Method for serially connecting valves and improving burner into gas cooker capably of controlling temperature and intensifying fire to form vigorous fire

A cooker and gas technology, which is applied to the inner and outer ring gas channel burners, the front manual gas switch and the temperature control solenoid valve, and can solve the problems of gas cookers that do not specify the temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

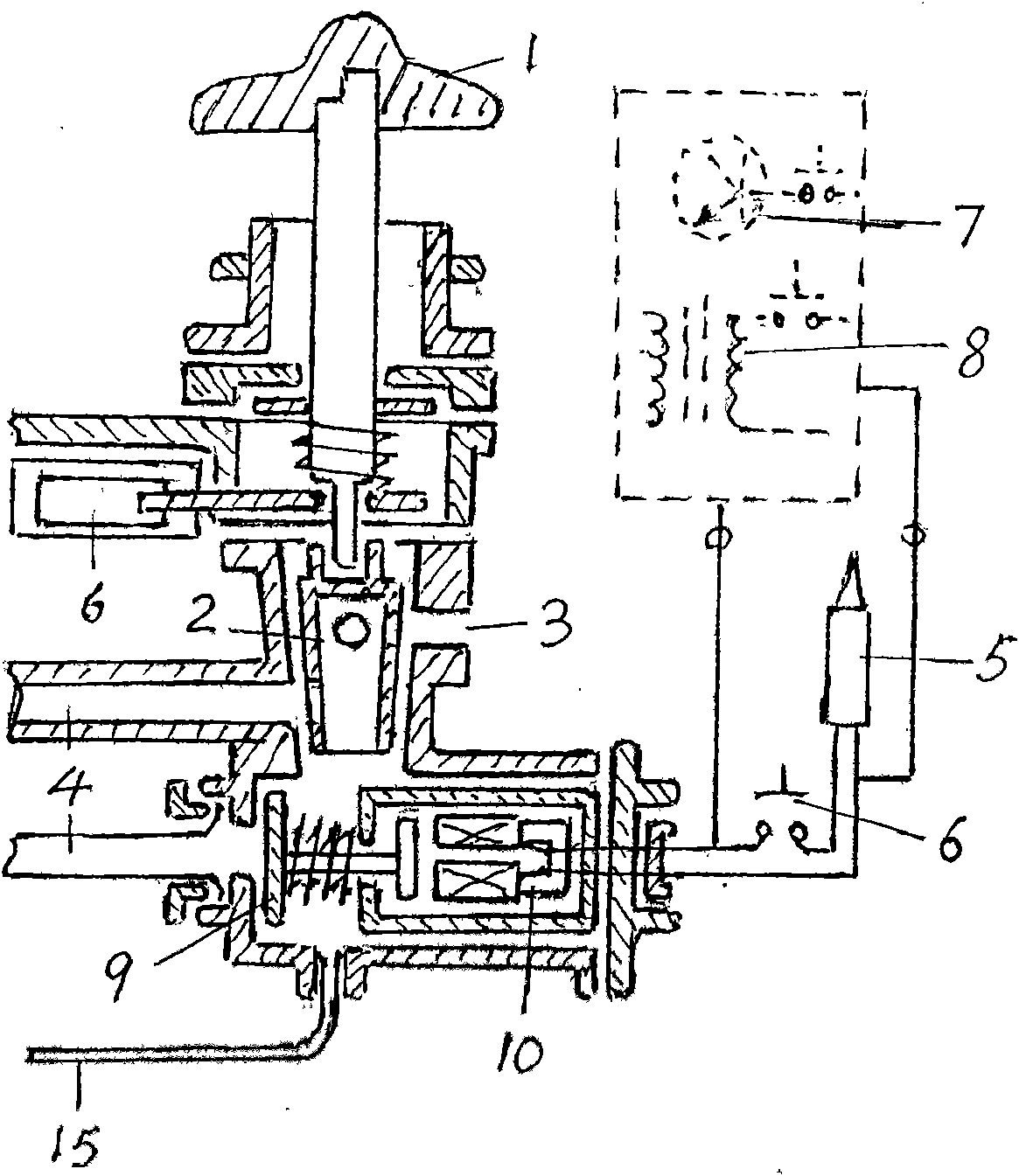

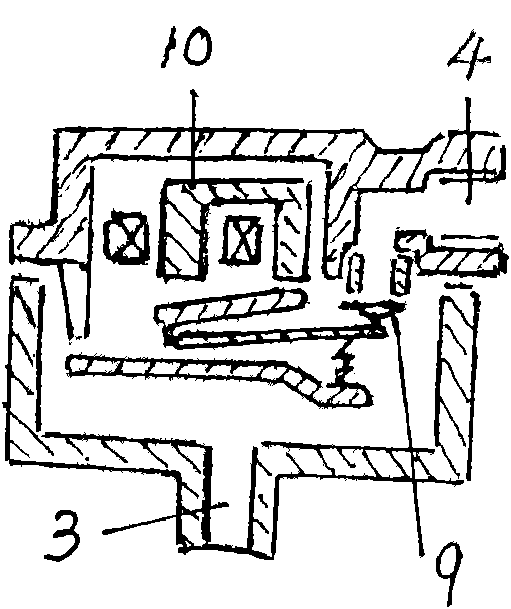

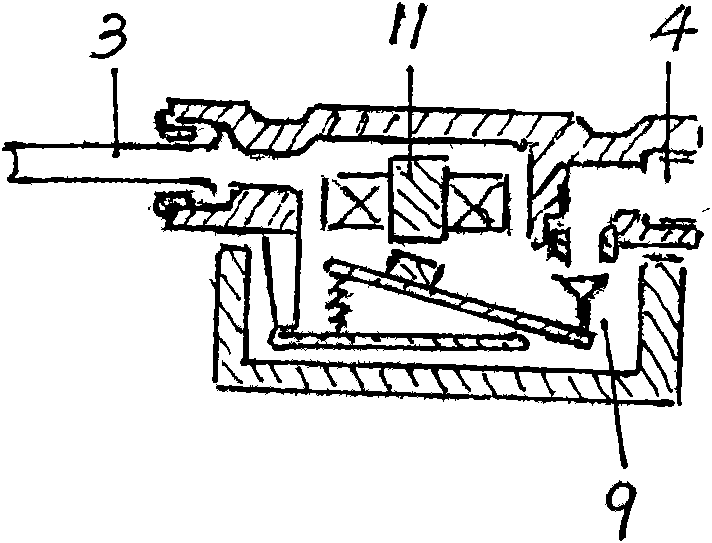

[0025] figure 1 It is a schematic diagram of a series connection combination valve of a solenoid valve used for a manual gas switch and a U-shaped magnetic core in a cooker. Its manual gas valve is equipped with a micro-electric switch 6, and when the manual knob 1 is turned, it will give the cooker The ignition and control circuits are energized. And drive the cock pipe 2 in the manual switch, the cock pipe wall is provided with the air inlet 3, when the manual switch only needs to open an air outlet, just open the cock pipe head (air passage with U-shaped electromagnetic valve in series below) ) air outlet 4. Just increase and open an air outlet 4 on the cock pipe wall when manual switch needs to open two air outlets (certainly just need to be provided with two air outlets on the cock pipe wall as blocking the bottom mouth of the cock pipe). When the manual switch has multiple air outlets, it is necessary to set up several air outlets layered on the pipe wall, and to set u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com