Tool changing and air blowing structure for end face of HSK taper hole

An end face and taper hole technology, applied in the field of machine tools, to achieve the effect of fast automatic tool change, guaranteeing performance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

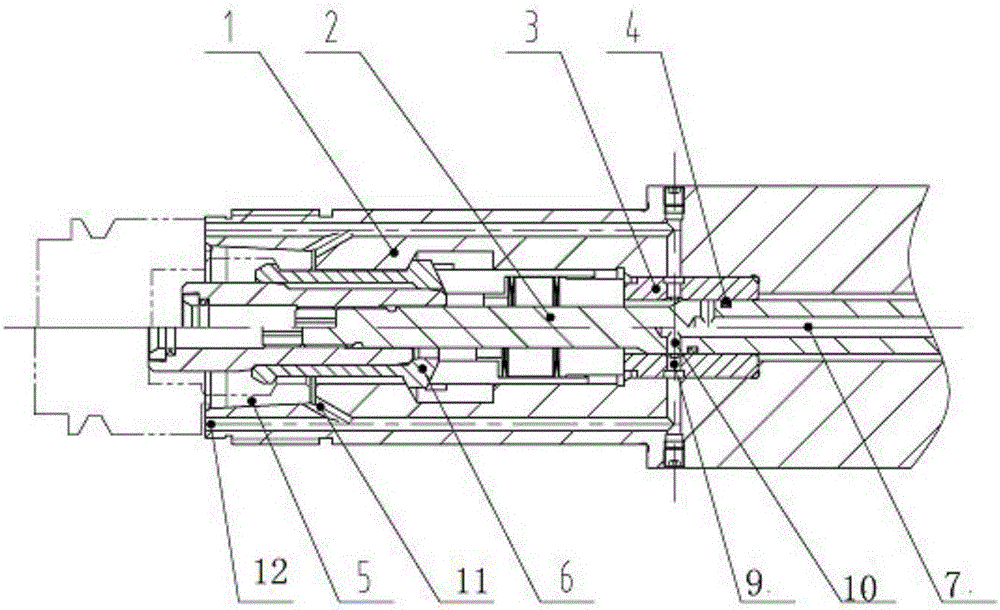

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] like figure 1 As shown in the figure, an HSK taper hole end face knife blowing structure is attached to the taper hole and the end face, and consists of the main shaft rotor 1, the tie rod 2, the shunt sleeve 3, the sealing ring 4, the HSK handle 5, and the HSK pull jaw 6. , the pull rod 2 is set inside the main shaft rotor 1, one end of the pull rod 2 is covered with a shunt sleeve 3, the HSK handle 5 and the HSK pull claw 6 are set at the other end of the pull rod 2, and the HSK handle 5 is further set on the HSK pull claw 6, the HSK claw 6 can push out the HSK tool handle 5, and the high-pressure airflow can enter from the airflow hole in the tie rod 2, and finally blow out from the blowing port to realize the blowing and cleaning function.

[0017] A sealing component is provided between the tie rod 2 and the shunt sleeve 3 . The sealing part is the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com