Filling-discharging drift tube seal air nozzle

A drift tube, filling and deflating technology, applied in the field of drift tube sealing, can solve the problems of gas leakage in the tube, inability to replace the gas, test performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

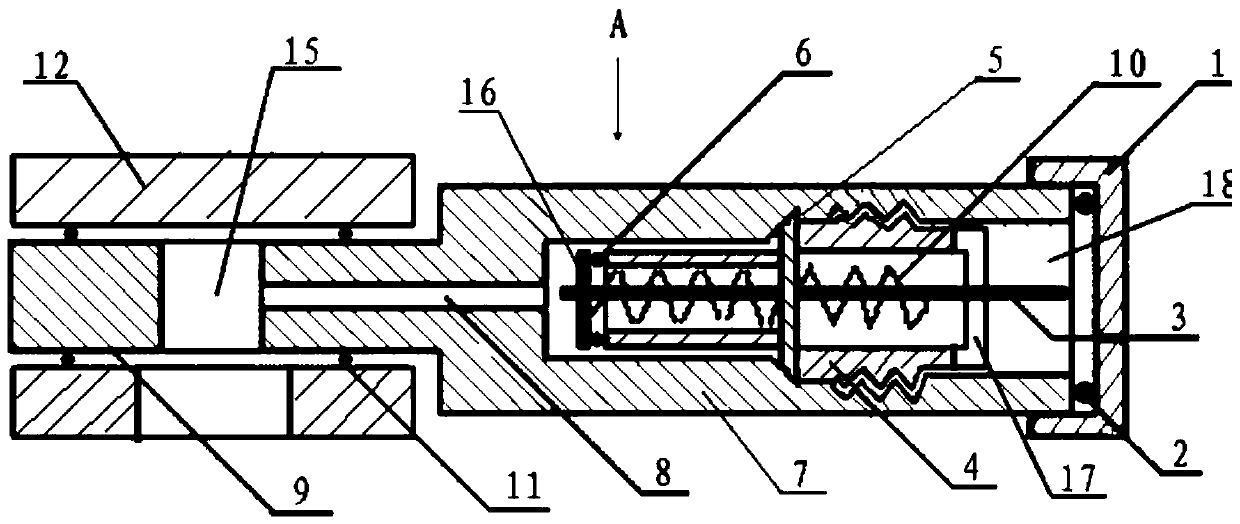

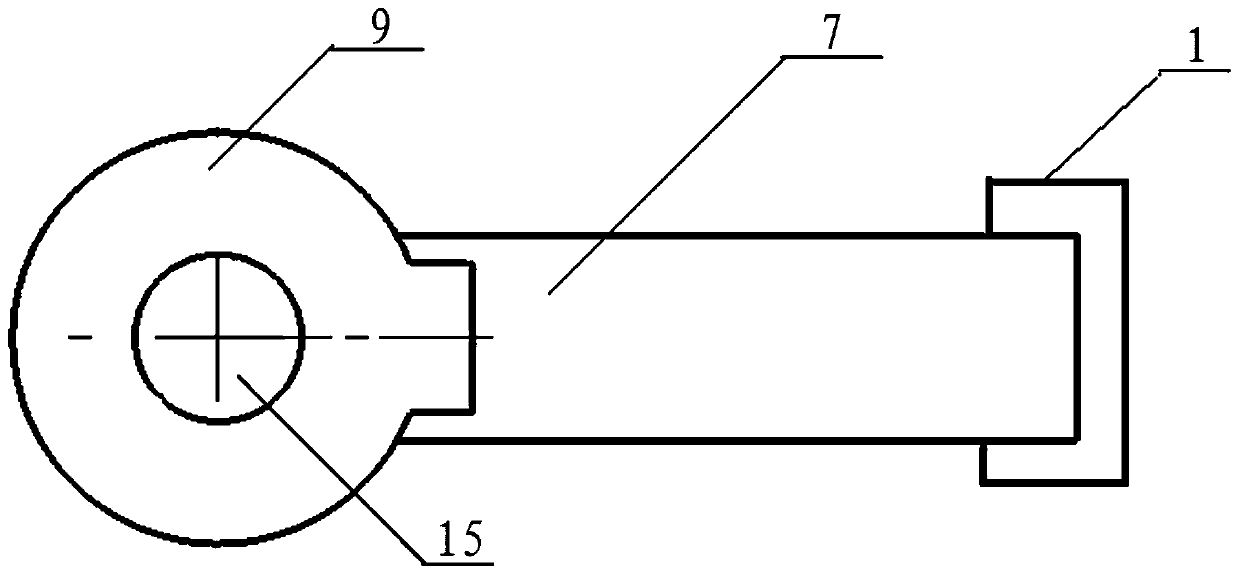

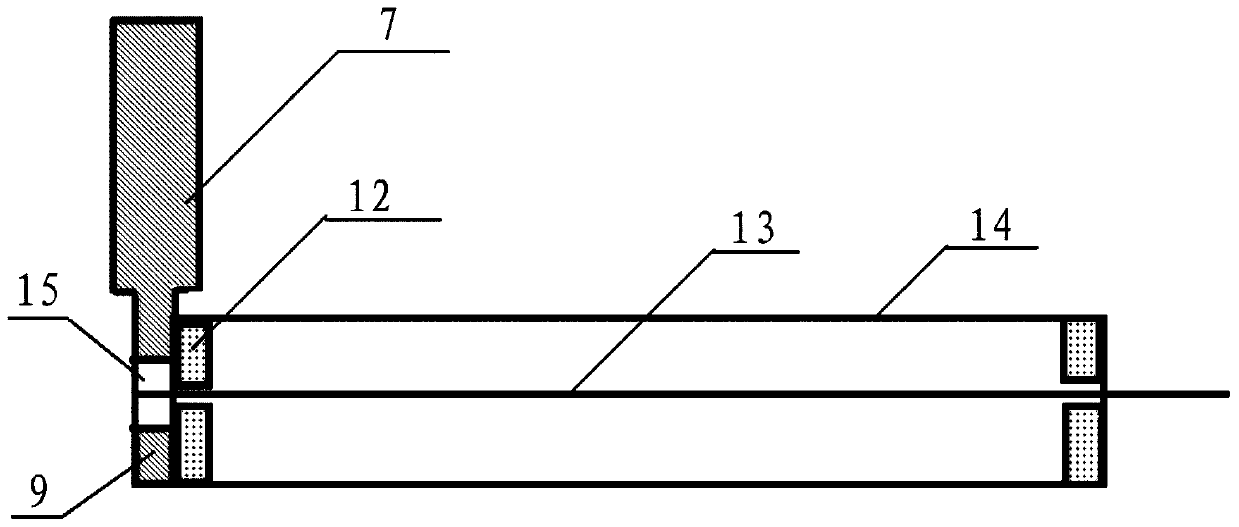

[0027] Such as Figure 1 to Figure 3 As shown, an inflatable and deflatable drift tube sealing nozzle provided by the present invention is arranged on the connection assembly 12 at the top of the drift tube with an anode wire 13 inside, and is used to realize sealing, inflating, and sealing of the drift tube. Deflate, vacuum function. The inflatable and deflated drift tube sealing air nozzle includes a cylindrical air nozzle housing 7 with a cavity inside; The connected opening 18 is provided with a through hole 15 in the center of the matching end face 9, through which the fixing head of the anode wire 13 passes, and the cavity communicates with the through hole 15 through the airflow hole 8; a cylindrical thimble is arranged in the cavity to fix Seat 4, the sealing connection between the thimble fixing seat 4 and the air nozzle shell 7, the top of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com