Patents

Literature

144 results about "Airflow orifice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

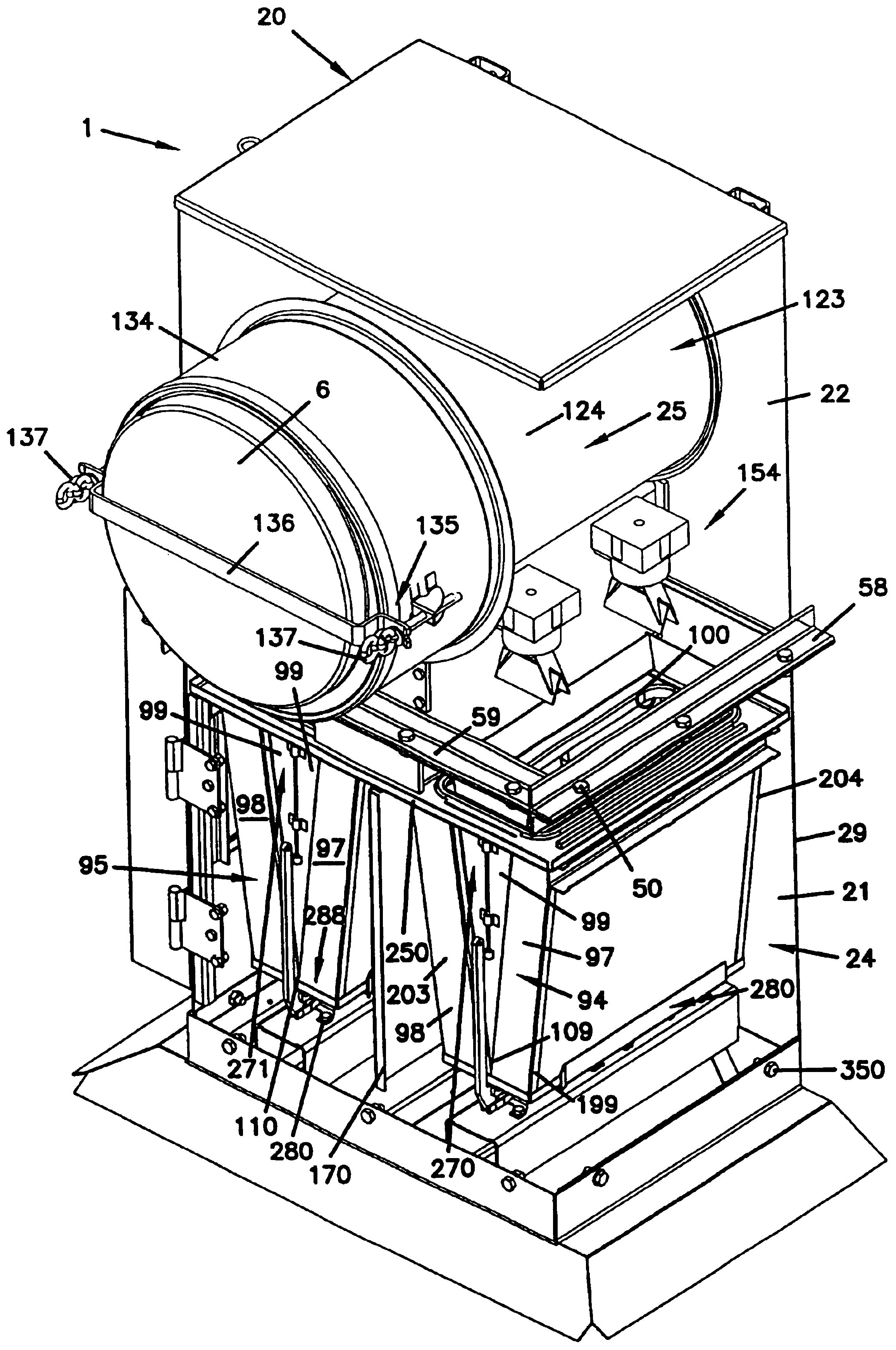

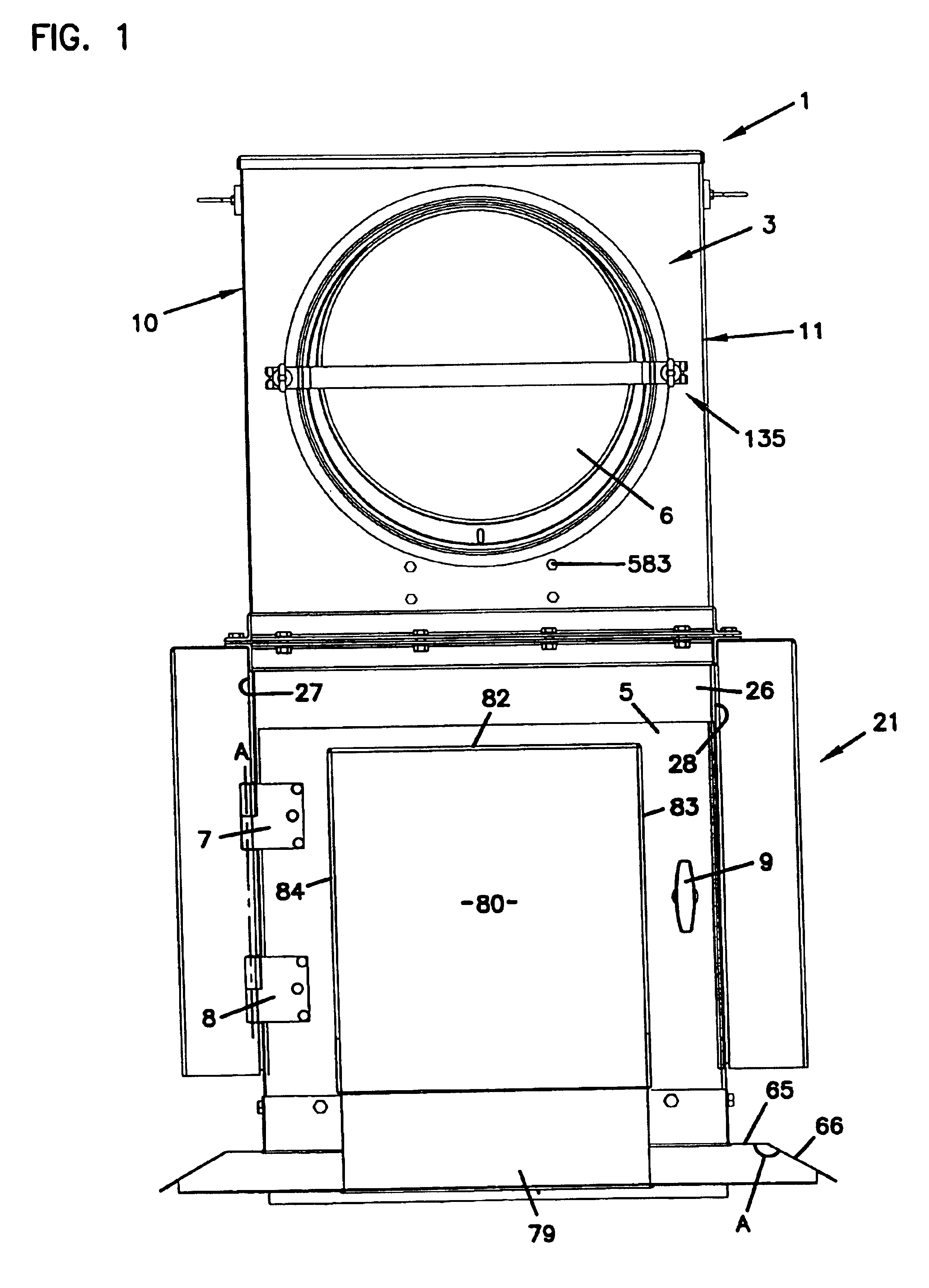

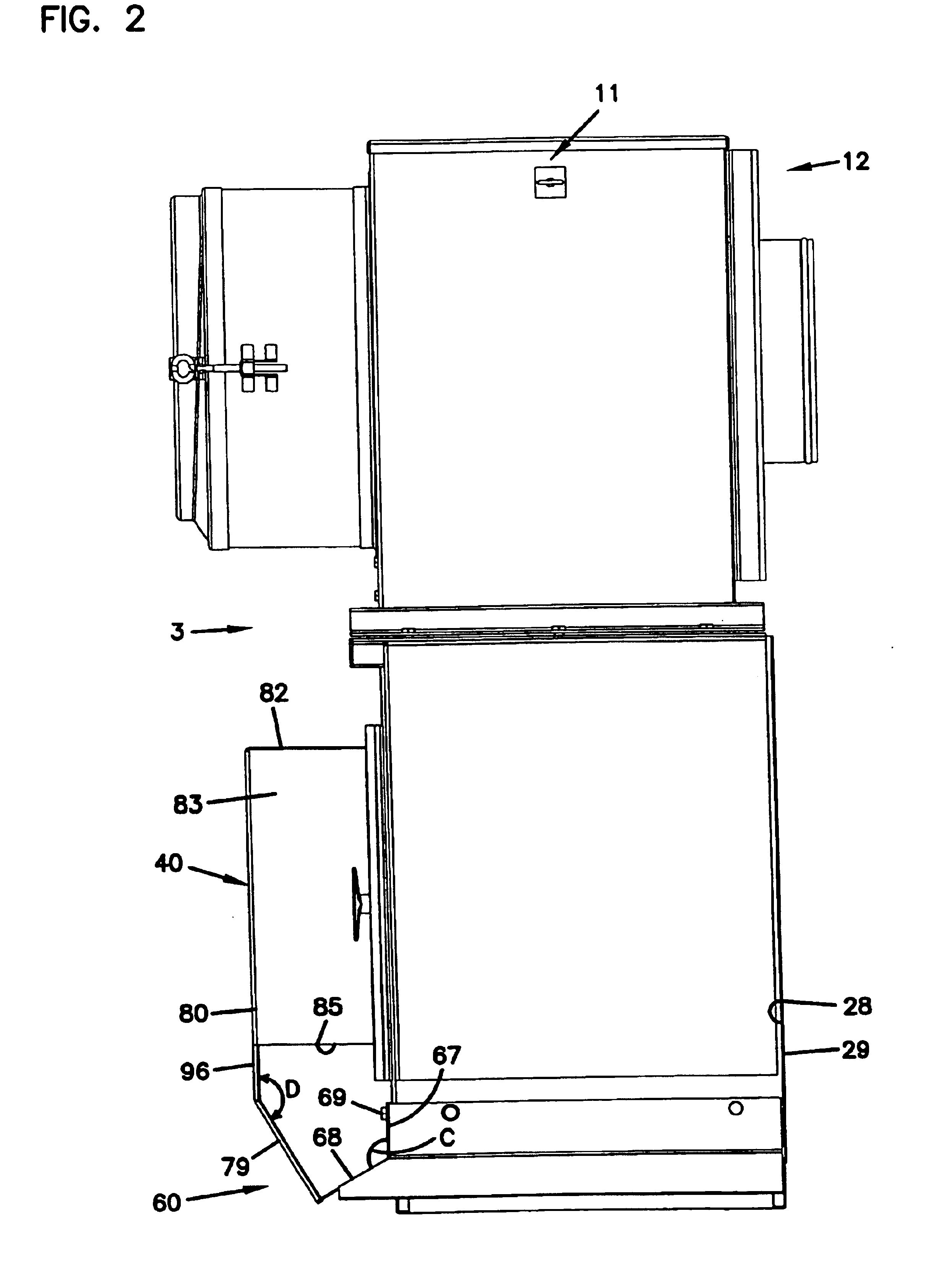

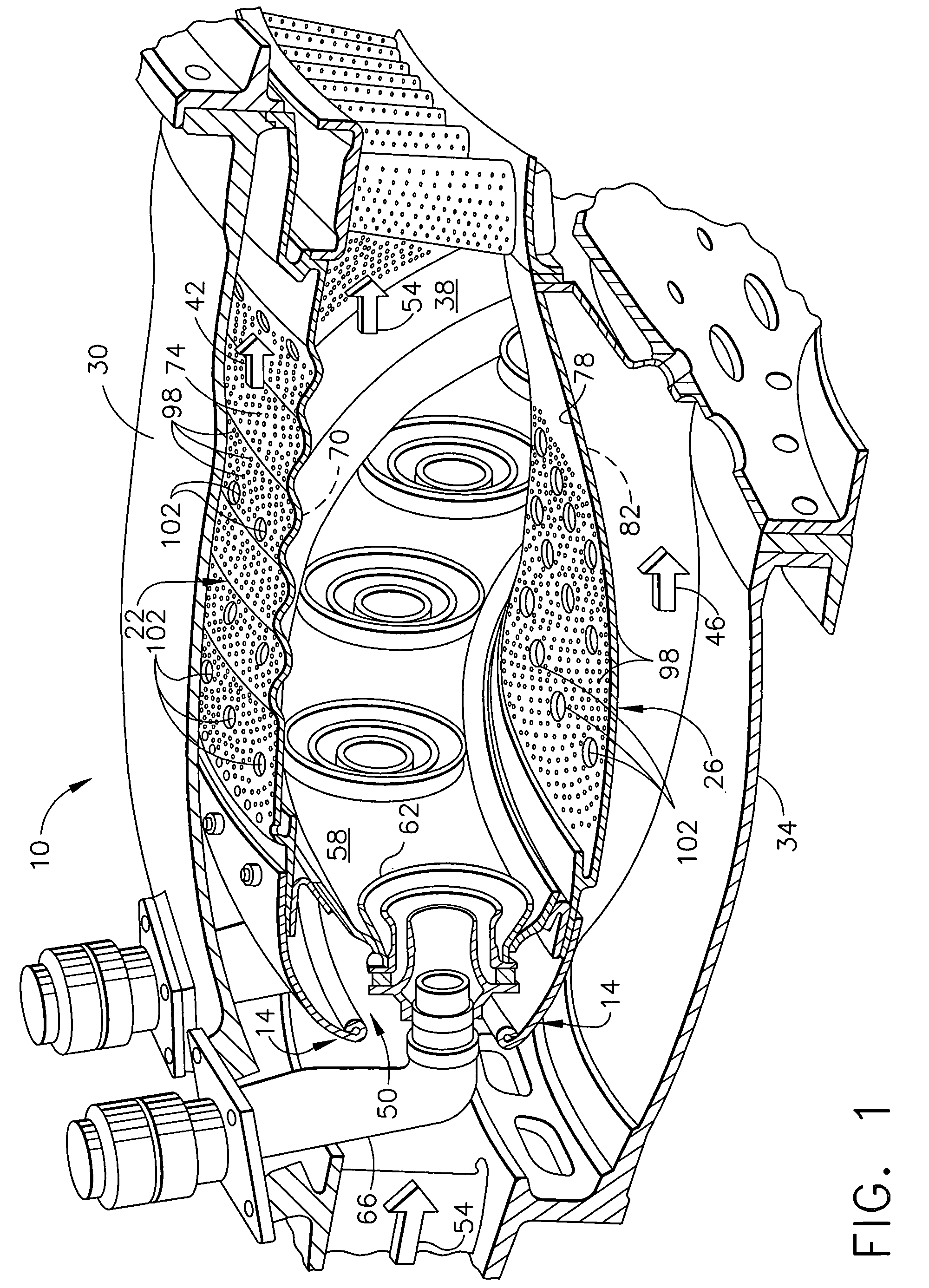

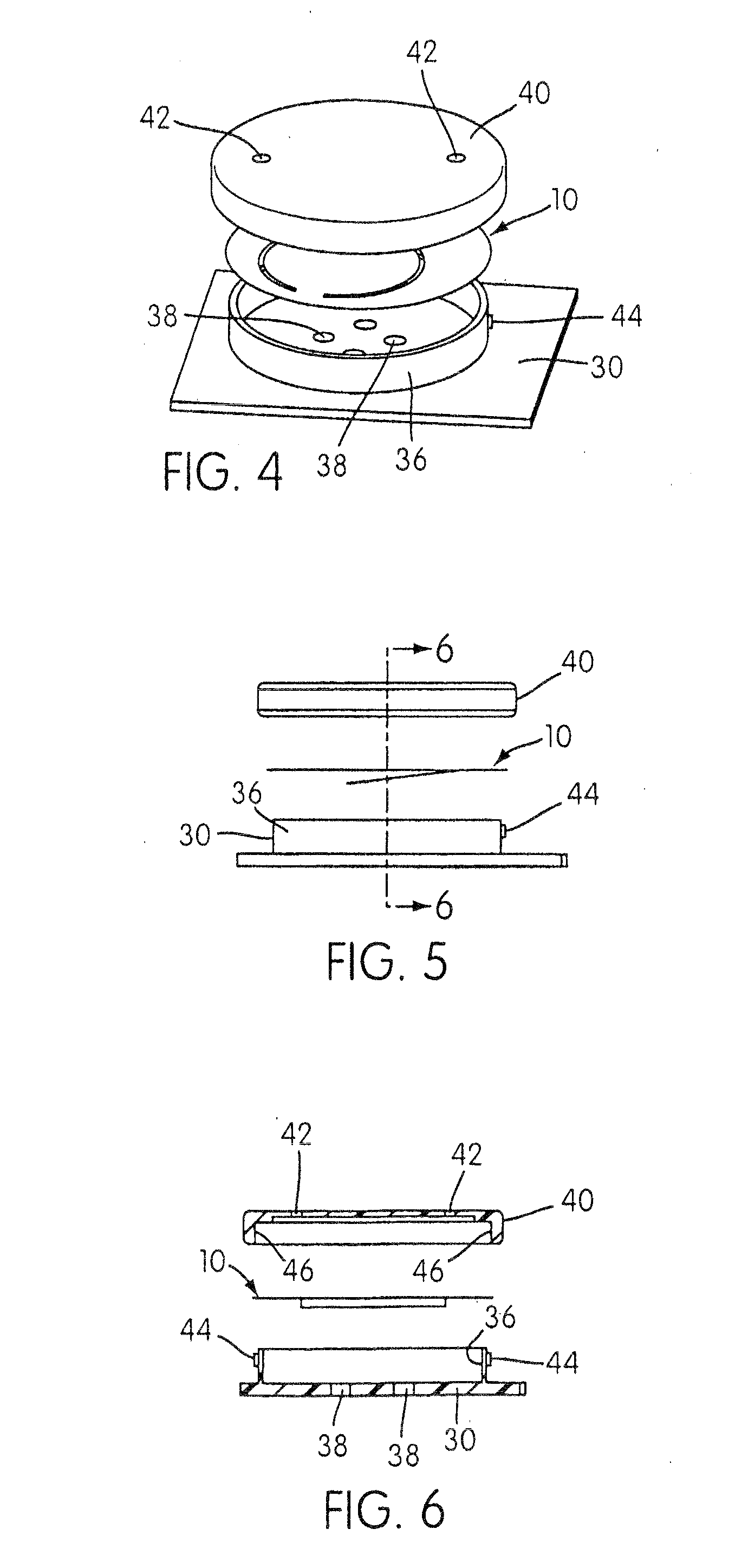

Multistage air cleaner including pulse cleaning system

InactiveUS6872237B2Combination devicesGas treatmentEngineeringElectrical and Electronics engineering

A V-pack filter includes a frame construction having a first frame structure and a second frame structure. The V-pack filter also includes first and second panel sections mounted in extension between the first and second frame structures. The first panel section has first and second ends. The second panel section has third and fourth ends. The first and third ends have a first distance therebetween while the second and fourth ends have a second distance therebetween. The second distance is generally greater than the first distance. The first and second panel sections and the second frame structure define an air flow aperture. A seal arrangement circumscribes the air flow aperture and projects outwardly from the second frame structure. The first frame structure defines a first receiver indent. Assemblies and methods are also included.

Owner:DONALDSON CO INC

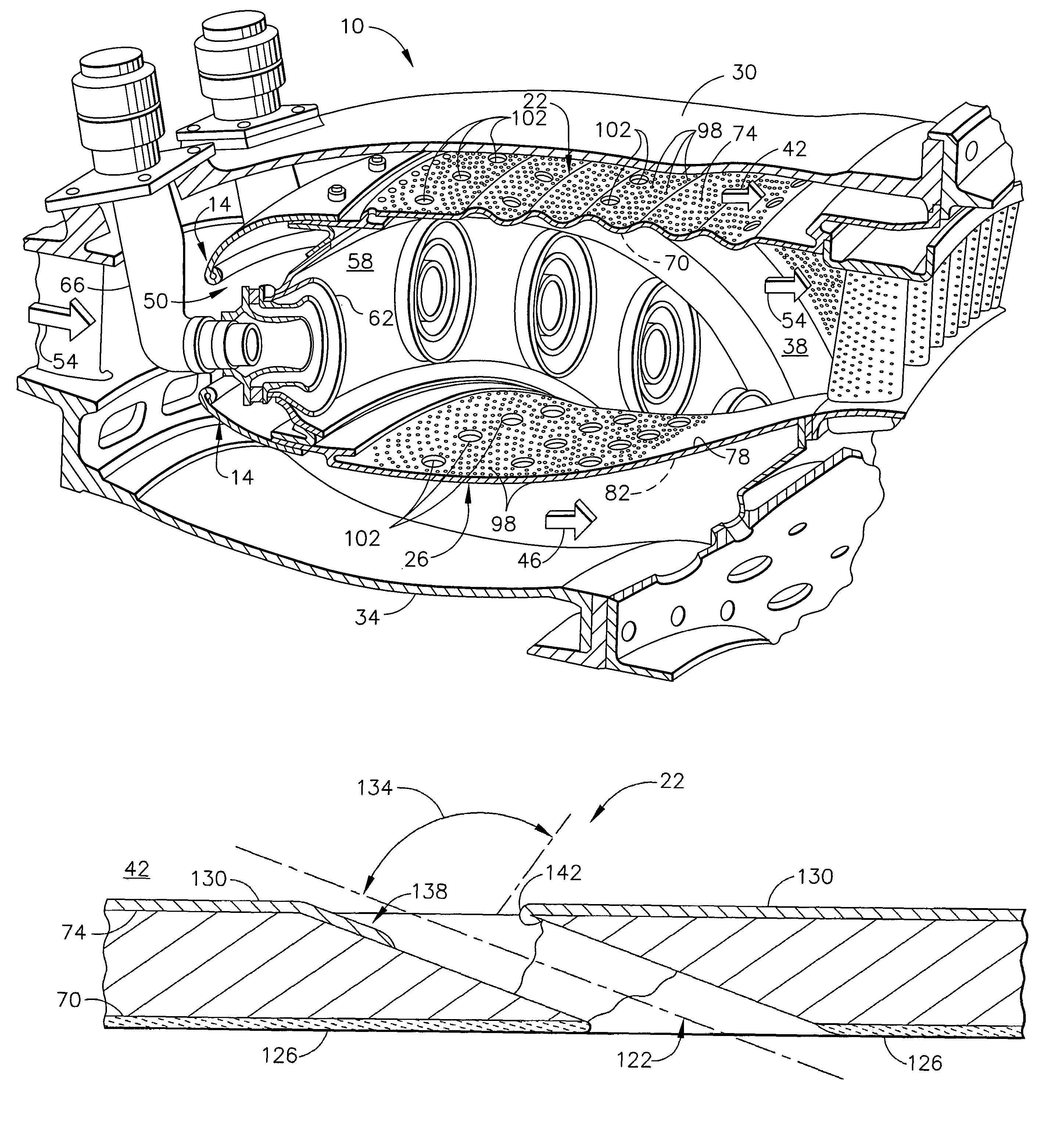

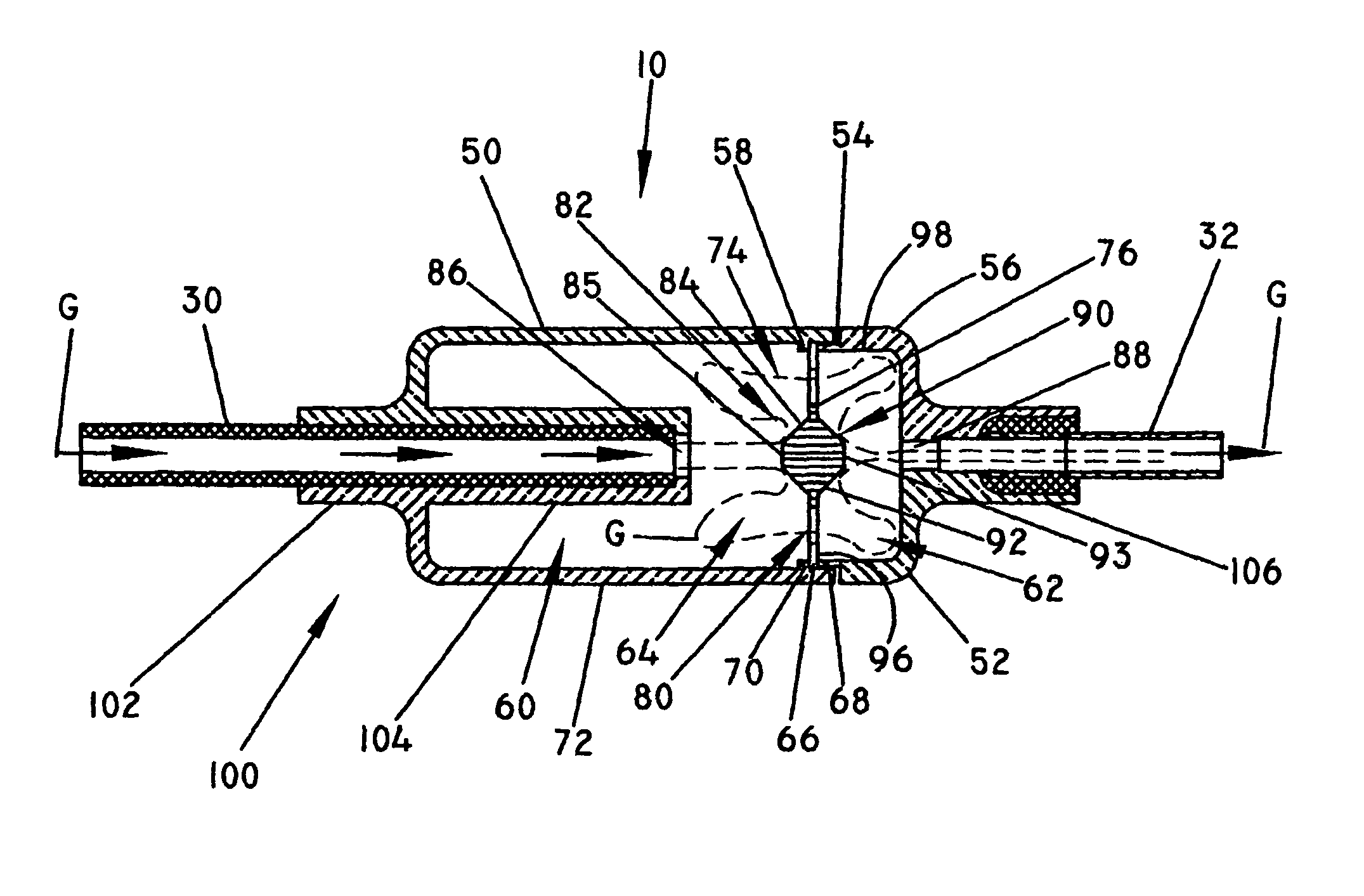

Adjusting airflow in turbine component by depositing overlay metallic coating

ActiveUS7216485B2Efficient and cost-effectiveContinuous combustion chamberMetal-working apparatusMetal coatingTurbine

A method for adjusting the airflow in a turbine component having a plurality of airflow holes. The method comprises the step of depositing an overlay metallic coating on the surface of the turbine component in a manner such that at least some of the airflow holes are partially filled such that the volume of the partially filled airflow holes is changed so as to adjust the airflow through the turbine component. Also provided is a turbine component having a plurality of airflow holes, at least some of the airflow holes being partially filled with the overlay metallic coating to change the volume thereof so as to adjust the airflow through the turbine component.

Owner:GENERAL ELECTRIC CO

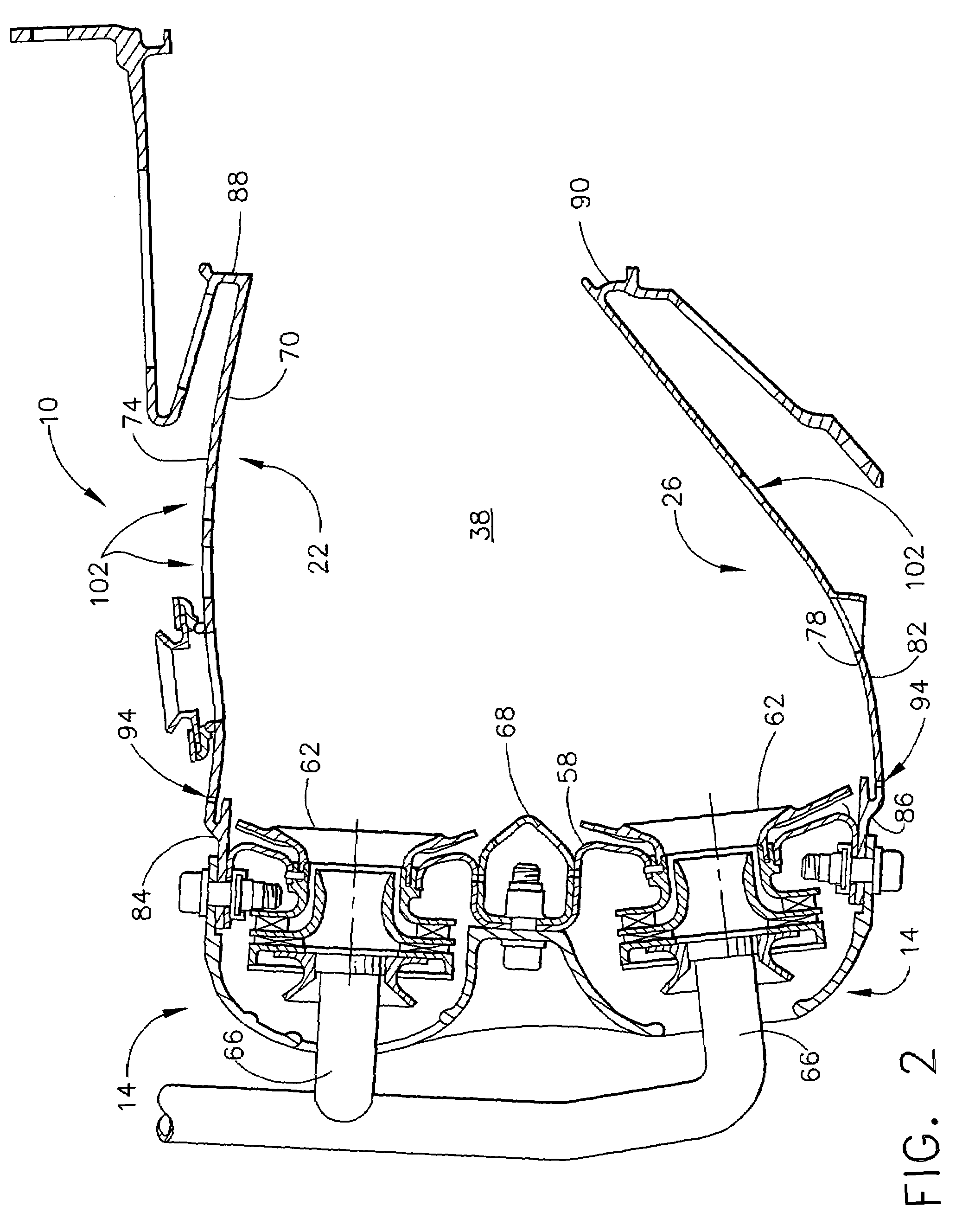

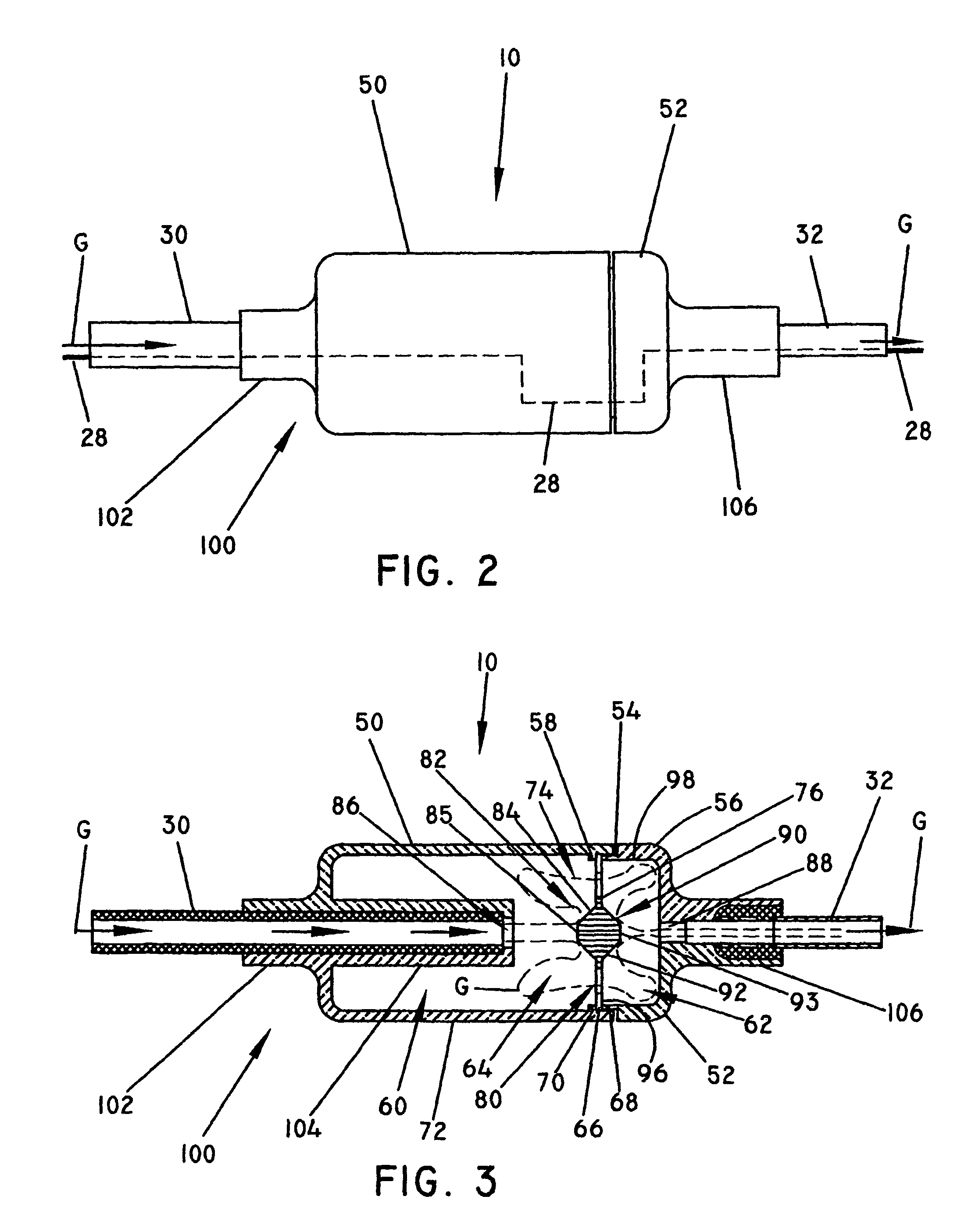

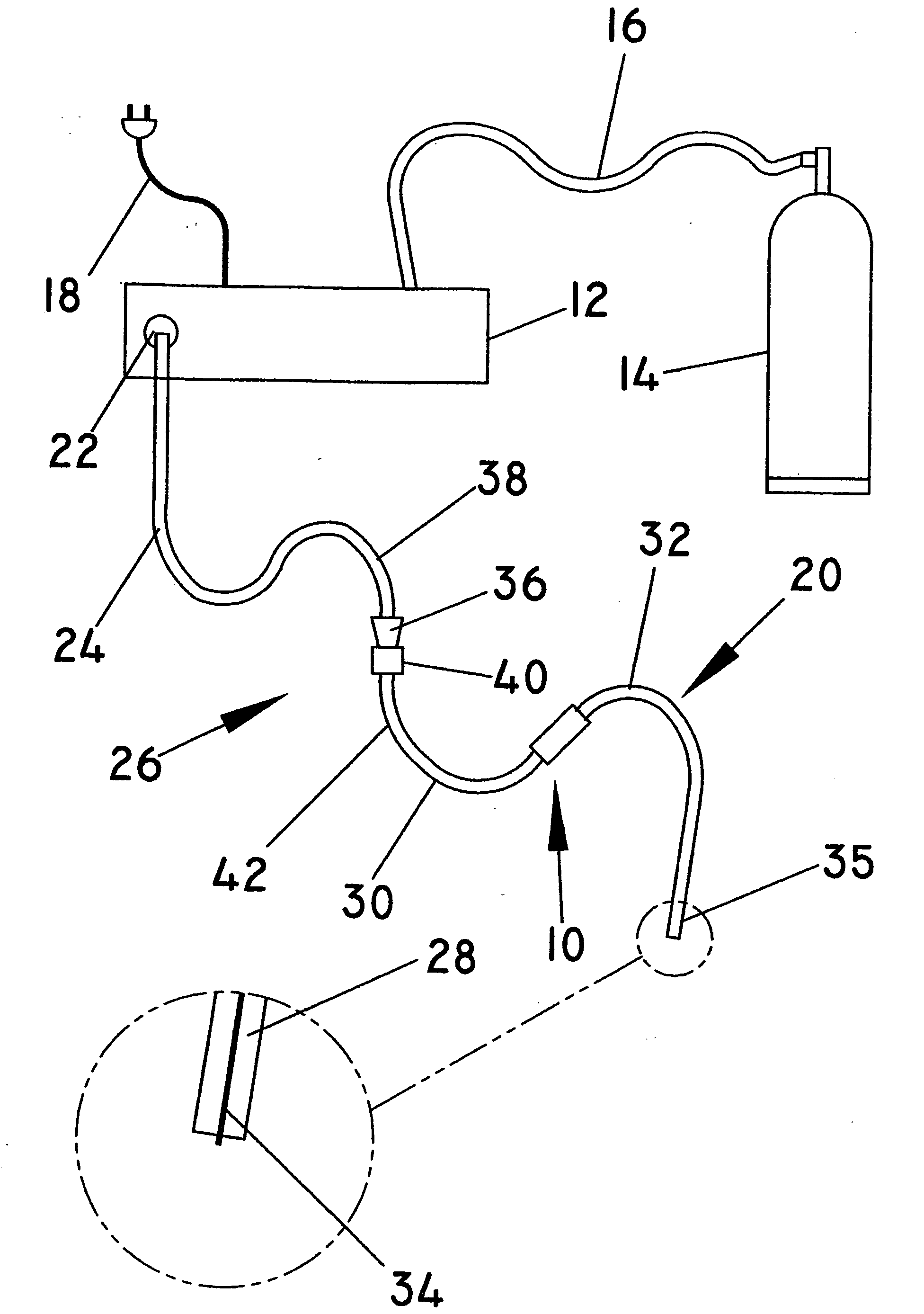

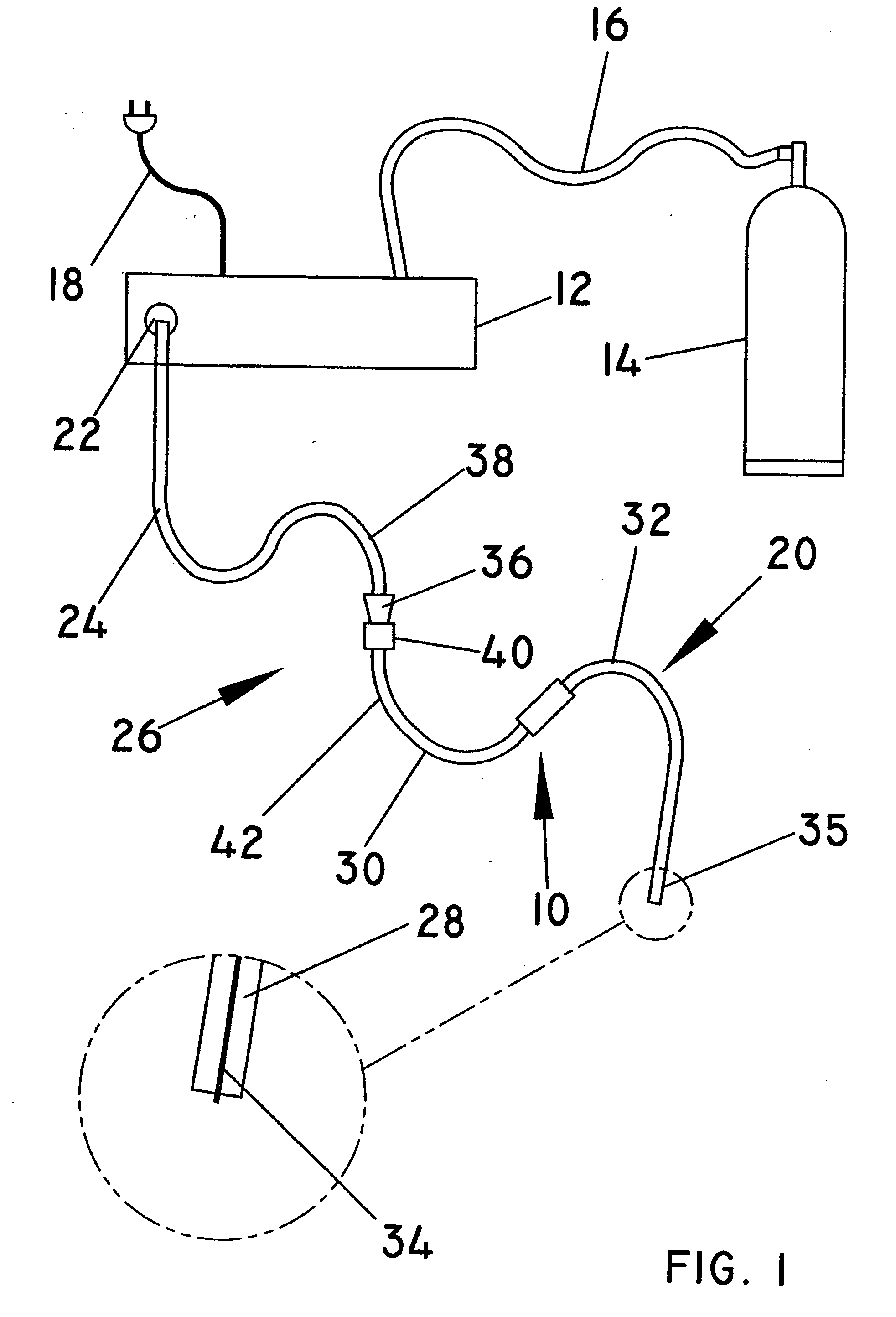

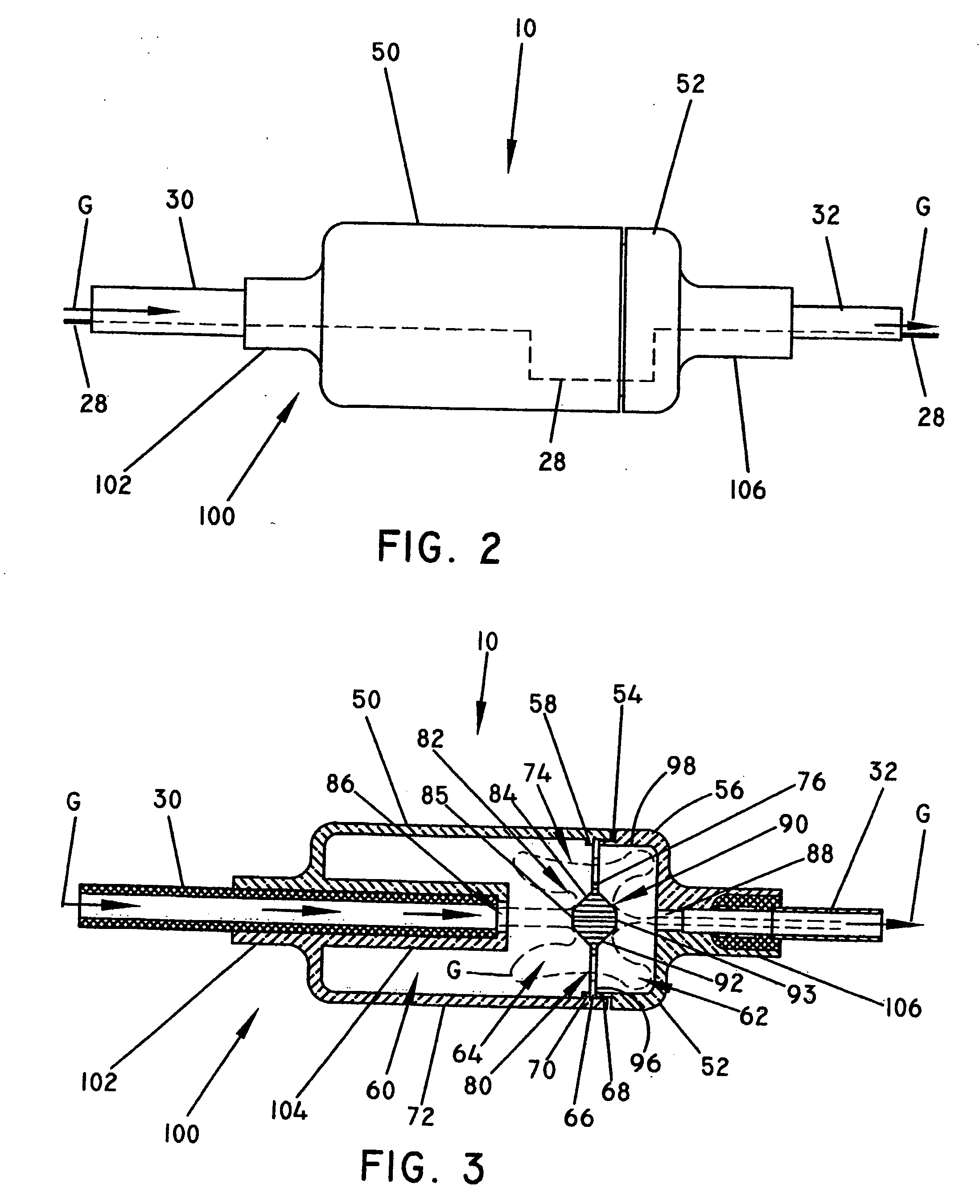

Reflux trap device

A reflux trap for use in a plasma generator and delivery system to prevent back flow of fluid and debris from a patient during a surgical procedure including a trap housing having a proximal diffuser chamber and a distal deflection chamber with a collection area separated by a baffle disposed within the trap housing including a diffuser member disposed in the proximal diffuser chamber to diffuse gas through a gas flow aperture to the surgical site on the patient and a deflection member disposed in the distal deflection chamber to deflect fluid and debris away from the gas flow aperture to the collection area to prevent fluid and debris from migrating into the proximal diffuser chamber to isolate the plasma generator against back flow of fluid and debris from the patient.

Owner:BOVIE MEDICAL CORP

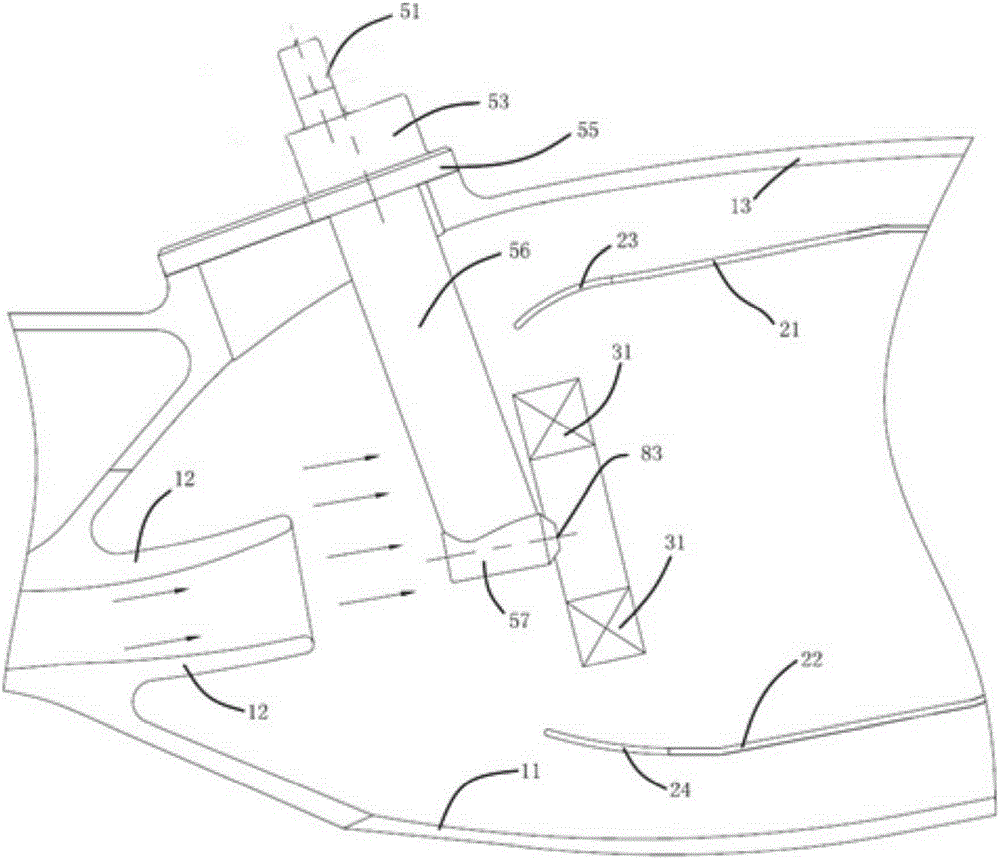

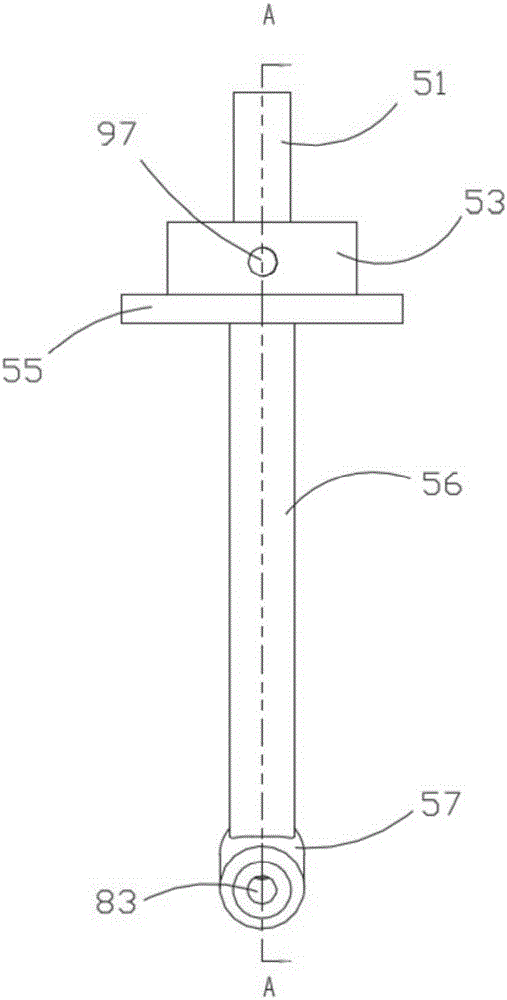

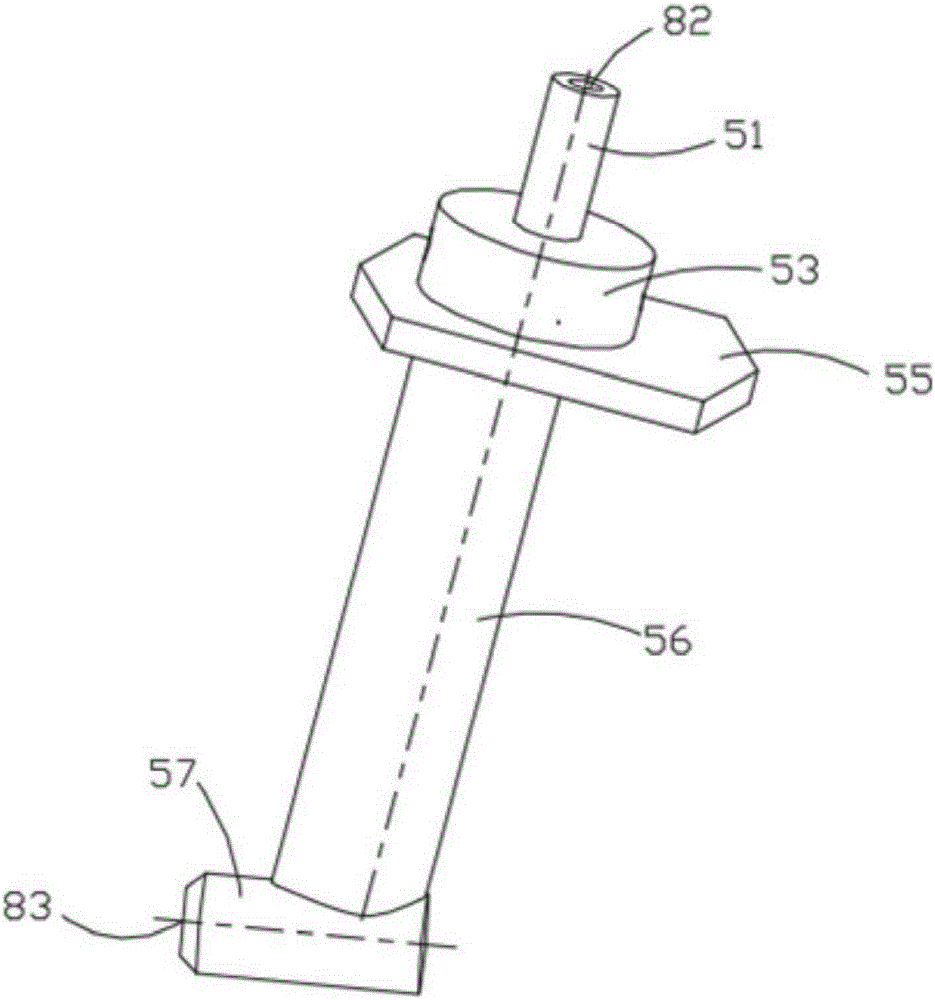

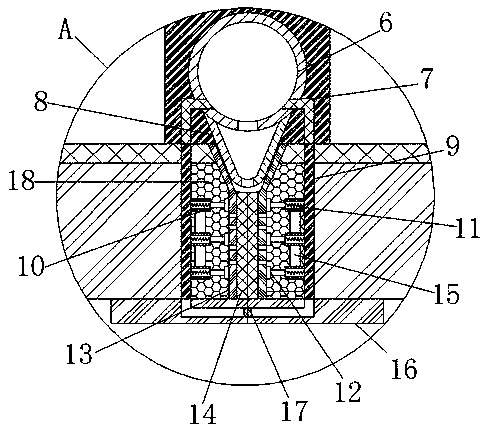

Combustor fuel nozzle and thermal protection structure thereof

ActiveCN106556030AImprove heat transfer performanceImprove thermal protection performanceContinuous combustion chamberAirflowCombustion chamber

The invention provides a combustor fuel nozzle and a thermal protection structure thereof. The thermal protection structure can reduce possibility that the nozzle is liable to coke fuel during an actual use process. The thermal protection structure comprises a thermal protection pipe and a heat exchange structure, wherein the thermal protection pipe is used for surrounding an oil inlet pipe; the inner wall surface of the thermal protection pipe is used for forming a thermal protection space together with the outer wall surface of the oil inlet pipe; the thermal protection space is divided into an air inlet part and an air outlet part, which are separated and located on two sides of the oil inlet pipe; the air inlet part and the air outlet part are used for forming a cooling air channel together with a pipe-wall inner cavity of an outlet section of the nozzle; the heat exchange structure is arranged in the thermal protection space and comprises a plurality of transverse rib plates and a plurality of longitudinal rib plates; the transverse rib plates are perpendicular to the flowing direction of cooling air; the longitudinal rib plates are radially distributed by taking the oil inlet pipe as a center and intersect the transverse rib plates respectively; and each transverse rib plate is provided with a plurality of airflow holes for allowing the cooling air to flow through.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

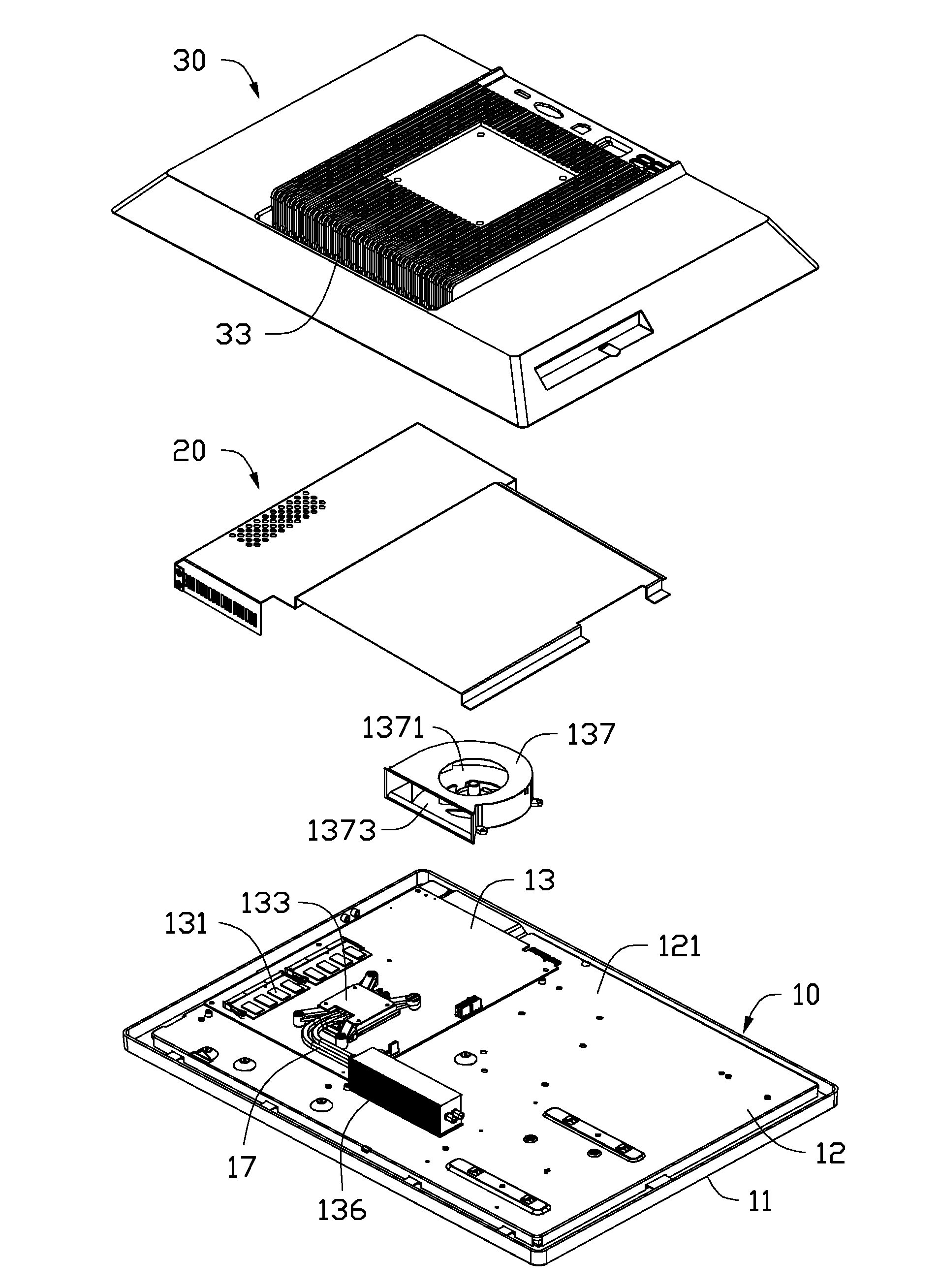

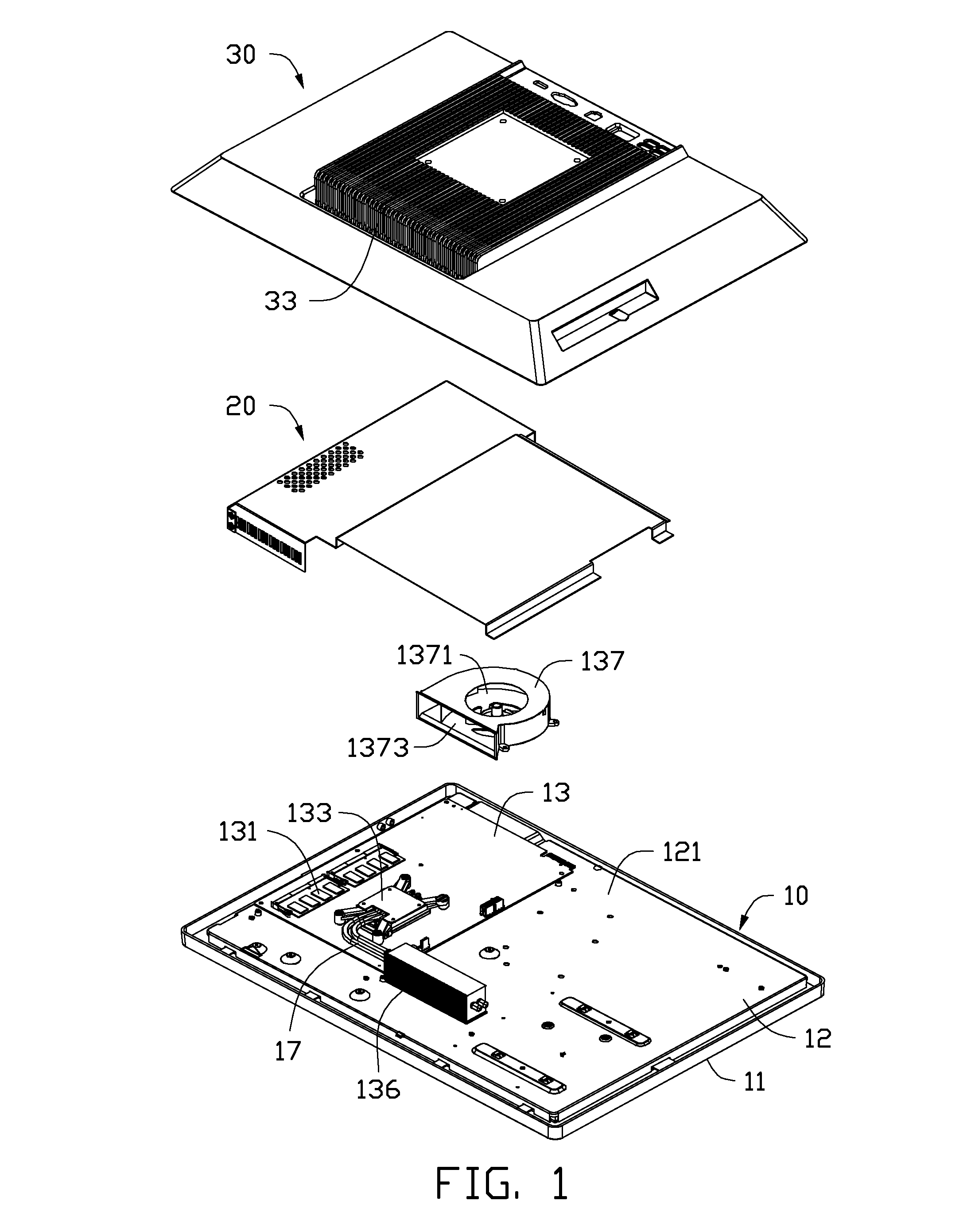

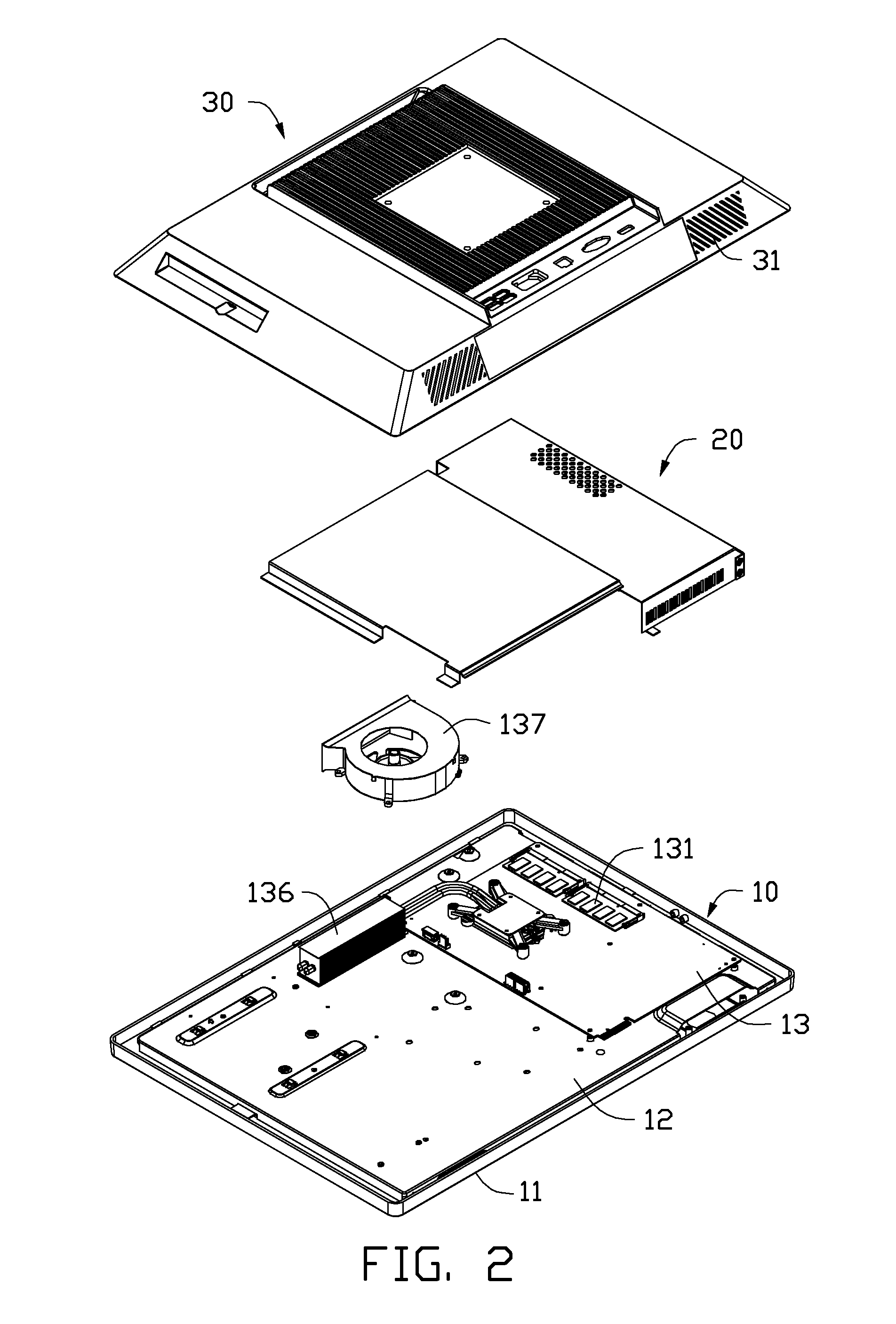

Computer system with heat dissipation apparatus

InactiveUS20130027876A1Digital data processing detailsCooling/ventilation/heating modificationsDisplay deviceComputerized system

A computer system includes a computer case, a cover, and an air duct. The computer case includes a display, a housing connected to the display, a motherboard attached to the housing, and a fan module. The motherboard includes a heat generating component. An input opening and an output opening are defined in the cover. The output opening corresponds to the fan module. The air duct is mounted over the heat generating component. The air duct includes a top plate substantially parallel to the motherboard and a first side plate extending from the top plate. The first side plate is substantially perpendicular to the top plate. The first side plate defines a plurality of first airflow holes corresponding to the input opening. The top plate defines a plurality of through holes corresponding to the heat generating component.

Owner:HON HAI PRECISION IND CO LTD

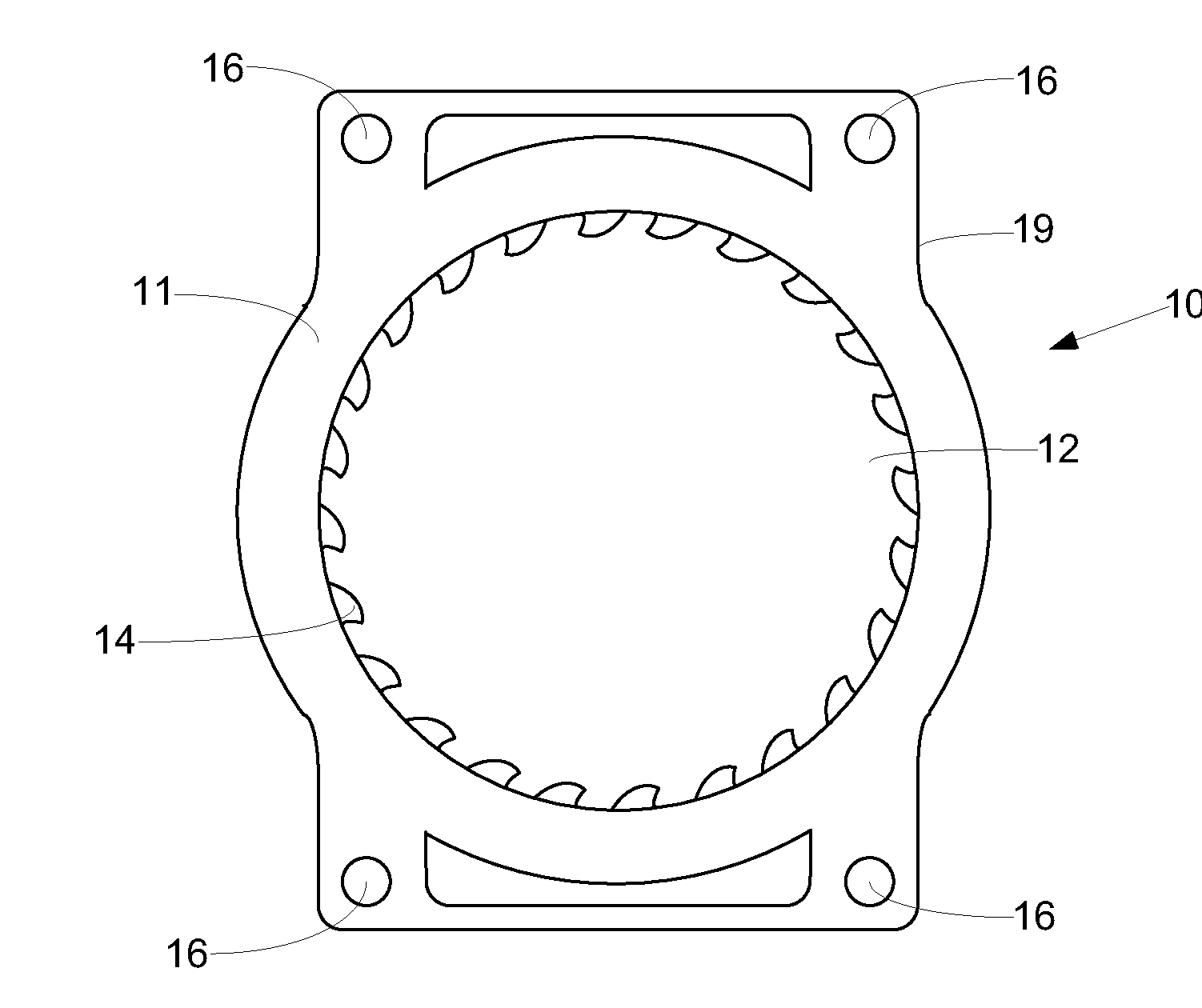

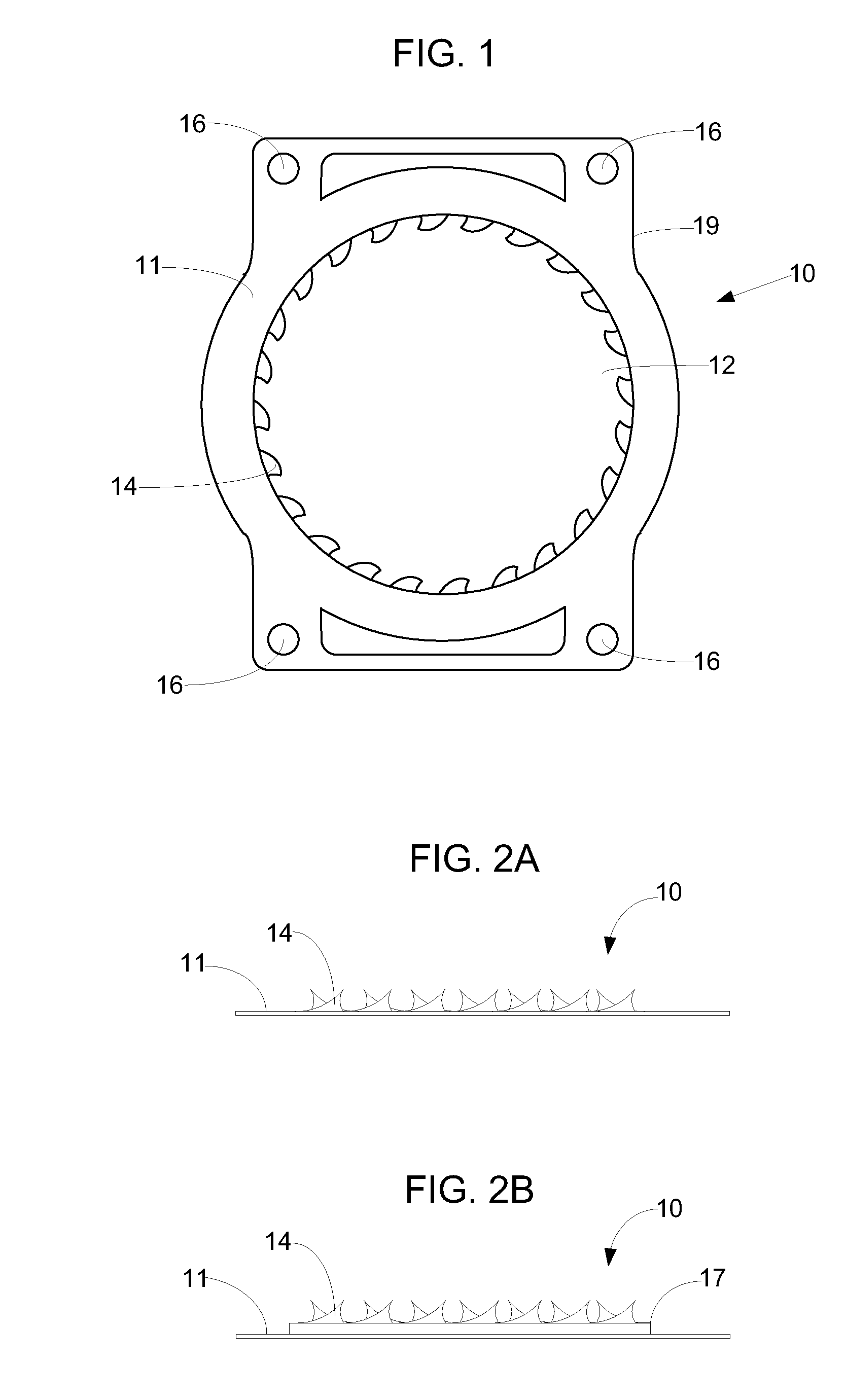

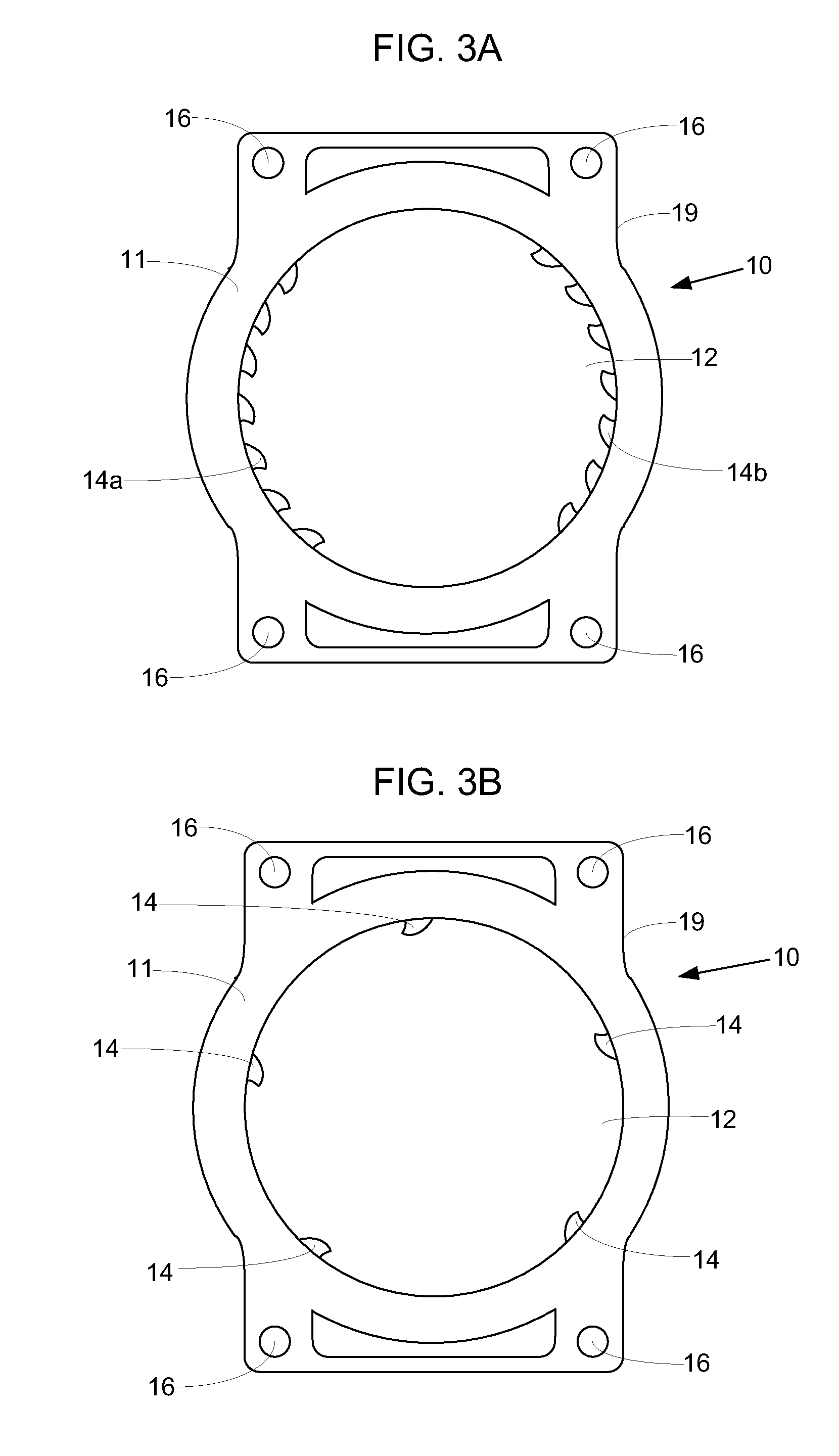

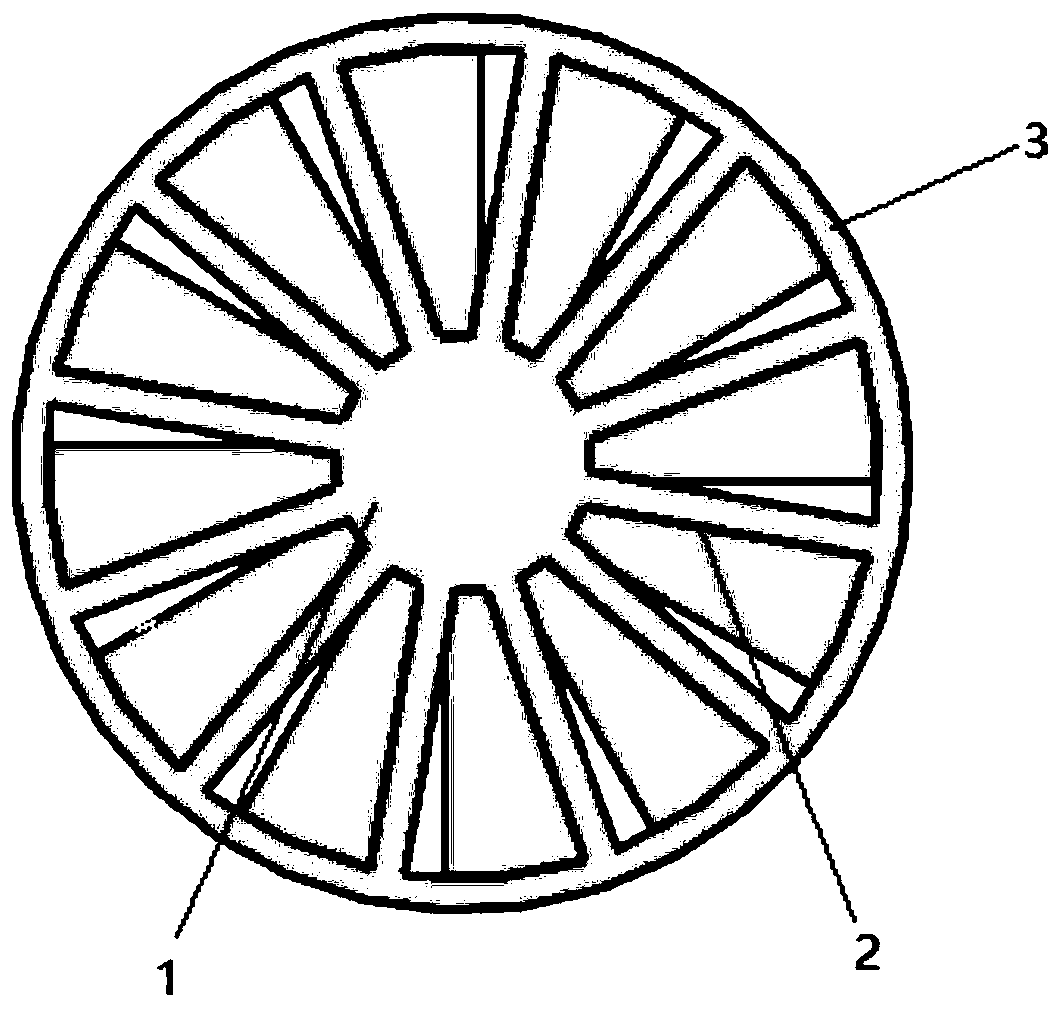

Throttle plate for use with internal combustion engine

ActiveUS7665442B1Improve fuel efficiencyEffectively increases horsepowerFluid heatersMixing methodsCombustionCarburetor

A throttle plate for use with internal combustion engines comprised of a relatively thin piece of material so that installation of the throttle plate between the carburetor or throttle body and intake manifold of a vehicle does not require additional brackets or components to correct throttle cable linkage length or geometry. The throttle plate comprises a plate having apertures to accommodate pre-existing connectors and a perimeter that corresponds to connections between, and the geometry of, the carburetor or throttle body and intake manifold. The plate fits between the carburetor or throttle body and intake manifold and defines at least one airflow hole corresponding to the airflow path in the carburetor or throttle body. If there are multiple airflow paths between the carburetor or throttle body and intake manifold, then there will be multiple airflow holes. One or more vanes integral with the plate extend radially from the perimeter of each airflow hole toward its center. The plurality of vanes can be a variety of shapes, including helical and inclined, and extend into the airflow hole only to the extent they work in proximity of the throttle valve(s) and do not obstruct operation of the throttle valve in the throttle body. As air flows from the throttle valve(s) through the throttle plate and into the intake manifold, the vanes redirect laminar airflow into turbulent airflow.

Owner:K&N ENGINEERING INC

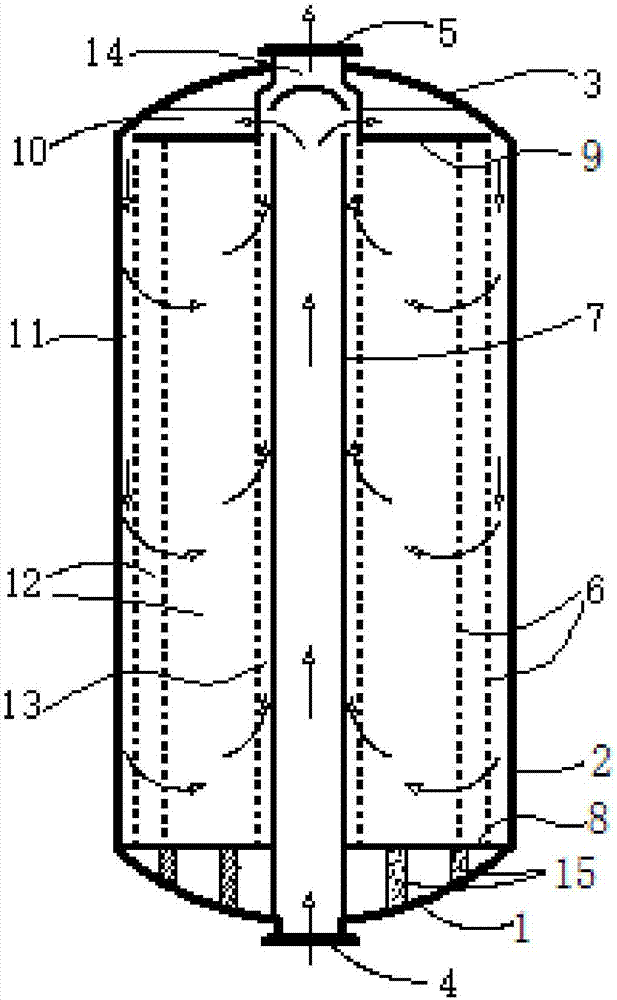

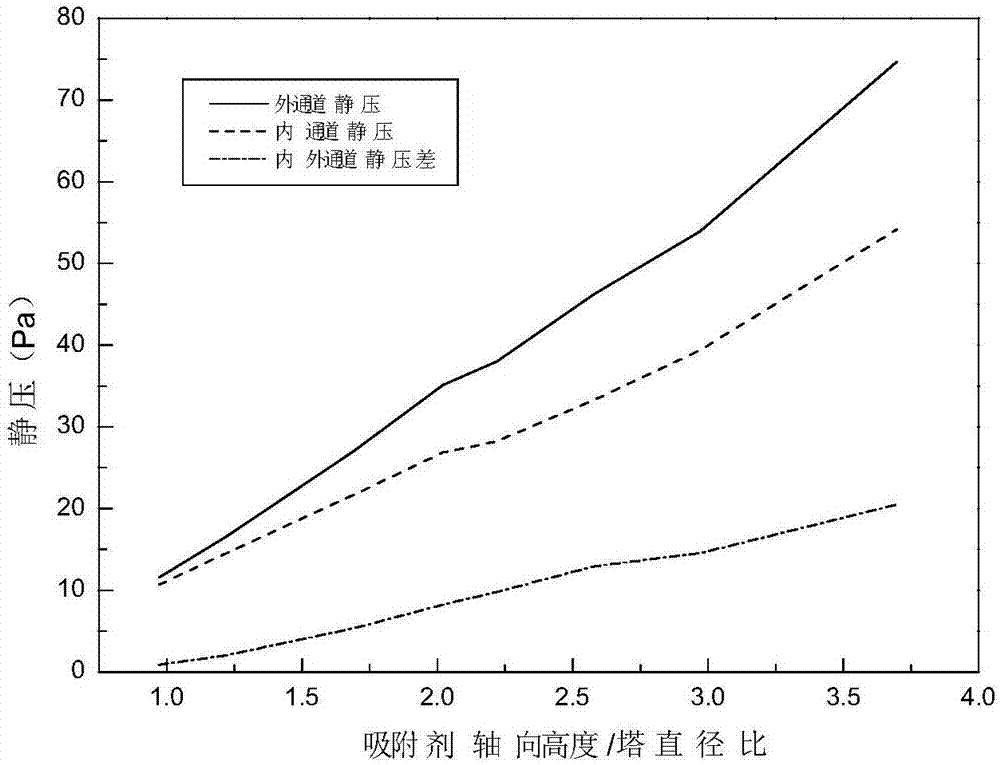

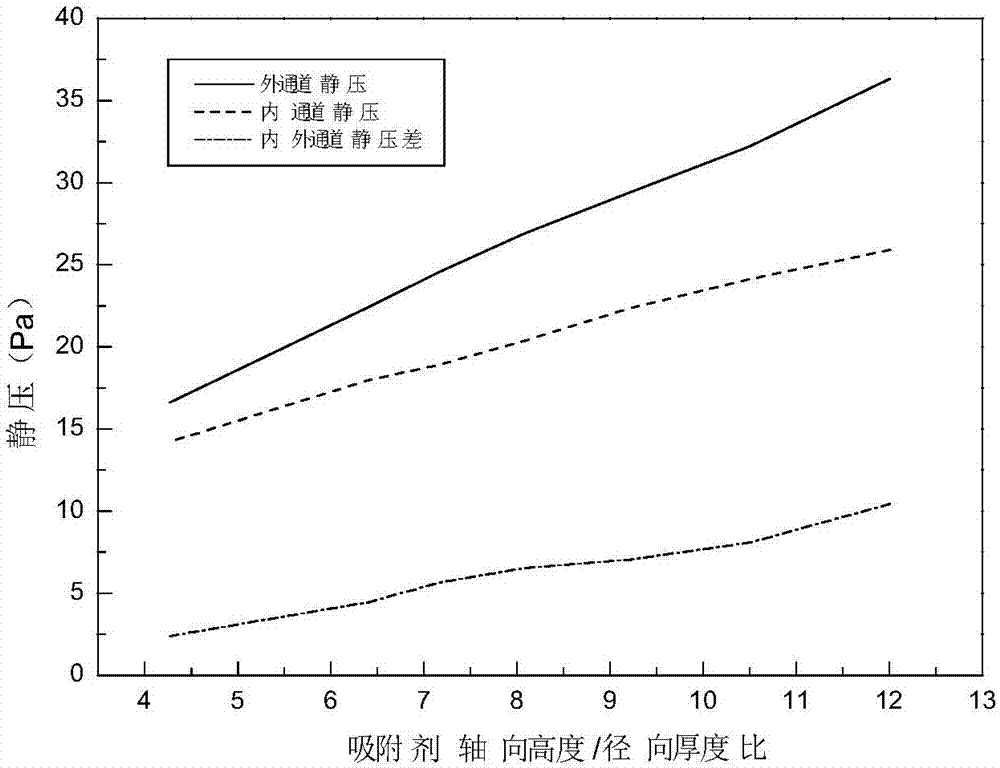

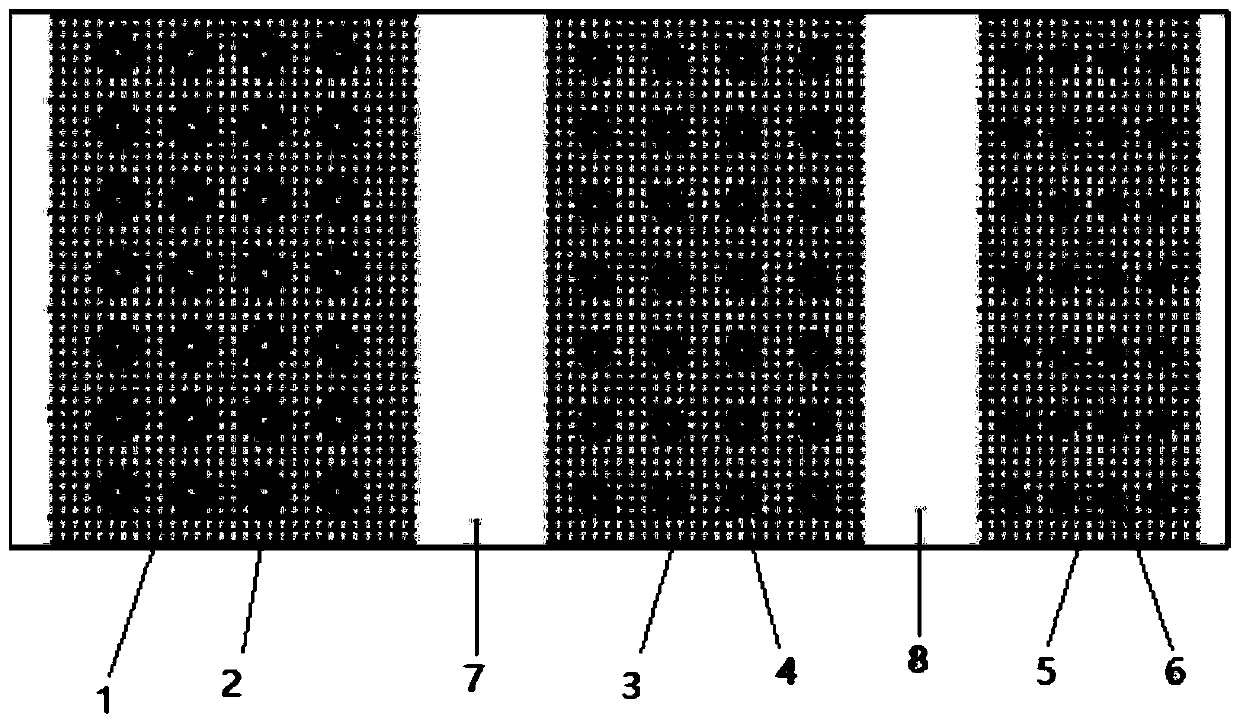

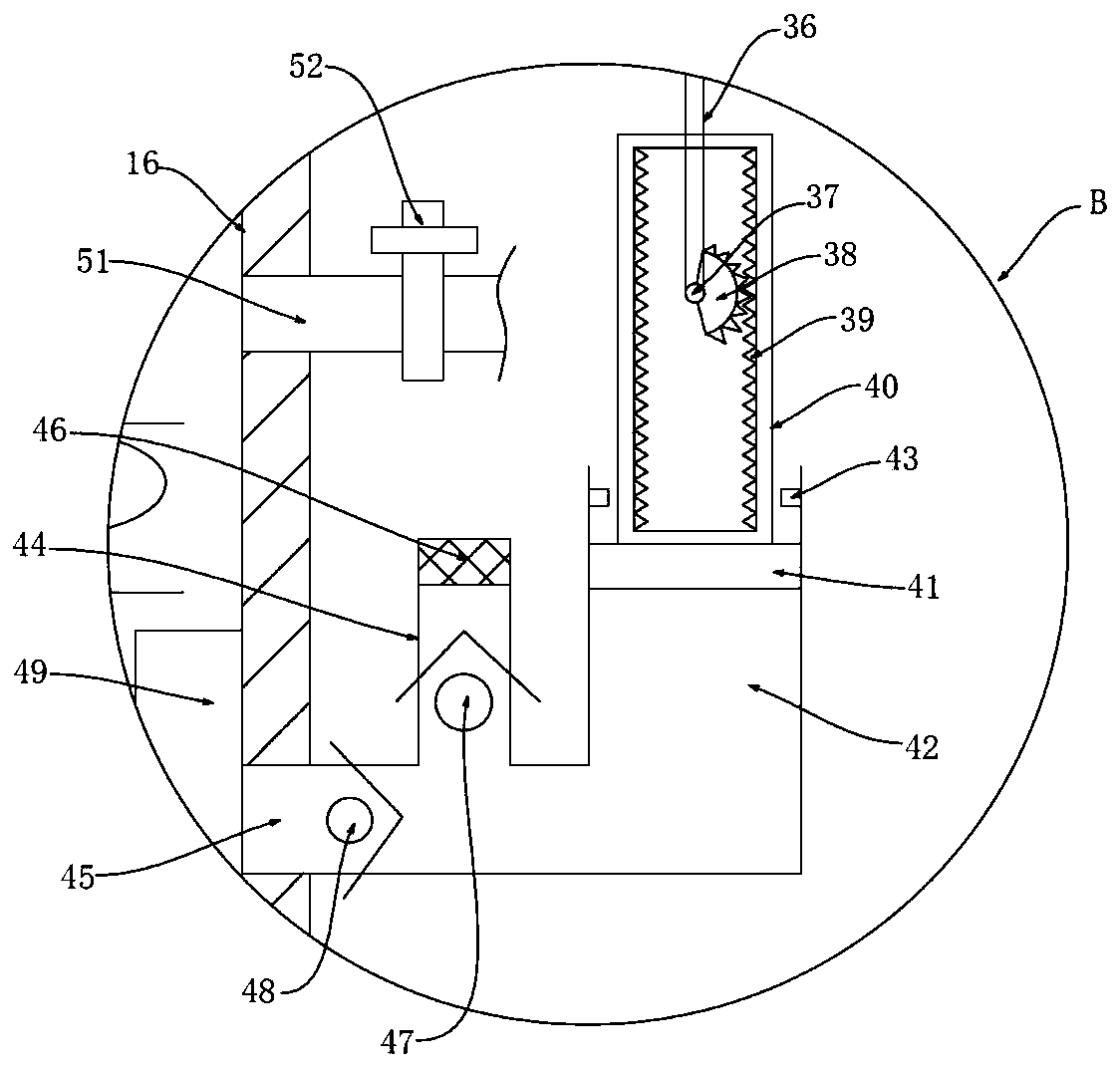

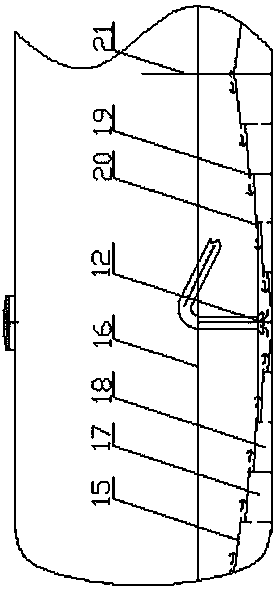

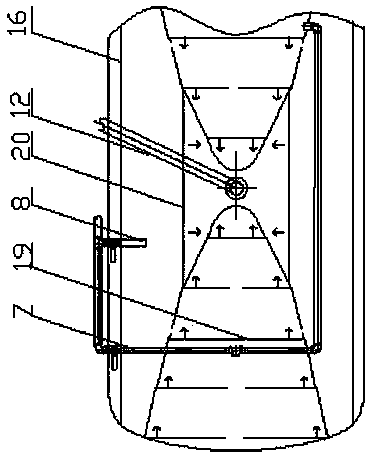

Novel radial flow adsorption tower for pressure swing adsorption

ActiveCN107126814AEvenly distributedReduce driftGas treatmentDispersed particle separationEngineeringTower

The invention provides a novel radial flow adsorption tower for pressure swing adsorption, and belongs to the technical field of adsorption tower. The novel radial flow adsorption tower comprises an upper seal head, a lower seal head, a tower cylinder body, an isolation drum and a center pipe, wherein the tower cylinder body, the isolation drum and the center pipe are distributed in a concentric circle way; an annular outer passage is formed between the outer drum wall of the isolation drum and the tower cylinder body, and an annular inner passage is formed between the inner drum wall of the isolation drum and the outer wall of the center pipe; a flow distributing pipe and an air exhaust pipe are arranged at the top part of the interior of the adsorption tower, the flow distributing pipe is used for communicating the center pipe and the annular outer passage, and the air exhaust pipe is connected and communicated with the annular inner passage; air flow hole passages are distributed on a drum body of the isolation drum, and an adsorbent is filled into the drum body. The novel radial flow adsorption tower has the advantages that the raw gas is guided into the annular outer passage by the center pipe passage via the flow distributing pipe, flown into the adsorbent layer in the radial way, and sent into the annular inner passage after adsorbing and separating; the gas flows outside the adsorption tower and in the inner passage to form the U-shaped flowing type, so that the change trends of static pressures in the inner passage and the outer passage are basically the same in the axial flowing direction of gas flow, and the uniform distribution of the gas flow is realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

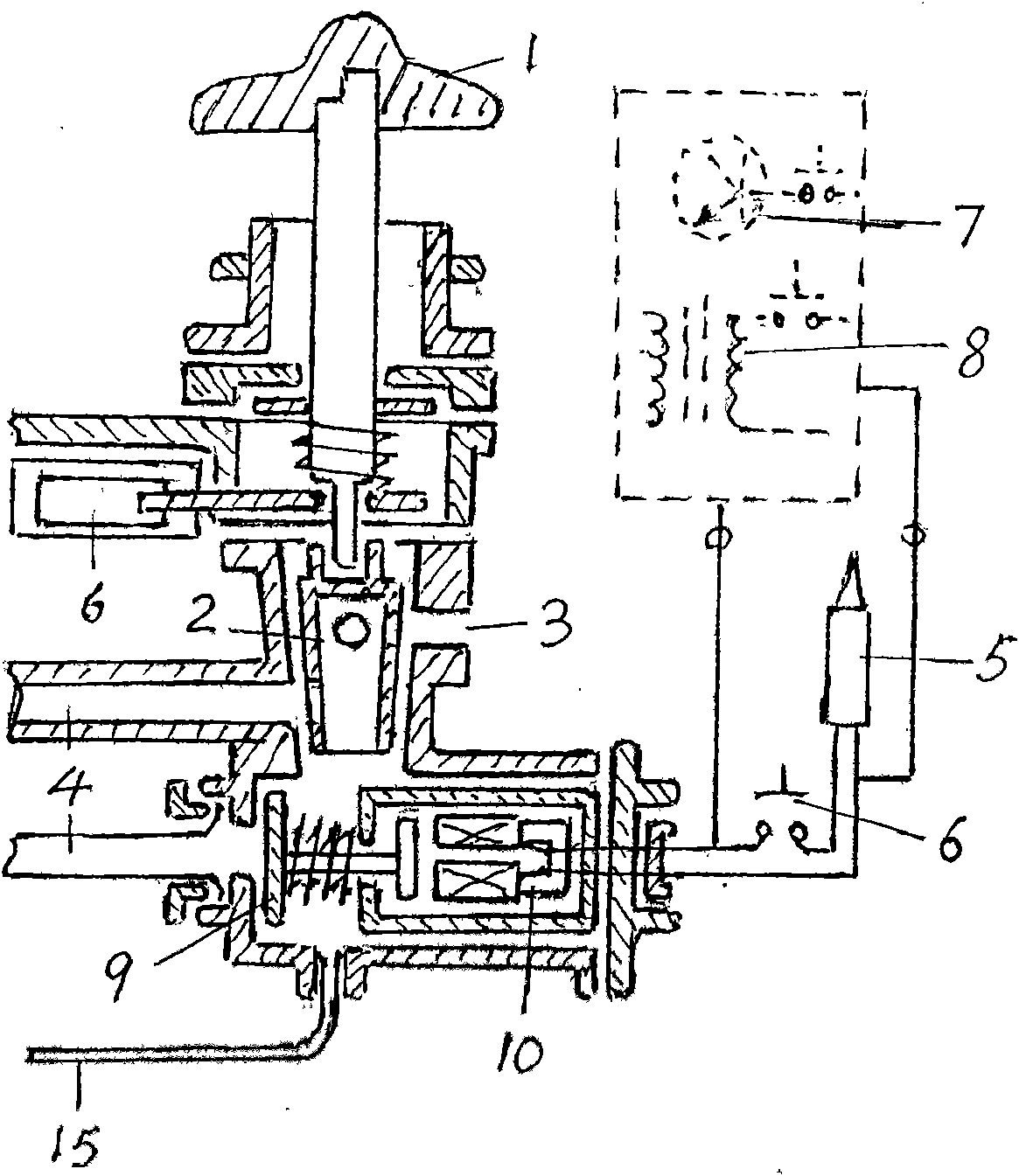

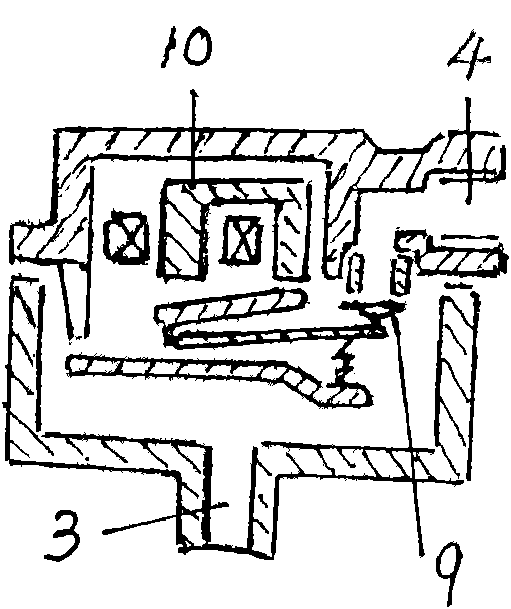

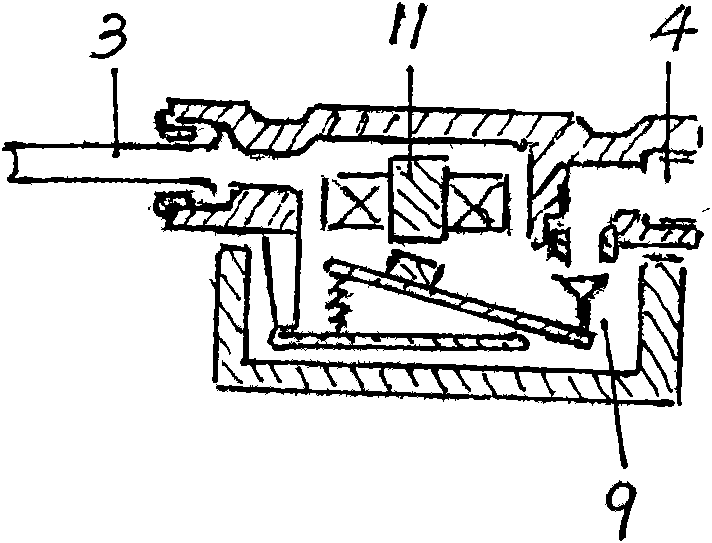

Method for serially connecting valves and improving burner into gas cooker capably of controlling temperature and intensifying fire to form vigorous fire

InactiveCN101846339AIncrease useFunction increaseFuel supply regulationDomestic stoves or rangesTemperature controlDetonation

The invention discloses a method for serially connecting valves and improving burner into gas cooker capably of controlling temperature and intensifying fire to form vigorous fir, aiming at providing a safe heating type cooker which controls temperature by using a combustible gas and can also intensify firepower into vigorous fire for heating. A single or multiple cooker hole type temperature control gas cooker in various shell shapes mainly comprises a manual gas switch, an electromagnetic valve and a burner or a burner special for the temperature control gas cooker, wherein the electromagnetic valve is internally provided with E-shaped and U-shaped or cylinder-shaped magnetic cores. The technical scheme puts emphasis on that the temperature control gas cooker does not limit that the burner is in any shape and whether the burner is provided with a mixed gas cavity or not and a small gas outlet of a gas pipe is positioned below flames or not by connecting in series with a big and small hole changed electromagnetic valve which can not cut off an airflow orifice and limits that the small gas outlet of the gas pipe must be arranged below the flames, and the burner is turned off without detonation sound by connecting in series with a switching type electromagnetic valve which can cut off the airflow orifice. The special burner of the temperature control gas cooker can be based on an upside-down small barrel shape, a shallow barrel shape, a deep barrel shape and an annular shape and must be internally provided with a pilot burner pipe used for repeatedly ignition.

Owner:王利虹

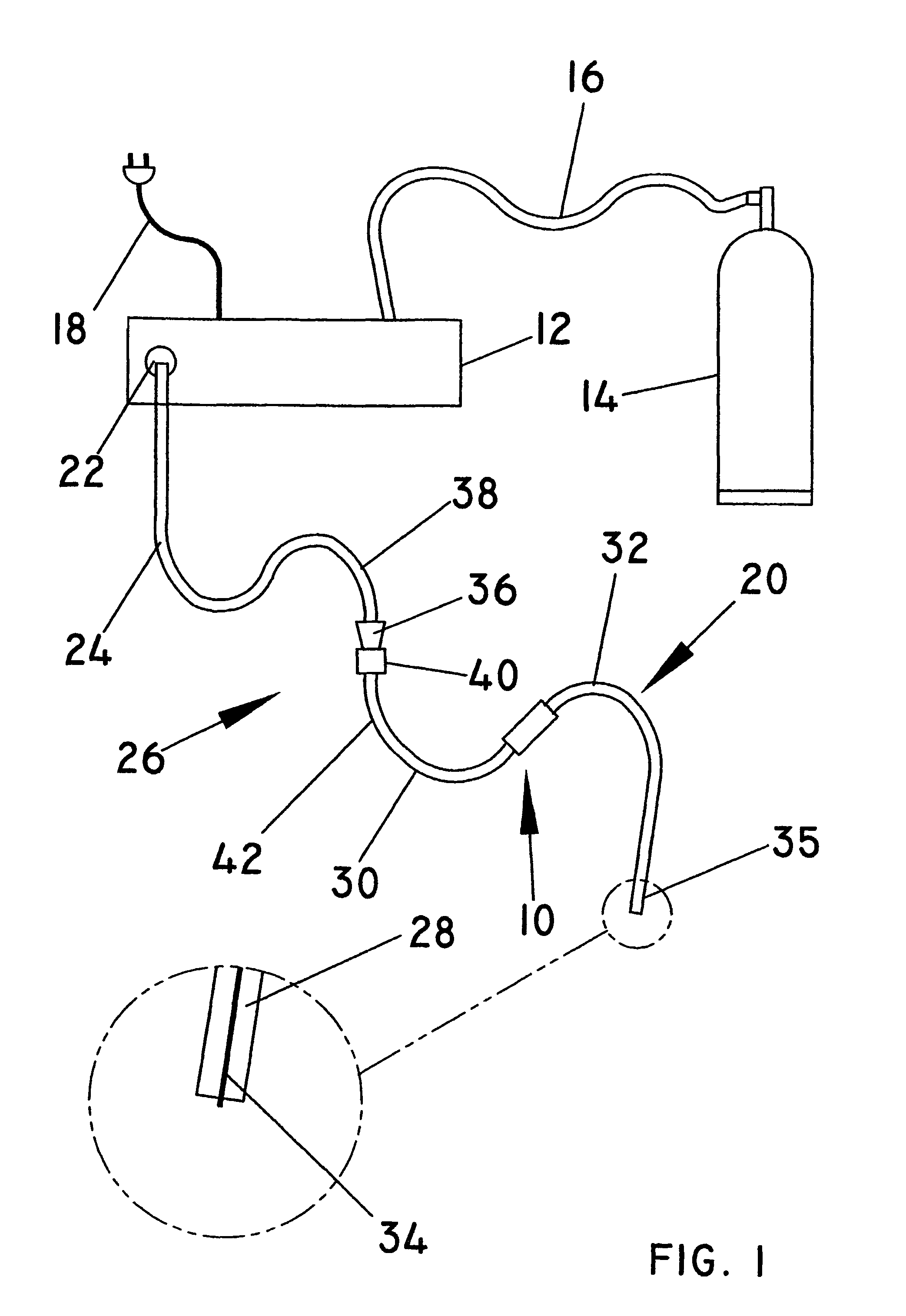

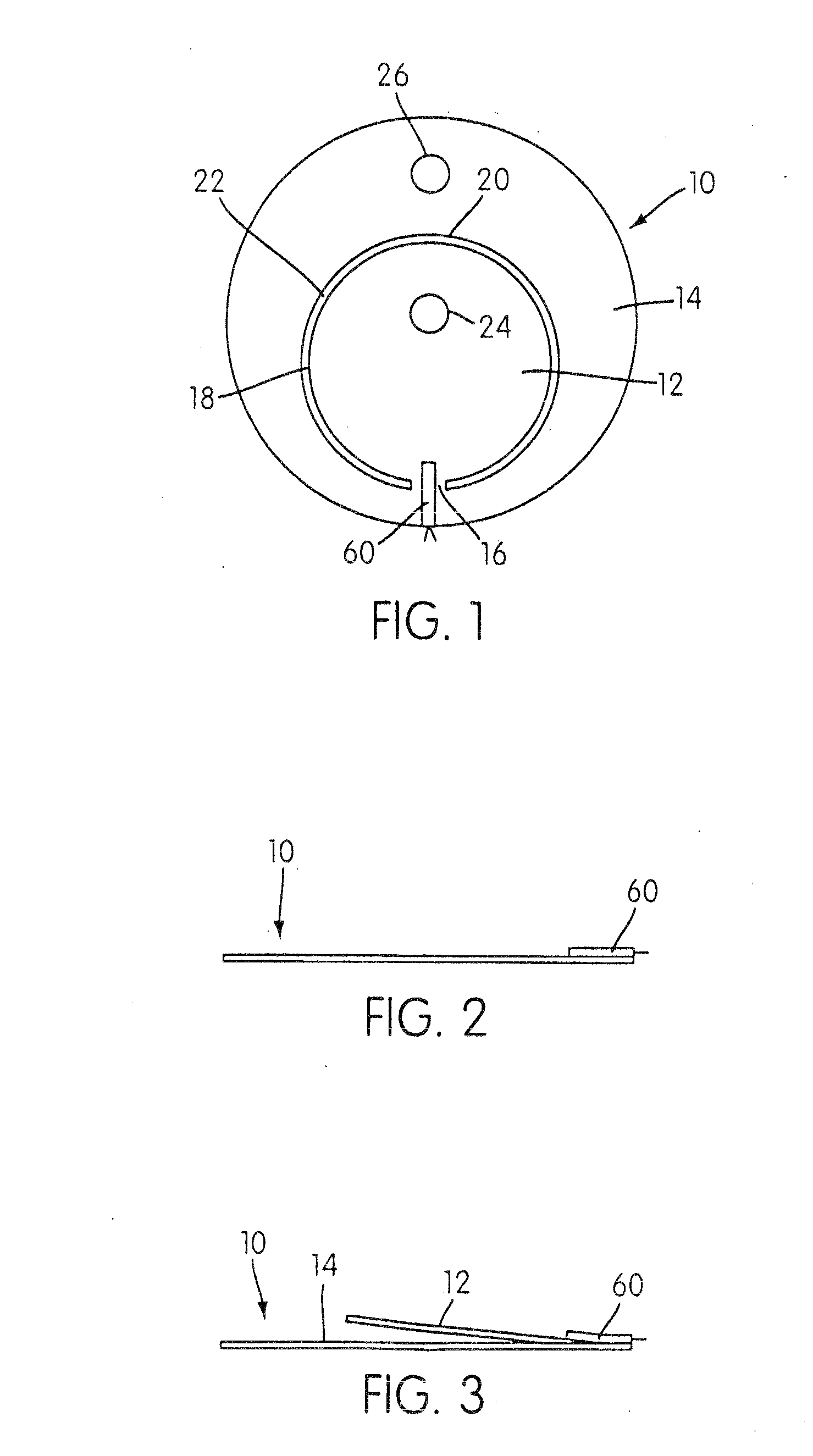

Flow regulation vent

A flow regulation vent includes a fixed portion adapted to engage a gas supply conduit and a spring force biased movable portion connected by a hinge to the fixed portion and flowingly connected to the pressurized gas supply. The fixed portion includes a gas flow orifice. The movable portion is pivotably movable between 1) a relaxed position, wherein at a specified minimum operating pressure, the movable portion is pivoted by the spring force away from the fixed portion to a position to establish a first gas washout flow area between the movable portion and the gas flow orifice; and 2) a fully pressurized position, wherein at a specified maximum operating pressure, the pressurized gas offsets the spring force to pivot the movable portion to a position adjacent the fixed portion to establish a minimum gas washout flow area between the movable portion and the gas flow orifice.

Owner:RESMED LTD

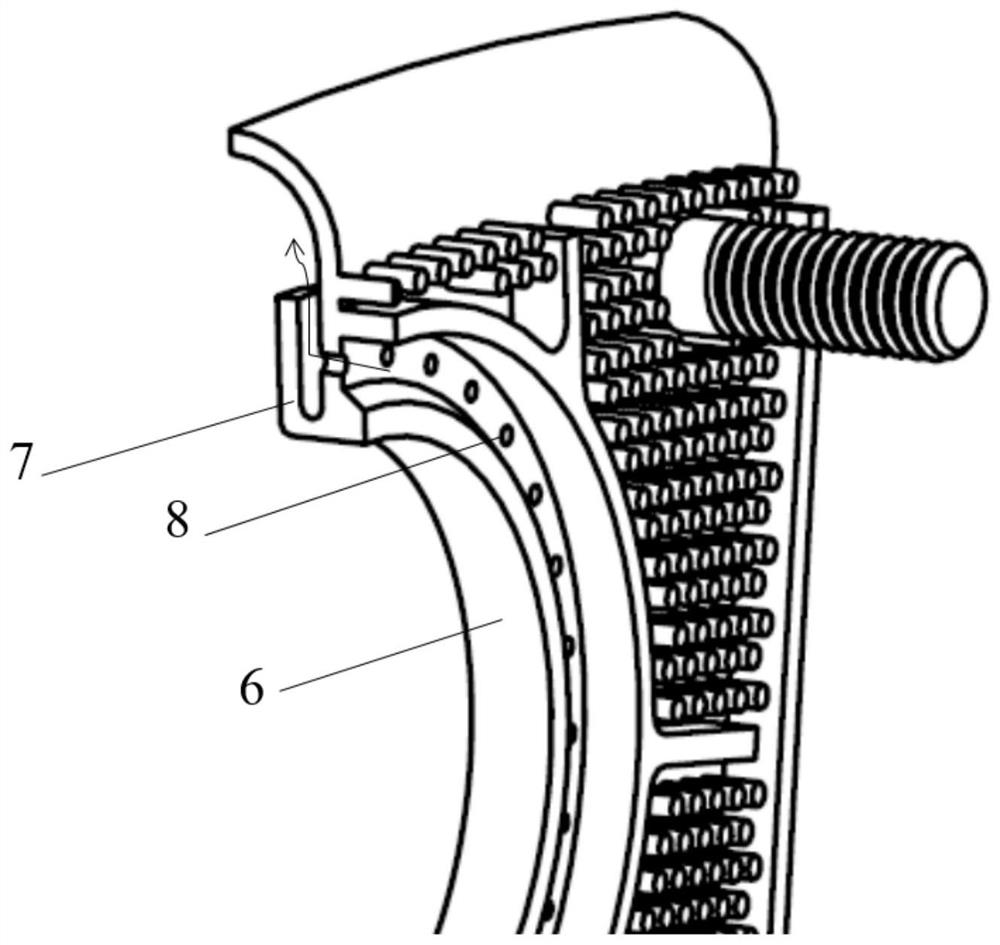

Combustion chamber with spiral-flow type flame tube

InactiveCN110925798AMaximum complete combustionEmission reductionContinuous combustion chamberCombustion chamberEngineering

The invention provides a combustion chamber with a spiral-flow type flame tube, and relates to the field of aero-engine combustion chambers. On the basis of different effects of a main combustion hole, a middle hole and a mixing hole of an original combustion chamber flame tube, spiral-flow type airflow holes are additionally formed in three different parts of the wall surface of the flame tube. Rotational flow gas entering the main combustion area is mixed with mixed fuel gas jetted near a swirler, and the area of a backflow area is increased. Then, the gas flow which is fully combusted in the main combustion area flows into the middle area and is further fully combusted with rotational flow entering from the middle hole, so that uncombusted gas and middle combustion products can be effectively and completely combusted. Finally, generated incomplete combustion products and residual fuel oil pass through the mixing area, lean oil combustion is conducted on the incomplete combustion products and the residual fuel oil and rotational flow gas entering the mixing hole through the tail portion of flame sprayed out of the main combustion area, and extremely-low emission of pollutants isachieved. The combustion chamber can be applied to low-pollution aero-engines.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

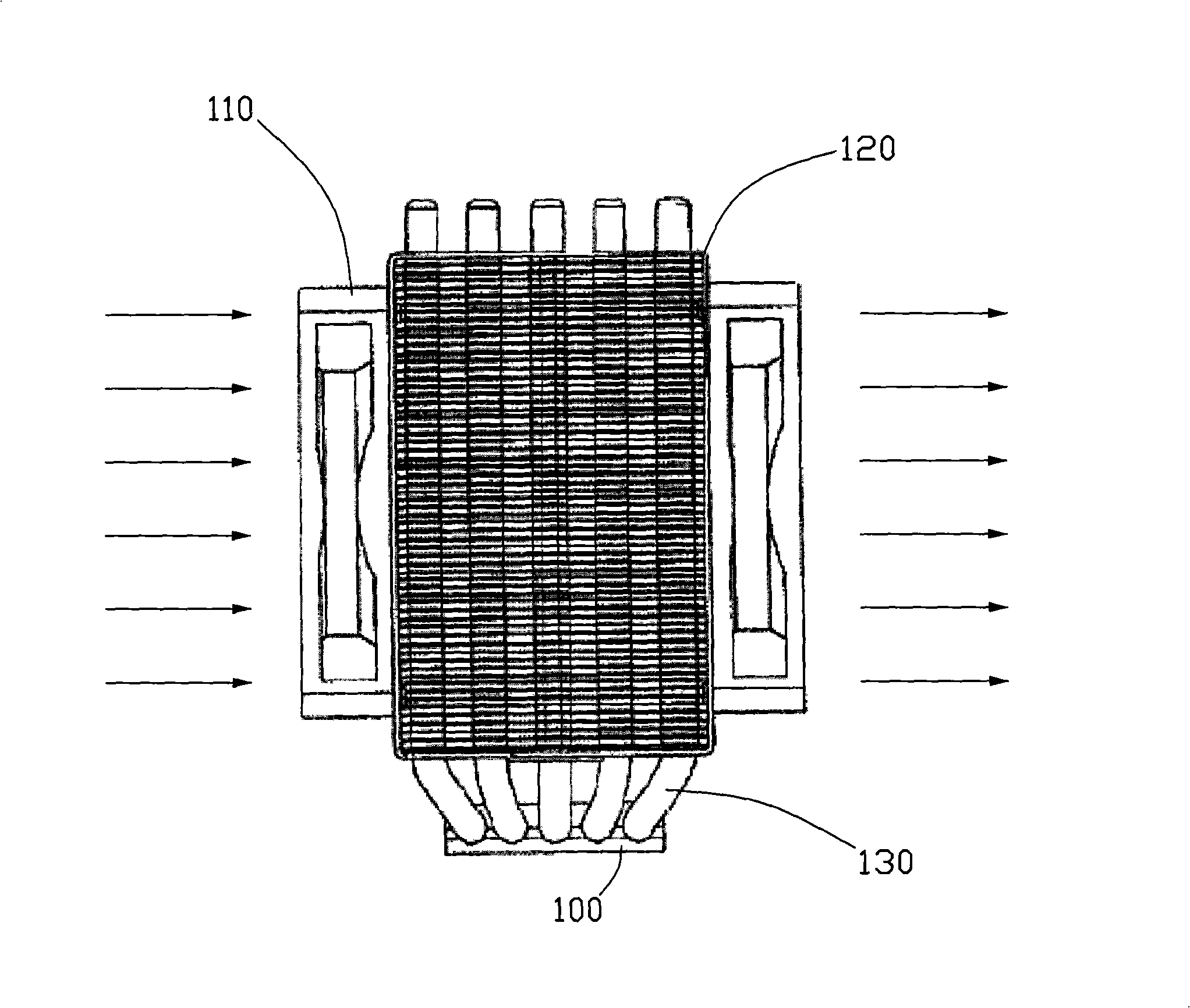

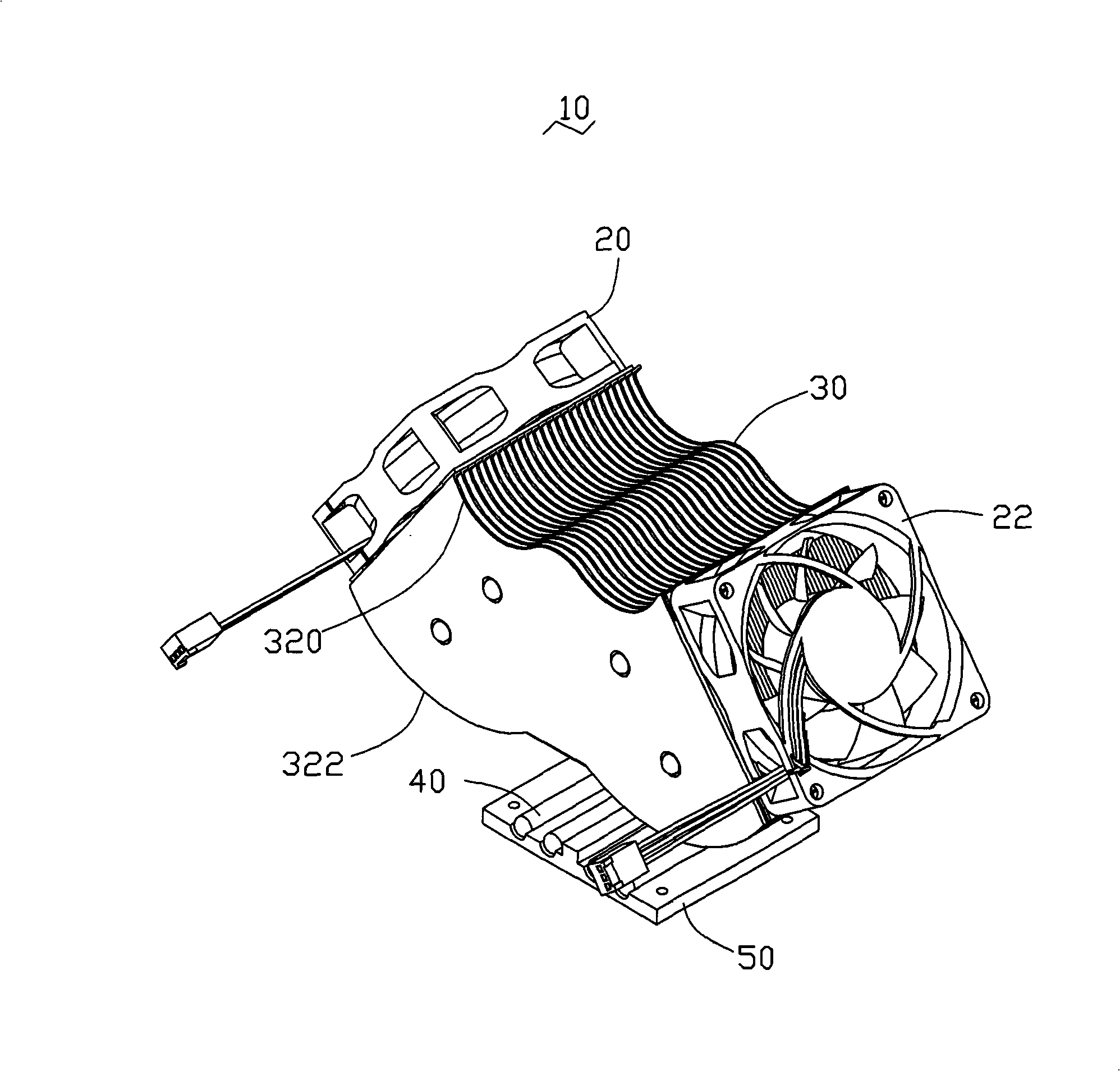

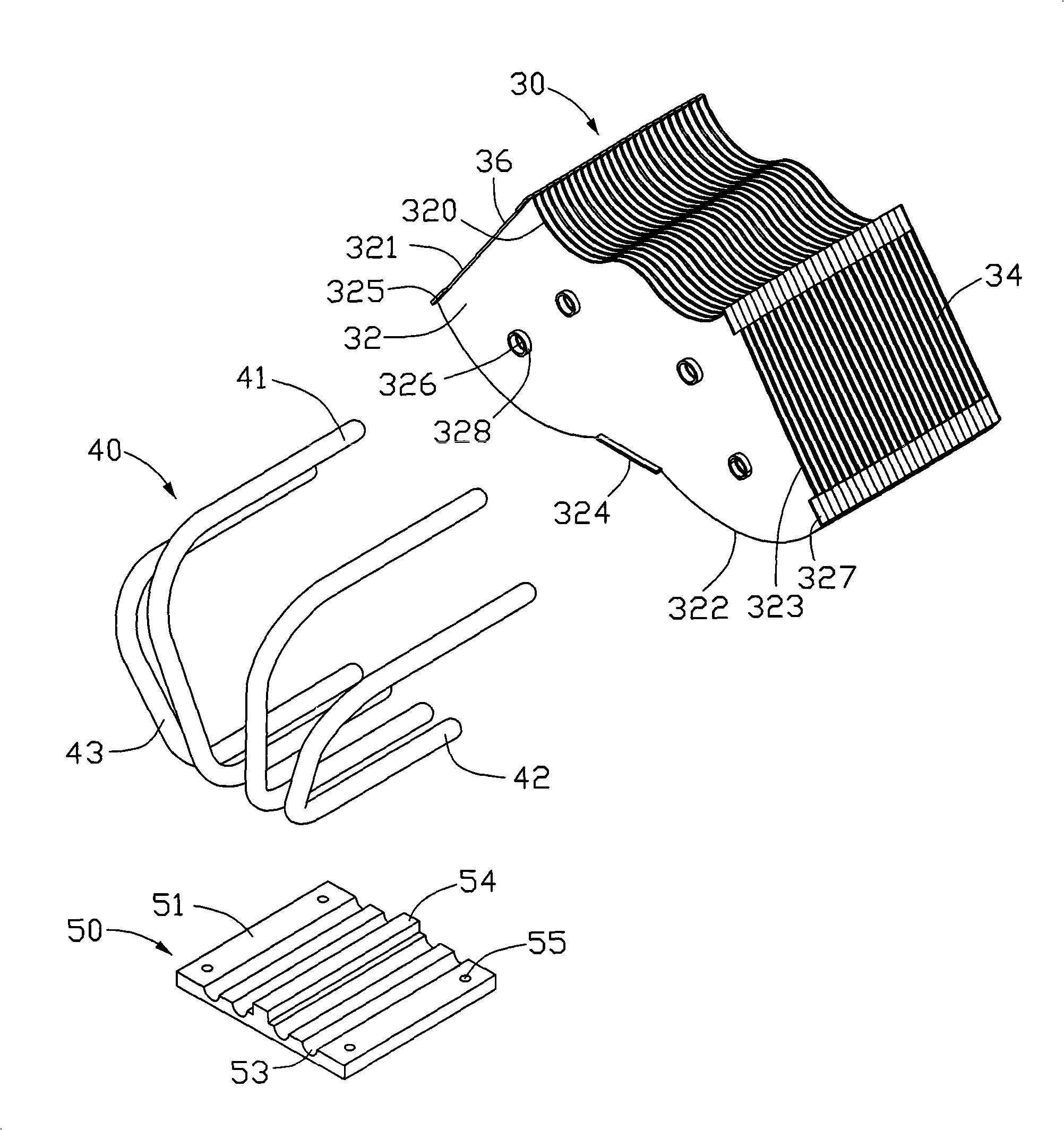

Heat sink assembly

InactiveCN101287348AAdequate heat dissipationImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The invention provides a heat dissipation module used for the heat dissipation of electronic elements. The heat dissipation module comprises a first group of cooling fins which consists of a plurality of the cooling fins mutually arranged at intervals. A plurality of air channels are formed among the cooling fins, and the two sides of the first group of the cooling fins, which are communicated with the air channel, are respectively provided with a first fan and a second fan. The first fan is inclined relatively to the second fan and all airflow orifices face the electronic elements. The airflow generated by the first fan flows through the first group of the cooling fins and blows to the direction of the electronic elements. The second fan extracts the airflow from the electronic elements and then the airflow is discharged by the first group of the cooling fins. The airflow generated by the heat dissipation module of the invention can directly blow to a high-temperature zone nearby the electronic elements so as to ensure the complete airflow heat dissipation, thus improving the cooling efficiency.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

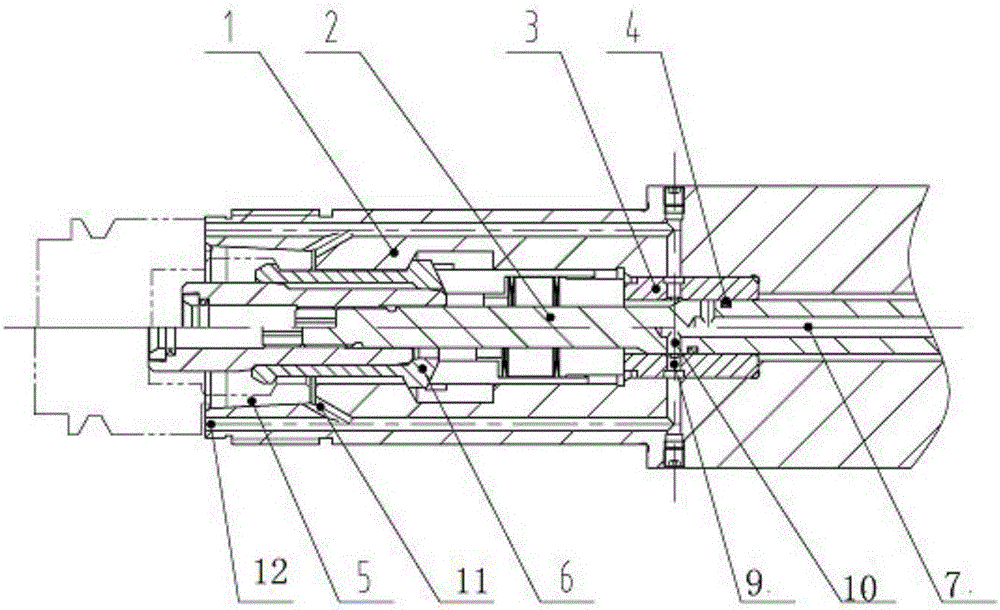

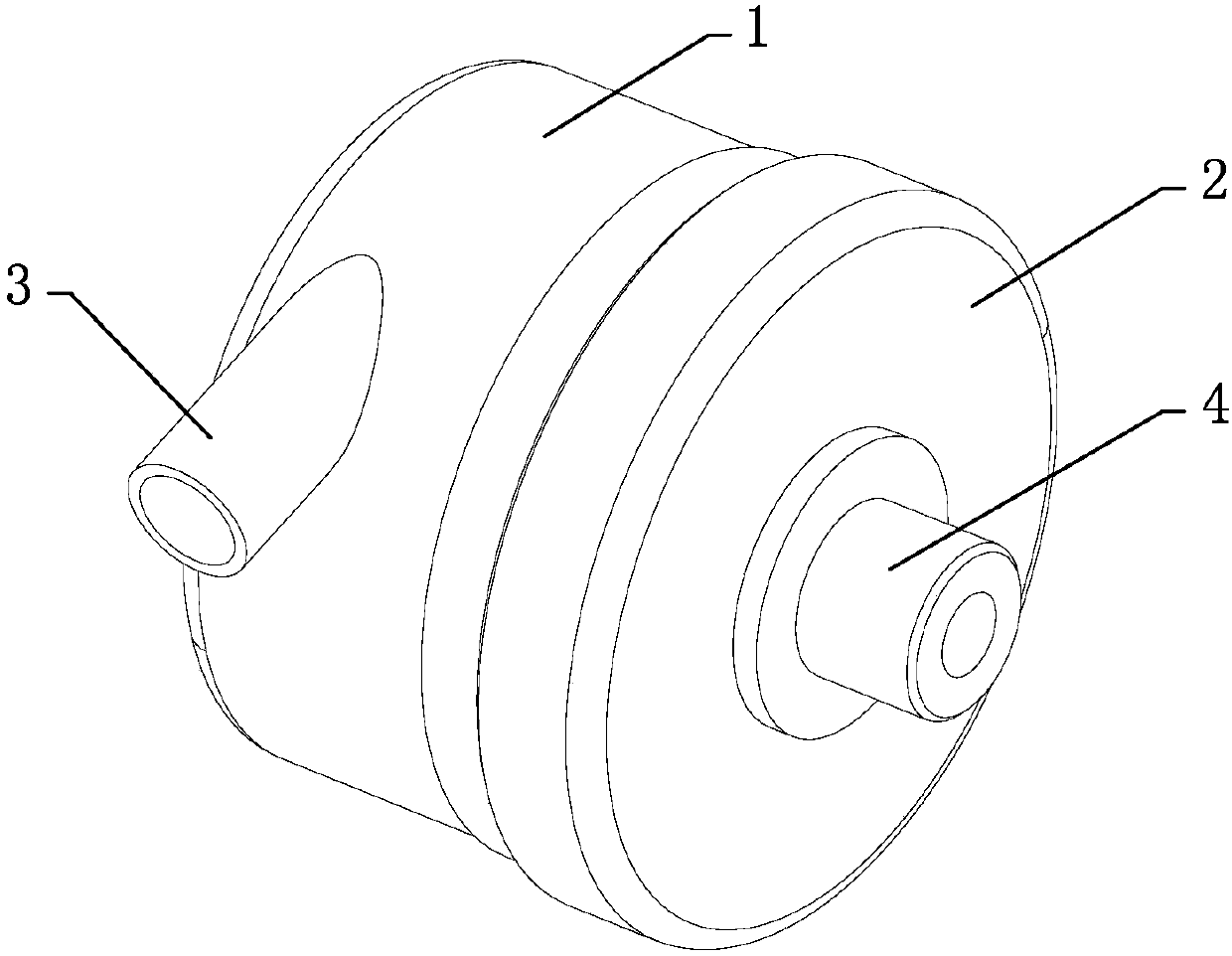

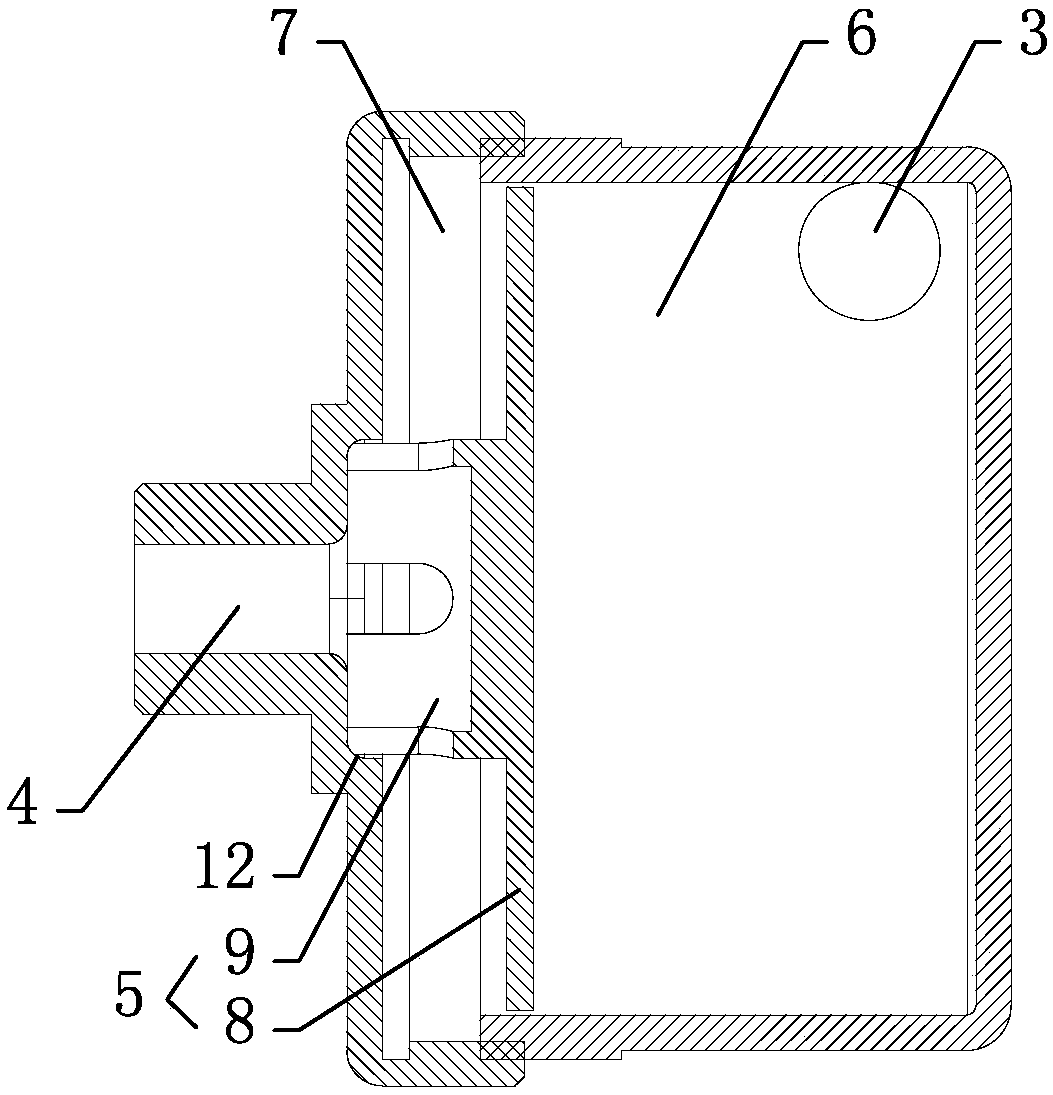

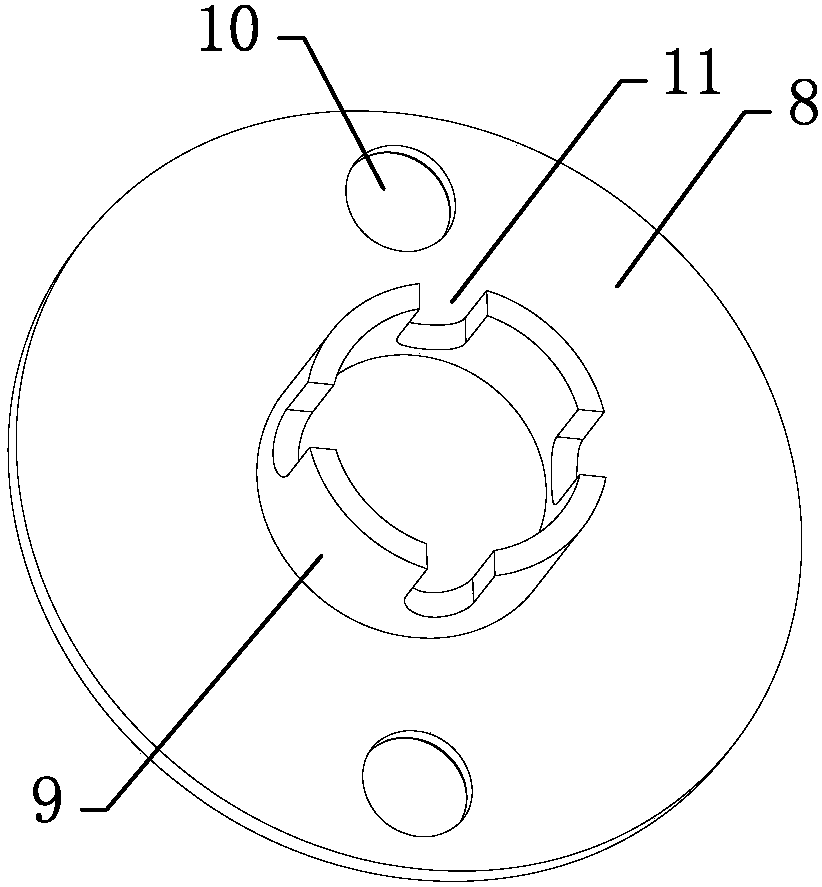

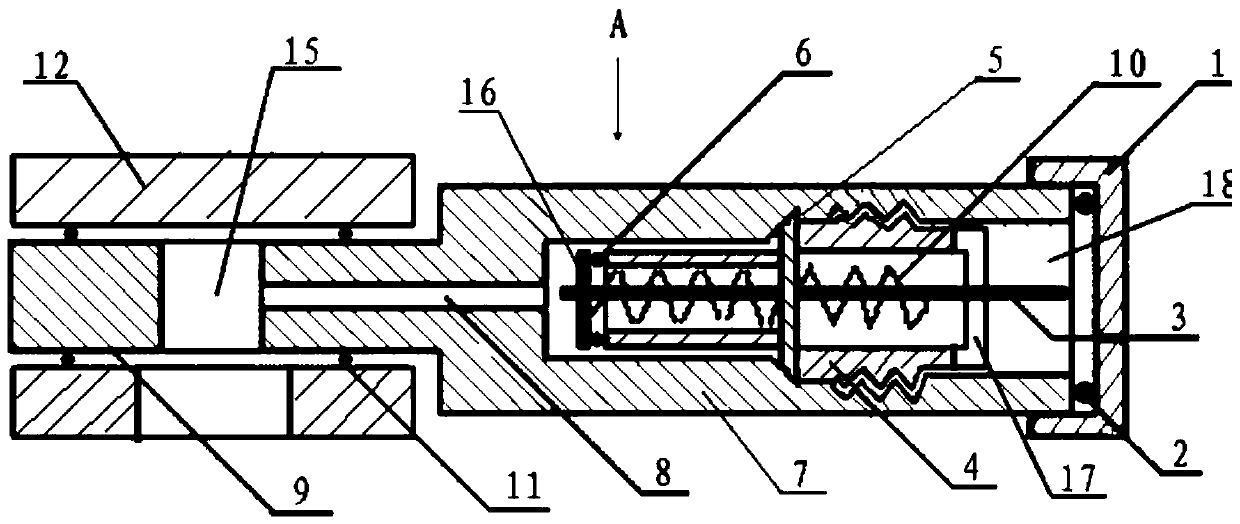

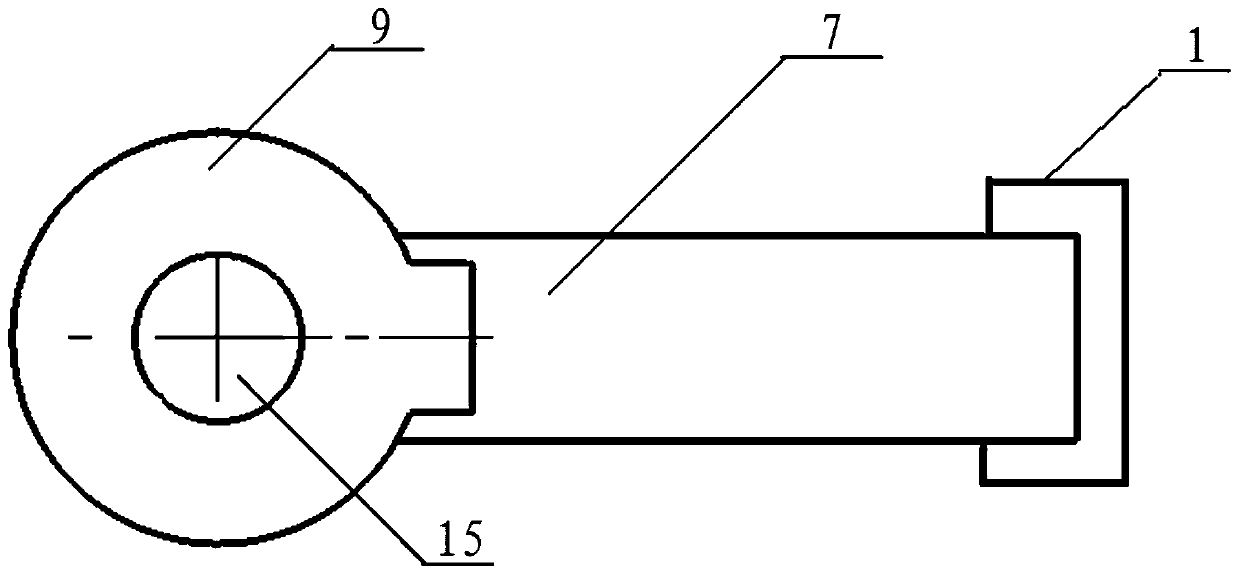

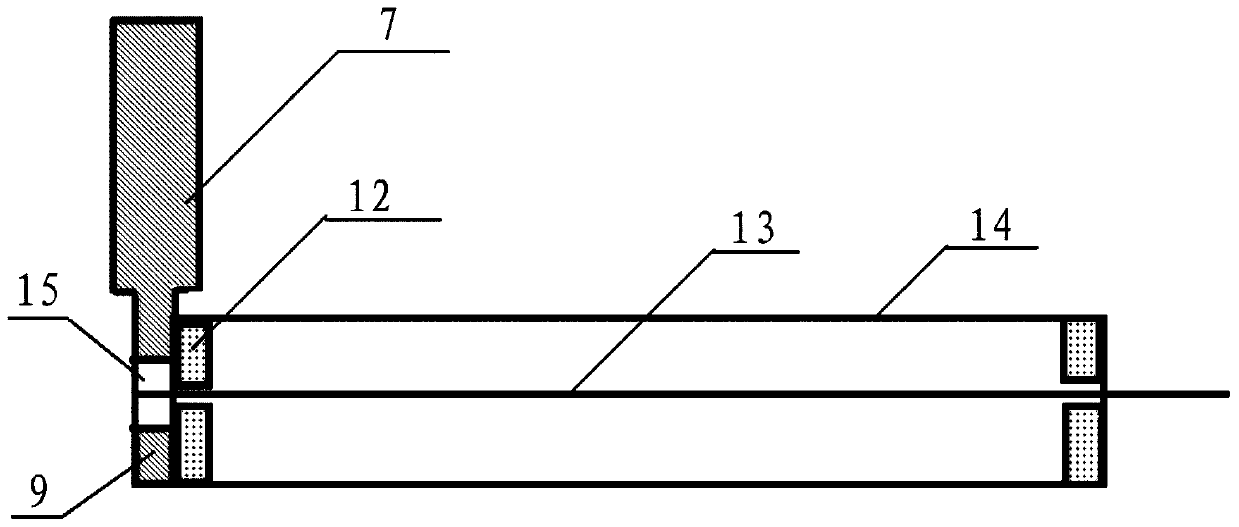

Tool changing and air blowing structure for end face of HSK taper hole

PendingCN107175533AQuick automatic tool changeImprove reliabilityPositioning apparatusMaintainance and safety accessoriesEngineeringAirflow orifice

The invention discloses a tool changing and air blowing structure for an end face of an HSK taper hole. The tool changing and air blowing structure is attached to the taper hole and the end face and comprises main shaft rotors and pull rods, wherein the pull rods are arranged in the main shaft rotors, one end of each pull rod is sleeved with a flow separation cover, an HSK tool holder and an HSK pull claw are arranged at the other end of each pull rod, the HSK tool holders are further arranged on the outer sides of the HSK pull claws, the HSK pull claws can push the HSK tool holders out, and high-pressure air flow can enter from air flow holes in the pull rods and finally is blown out of air blowing holes, thereby achieving the air blowing cleaning function. The tool changing and air blowing structure for the end face of the HSK taper hole is simple in structure, safe and compact, rapid and automatic tool changing of main shafts is guaranteed, the taper hole and the end face are cleaned, meanwhile the high-pressure air flow is prevented from entering a main shaft broach system, the reliability of the main shafts is improved, simultaneous contact positioning of the taper hole and the end face is realized, and the usability of an HSK tool system is ensured.

Owner:SHENZHEN SUFENG TECH

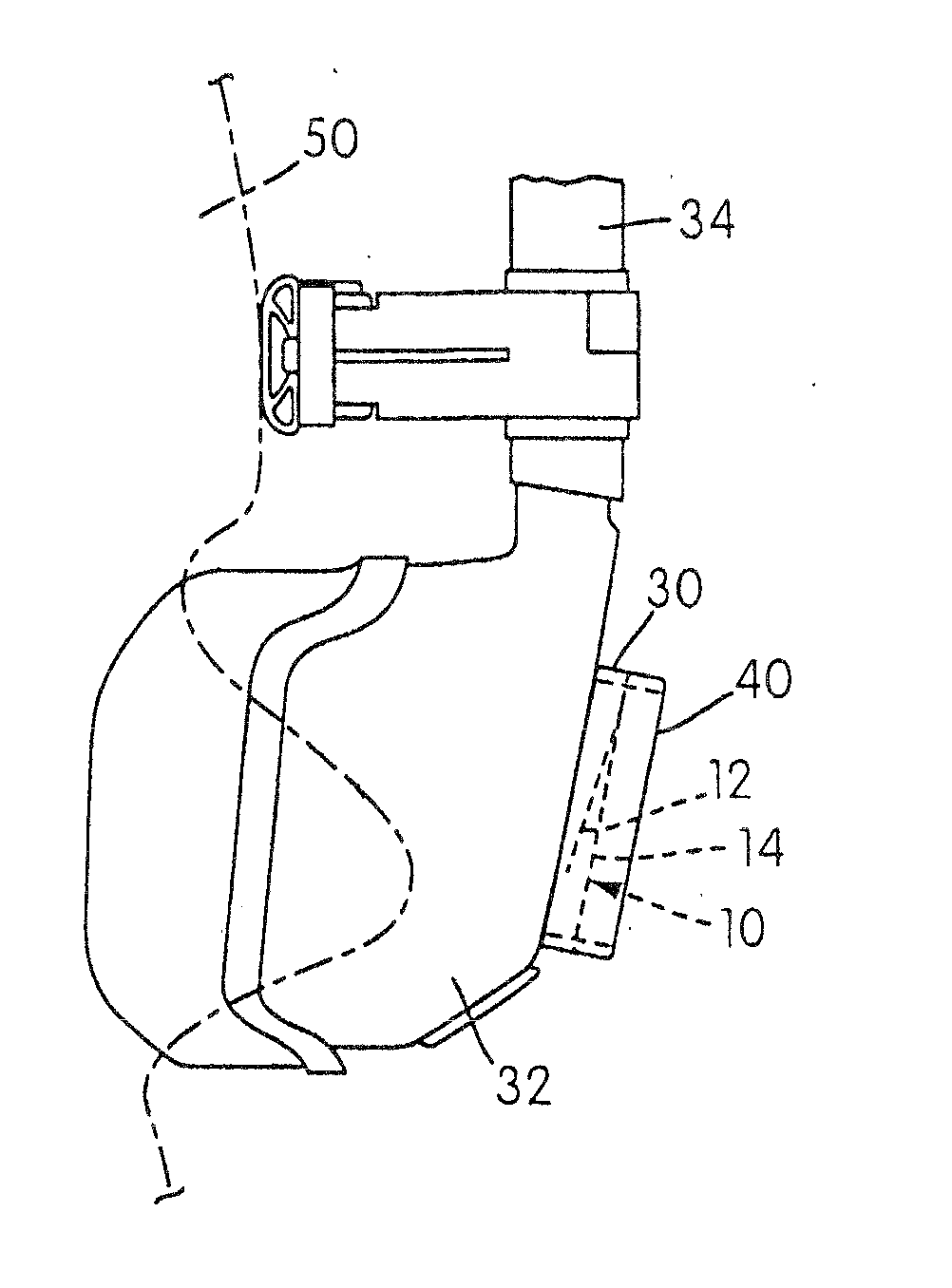

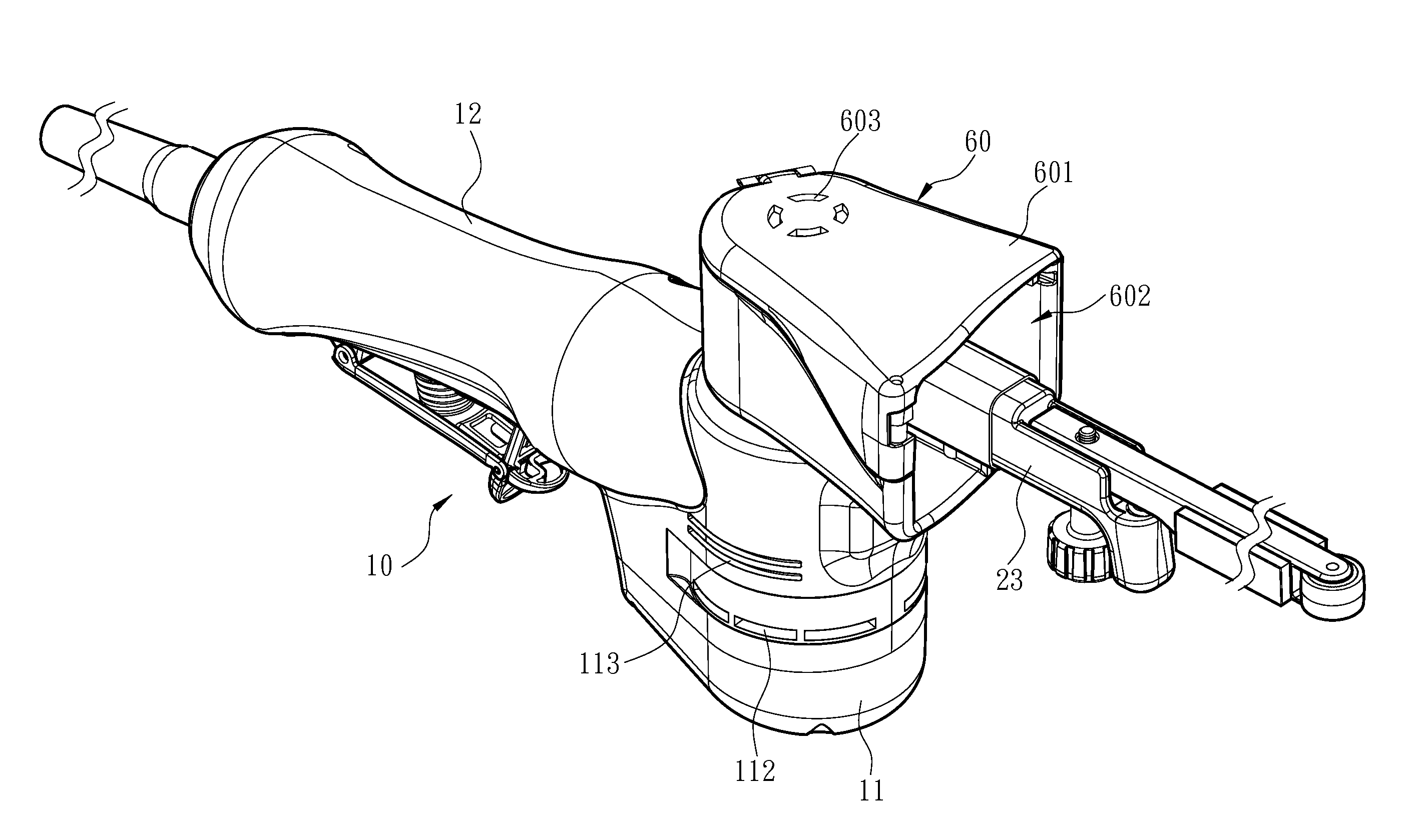

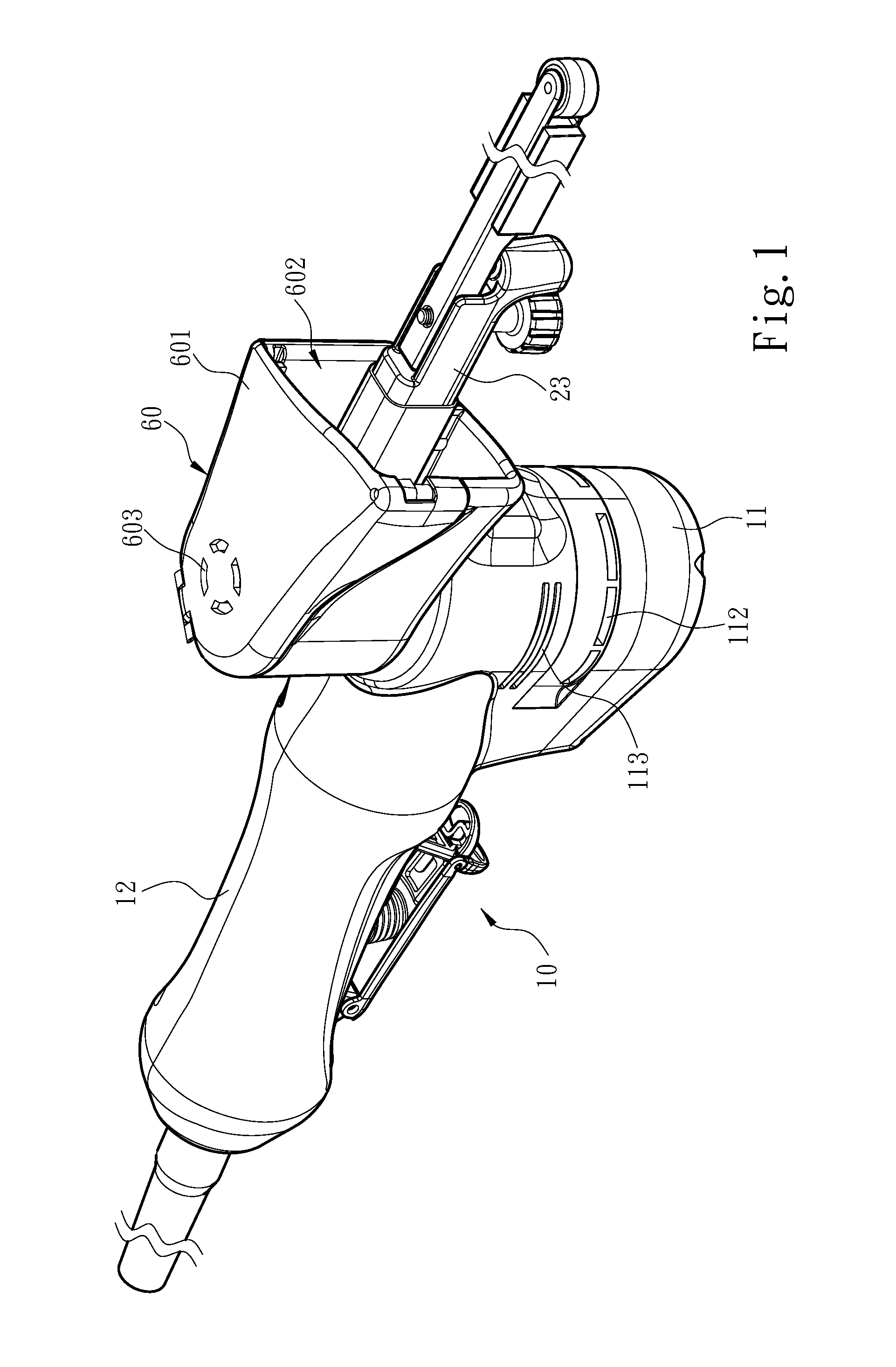

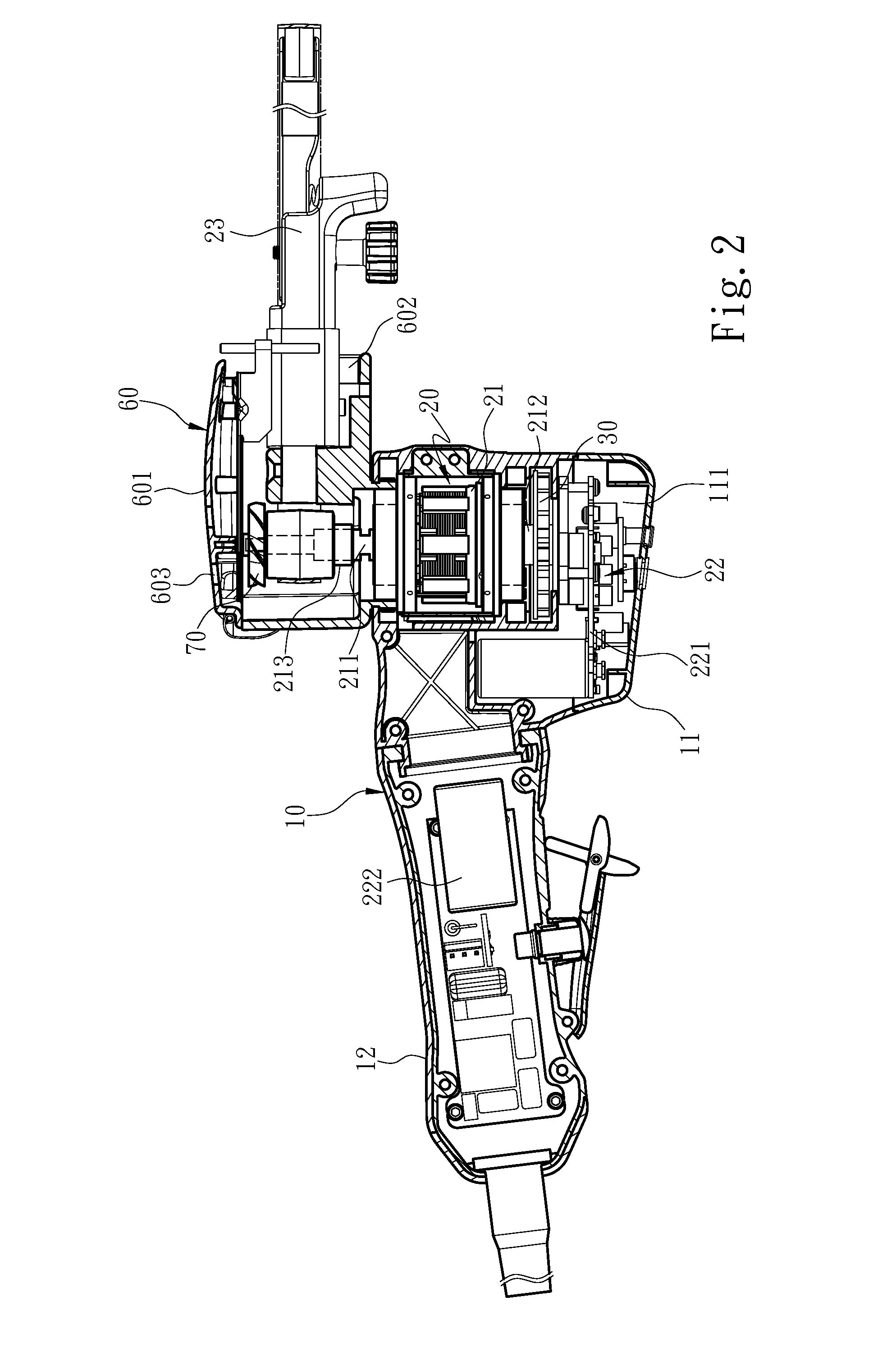

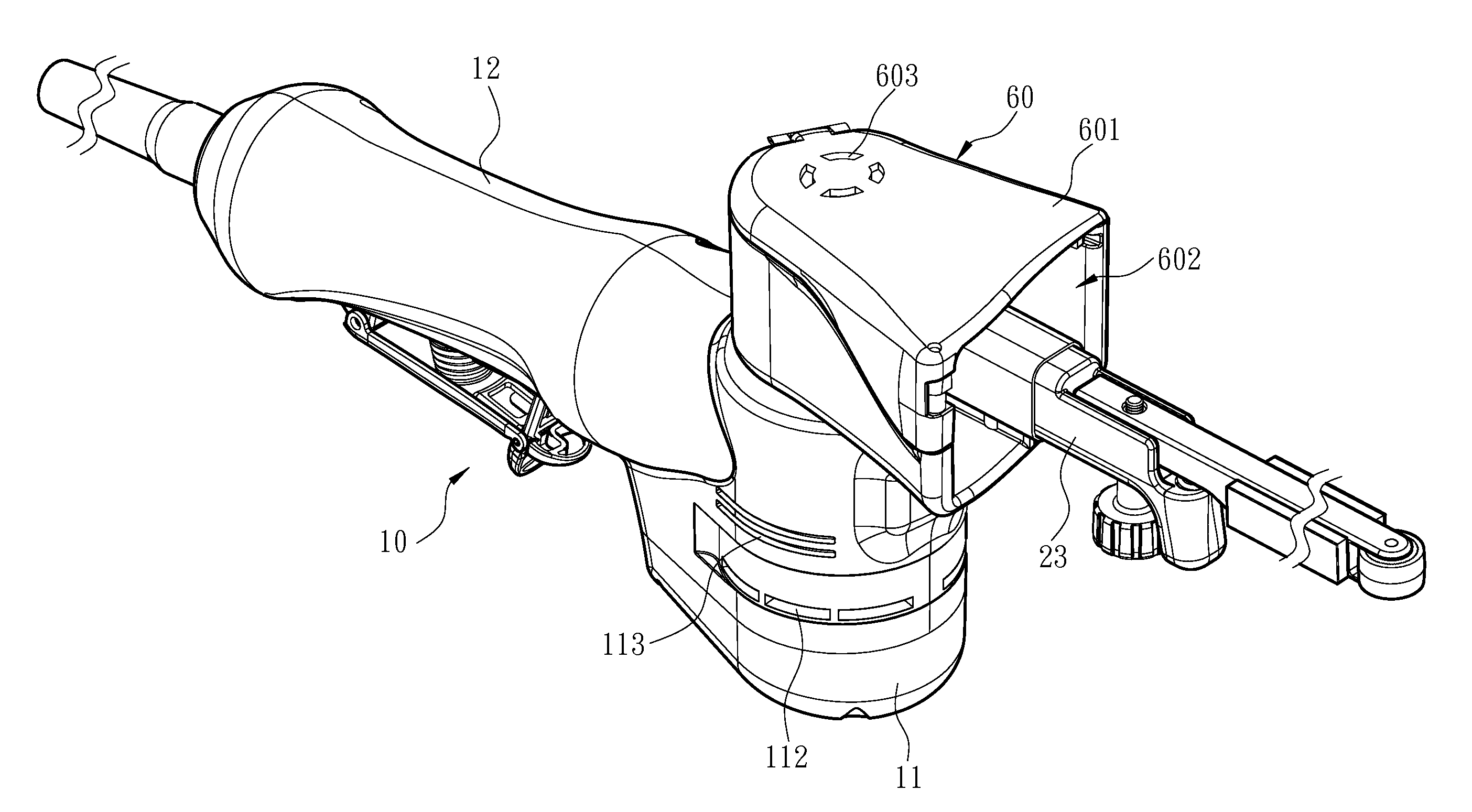

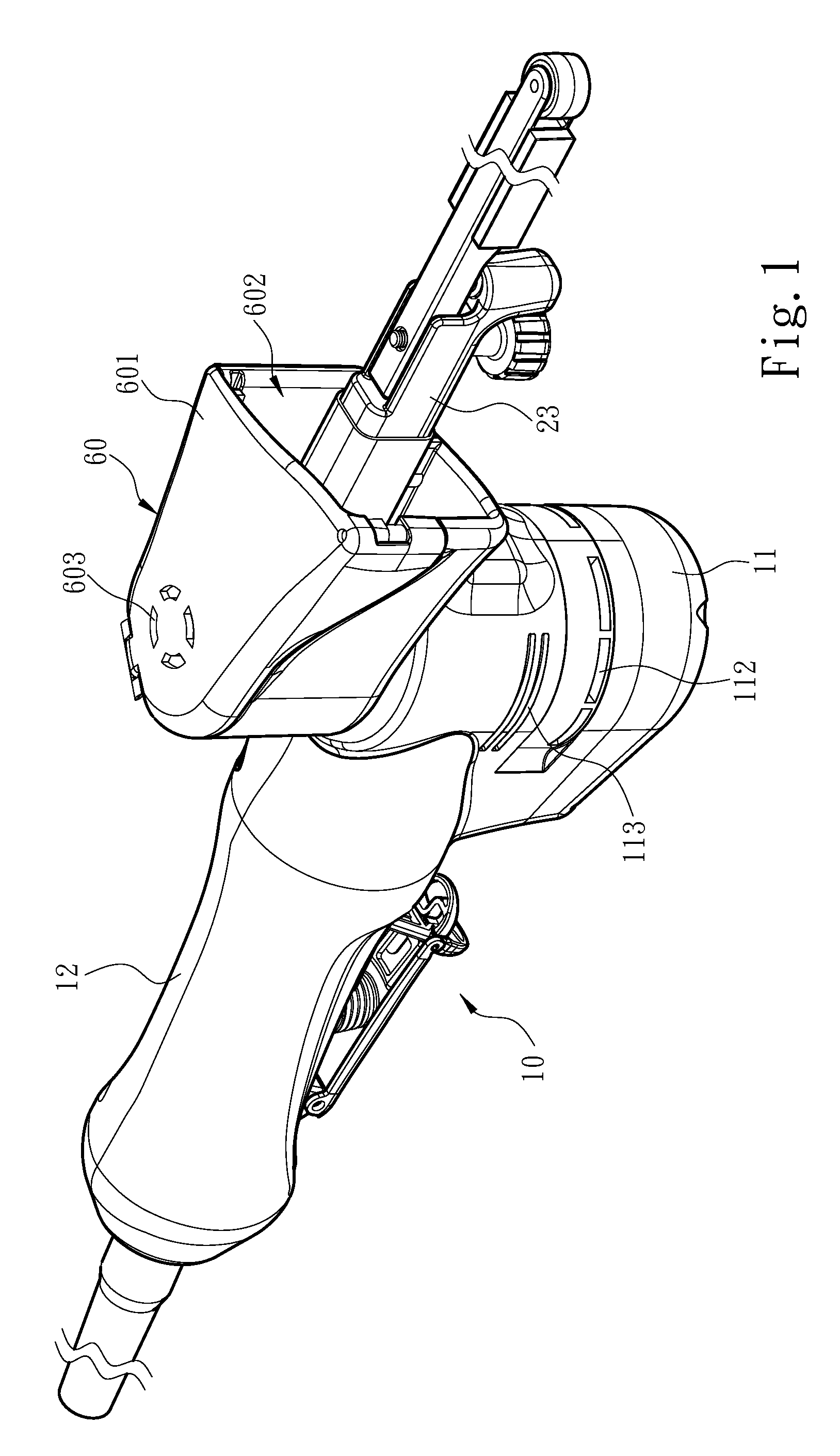

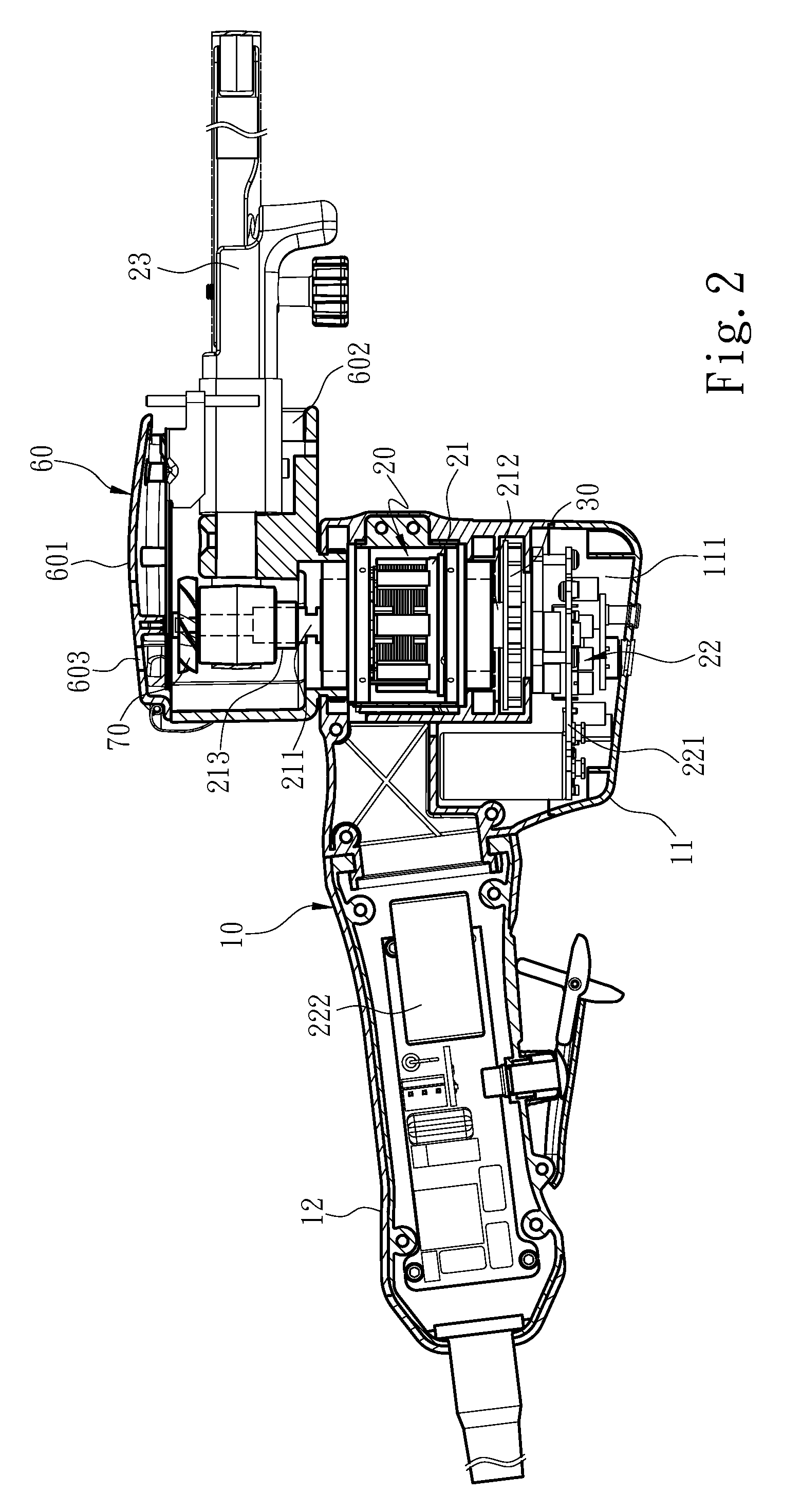

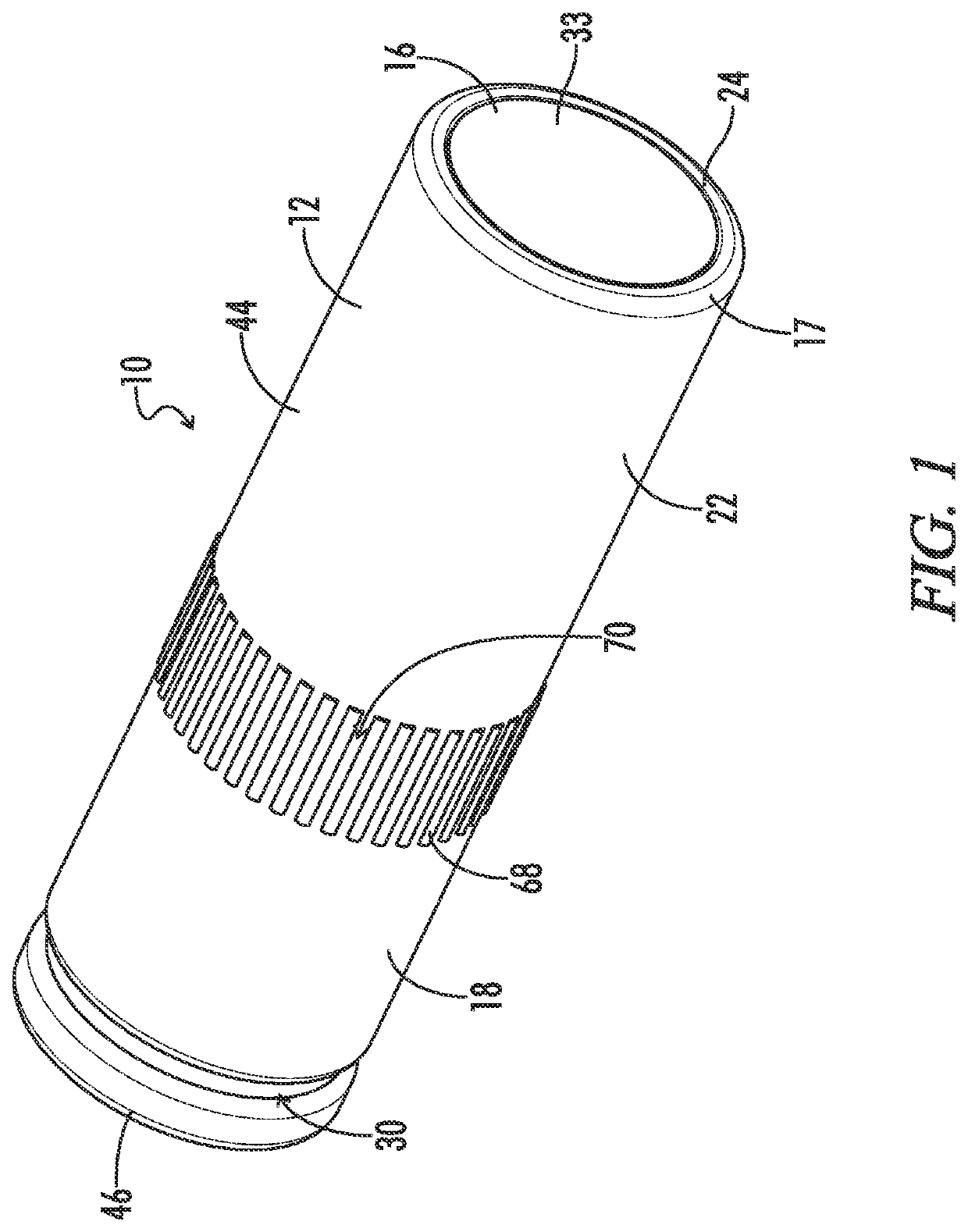

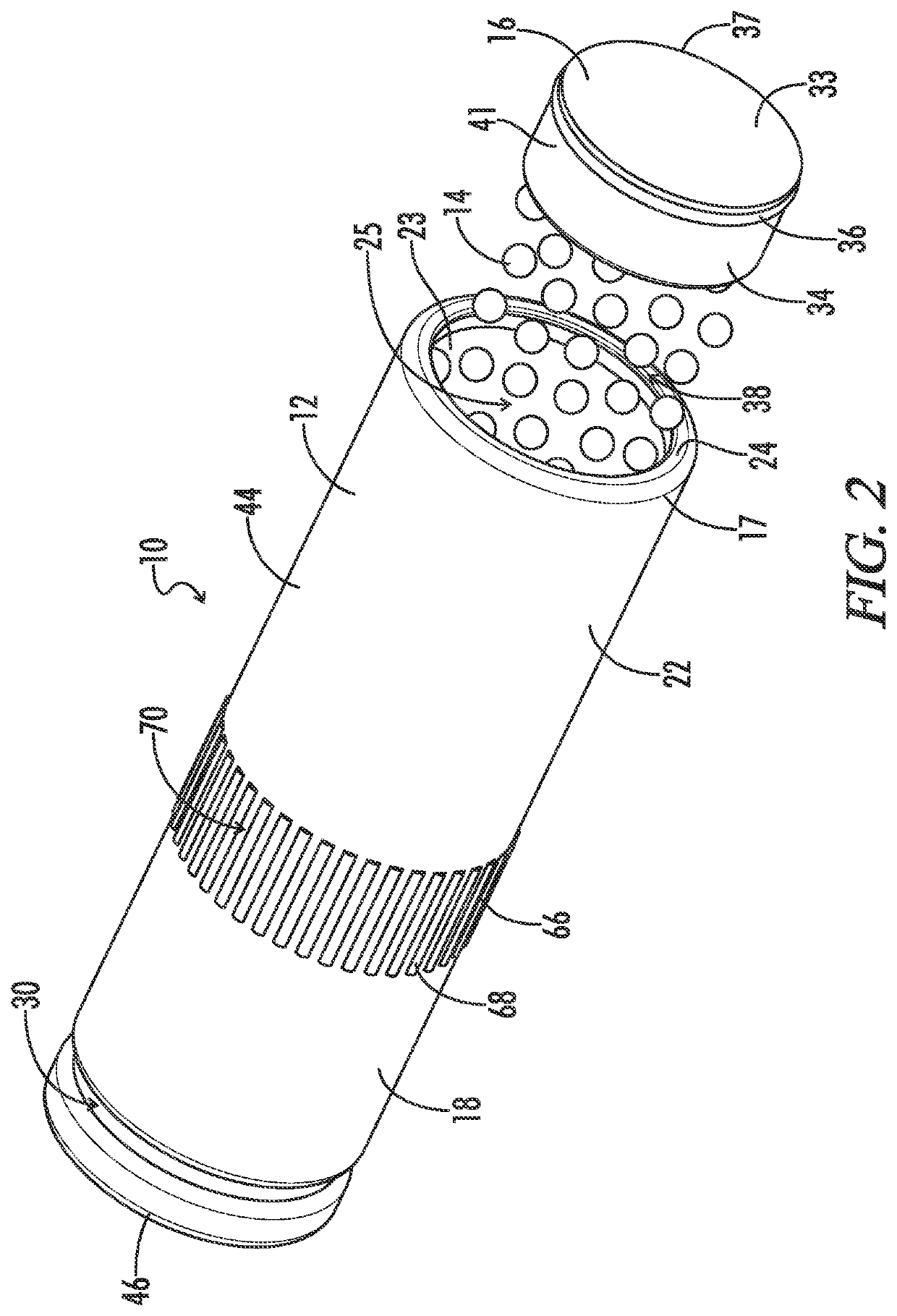

Electric handheld sanding tool providing improved cooling efficiency

ActiveUS20160243693A1Improve cooling efficiencyReduce heatPortable grinding machinesPortable power-driven toolsHand heldEngineering

An electric handheld sanding tool with improved cooling efficiency includes a host body and a sanding assembly. The sanding assembly is installed in the host body and includes an electric motor, a circuit module and a sanding element. The circuit module and the electric motor are interposed by a cooling fan which is synchronously moved with the electric motor. The host body has at least one air outlet corresponding to the cooling fan and at least one air inlet corresponding to either of the circuit module and the electric motor such that when the electric motor is driven by the circuit module and drives synchronously the sanding element and the cooling fan, the spinning cooling fan draws cold airflow through the air inlet to pass through an airflow orifice and dispel operation heat generated by the electric motor and the circuit module through the air outlet.

Owner:XPOLE PRECISION TOOLS

Reflux Trap Device

A reflux trap for use in a plasma generator and delivery system to prevent back flow of fluids and debris from a patient to the plasma generator during a surgical procedure comprising a trap housing including a proximal diffuser chamber and a distal deflection chamber having a collection area separated by a baffle disposed within the trap housing having at least one gas flow aperture formed therethrough, a proximal inlet port and a distal outlet port formed on opposite end portions of the trap housing to feed gas to and from the trap housing through the proximal diffuser chamber, gas flow aperture and the distal deflection chamber, the baffle further includes a diffuser member disposed in the proximal diffuser chamber such that gas fed into the proximal diffuser chamber through the proximal inlet port impigns thereon and diffused through the gas flow aperture into the distal deflection chamber and through the distal outlet port to the surgical site on the patient and a deflection member disposed in the distal deflection chamber such that fluids and debris flowing back from the patient through the outlet port into the distal deflection chamber impign thereon and are deflected away from the gas flow aperture to the collection area preventing fluids and debris from migrating through the gas flow aperture into the proximal diffuser chamber isolating the plasma generator against any back flow of fluid and debris from the patient.

Owner:BOVIE MEDICAL CORPORATION

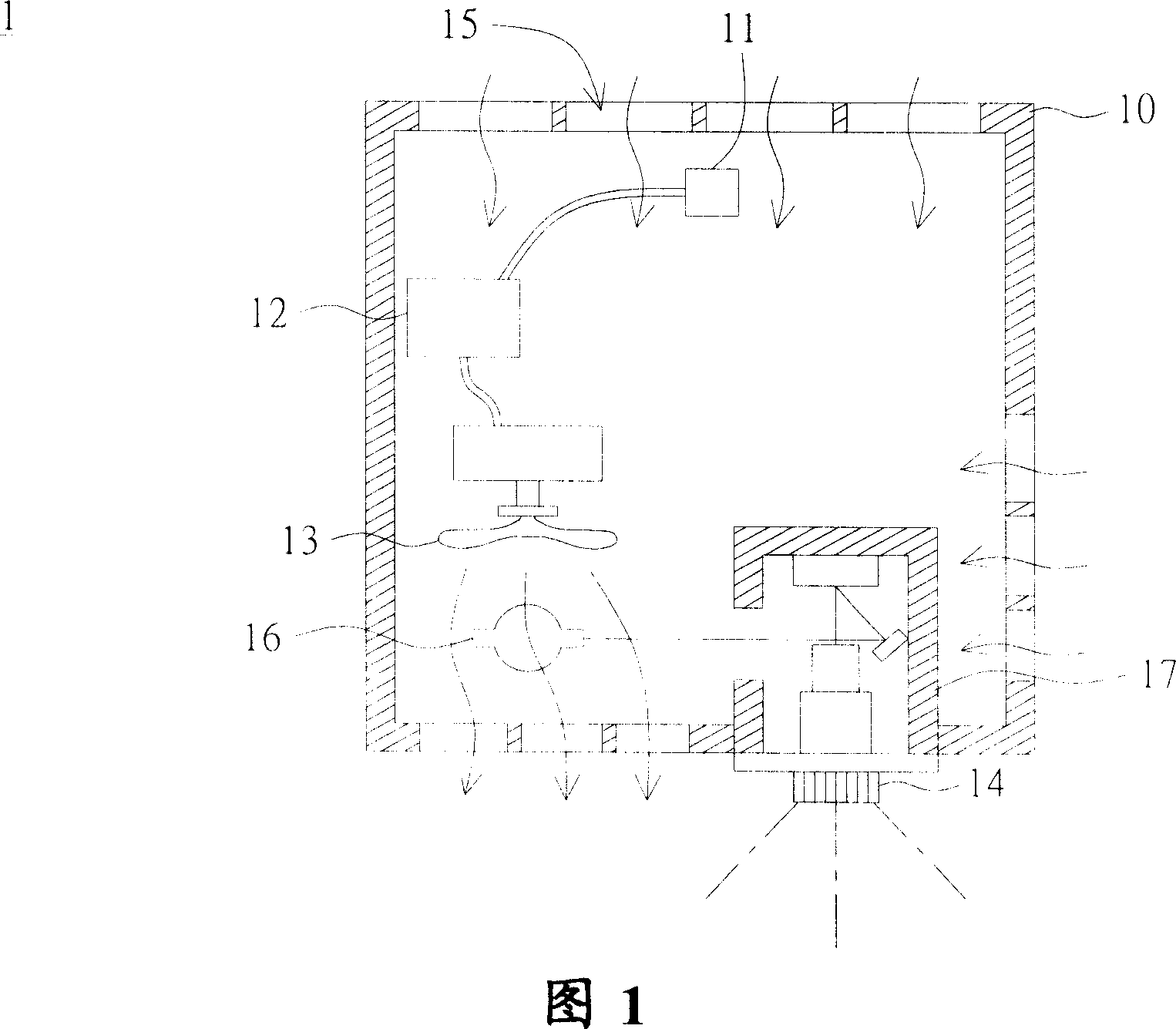

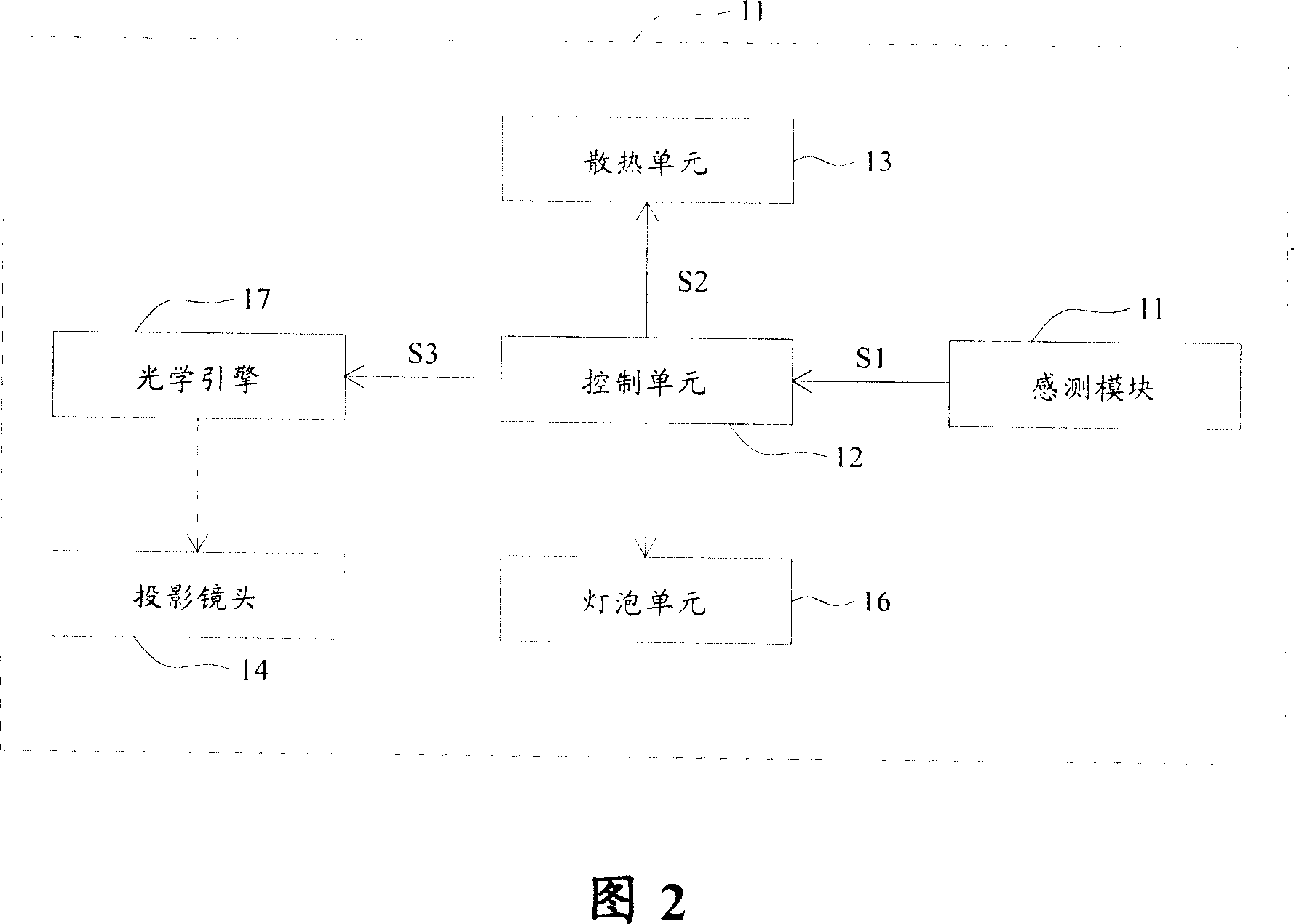

Optical projection apparatus

InactiveCN101101438AReduce heat dissipationImprove cooling effectProjectorsCamera lensProjection lens

The invention is an optical projector, comprising main body and sensing module, where the main body has control unit, radiation unit, projection lens and at least an airflow orifice, where the sensing module is arranged in the main body and the sensing module and the radiation unit are connected with the control unit; hot airflow in the main body exchanges with cold airflow outside the main body; when the sensing module detects object enters into a preset range around the airflow orifice, the sensing module will send signal to the control unit to make the control unit start up overheat mechanism.

Owner:BENQ CORP

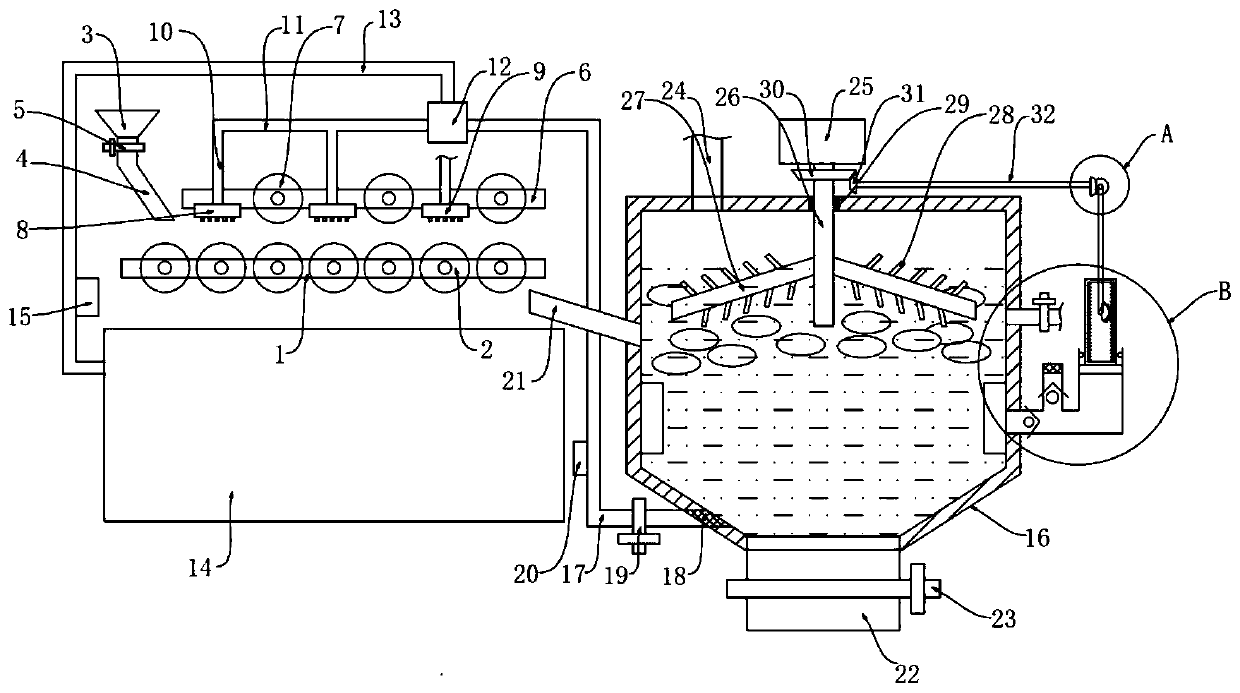

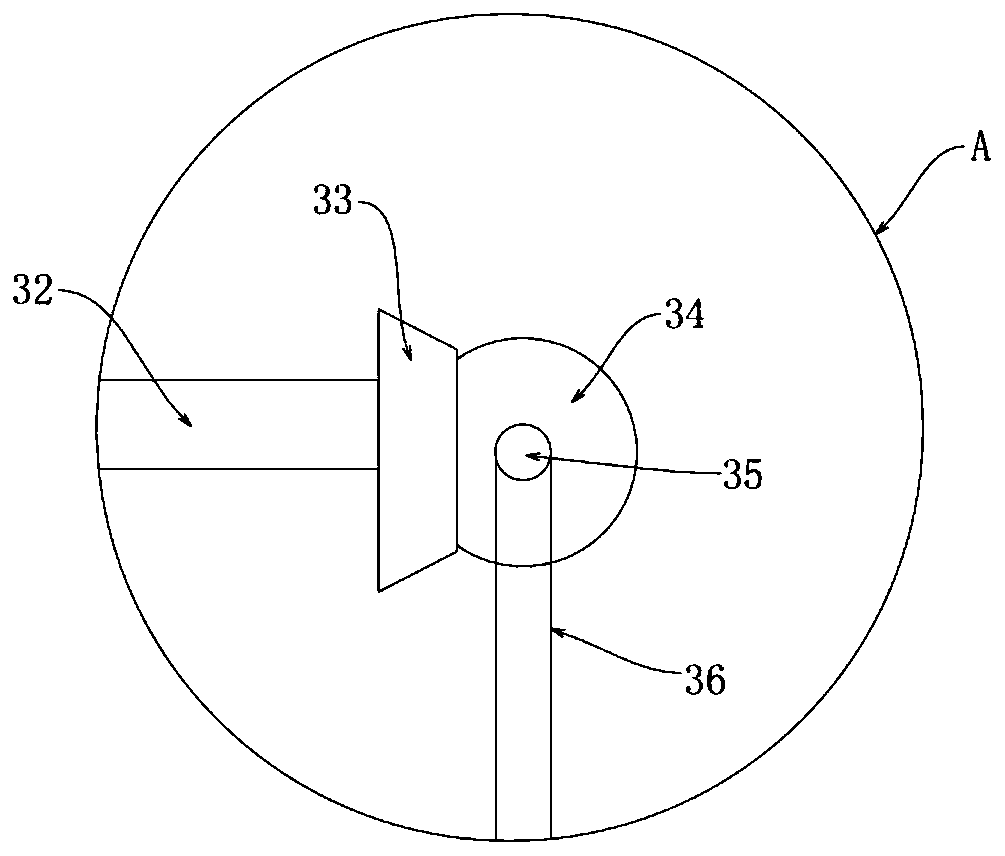

Device for jujube powder processing, washing and crushing

InactiveCN111248462AImprove processing efficiencyFeature ConcentrationClimate change adaptationFruit stoningWater resourcesStructural engineering

The invention discloses a device for jujube powder processing, washing and crushing. The device comprises a lower end bracket, wherein a plurality of groups of lower brush rollers are movably arrangedon the lower end bracket; a plurality of groups of rough washing spray plates and fine washing spray plates are sequentially arranged above the lower end bracket; a first branch pipe communicates with a three-way valve; a crushing tank is arranged on the side surface of a water collecting tank; a third branch pipe is arranged between the crushing tank and the three-way valve in a communication mode; a pit outlet pipe is arranged at the bottom of the crushing tank in a communication mode; a plurality of crushing blades are fixedly arranged on the crushing rod; a hollow pipe is attached to theside wall of an inner cavity of the crushing tank; and the hollow pipe is provided with an airflow hole. The device for jujube powder processing, washing and crushing can be used to automatically complete a series of operations such as washing, crushing, pit removing and the like of jujubes, and a water resource can be repeatedly utilized. Jujube flesh and jujube kernels are separated by using a flotation mode, and airflow is generated continuously in a crushing process so as to improve the flotation effect, so that the device is efficient, simple and convenient and is very worthy of popularization.

Owner:BENGBU COLLEGE

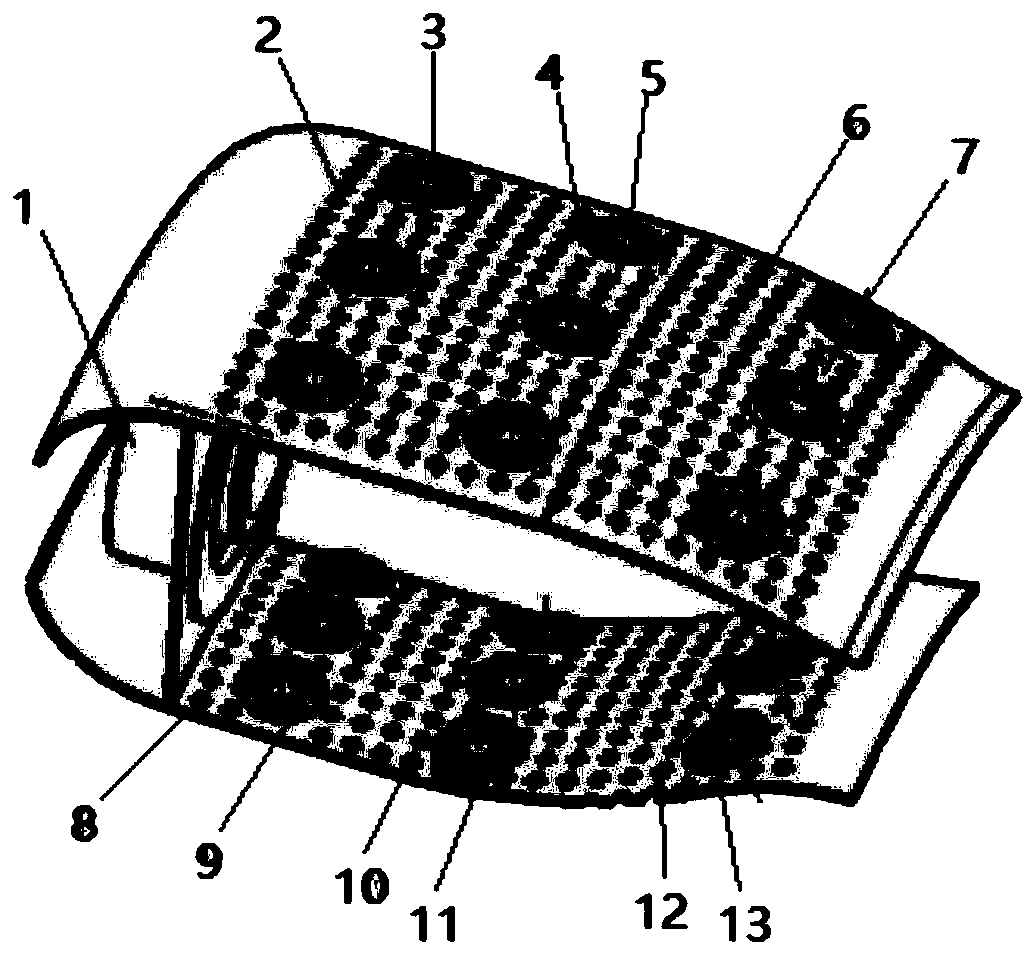

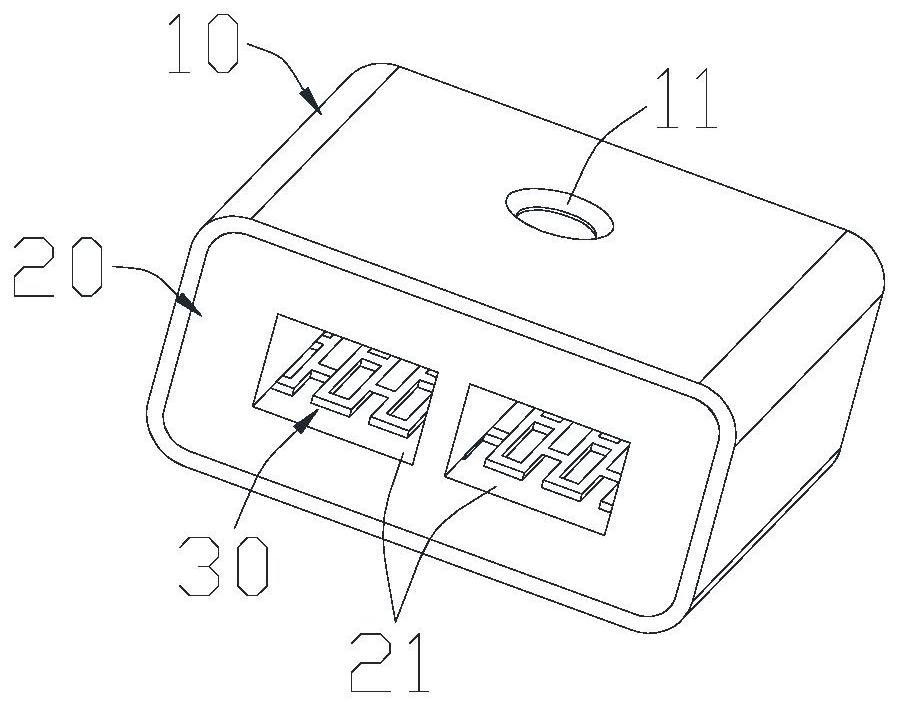

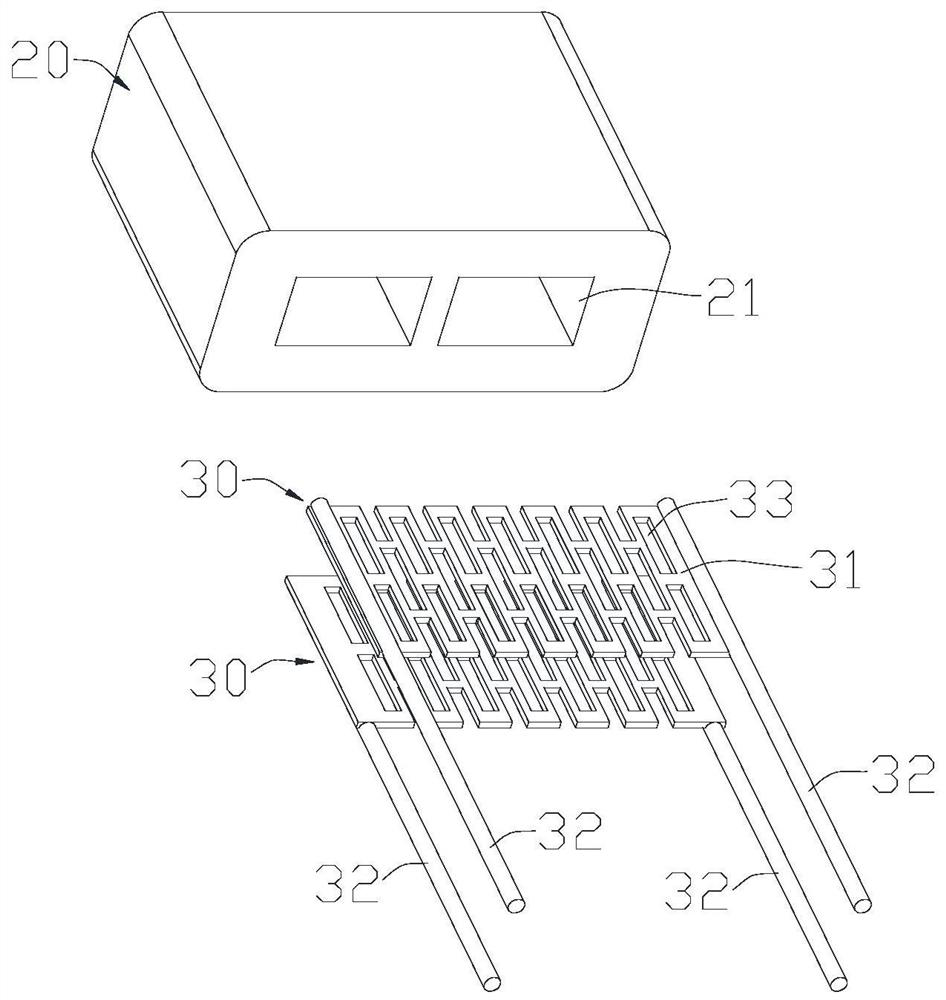

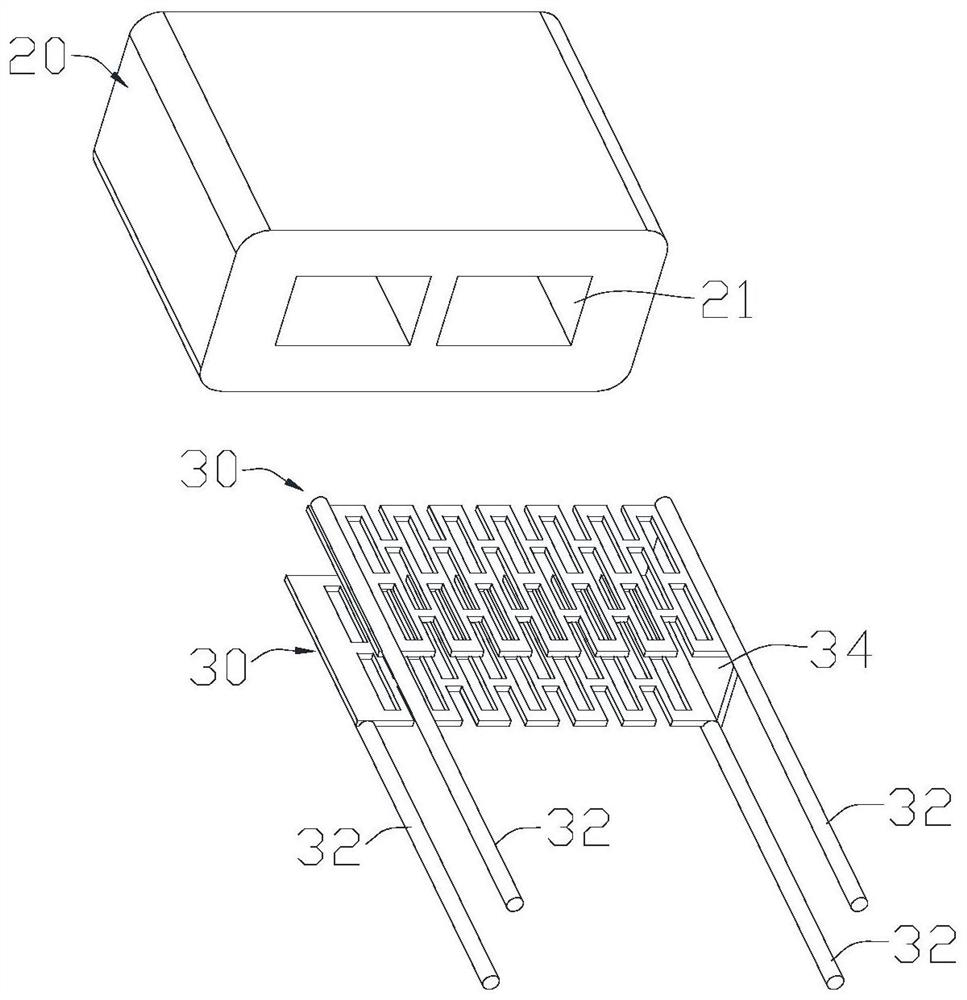

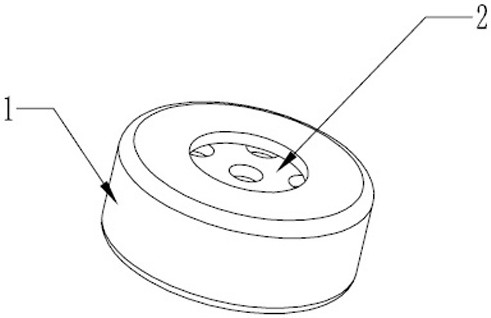

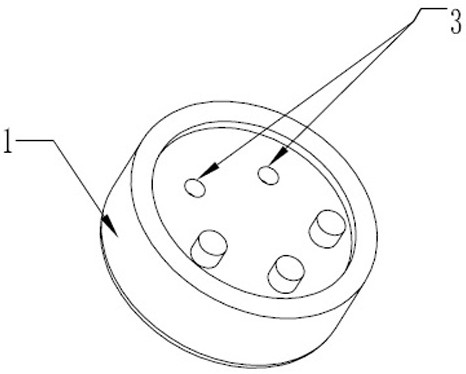

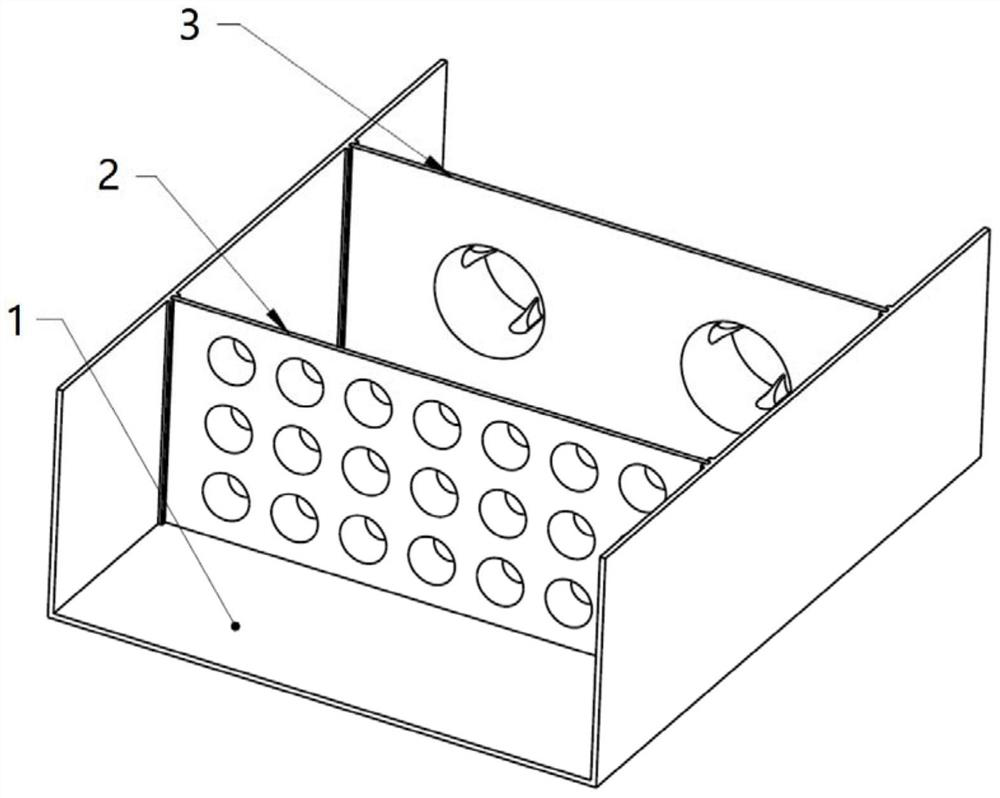

Multi-surface heating and atomizing assembly and atomizing and heating method thereof

PendingCN111887479AMeet the requirements of vaping experienceReduce or avoid carbon build-upTobaccoCarbon depositMechanical engineering

The invention discloses a multi-surface heating and atomizing assembly and an atomizing and heating method thereof. The multi-surface heating and atomizing assembly comprises a liquid guide body and at least two heating bodies arranged in the liquid guide body; airflow holes penetrating through the two opposite ends of the liquid guide body are formed in the liquid guide body; the at least two heating bodies are respectively positioned on different inner wall surfaces of the airflow holes; one end, used for being externally connected with a power source, of each heating body protrudes out of one end of the liquid guide body; and atomization surfaces are formed on the surfaces of the heating bodies. According to the multi-surface heating and atomizing assembly of the invention, the two or more heating bodies are matched with the liquid guide body, so that the assembly is provided with the two or more atomizing units, atomizing and heating work can be independently or alternately carriedout, the service life or atomizing amount of the assembly is twice or more of that of an assembly provided with a traditional single atomizing unit, a carbon deposition problem is reduced or avoided,and the atomizing experience requirements of different users are met.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

Silencer and silencing method thereof

PendingCN107725323AInto the uniformBlock the crashPositive displacement pump componentsPositive-displacement liquid enginesEngineeringAir compressor

The invention discloses a silencer and aims to provide a silencer which is simple in structure and good in silencing effect. According to the key points of the technical scheme of the silencer, the silencer comprises an outer hood and a fixing seat placed on one side of the outer hood, an air inlet pipe is arranged on the outer hood, and an air outlet pipe is arranged on the fixing seat; a silencing device body is arranged in the outer hood and comprises a partition plate dividing the outer hood into a first cavity and a second cavity and a flow distributing hood placed at the air inlet end ofthe air outlet pipe; the first cavity communicates with the air inlet pipe, the air inlet direction of the air inlet pipe is tangent with the inner circumferential wall of the first cavity, and the second cavity communicates with the air outlet pipe; and the partition plate is provided with an air flow hole communicating with the first cavity and the second cavity, and the side wall of the flow distributing hood is provided with a plurality of flow distributing holes. The silencer is suitable for the technical field of air compressor parts.

Owner:台州宝乾机电股份有限公司

Electric handheld sanding tool providing improved cooling efficiency

ActiveUS9505119B2Improve cooling efficiencyReduce heatPortable grinding machinesPortable power-driven toolsCooling efficiencyAirflow orifice

An electric handheld sanding tool with improved cooling efficiency includes a host body and a sanding assembly. The sanding assembly is installed in the host body and includes an electric motor, a circuit module and a sanding element. The circuit module and the electric motor are interposed by a cooling fan which is synchronously moved with the electric motor. The host body has at least one air outlet corresponding to the cooling fan and at least one air inlet corresponding to either of the circuit module and the electric motor such that when the electric motor is driven by the circuit module and drives synchronously the sanding element and the cooling fan, the spinning cooling fan draws cold airflow through the air inlet to pass through an airflow orifice and dispel operation heat generated by the electric motor and the circuit module through the air outlet.

Owner:XPOLE PRECISION TOOLS

Airflow sensor and oleophobic and hydrophobic treatment method

PendingCN112525240AWill not hinder normal entry and exitWork lessMeasurement apparatus componentsCoatingsProduction linePolymer science

The invention discloses an airflow sensor and an oleophobic and hydrophobic treatment method. The airflow sensor comprises an airflow sensor body, which is provided with an airflow hole and an air inlet hole, wherein the airflow hole is provided with an air outlet hole protective film, the air outlet hole protective film covers the airflow hole, an air inlet hole protective film is arranged on theair inlet hole, the air inlet hole protective film covers the air inlet hole, and the air outlet hole protective film and the air inlet hole protective film are protective films subjected to oleophobic and hydrophobic treatment. The oleophobic and hydrophobic treatment method comprises primary oleophobic and hydrophobic treatment and secondary oleophobic and hydrophobic treatment. Compared with the prior art, the oleophobic and hydrophobic treatment method of the invention has the advantages that liquid such as water, smoke oil and the like does not remain on the protective film or in the peripheral area, normal inlet and outlet of airflow are not hindered, the airflow sensor can be used in a harsh environment, such as still work normally after being immersed in smoke oil for 192 hours, the technological process is simple, spraying or soaking operation can be conducted on a production line, the drying time is short, or the airflow sensor can be directly dried at the room temperature.

Owner:YANTAI NIVO NEW MATERIAL CO LTD

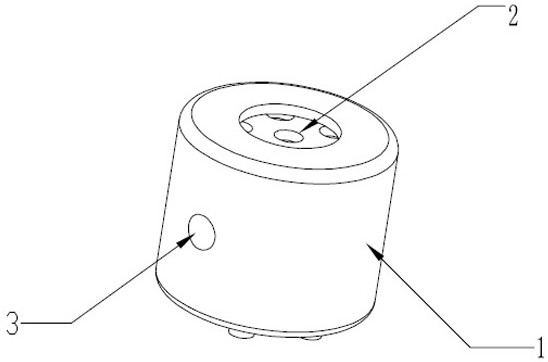

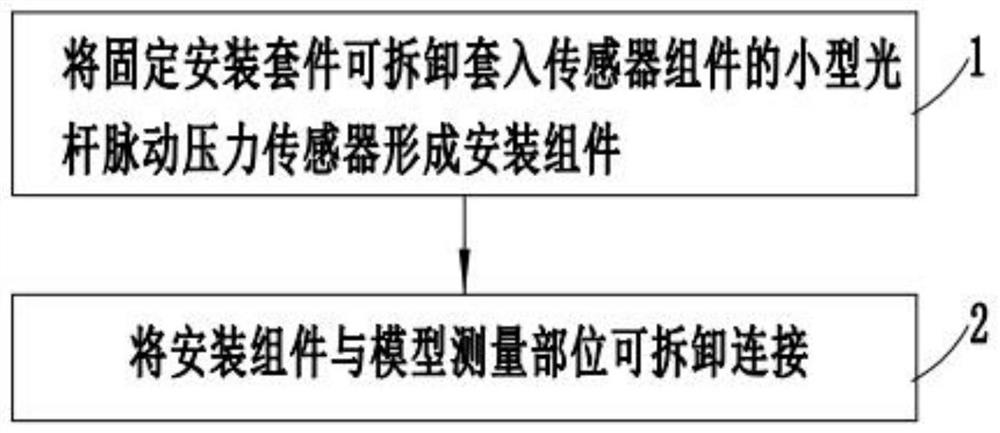

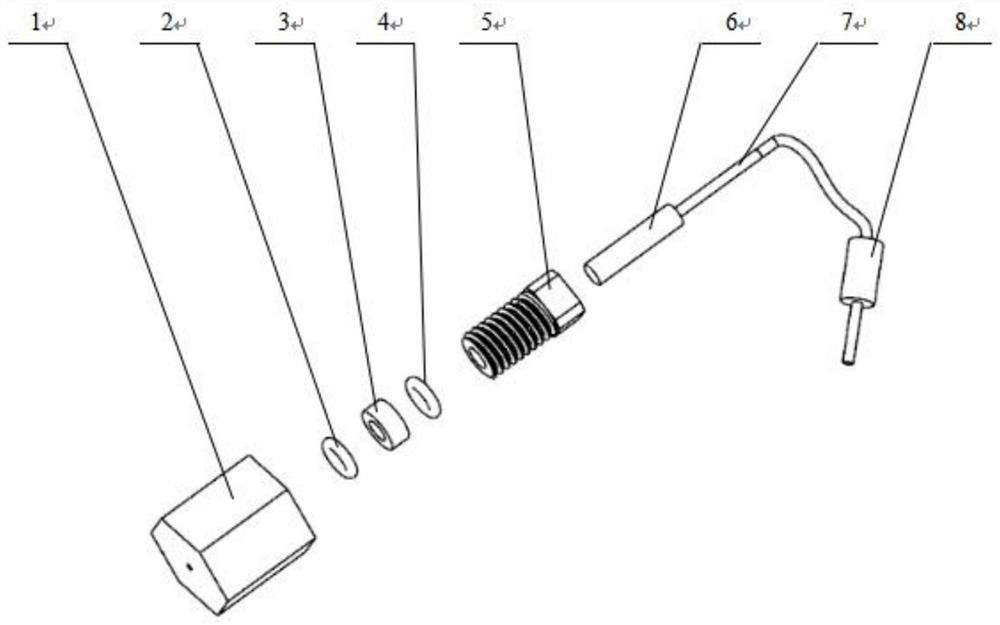

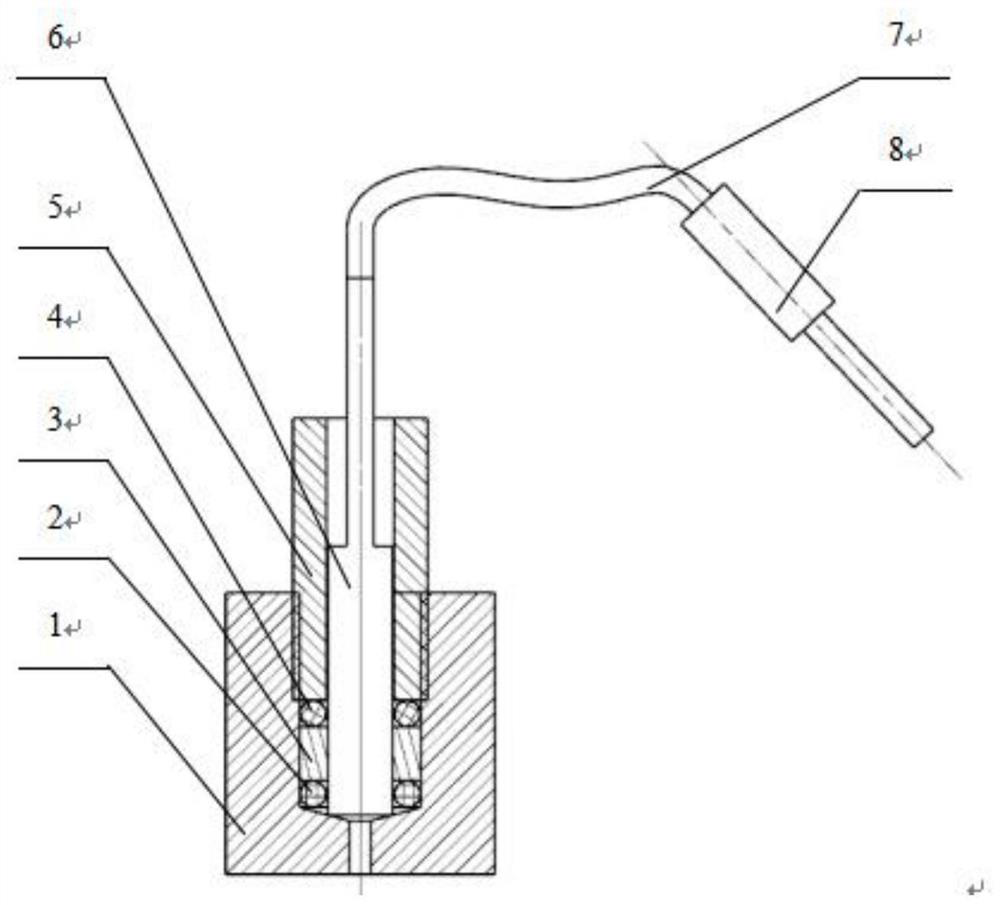

Double-sealing-ring axial fixing method for small polish rod sensor for high-enthalpy pulse wind tunnel

ActiveCN112945512ASo as not to damageEasy to disassembleAerodynamic testingPneumaticsPressure sensor

The invention belongs to the technical field of experimental aerodynamics, and discloses a double-sealing-ring axial fixing method for a small polish rod sensor for a high-enthalpy pulse wind tunnel, and the method comprises the following steps: 1, enabling a fixed mounting kit to be detachably sleeved with a small polish rod pulsating pressure sensor of a sensor assembly, and forming amounting assembly; and 2, detachably connecting the mounting assembly with a model measurement part. The fixed mounting kit comprises a first sealing ring, a first pressing ring, a second sealing ring and a fixing part; the sensor assembly comprises a small polish rod pulsating pressure sensor, a sensor cable and a temperature compensation unit; and the model mounting part is coaxially provided with an air flow hole and an mounting hole, and the air flow hole is communicated with the mounting hole. The mounting and fixing structure is small in enveloping size, reliable in fixation, convenient to disassemble and suitable for experimental researches such as static pressure, space total pressure or pitot pressure and boundary layer parameter measurement in the high-enthalpy pulse wind tunnel.

Owner:中国空气动力研究与发展中心空天技术研究所

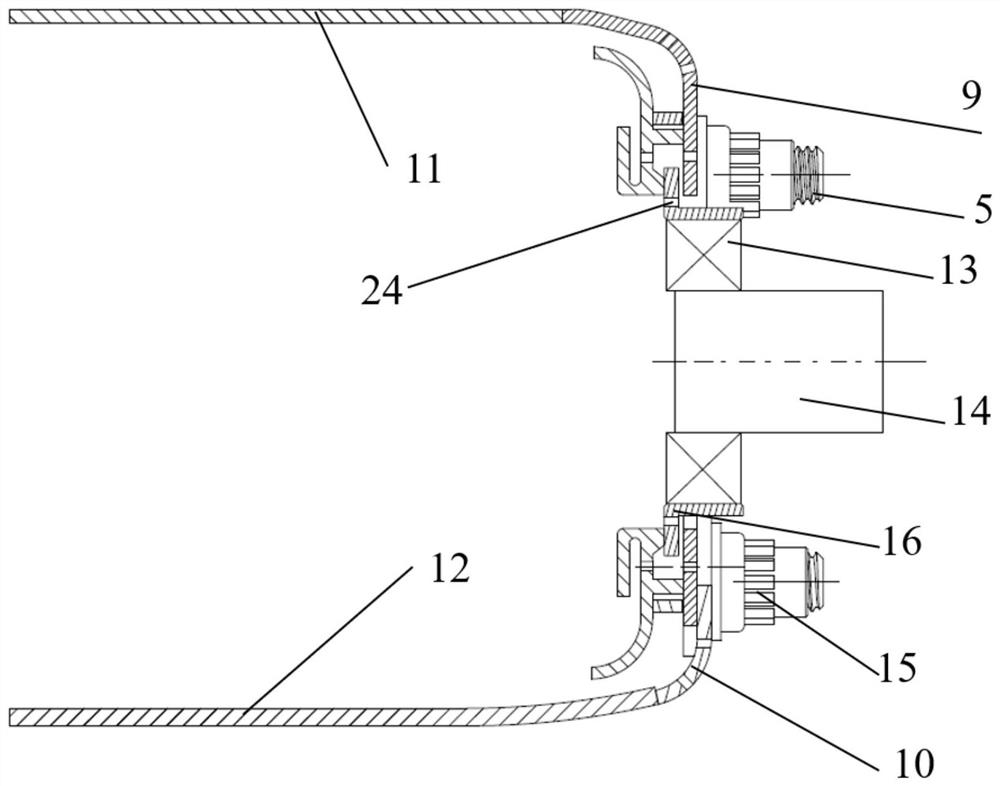

Filling-discharging drift tube seal air nozzle

ActiveCN110939761AEasy to measureExtend your lifeCheck valvesFluid pressure measurementDrift tubeAirflow orifice

The invention belongs to the technical field of drift tube sealing, in particular to a filling-discharging drift tube seal air nozzle, which comprises a cylindrical air nozzle shell with a cavity inside. One end of the air nozzle shell is provided with an oblate matching end face, the other end is provided with an opening communicated with the cavity, the center of the matching end face is provided with a through hole, and the cavity and the through hole are communicated through an air flow hole; a cylindrical ejector pin fixing seat is arranged in the cavity, the top end of the ejector pin fixing seat is close to the air flow hole, and the tail end of the ejector pin fixing seat is close to the opening; an ejector pin connected with a spring is arranged in the ejector pin fixing seat, thetop end of the ejector pin is close to the air flow hole and is provided with a chassis, when the tail end of the ejector pin is not stressed, the chassis is tightly pressed on the top end of the ejector pin fixing seat under the action of the spring to form a seal; and when the tail end of the ejector pin is pushed in the direction of the air flow hole, the chassis is out of contact with the topend of the ejector pin fixing seat, and a passage capable of passing through the air flow is formed between the chassis and the top end of the ejector pin fixing seat.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

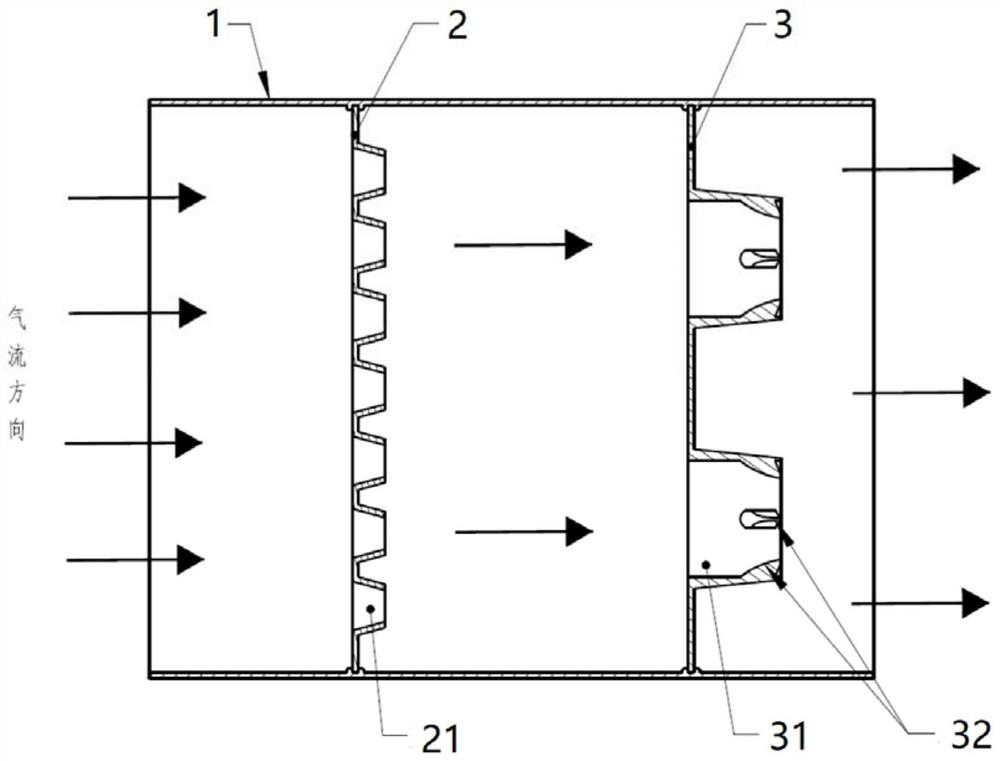

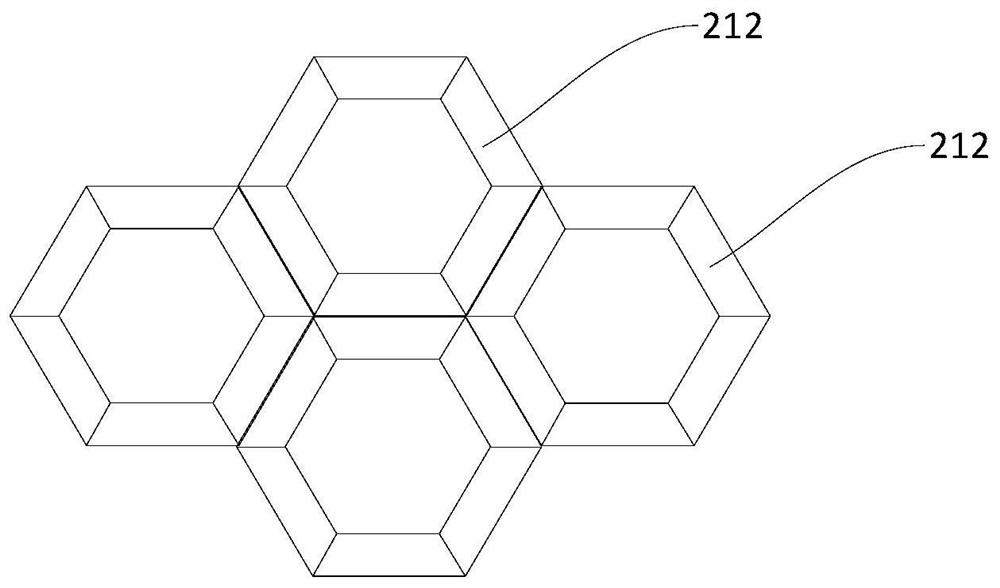

Airflow cooling and noise reduction device and compressor

PendingCN113294319ASolve the noiseSolve the cooling problemPositive displacement pump componentsPositive-displacement liquid enginesEngineeringAirflow orifice

The embodiment of the invention discloses an airflow cooling and noise reduction device and a compressor. The airflow cooling and noise reduction device comprises an air duct, a passive acceleration section and a flow dividing section, wherein the passive acceleration section is fixed in the air duct and passively accelerates and cools airflow. At least one porous plate is arranged in the passive acceleration section; and the porous plate is provided with a plurality of airflow holes with the air inlet end sectional area larger than the exhaust end sectional area. According to the airflow cooling and noise reduction device provided by the invention, a step-by-step vibration reduction manner is adopted, and a two-stage vibration reduction and noise reduction scheme of passively accelerating energy attenuation and flow dividing is adopted for high-temperature and high-speed gas, so that the problem that noise and heat dissipation cannot be considered at the same time due to the too single vibration reduction and noise reduction manner in the prior art is effectively solved; and therefore, the service cycle of air-cooled products such as the compressor is effectively prolonged, and the safety of a user and the surrounding environment is guaranteed.

Owner:SHENZHEN COMEN MEDICAL INSTR

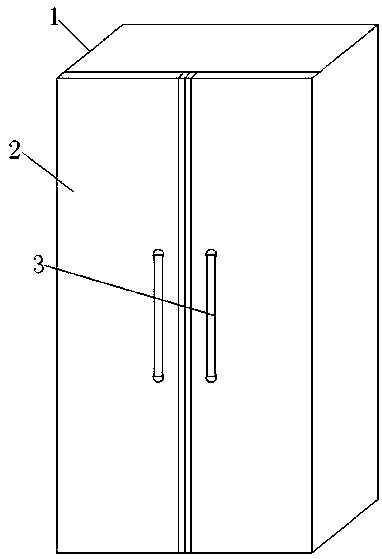

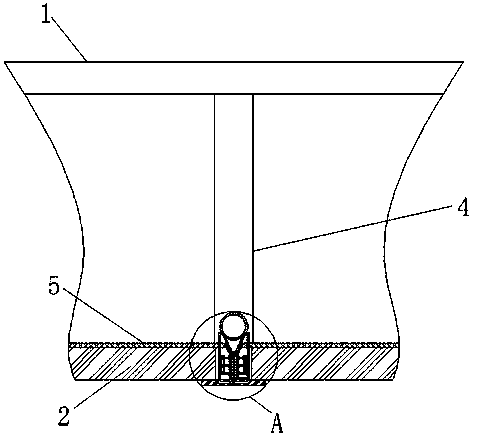

An anti-condensation device for a side-by-side refrigerator

ActiveCN108955043BNo condensationEasy to passLighting and heating apparatusCooling fluid circulationIceboxEngineering

The invention discloses an anti-condensation device used for a side-by-side combination refrigerator. The anti-condensation device comprises a refrigerator body, two refrigerator doors and two handles; one side of each of the two refrigerator door is hinged to the refrigerator body; the other sides of the two refrigerator doors are resisted against each other; the handles are fixedly connected tosidewalls of the corresponding refrigerator doors; and hot air in an anti-condensation pipe is emitted through heat dissipation holes, passes through a ventilation hole in a connection plate, and thenis blown to sponge blocks, so that the temperature of the sponge blocks cannot be excessively different from that of the outside, and thus condensation is avoided. The hot air flows out of first ventilation pipes and flows out of air flow holes through second ventilation pipes, so that condensation at the connection parts of two sealing strips is also prevented; the heat of the first ventilationpipes is transmitted to sleeves; then heat is conducted through heat conduction rods, so that heat transmission is accelerated; finally, the heat is transmitted to rubber blocks from extrusion rods; the heat is dissipated by the rubber blocks, so that temperature difference is changed; and condensation is prevented.

Owner:合肥美科制冷技术有限公司

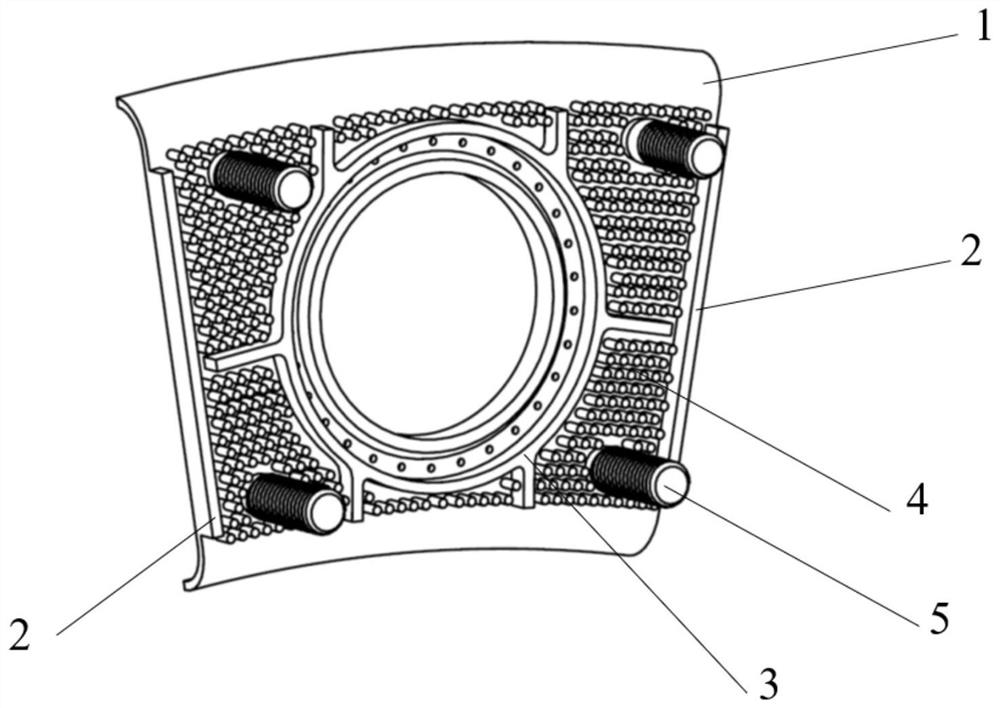

Efficient cooling structure of flame tube head

ActiveCN112484077AIncrease the heat exchange areaReduce wall temperatureContinuous combustion chamberCold airCombustion chamber

The invention relates to an efficient cooling structure of a flame tube head. The structure can be applied to head cooling of combustion chambers of gas turbines and aero-engines, and a flow guide plate is of an integrated structure and comprises a flow guide plate base plate, columnar protrusions, cooling airflow holes, straight ribs on the left side and the right side, a central circular rib, connecting pieces and the like. The flow guide plate is installed on a flame tube head end plate through the connecting pieces, cold air entering from a flame tube flows through the gaps between the columnar protrusions, the gaps between the columnar protrusions and the ribs and the gaps between the columnar protrusions and the connecting pieces, air flow bypasses the multiple columnar protrusions and efficiently cools the flow guide plate and the flame tube head through the gaps, and the wall surface temperature is reduced. The flow guide plate in the structure is simple in structure and can beformed through casting or additive manufacturing printing, compared with a traditional flame tube head flow guide plate structure, the heat exchange area is obviously increased, and the service lifeof the flame tube head and the flow guide plate can be obviously prolonged.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

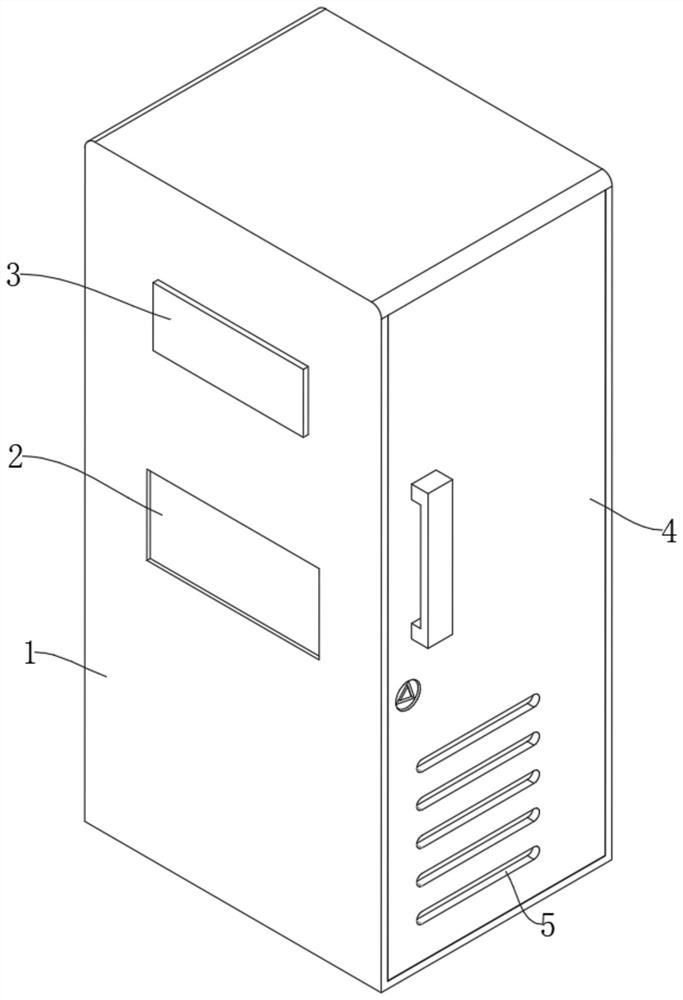

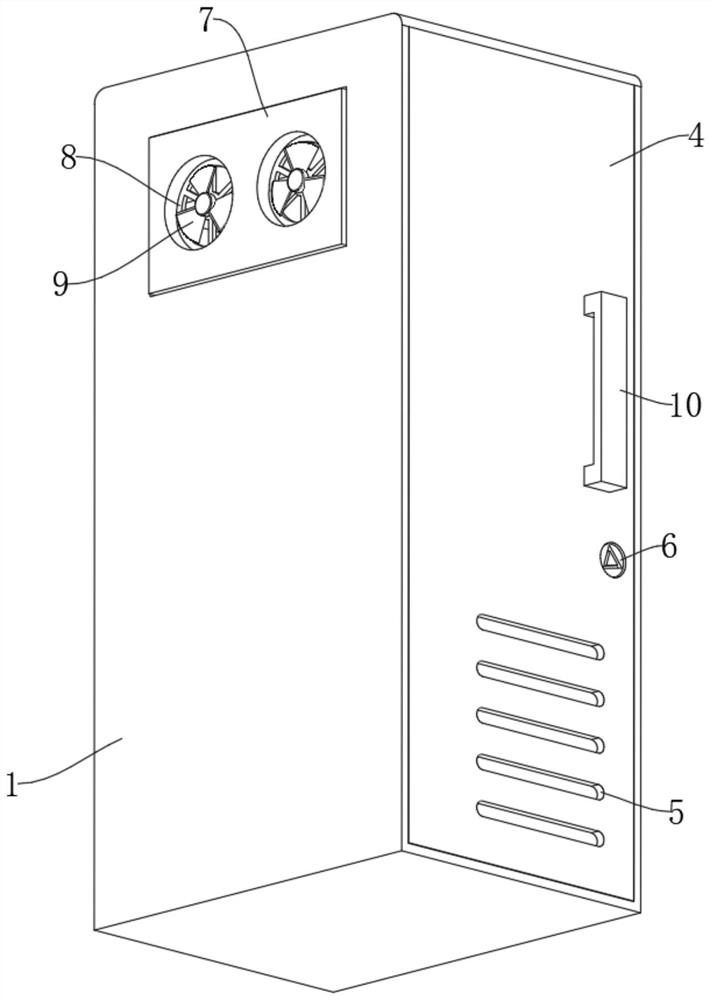

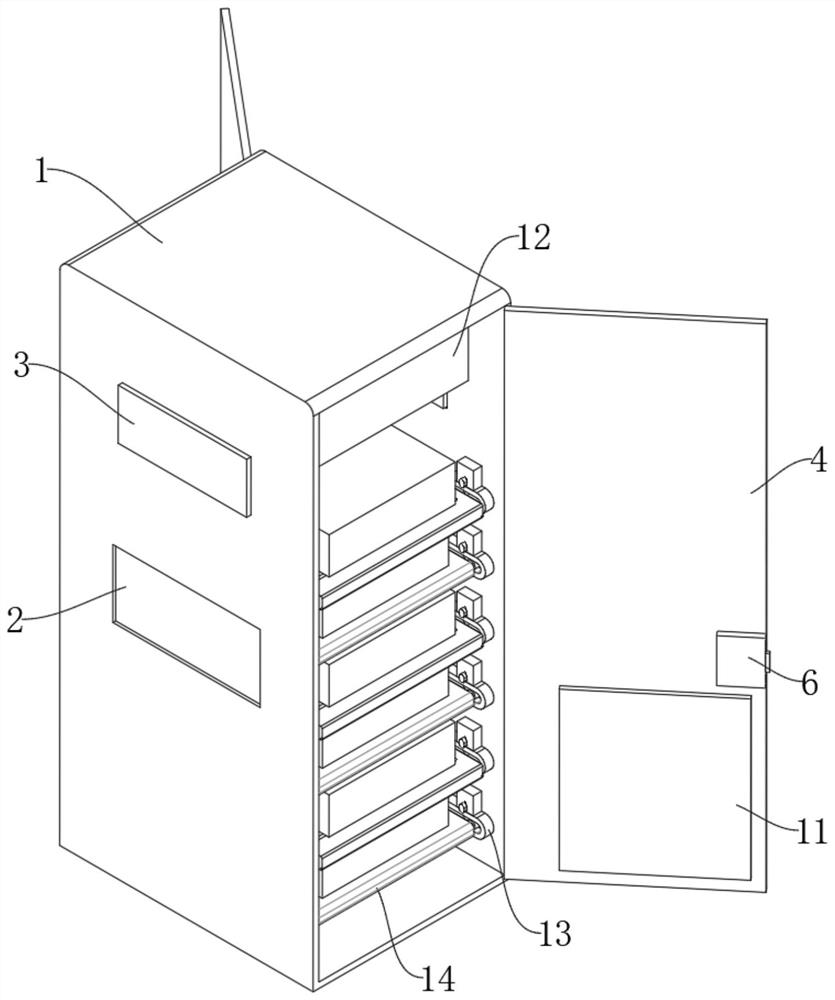

Industrial internet intelligent control system convenient to maintain and use method thereof

PendingCN113867296AEasy maintenanceFacilitate later maintenance and repairTotal factory controlProgramme total factory controlControl engineeringControl cell

The invention provides an industrial internet intelligent control system convenient to maintain and a using method thereof, and belongs to the field of industrial internet intelligent control devices. The system comprises a box body; a plurality of supporting plates that are arranged between the upper inner wall and the lower inner wall of the box body in parallel from top to bottom, and an airflow hole is formed in the top of each supporting plate; a plurality of integrated control units which are fixedly connected to the tops of the multiple supporting plates correspondingly, wherein the two rotating shafts drive the two power rolling wheels to roll at the tops of the two sliding sleeves, and the two power rolling wheels pushes the four auxiliary rolling wheels to slide in the two sliding sleeves, so that the supporting plate is pushed outwards from the inside of the box body, the damaged integrated control unit is pushed out. According to the structure, the damaged integrated control unit can be pushed out, single-layer maintenance can be carried out when a single integrated control unit is damaged, and overall power-off maintenance is not needed; the structure simplifies maintenance, facilitates later maintenance, and improves the maintenance efficiency.

Owner:崔晨雨

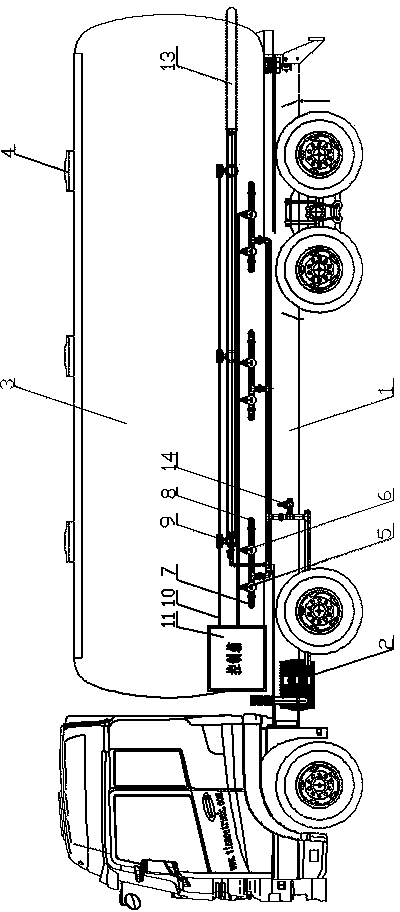

Powder and particle material transport vehicle

InactiveCN103434768AAvoid affecting efficiencyIncreased fluidization speedLarge containersFluidized bedControl system

The invention discloses a powder and particle material transport vehicle which comprises an automobile chassis, a tank, an air compressor and an unloading control system, wherein fluidized beds which are arranged in a centralized way towards the center layer by layer are adopted as a plurality of branch bins of the tank; the powder and particle material transport vehicle has the structure that a plurality of layers of main guide plates which are gradually lowered towards the center are symmetrically arranged at the two sides of the length direction of each branch bin by taking a discharge hole as the center; diversion air holes are respectively arranged between air chambers under the plurality of layers of main guide plates and the main guide plates; the direction of the air flow of the diversion air holes are set towards the discharge hole; an air flow hole is formed in a clapboard between each air chamber and each diversion air hole; two side guide plates are symmetrically arranged at the two sides of each branch bin; the lower part of each side guide plate is provided with a lower layer diversion air hole; the direction of the air flow of the main guide plate and the side guide plate at the bottommost layer is set towards the center of the discharge hole, so that a rectangular region can be formed; particles or powder can be blown to the discharge hole and is collided with the air flow which is blown head-on, so that the residual material in the tank can be thoroughly removed. The powder and particle material transport vehicle is suitable for bulk grain particles and bulk cement powder.

Owner:SHIYAN DAY SPECIAL PURPOSE VEHICLE TECH DEV

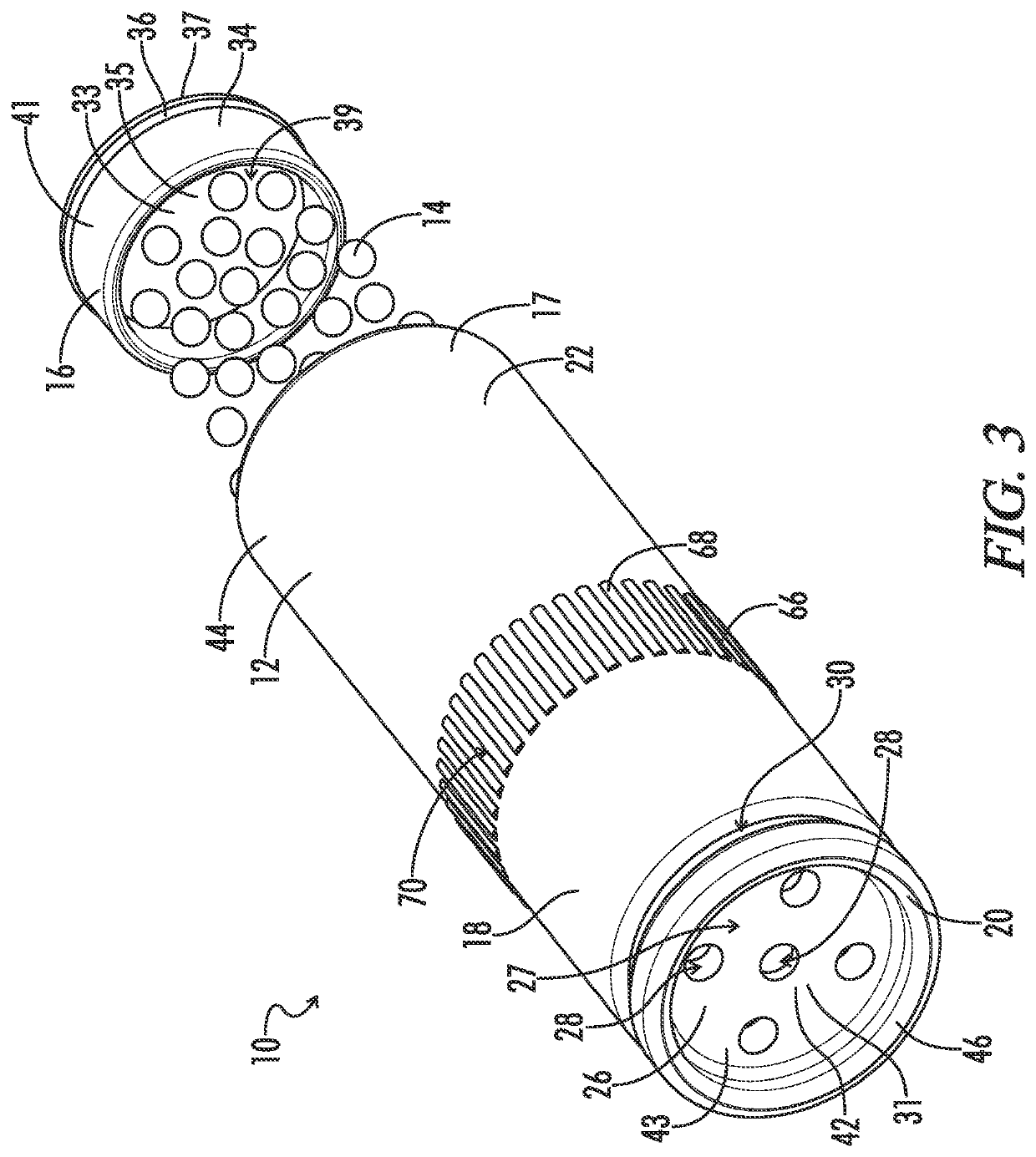

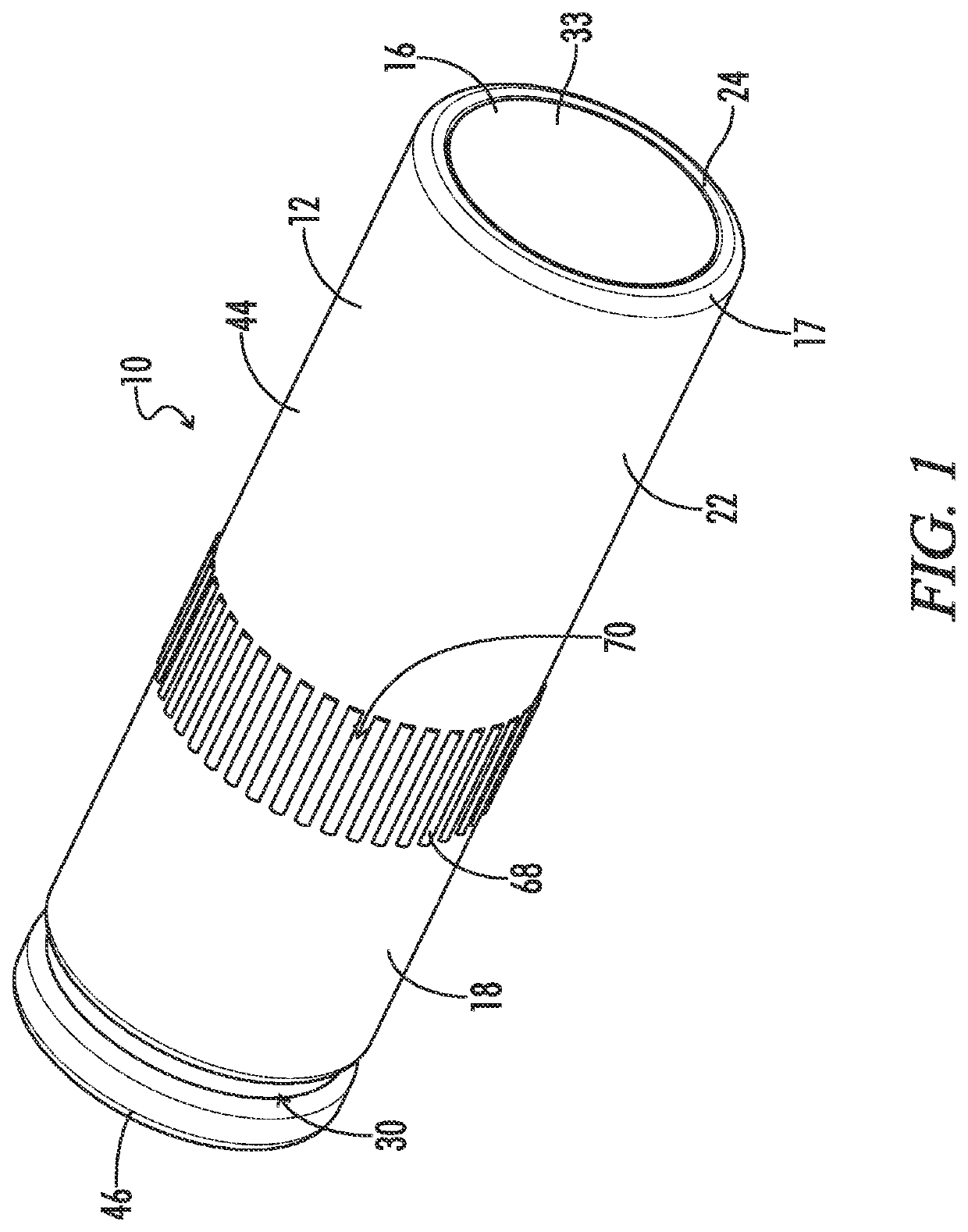

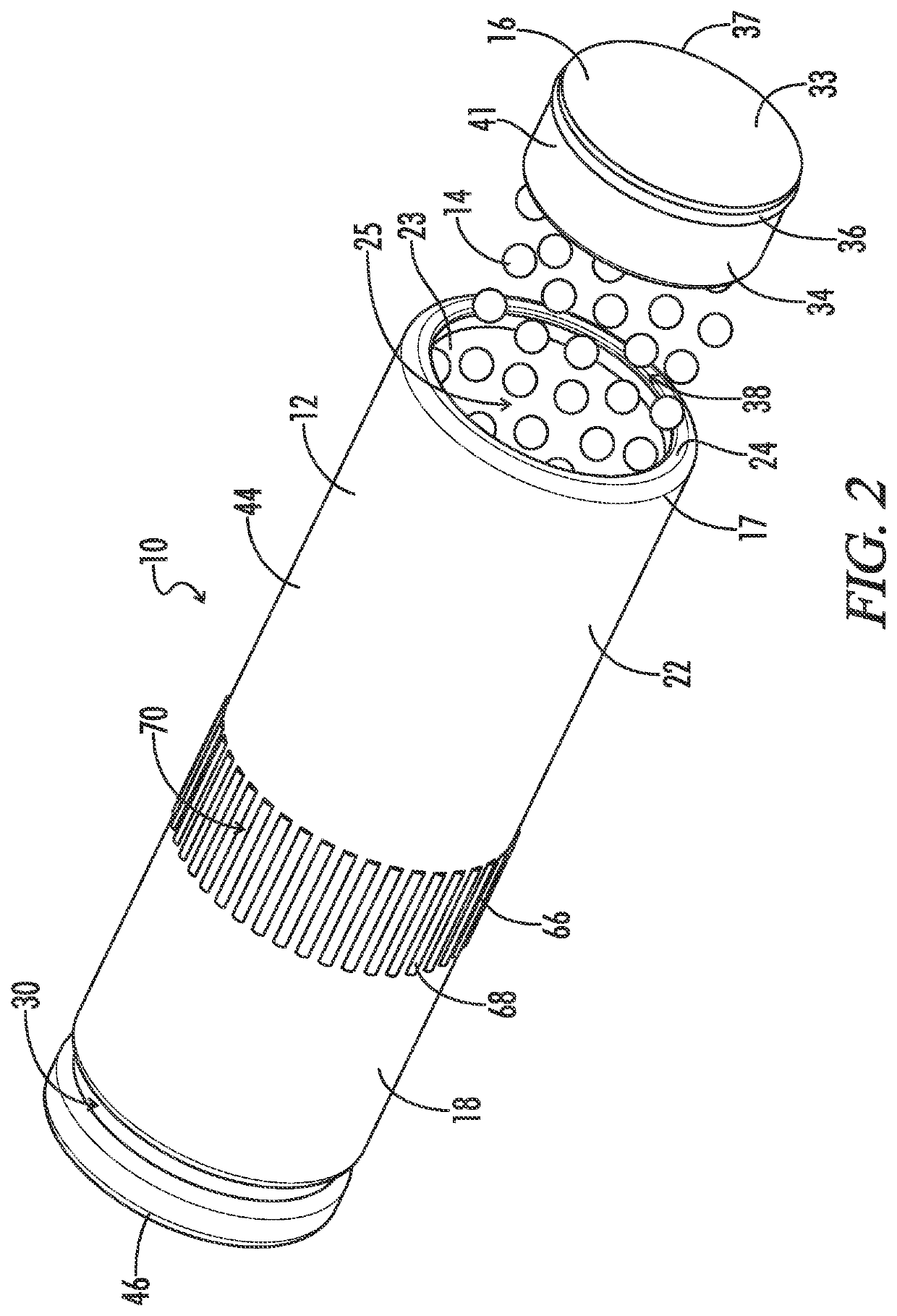

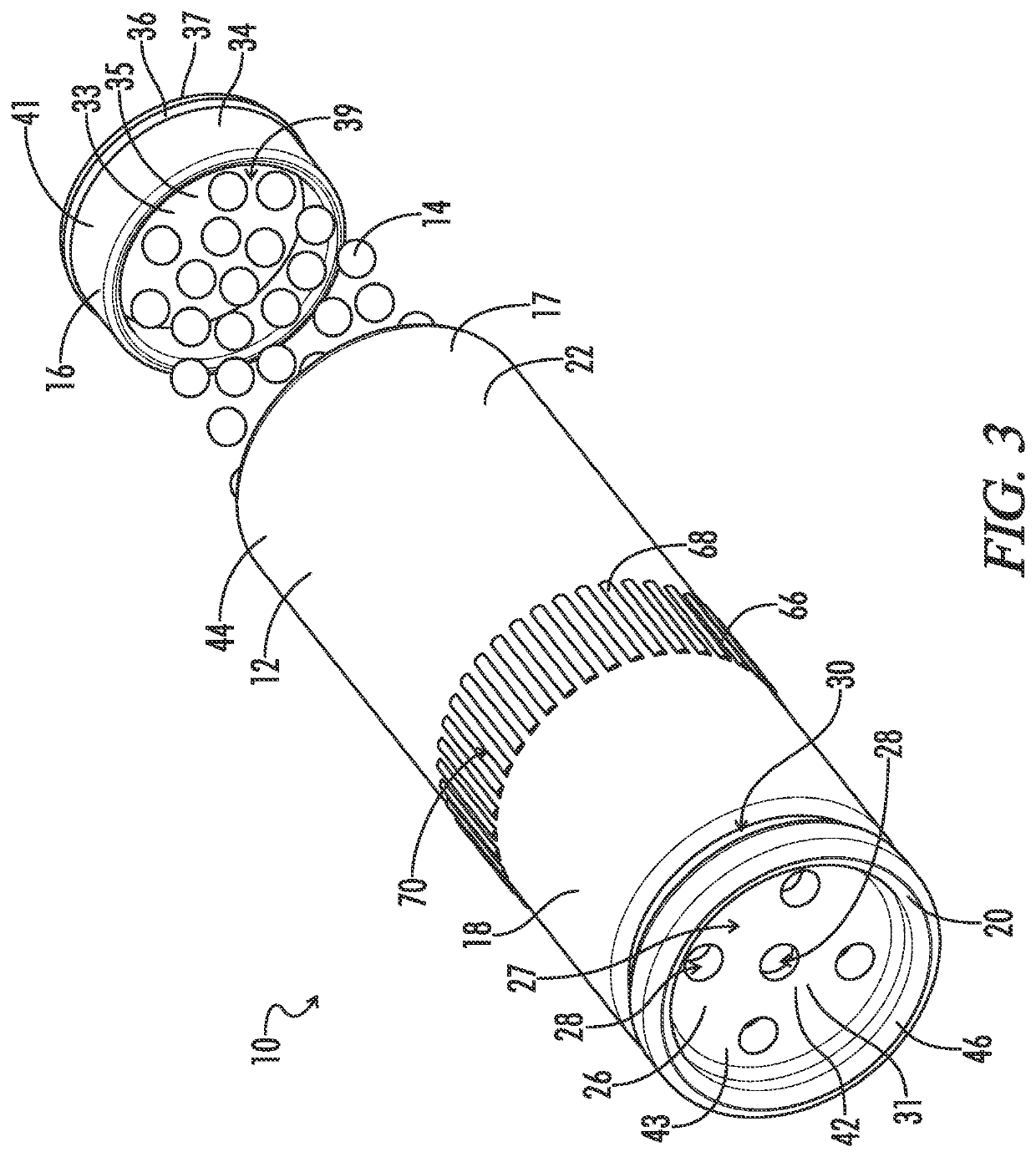

Ammunition cartridge for an air gun

ActiveUS20210381812A1Improve operational capabilitiesAccuracyAmmunition projectilesCartridge ammunitionInterior spaceAirgun pellet

An ammunition cartridge for an air gun includes a housing, a partition, a cap, at least one projectile, and at least one gas flow aperture. The housing defines an interior space. The housing has a rear portion and a forward portion. The partition is disposed in the interior space and engaged with the rear portion. The cap is releasably engaged with the forward portion. The at least one projectile is received in the interior space between the partition and the cap. The at least one gas flow aperture extends through the partition and provides a fluid flow path through which a pressurized gas provided by the air gun enters and pressurizes the interior space to propel the cartridge through a barrel bore of the air gun.

Owner:BRAUN JOEL

Ammunition cartridge for an air gun

ActiveUS11402184B2Improve operational capabilitiesAccuracyAmmunition projectilesCartridge ammunitionInterior spaceAirgun pellet

Owner:BRAUN JOEL

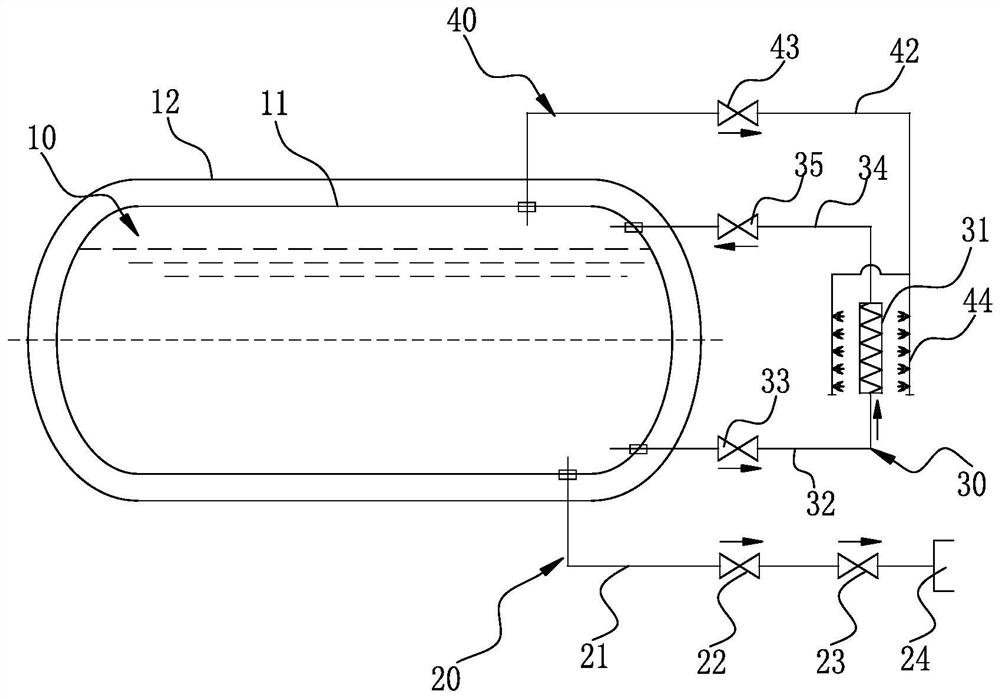

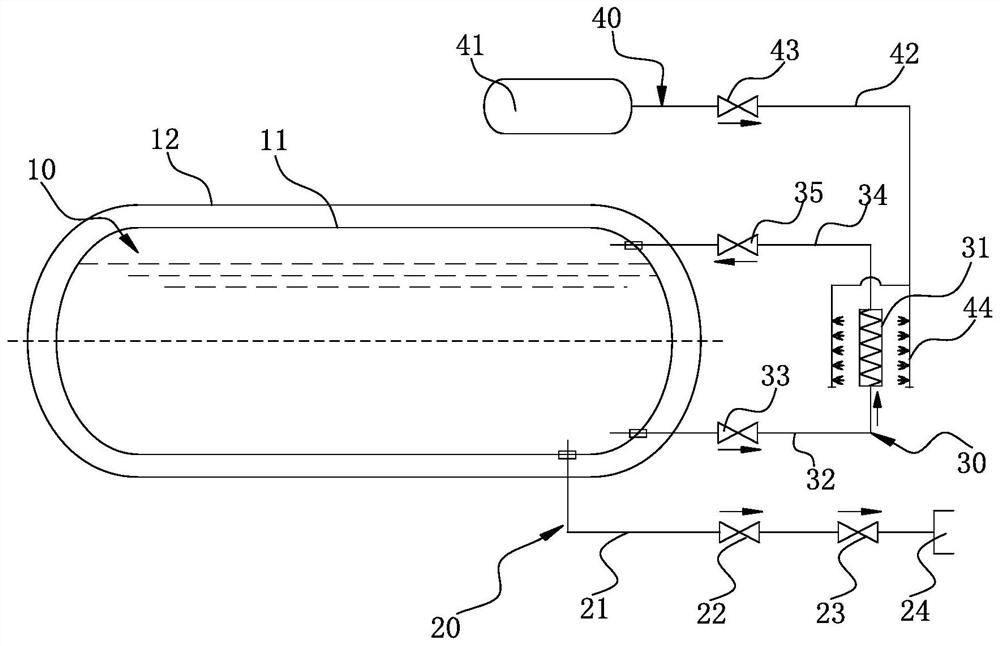

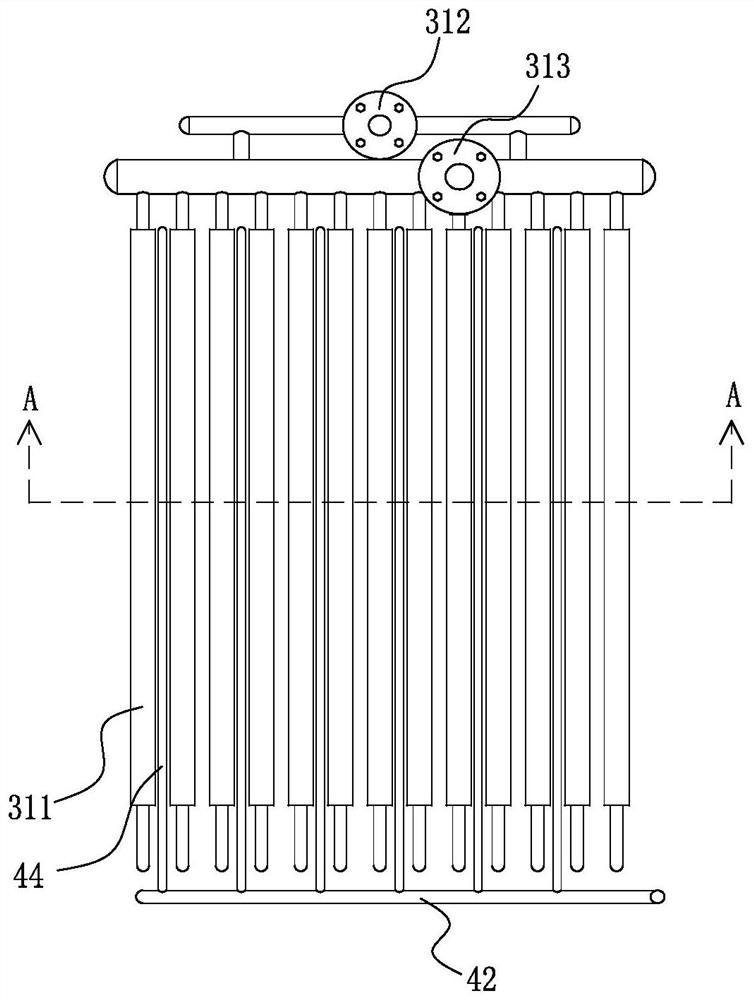

Low-temperature tank truck

PendingCN111878696ARealize the function of defrostingGuaranteed vaporization effectTank vehiclesVessel geometry/arrangement/sizeTank truckControl valves

The invention relates to a low-temperature tank truck. The low-temperature tank truck comprises a storage tank, a vaporizer and a defrosting unit; the vaporizer communicates with the storage tank; thedefrosting unit comprises a high-pressure gas source, a connecting pipe, a control valve and a blowing pipe the high-pressure gas source, the connecting pipe and the blowing pipe sequentially communicate; the control valve is arranged on the connecting pipe; and the blowing pipe is arranged close to the vaporizer, and a plurality of gas flow holes are formed in the blowing pipe and face the vaporizer. According to the tank truck, the defrosting unit is additionally arranged on the vaporizer of the tank truck; the blowing pipe is arranged close to the vaporizer and matched with the gas flow holes in the blowing pipe, and the defrosting operation is conducted on the vaporizer through high-pressure gas provided by the high-pressure gas source; and when the surface of the vaporizer frosts dueto long-time work, the control valve can be opened to enable the high-pressure gas in the high-pressure gas source to be blown to the vaporizer at a high speed through the gas flow holes, so that frost covering the surface of the vaporizer is blown off, the function of defrosting the vaporizer is achieved, and the vaporization effect of the vaporizer is effectively guaranteed.

Owner:CIMC JINGMEN HONGTU SPECIAL AIRCRAFT MFG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com