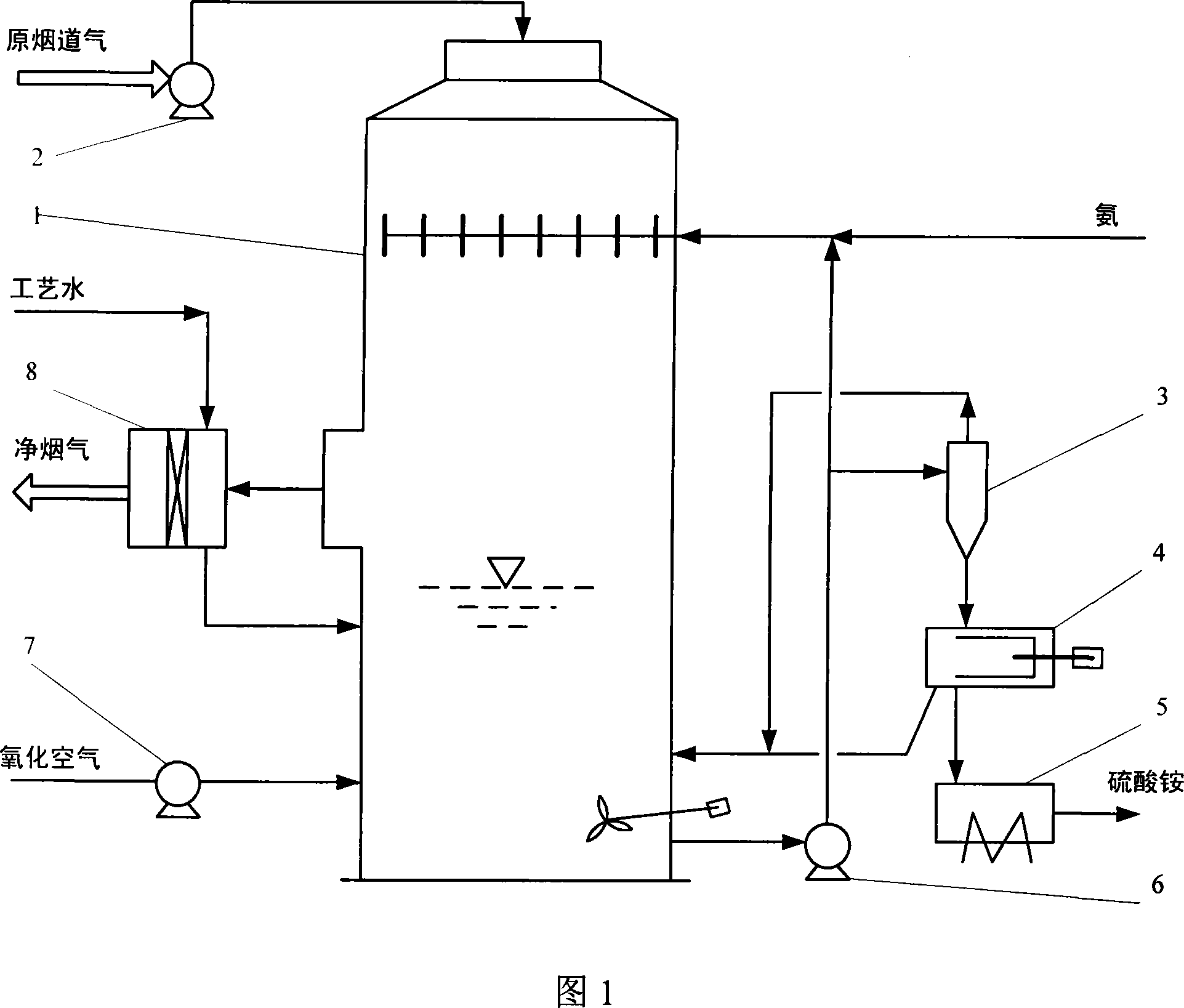

Method, system and product for reclaiming sulfoxides from flue gas

A technology for sulfur oxides and sulfur recovery, applied in chemical instruments and methods, separation methods, ammonium sulfate, etc., can solve the problems of consuming natural resources, difficult to use FRP, and large investment, and achieve large processing capacity and short construction period , reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

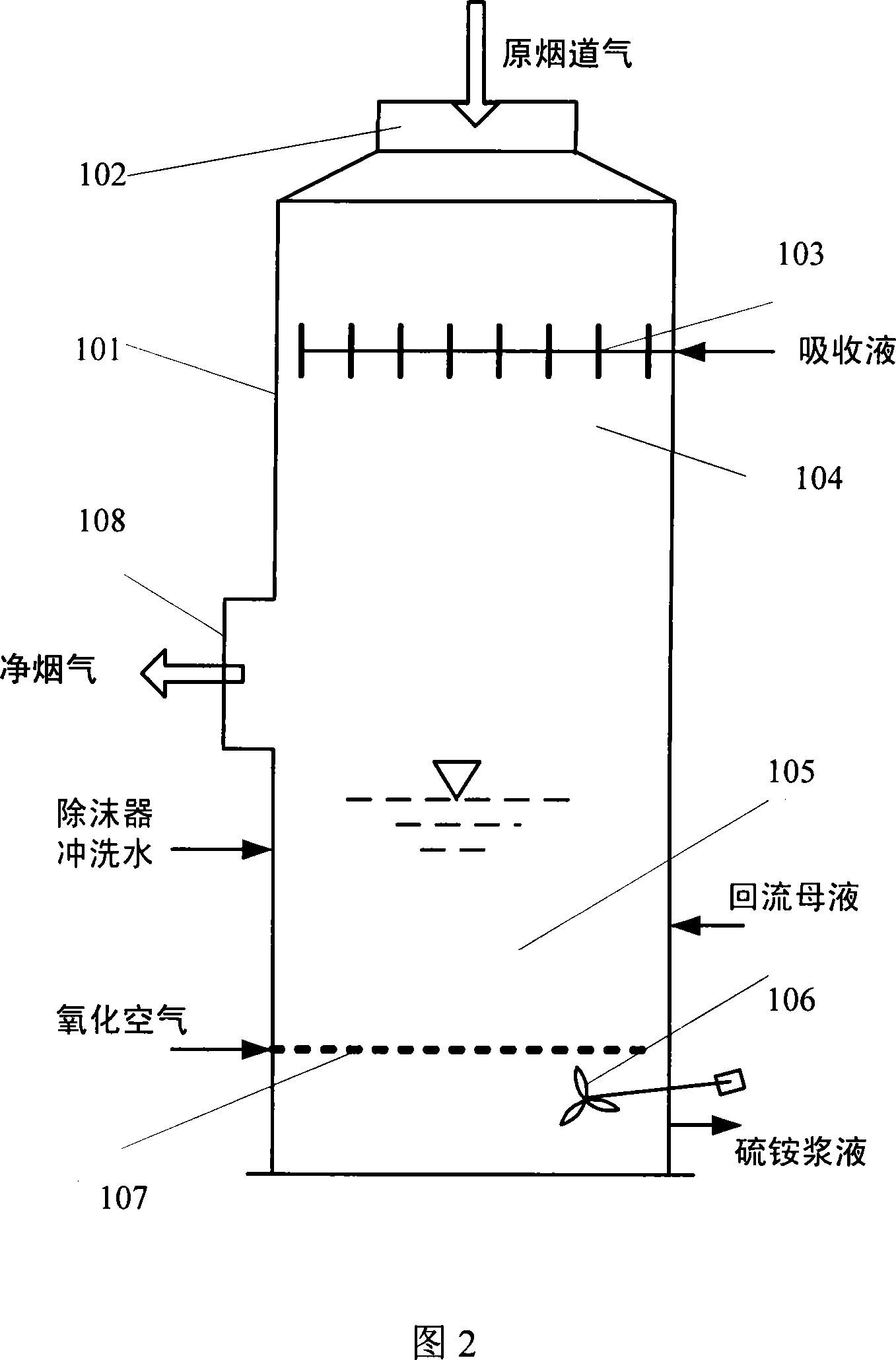

Embodiment 1

[0080] A 220T / h boiler burns coal with a sulfur content of 1.5%, and the flue gas flow rate is 260,000 Nm 3 / hr, SO 2 The content is 3200mg / Nm 3 , the electrostatic precipitator is 4 electric fields, and the dust content of the flue gas is 80mg / Nm 3 , the flue gas temperature is 140°C. The sulfur oxide absorption tower 1 has a diameter of 6.3m and a height of 22m. The tower body 101 is made of FRP with an average thickness of 32mm. Among them, the mass transfer member 104 adopts grid packing with an area of 65m 2 / m 3 , with a height of 3.5m.

[0081] The temperature of the flue gas is 135°C, and it is sent to the sulfur oxide absorption tower by the booster fan, where it contacts the absorption liquid and enters the mass transfer component layer. The flow rate of the circulating absorption liquid is 1450m 3 / h. The desulfurization agent adopts 18% concentration of ammonia water mixture, the flow rate is 2.5m 3 / h. The sulfur removal rate is 98.5%, SO in the tail ga...

Embodiment 2

[0084] A 670T / h thermal power generation unit, namely 200MW, burns coal with a sulfur content of 0.8%, and the flue gas flow rate is 800,000 Nm 3 / hr, the electrostatic precipitator is 3 electric fields, and the dust content of the flue gas is 200mg / Nm 3 , the flue gas temperature is 125°C.

[0085] The sulfur oxide absorption tower has a diameter of 10.0m and a height of 25m. The tower body is made of FRP with an average thickness of 38mm. Among them, the mass transfer layer is fine liquid droplets produced by the atomizing nozzle of the absorbing liquid distributor, with an average diameter of 1 mm.

[0086] The temperature of the flue gas is 135°C, and it is sent to the sulfur oxide absorption tower by the booster fan, where it contacts the absorption liquid and enters the mass transfer component layer. The flow rate of the circulating absorption liquid is 3250m 3 / h. The desulfurization agent uses 99.6% concentration of liquefied ammonia with a flow rate of 1.26m 3 / h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com