Recycling method of ammonia from ammonia-bearing multi-phase mixed wastewater

A technology of multi-phase mixing and recovery methods, which is applied in the direction of separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of insufficient cooling speed, low cooling efficiency, complex recovery process, etc., achieve low cost and improve efficiency , wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

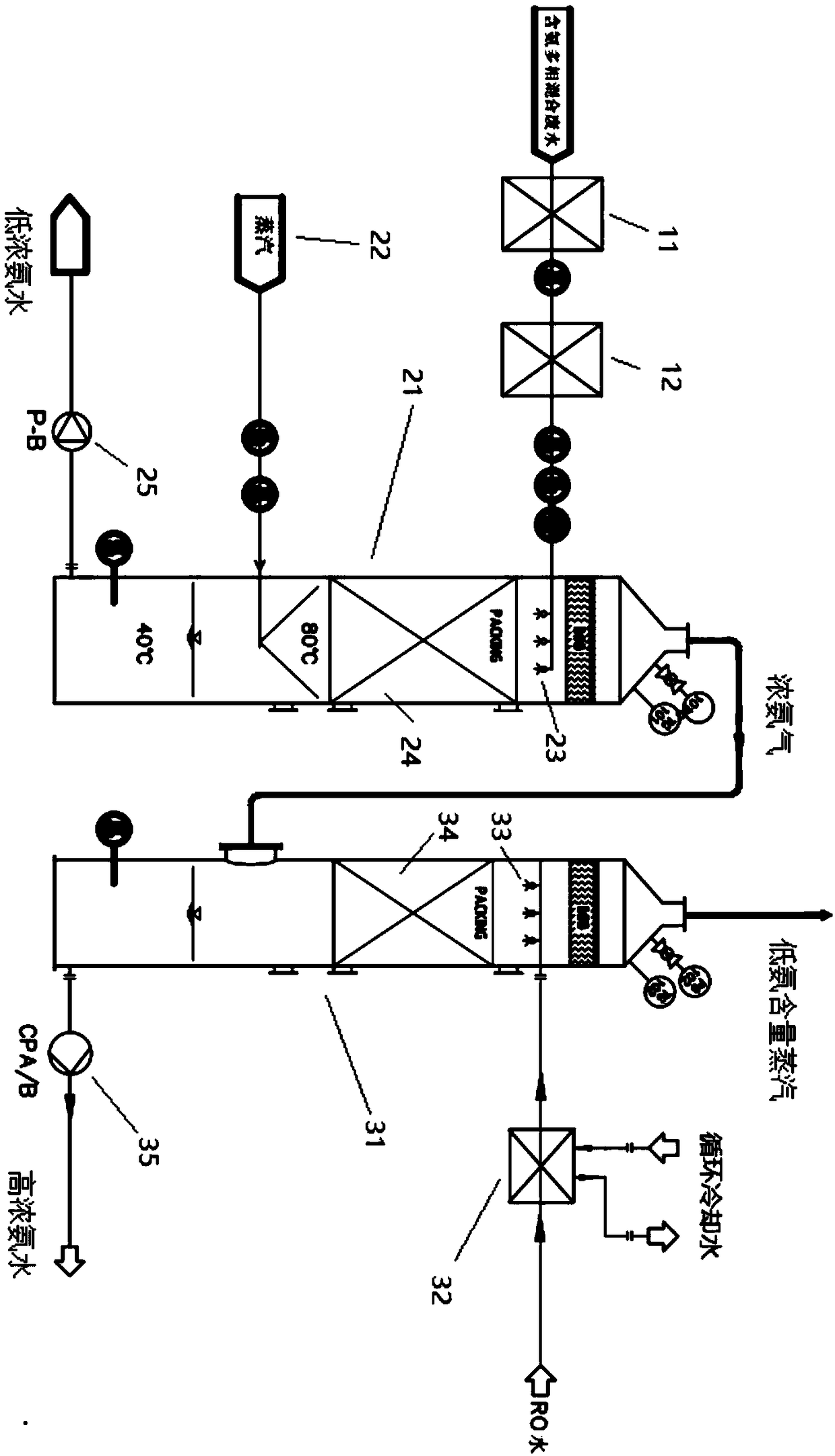

[0026] The present invention will now be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0027] A method for recovering ammonia in ammonia-containing multiphase mixed wastewater, the steps taken are as follows:

[0028] 1. Pour ammonia-containing wastewater with ammonia content of 150kg / h at 20°C into pH adjustment tank 11 with a flow rate of 5m 3 / h. Sodium hydroxide solution was added to the pH adjustment tank 11 to adjust the pH value of the wastewater system to 12.0. Afterwards, the EH-01 electric heater 12 is used to heat the ammonia-containing multiphase mixed wastewater to be treated to 40°C, which is favorable for the smooth progress of the stripping process.

[0029] The ammonia-containing multiphase mixed wastewater with pH value of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com