Airflow sensor and oleophobic and hydrophobic treatment method

An airflow sensor and hydrophobic treatment technology, applied in the field of sensors, can solve the problems of not being able to pass through the airflow sensor, block the air holes of the dust-proof net, reduce the service life of electronic cigarettes, etc., and achieve the effect of simple process and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

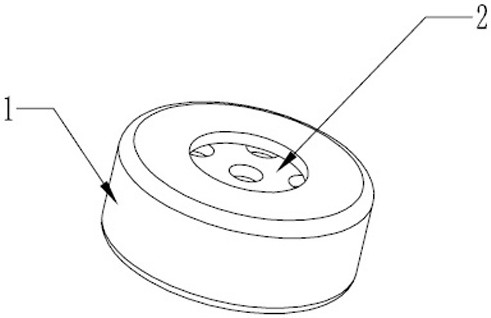

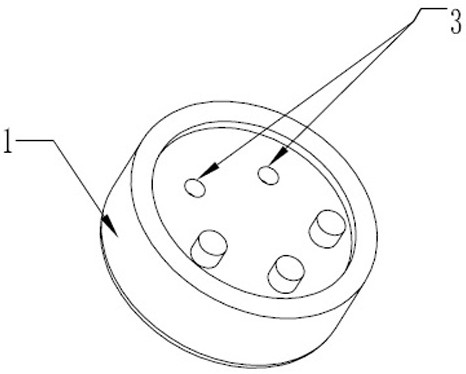

[0047] Example 1, such as figure 1 , 2 , 6 and 8, an airflow sensor includes an airflow sensor body 1, the airflow sensor body 1 is a hollow cylindrical tube, the top of the airflow sensor body 1 is provided with an airflow hole 2, and the bottom of the airflow sensor body 1 is provided with an air inlet 3. An air outlet protective film 4 is fixed on the airflow hole 2, and the air outlet protective film 4 just covers the top of the airflow sensor body 1, and an air inlet protective film 5 is fixed on the air inlet 3, and the air inlet protective film 5 just covers the top of the airflow sensor body 1. Air intake hole 3.

Embodiment 2

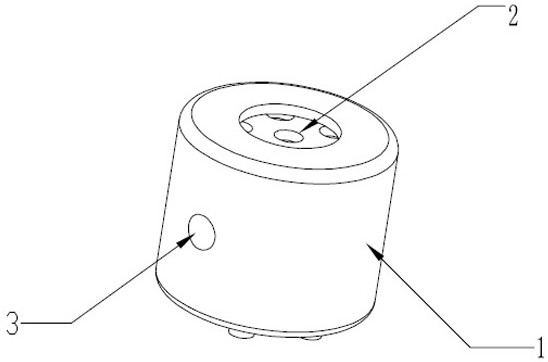

[0048] Example 2, such as image 3 , 7 As shown in and 9, another airflow sensor has basically the same structure as the above-mentioned airflow sensor, the only difference is that the air inlet 3 is arranged on the side of the airflow sensor body 1, and an air inlet protective film 5 is fixed on the air inlet 3, Air inlet protective film 5 just covers air inlet 3.

[0049] The structure of the airflow sensor also has various forms, and its structure is roughly similar.

[0050] The air outlet protective film 4 and the air inlet protective film 5 are respectively oleophobic and water repellent treated protective films, which have the same structure and composition, and are referred to as the air outlet protective film 4 and the air inlet protective film 5 for convenience of description.

[0051] There are two types of protective film, the first is a single-layer PTFE film, and the second is a double-layer protective film composed of PTFE film + non-woven fabric.

[0052] PT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com