adsorption and adsorption tower technology, applied in the field of adsorption towers, can solve the problems of complex structure in the tower, difficult processing, high load-bearing pressure, high construction cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

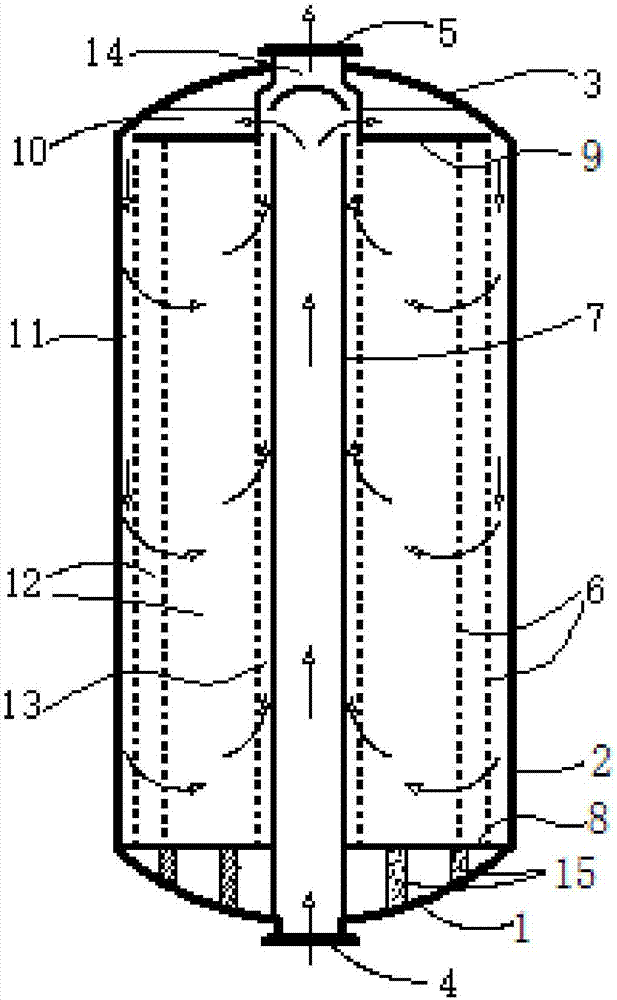

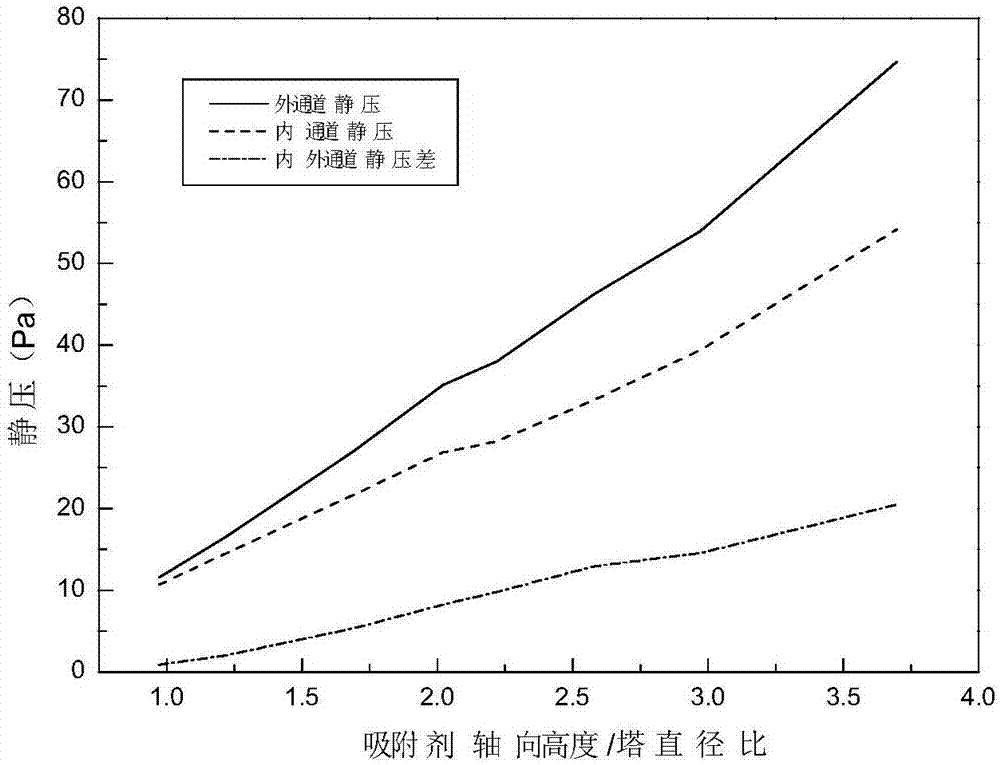

[0052] Example 1 The ratio of the axial height of the adsorbent layer to the diameter of the adsorption tower is set to be in the range of 0.9 to 3.8

[0053] In this example, select VPSA-O 2 Two-tower process, the range of gas entering the tower is 29100m 3 / h~100200m 3 / h Raw material air, among which, the product air flow rate is 3200Nm 3 / h~11000Nm 3 / h, choose a radial flow adsorption tower suitable for expressway transportation for optimal design and calculation.

[0054] The size of the selected radial flow adsorption tower is suitable for the adsorption tower within the maximum height limit of 4.2m for expressway transportation, and the diameter of the tower should not be greater than 3.4m.

[0055] As mentioned above, the raw air enters the central pipe and the splitter pipe sequentially from the bottom of the radial flow adsorption tower, and then splits into the annular outer channel, enters the two kinds of adsorbent layers from the radial direction of the tower,...

example 2

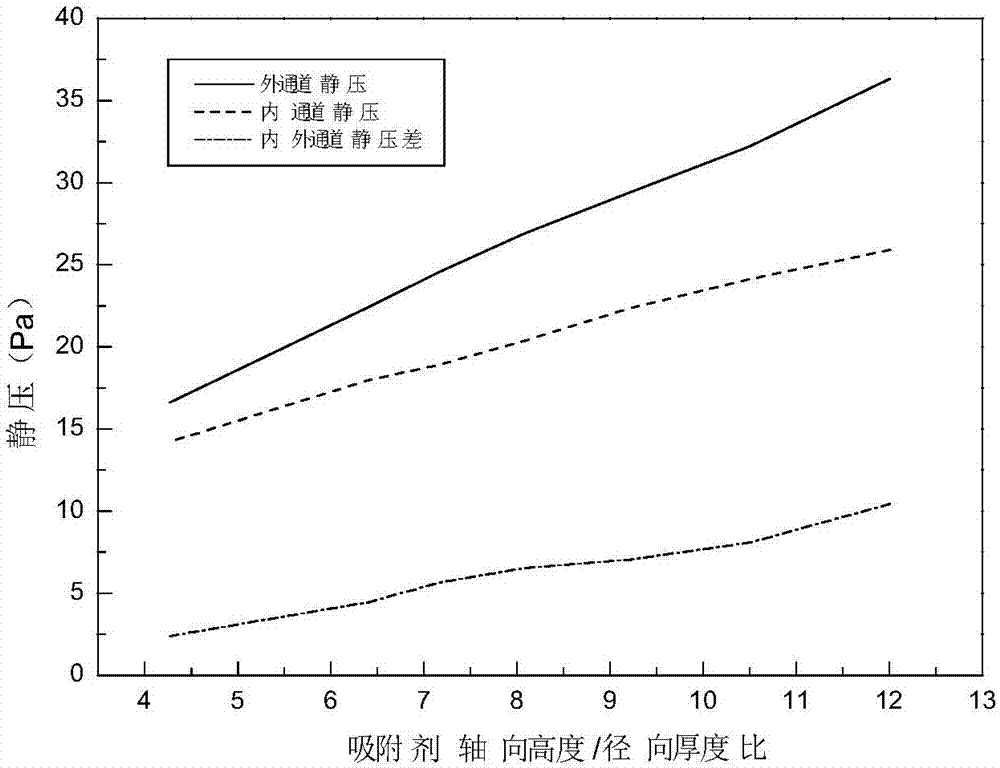

[0064] Example 2 The ratio of the axial height of the adsorbent layer to the radial thickness of the adsorbent layer is set in the range of 4.0 to 12.0

[0065] In this example, select VPSA-O 2 Two-tower process, the amount of gas entering the tower is 59200m 3 / h Raw material air, its product air flow is 6500Nm 3 / h, select the tower diameter in the range of 2.8m to 4.2m, and optimize the calculation of its adsorption process.

[0066] In this example, the direction of air flow in and out of the radial flow adsorption tower is as above. In this embodiment, the fluid in the adsorption process that is representative of the gas flow distribution is selected for the process.

[0067] Table 2 Static pressure and pressure difference data in the adsorption tower under different ratios of the axial height of the adsorbent layer to its radial thickness

[0068]

[0069] As shown in Table 2 above, for 59200m 3 / h feed gas air and 6500Nm 3 / h product gas, select different tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com