Double-sealing-ring axial fixing method for small polish rod sensor for high-enthalpy pulse wind tunnel

A technology with axial fixation and double sealing rings, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of narrow measurement space, dense distribution of measurement points and effective test time in milliseconds, and shorten the response time, avoid loosening and movement, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as figure 1 , figure 2 with image 3 As shown, the axial fixation method of the small polished rod sensor for the high-enthalpy pulsed wind tunnel with double sealing rings includes the following steps:

[0033] Step 1: The small-sized polished rod pulsation pressure sensor 6 detachably inserted into the sensor assembly by the fixed installation kit forms an installation assembly;

[0034] Step 2: detachably connect the installation component to the model measurement part 1;

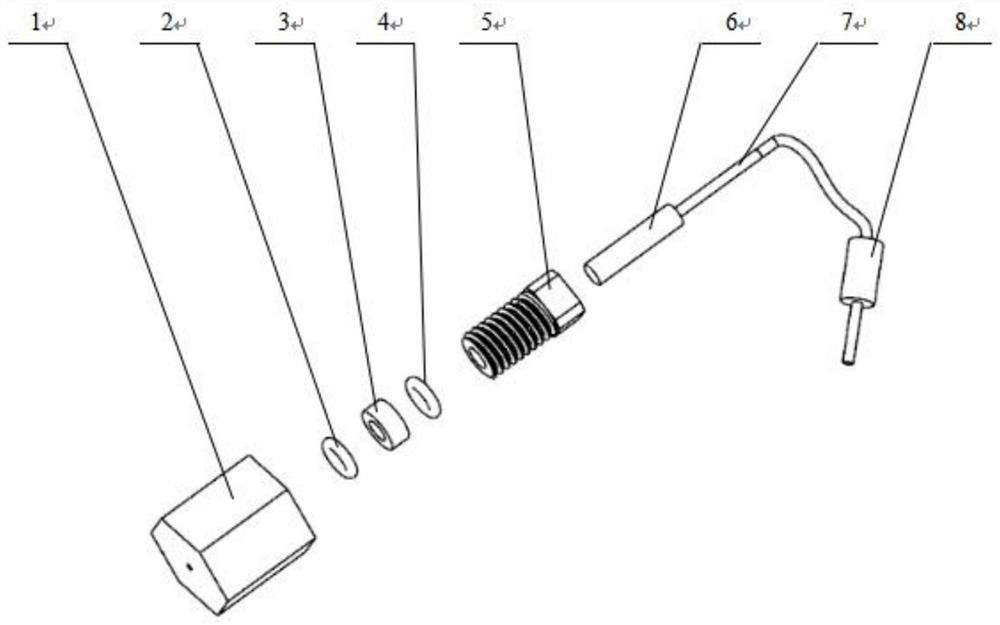

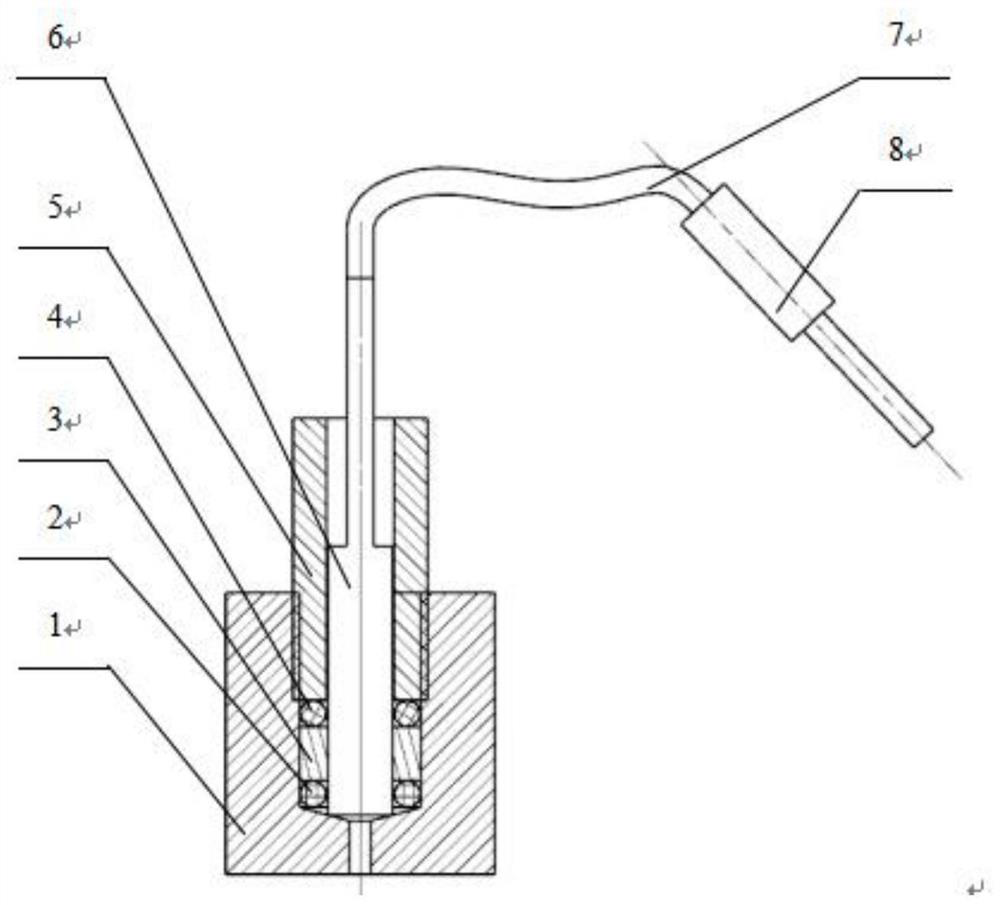

[0035] Wherein, the fixed installation kit includes a first sealing ring 2, a first compression ring 3, a second sealing ring 4 and a fixing part 5, and the sensor assembly includes a small polished rod pulsation pressure sensor 6, a sensor cable 7 and a temperature compensation unit 8;

[0036] Model measurement part 1 is coaxially provided with an airflow hole and a mounting hole, and the airflow hole and the mounting hole are connected, the diameter of the airflow hole is Φ1mm, the de...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the fixing part 5 includes a fixing block 11 and a second pressure ring 10, the fixing block 11 is coaxially provided with a through hole and a counterbore, and the through hole and the counterbore penetrate through, and the second pressure ring The outer diameter of 10 is adapted to the inner diameter of the counterbore, and the inner diameter of the second pressure ring 10 and the inner diameter of the through hole are adapted to the outer diameter of the small polished rod pulsation pressure sensor 6; the fixed block 11 is connected with the model measuring part 1 by screws 12 .

[0044] refer to Figure 4 with Figure 5 , the double seal ring axial fixed structure of the small polished rod sensor used in the high-enthalpy pulsed wind tunnel of Embodiment 2 can be applied to the boundary layer total pressure measurement bent frame 9 composed of three total pressure measurement points, and the sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com