Heat sink assembly

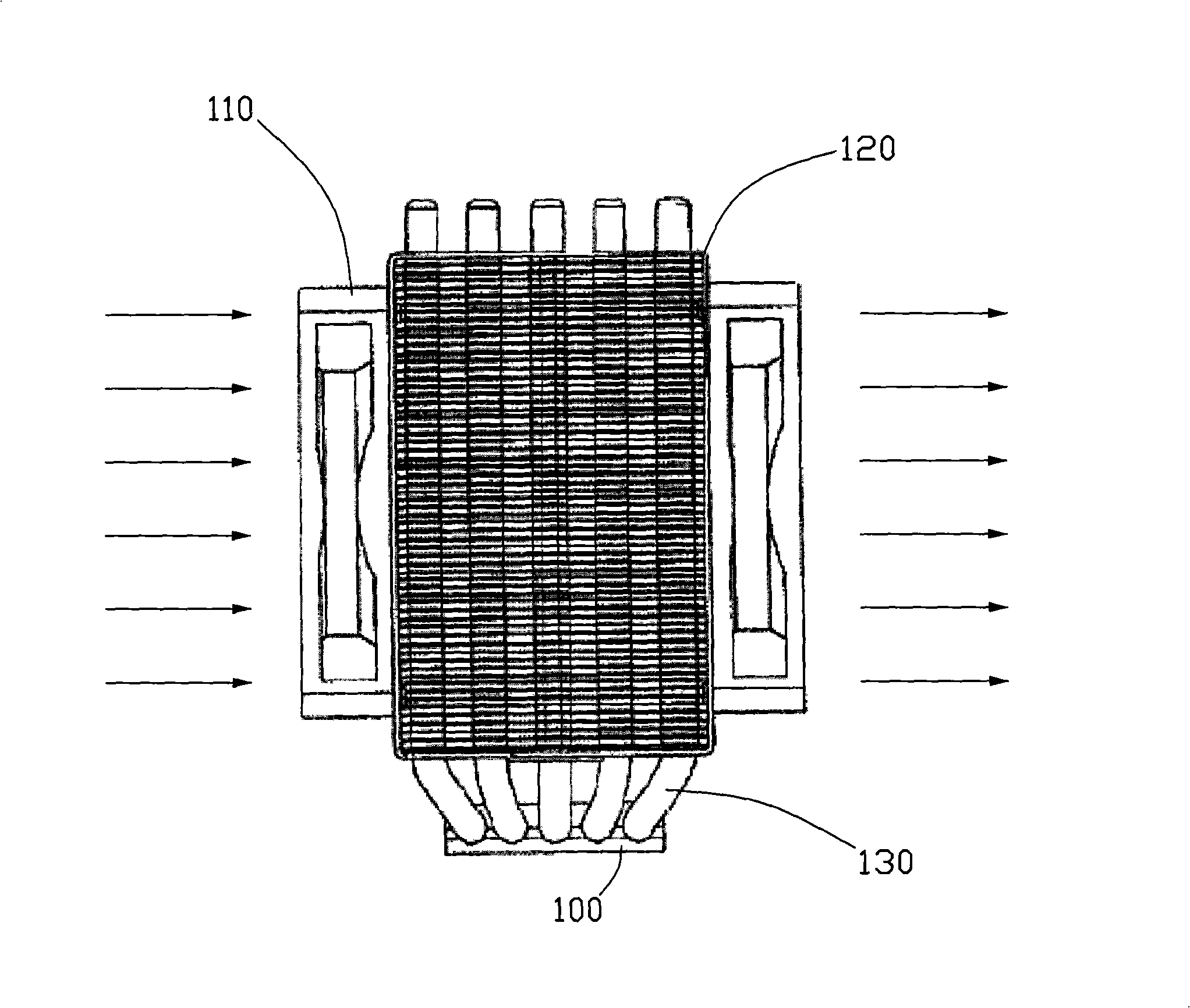

A technology of heat dissipation module and heat dissipation fins, applied in cooling/ventilation/heating transformation, electrical components, electric solid state devices, etc., can solve the problems of affecting the natural convection of fins, low airflow utilization rate of fan 110, etc., to improve heat dissipation The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

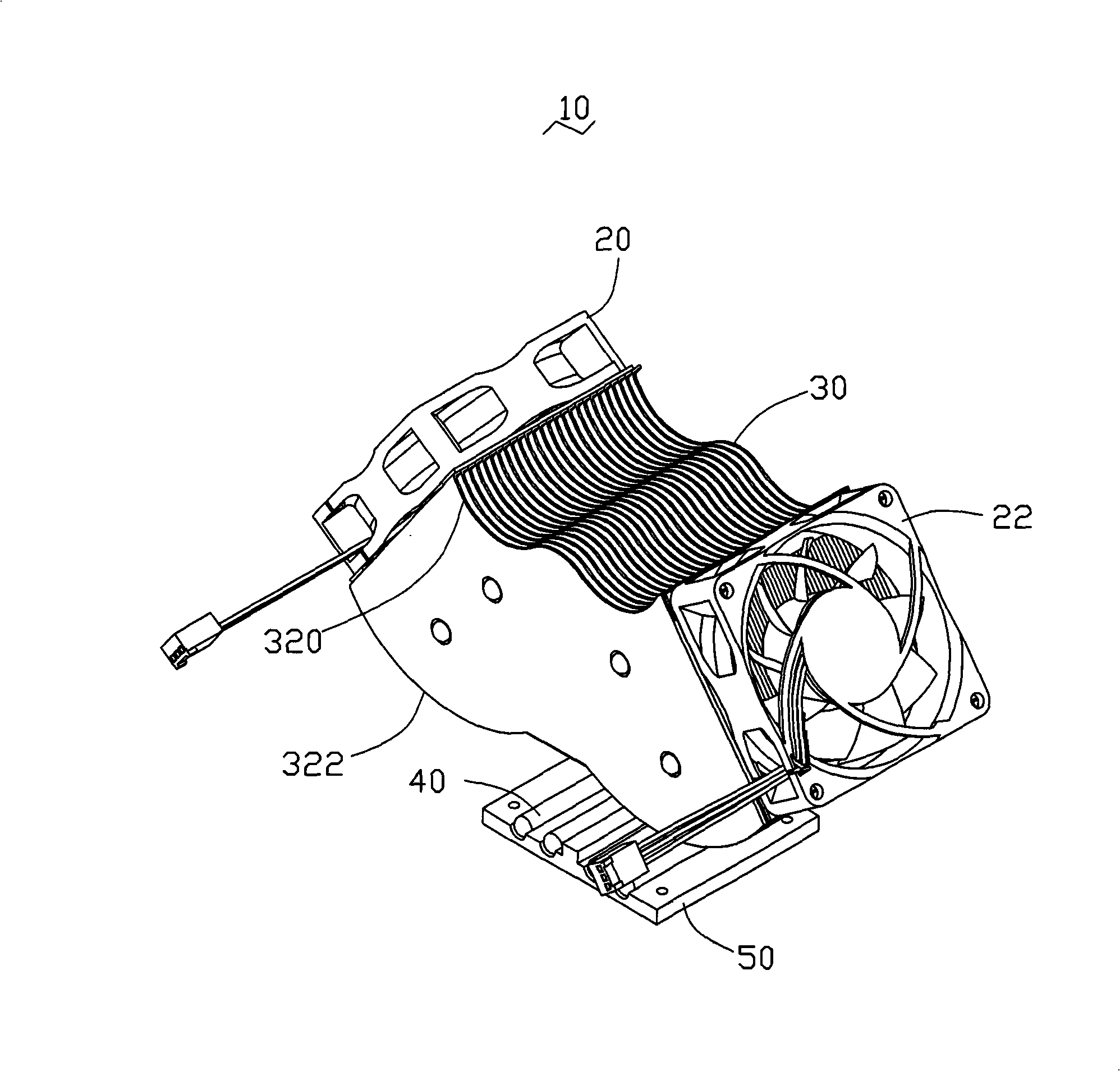

[0016] The heat dissipation module according to the first embodiment of the present invention is used to be installed on heat-generating electronic components such as a central processing unit (not shown in the figure) to dissipate heat.

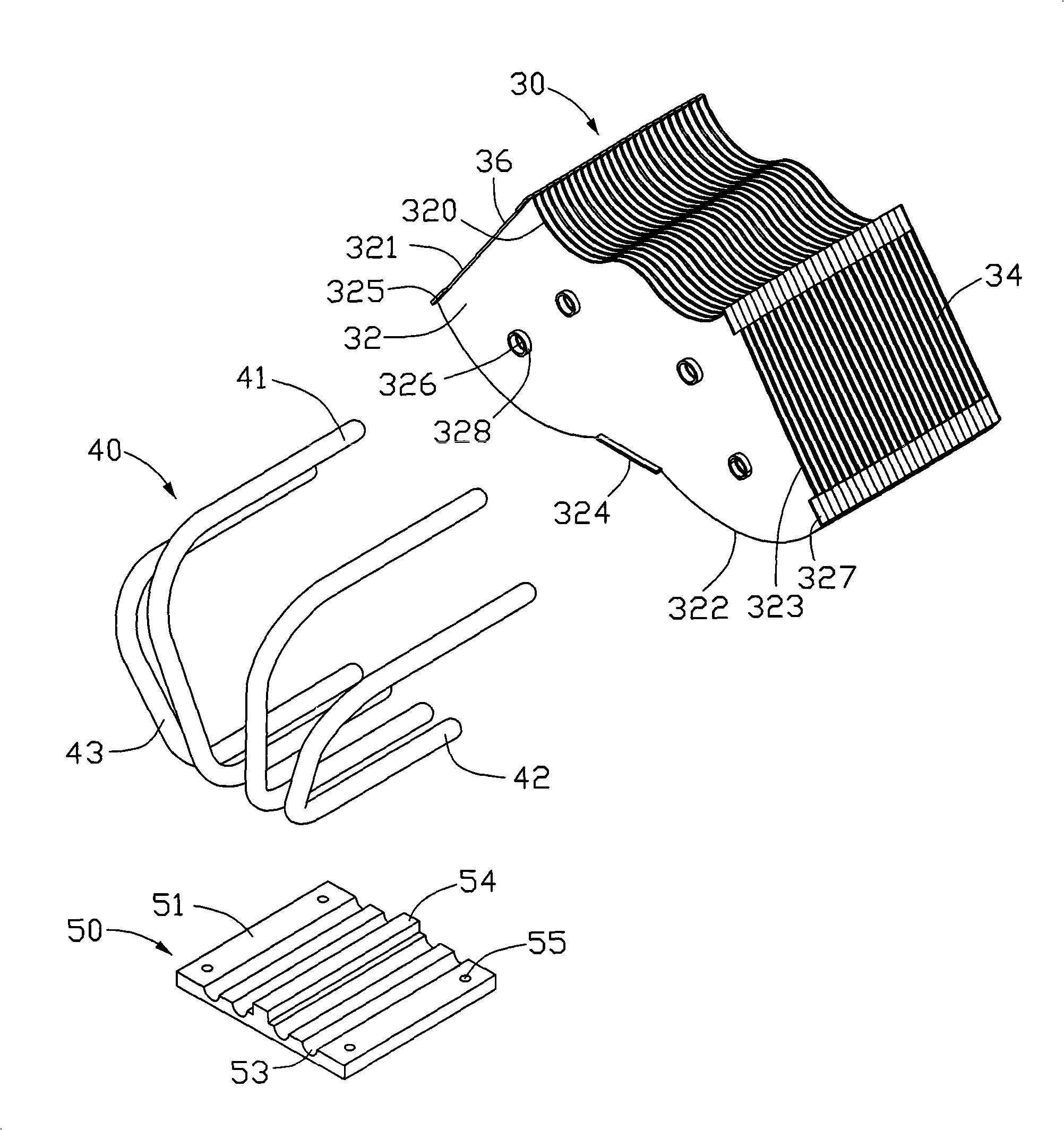

[0017] see Figure 2 to Figure 4 , shows the heat dissipation module 10 of the first embodiment of the present invention. The heat dissipation module 10 includes a heat conduction base 50, a first fin group 30 arranged above the heat conduction base 50 at a certain distance, a plurality of heat pipes 40 connecting the first fin group 30 and the heat conduction base 50, and The first fan 20 and the second fan 22 are arranged on two sides of the first fin set 30 and are inclined relative to each other.

[0018] The heat conduction base 50 is roughly square, and its bottom surface extends downward to form a roughly square bump 52. The lower surface 521 of the bump 52 is used to contact with the heat-generating electronic components; There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com