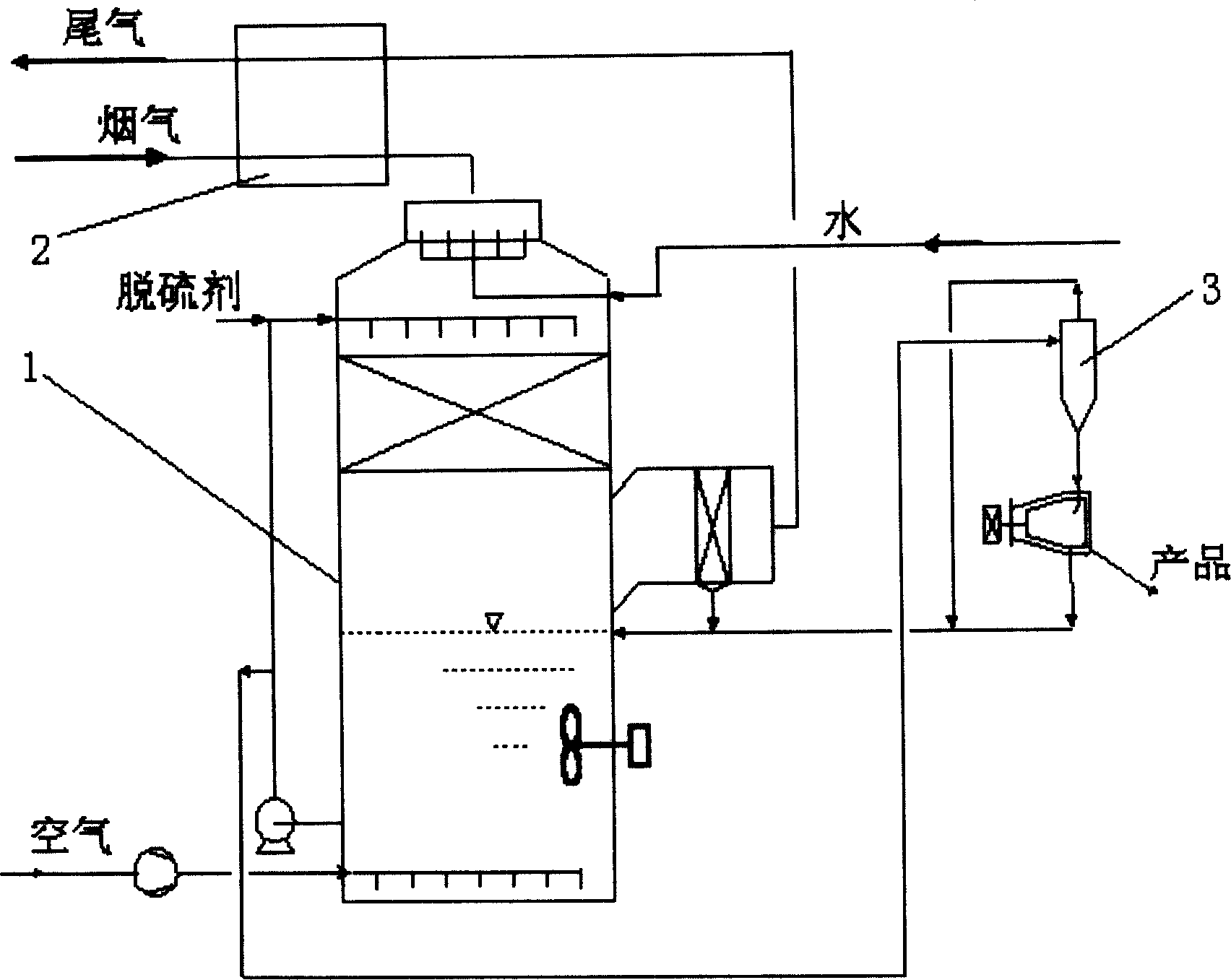

Method and device for producing thiamine from surface dioxide in recovered waste gas

A sulfur dioxide and ammonium sulfate technology, applied in chemical instruments and methods, separation methods, ammonium sulfate, etc., can solve the problems of difficult glass fiber reinforced plastics, consumption of natural resources, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

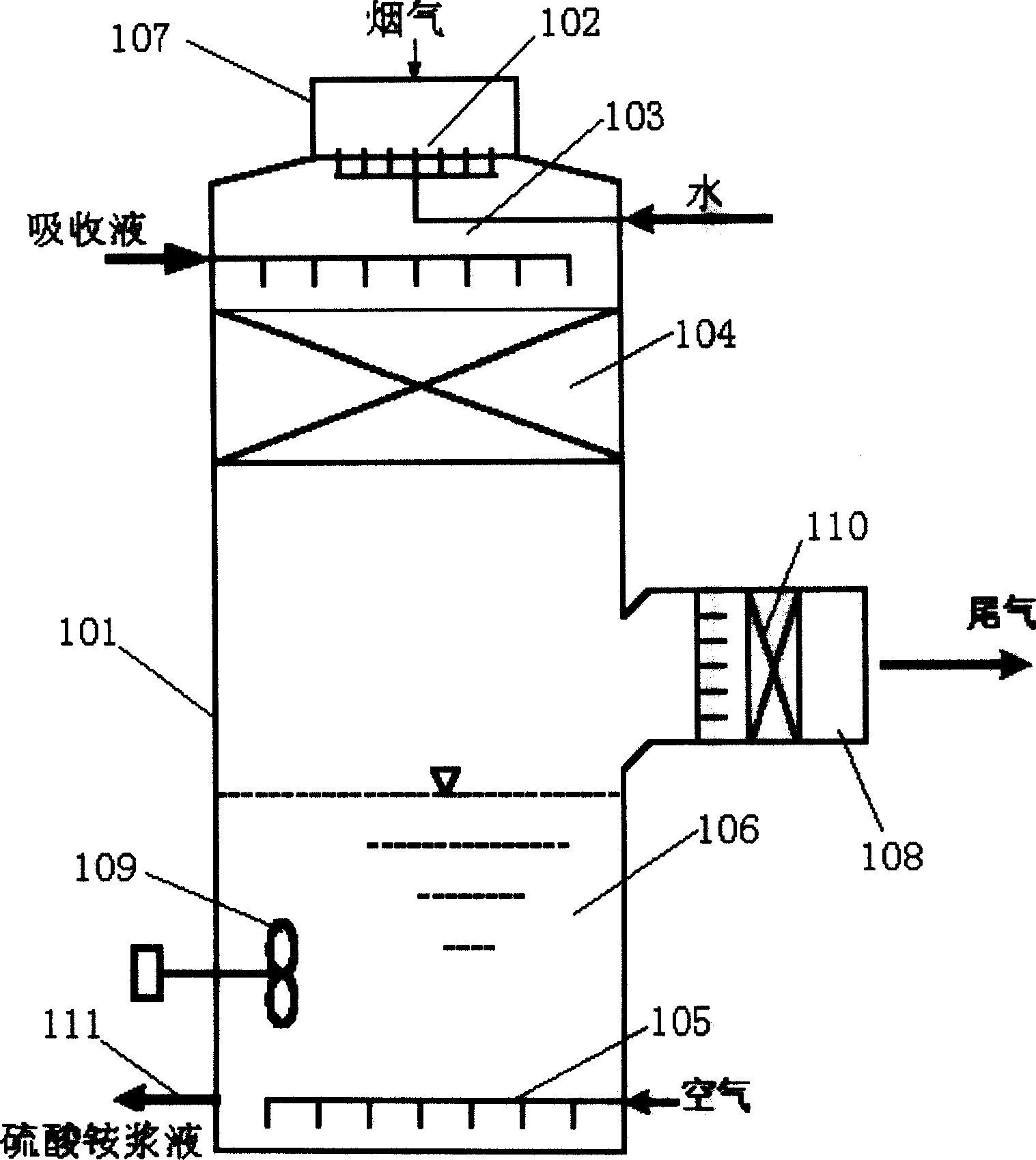

[0073] A 220T / h boiler, burning coal with a sulfur content of 1.5%, and a flue gas flow rate of 330,000 Nm 3 / hr, SO 2 The content is 3200mg / Nm 3 , The electrostatic precipitator is 4 electric fields, and the dust content of the flue gas is 80mg / Nm 3 , The flue gas temperature is 140℃.

[0074] The desulfurization tower 1 has a diameter of 6m and a height of 18m. The tower body 101 is made of glass fiber reinforced plastic (FRP) with an average thickness of 23mm. Among them, the mass transfer member layer 104 uses grid packing, with an area of 65m 2 / m 3 , The height is 4m, the height of the oxidation crystallization pool is 8m.

[0075] After the flue gas passes through the reheater, the temperature drops to 110°C and enters the desulfurization tower. After being chilled by cold shock water, the temperature drops to 70℃, and then enters the mass transfer component layer, and the flow rate of the circulating absorption liquid is 500m 3 / h. The desulfurizer adopts 18% ammonia wat...

Embodiment 2

[0079] A 670T / h thermal power generating unit, namely 200MW, uses coal with a sulfur content of 3.0%, and a flue gas flow rate of 800,000 Nm 3 / hr, SO 2 The content is 7250mg / Nm 3 , The electrostatic precipitator is 3 electric fields, and the dust content of the flue gas is 250mg / Nm 3 , The flue gas temperature is 145℃.

[0080] The desulfurization tower has a diameter of 9.5m and a height of 20m. The shell is made of glass fiber reinforced plastic (FRP) with an average thickness of 26mm. The mass transfer layer adopts 100Y corrugated plate structured packing with an area of 100m 2 / m 3 , The height is 4m. The height of the oxidation crystallization pool is 8m.

[0081] After the flue gas passes through the reheater, the temperature drops to 110°C and enters the desulfurization tower. After being quenched by cold water, the temperature drops to 70℃, and then enters the mass transfer component layer, and the flow rate of the circulating absorption liquid is 3000m 3 / h. The desulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com